Failure Codes in IBM Maximo Asset Management

- 1. Robert Zientara di-rz.pl Failure Codes in IBM Maximo Asset Management

- 2. What is Failure Code? Failure code is a reason asset failed. In Maximo, Failure codes are part of the complex categorization mechanism of Work Orders. They are usually entered when closing the WO (at this time the reason of the failure should be known). Failures codes represent hierarchical structure describing the cause of the failure and suggesting the potential solution. The Failure Codes catalog represents the most common failures in the infrastructure.

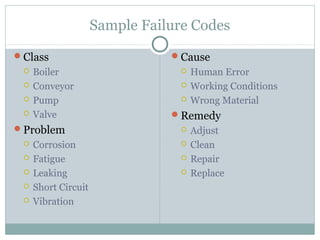

- 3. Structure of Failure Codes Failure Code consists of following elements: Class Problem Cause • Remedy Failure Code can be a number or alphanumeric code. In some industries the predefined Failure Codes may already exist e.g. VMRS for vehicle maintenance. When designing the catalog, make sure the lists are not too big (10-20 positions) and include “OTHER” position for all issues not listed before.

- 4. Sample Failure Codes Class Boiler Conveyor Pump Valve Problem Corrosion Fatigue Leaking Short Circuit Vibration Cause Human Error Working Conditions Wrong Material Remedy Adjust Clean Repair Replace

- 5. Benefits of using Failure Codes Speed up the repair process Right resources can be assigned based on failure class Cause and remedy information built upon previous experience help to fix the issue quickly Improve the reliability of the infrastructure Analysis of the historical data can help in identifying and eliminating repeatable issues Failure Codes help in optimization of PM schedules too Performance of the same machines can be compared In the long term the above should reduce the maintenance costs

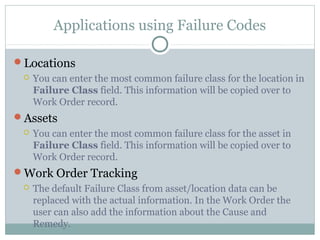

- 6. Applications using Failure Codes Locations You can enter the most common failure class for the location in Failure Class field. This information will be copied over to Work Order record. Assets You can enter the most common failure class for the asset in Failure Class field. This information will be copied over to Work Order record. Work Order Tracking The default Failure Class from asset/location data can be replaced with the actual information. In the Work Order the user can also add the information about the Cause and Remedy.

- 7. Failure Codes Application From Go To menu choose: Asset Failure Codes

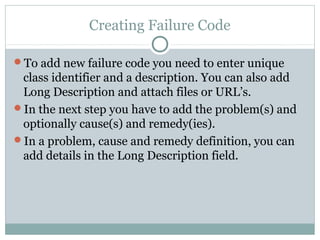

- 8. Creating Failure Code To add new failure code you need to enter unique class identifier and a description. You can also add Long Description and attach files or URL’s. In the next step you have to add the problem(s) and optionally cause(s) and remedy(ies). In a problem, cause and remedy definition, you can add details in the Long Description field.

- 9. If you want to learn more about Maximo… Please read my book: IBM Maximo Asset Management. The Consultant’s Guide

- 10. Legal information All product and company names mentioned in this publication may be trademarks or registered trademarks of their respective owners.

Editor's Notes

- Historia zmian: 1.0.0, 2015-08-12 – wersja inicjalna