Etm551 lecture10

- 1. ETM 551 Design for Manufacturing 1 Product Design & Development Design for Manufacturing

- 2. ETM 551 Design for Manufacturing 2 Design for Manufacturişng (DFM) • Detail design decisions can have substantial impact on product quality and cost • Development teams face multiple, and often conflicting, goals • It is important to have matrics with which to compare alternative designs • A well-defined method assists the decision –making process

- 3. ETM 551 Design for Manufacturing 3 Design for Manufacturing (DFM) • Customer needs and product specs are hard to link with downstream product development • Many teams use “design for X” where X means reliability, robustness, environmental impact, manufacturing,... • Economically successful design is about ensuring high product quality while minimizing manufacturing cost – the goal of DFM

- 4. ETM 551 Design for Manufacturing 4 DFM requires a cross-functional team • One of the most integrative practices in PD • Inputs to DFM include: – sketches, drawings, product specs, design alternatives; – detailed understanding of production and assembly processes; – estimates of manufacturing costs, production volumes and ramp-up timing.

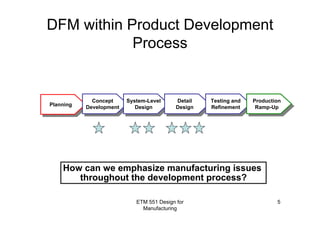

- 5. ETM 551 Design for Manufacturing 5 PlanningPlanning DFM within Product Development Process Concept Development Concept Development System-Level Design System-Level Design Detail Design Detail Design Testing and Refinement Testing and Refinement Production Ramp-Up Production Ramp-Up How can we emphasize manufacturing issues throughout the development process?

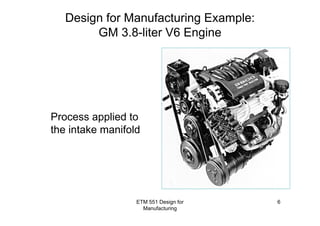

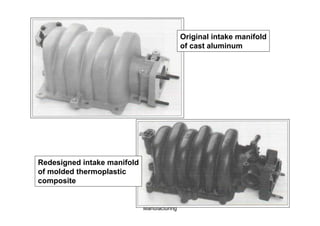

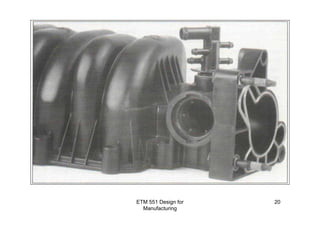

- 6. ETM 551 Design for Manufacturing 6 Design for Manufacturing Example: GM 3.8-liter V6 Engine Process applied to the intake manifold

- 7. ETM 551 Design for Manufacturing 7 Original intake manifold of cast aluminum Redesigned intake manifold of molded thermoplastic composite

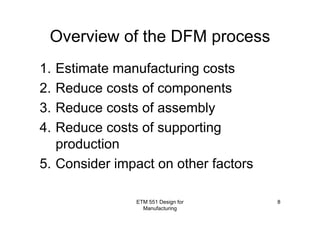

- 8. ETM 551 Design for Manufacturing 8 Overview of the DFM process 1. Estimate manufacturing costs 2. Reduce costs of components 3. Reduce costs of assembly 4. Reduce costs of supporting production 5. Consider impact on other factors

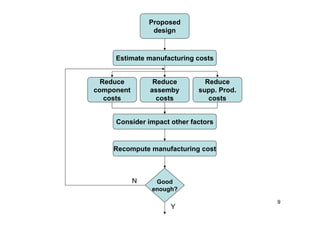

- 9. 9 Estimate manufacturing costs Consider impact other factors Reduce component costs Reduce assemby costs Reduce supp. Prod. costs Recompute manufacturing cost Proposed design Good enough? Y N

- 10. 10 Step 1: Estimate manufacturing cost Equipment Tooling Raw materials Labor Purchased components SuppliesEnergy Services Waste Information Finished goodsMANUFACTURING SYSTEM

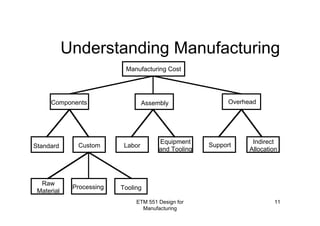

- 11. ETM 551 Design for Manufacturing 11 Understanding Manufacturing CostsManufacturing Cost Components Assembly Overhead Standard Custom Labor Equipment and Tooling Support Indirect Allocation Raw Material Processing Tooling

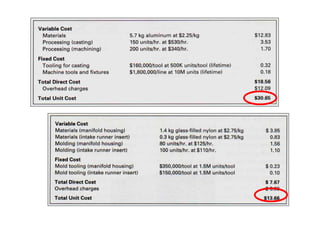

- 12. ETM 551 Design for Manufacturing 12 Estimating manufacturing cost • Fixed costs versus variable costs • Estimate the costs of standard components • Estimate the costs of custom components • Estimate the cost of assembly • Estimate the overhead costs

- 13. 13

- 14. ETM 551 Design for Manufacturing 14 Step 2: Reduce Cost of Components • Understand the process constraints • Redesign the components to eliminate processing steps • Choose the appropriate economic scale for the part process • Standardize components and processes • “Black-box” component procurement

- 15. ETM 551 Design for Manufacturing 15

- 16. ETM 551 Design for Manufacturing 16 Step 3: Reduce cost of assembly • Design for assembly (DFA) is a subset of DFM • Keeping score – Ask of each part in a candidate design: 1.Does the part need to move relative to the rest of the device? 2.Does it need to be of a different material because of fundamental physical properties? 3.Does it need to be separated from the rest of the device to allow for assembly, access, or repair? – Parts satisfying one or more of the questions should theoretically be separate. time)assemblytotal(Estimated seconds)(3parts)ofnumberminimumal(Theoretic indexDFA × =

- 17. ETM 551 Design for Manufacturing 17 Reduce cost of assembly (cont) • Integrate parts – Integrated parts do not have to be assembled – Integrated parts are often less expensive to fabricate than the separate parts they replace – Integrated parts allow for the geometrical dimensions and tolerances to be more precisely controlled

- 18. ETM 551 Design for Manufacturing 18 Reduce cost of assembly (cont) • Maximize ease of assembly – Part is inserted from the top of the assembly – Part is self-aligning – Part does not need to be oriented – Part requires only one hand for assembly – Part requires no tools – Part is assembled in a single, linear movement – Part is secured immediately upon insertion

- 19. ETM 551 Design for Manufacturing 19 Reduce cost of assembly (cont) • Consider customer assembly – Look into it if purchasing and handling by the customer are substantially easier – Substantial challenge to design a product to be assembled by the most inept customers, many of whom will ignore directions

- 20. ETM 551 Design for Manufacturing 20

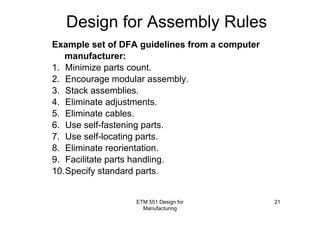

- 21. ETM 551 Design for Manufacturing 21 Design for Assembly Rules Example set of DFA guidelines from a computer manufacturer: 1. Minimize parts count. 2. Encourage modular assembly. 3. Stack assemblies. 4. Eliminate adjustments. 5. Eliminate cables. 6. Use self-fastening parts. 7. Use self-locating parts. 8. Eliminate reorientation. 9. Facilitate parts handling. 10.Specify standard parts.

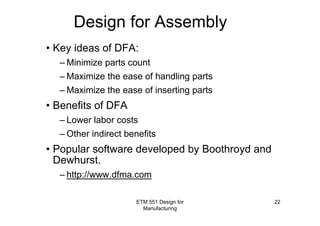

- 22. ETM 551 Design for Manufacturing 22 Design for Assembly • Key ideas of DFA: – Minimize parts count – Maximize the ease of handling parts – Maximize the ease of inserting parts • Benefits of DFA – Lower labor costs – Other indirect benefits • Popular software developed by Boothroyd and Dewhurst. – http://www.dfma.com

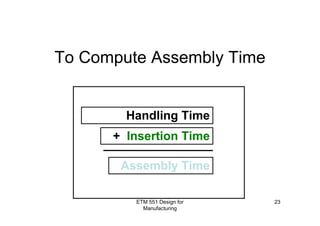

- 23. ETM 551 Design for Manufacturing 23 To Compute Assembly Time Handling Time + Insertion Time Assembly Time

- 24. ETM 551 Design for Manufacturing 24 Step 4: Reduce cost of supporting production • Minimize systemic complexity • Error proofing

- 25. ETM 551 Design for Manufacturing 25 Step 5: Consider impact of DFM decisions on other factors • Impact of DFM on development time – Reduction of $1 on each manifold would be worth $1 million in annual cost savings, but would not be worth a six-month delay in the project • Impact of DFM on development cost – If properly integrated in product development, extra cost is meaningless

- 26. ETM 551 Design for Manufacturing 26 Impact of DFM decisions on other factors (cont) • Impact of DFM on product quality – Usually DFM results in improved serviceability, ease of disassembly, and recycling – Can cause adverse effects in product reliability and robustness • Impact of DFM on external factors – Component reuse – Life cycle cost

- 27. ETM 551 Design for Manufacturing 27 Summary • DFM begins with the concept development phase and system-level design phase • DFM utilizes estimates of manufacturing cost to guide and prioritize cost reduction efforts • DFM practice involves making decisions in the absence of detailed data