Fancy weaves

- 1. + WOVEN FABRICS - Review

- 2. + Decorative Effects Plain Weave Examples: Warp and/or Filling direction stripes Stripes gingham plaids Twill Weave Examples: Houndstooth Herringbone Plaids

- 3. + Unbalanced Plain Weave (RIB) with Warp Stripes (Yarn Dyed)

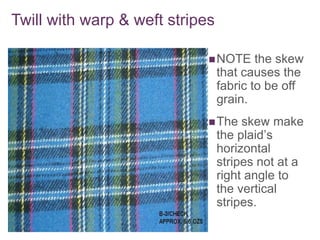

- 4. Twill with warp & weft stripes NOTE the skew that causes the fabric to be off grain. The skew make the plaid’s horizontal stripes not at a right angle to the vertical stripes.

- 5. + Fancy / Complex Weaves Interlacing pattern is controlled by: warp yarns’ position during weaving

- 6. + Production of Fancy Weaves Complex Cost Specialized Techniques

- 7. + Fancy/Complex Weave main categories: Figure, or novelty weaves Surface figure weaves Pile weaves Double cloth Leno weave Crepe weave Slack-tension weave

- 8. + Figureor Novelty Weaves Variationor combination of basic weaves - plain, satin, and twill. Simple designs Complicated designs Damask, Brocade, Brocatelle, Jacquard Tapestry, & Wilton Rugs

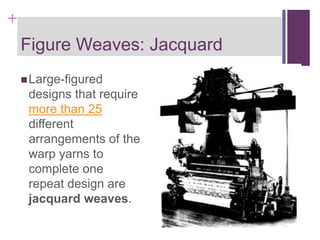

- 9. + Figure Weaves: Jacquard Large-figured designs that require more than 25 different arrangements of the warp yarns to complete one repeat design are jacquard weaves.

- 10. + Figure Weaves – Jacquard Figure weaves with large repeats or non- repeating designs with curves. Each yarn is controlled independently to create intricate designs.

- 11. + Figure Weaves – Jacquard

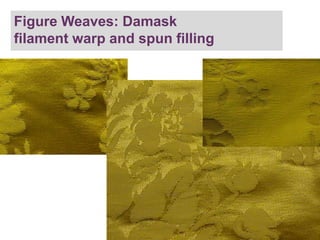

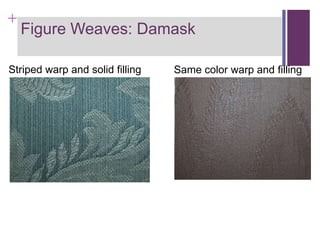

- 12. + Figure Weaves: Damask green warp and beige filling Satin floats on a satin background The floats in the design are opposite those in the ground

- 13. Figure Weaves: Damask filament warp and spun filling

- 14. + Figure Weaves: Damask Striped warp and solid filling Same color warp and filling

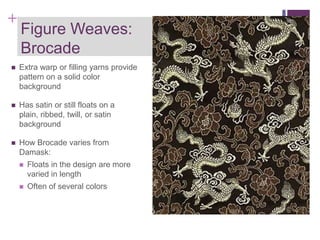

- 15. + Figure Weaves: Brocade Extra warp or filling yarns provide pattern on a solid color background Has satin or still floats on a plain, ribbed, twill, or satin background How Brocade varies from Damask: Floats in the design are more varied in length Often of several colors

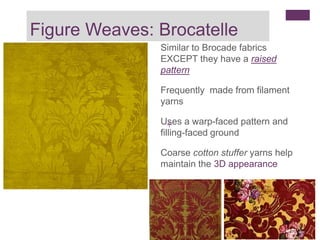

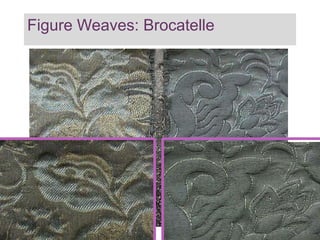

- 17. Figure Weaves: Brocatelle Similar to Brocade fabrics EXCEPT they have a raised pattern Frequently made from filament yarns Uses a warp-faced pattern and + filling-faced ground Coarse cotton stuffer yarns help maintain the 3D appearance

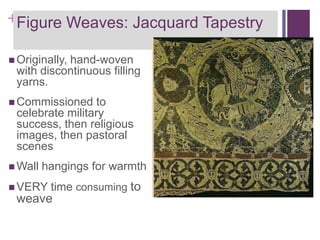

- 19. +Figure Weaves: Jacquard Tapestry Originally, hand-woven with discontinuous filling yarns. Commissioned to celebrate military success, then religious images, then pastoral scenes Wall hangings for warmth VERY time consuming to weave

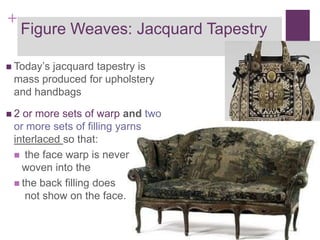

- 20. + Figure Weaves: Jacquard Tapestry Today’s jacquard tapestry is mass produced for upholstery and handbags 2 or more sets of warp and two or more sets of filling yarns interlaced so that: the face warp is never woven into the the back filling does not show on the face.

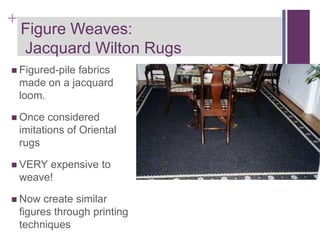

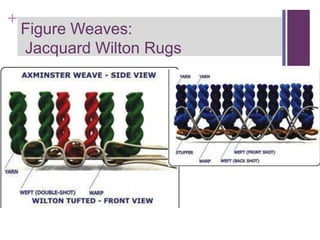

- 21. + Figure Weaves: Jacquard Wilton Rugs Figured-pile fabrics made on a jacquard loom. Once considered imitations of Oriental rugs VERY expensive to weave! Now create similar figures through printing techniques

- 22. + Figure Weaves: Jacquard Wilton Rugs

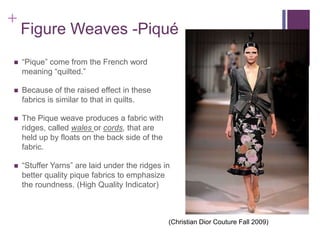

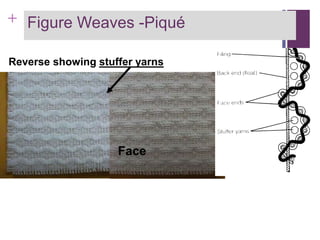

- 23. + Figure Weaves -Piqué “Pique” come from the French word meaning “quilted.” Because of the raised effect in these fabrics is similar to that in quilts. The Pique weave produces a fabric with ridges, called wales or cords, that are held up by floats on the back side of the fabric. “Stuffer Yarns” are laid under the ridges in better quality pique fabrics to emphasize the roundness. (High Quality Indicator) (Christian Dior Couture Fall 2009)

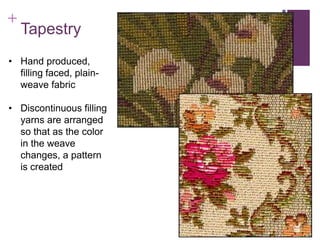

- 24. + Tapestry Weave Not the same as jacquard tapestry Usually identified with hand-woven textiles Jacquard tapestry “imitates” many hand- woven textiles

- 25. + Tapestry • Hand produced, filling faced, plain- weave fabric • Discontinuous filling yarns are arranged so that as the color in the weave changes, a pattern is created

- 26. + Figure Weaves -Piqué Reverse showing stuffer yarns Face

- 27. + –

- 28. + –

- 29. + Figure Weaves – Crisscross pattern

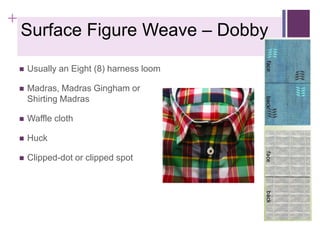

- 30. + Surface Figure Weave – Dobby Usually an Eight (8) harness loom Madras, Madras Gingham or Shirting Madras Waffle cloth Huck Clipped-dot or clipped spot

- 31. + Surface Figure Weave: Dobby Hole-punch Loom System CAD system

- 32. + Surface Figure Weave: Dobby

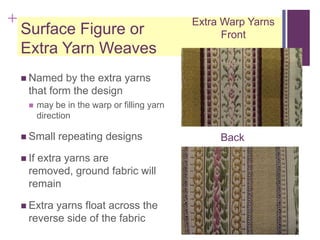

- 33. + Extra Warp Yarns Surface Figure or Front Extra Yarn Weaves Named by the extra yarns that form the design may be in the warp or filling yarn direction Small repeating designs Back Ifextra yarns are removed, ground fabric will remain Extra yarns float across the reverse side of the fabric

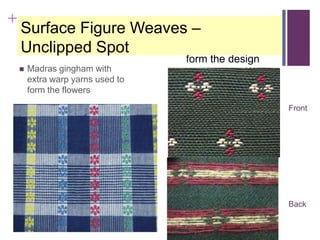

- 34. + Surface Figure Weaves – Unclipped Spot Extra filling yarns form the design Madras gingham with extra warp yarns used to form the flowers Front Back

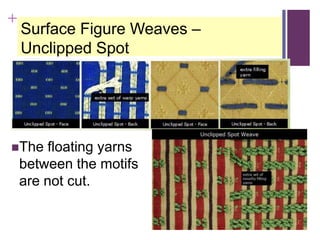

- 35. + Surface Figure Weaves – Unclipped Spot The floating yarns between the motifs are not cut.

- 36. + Surface Figure Weaves – Unclipped Spot

- 37. + Surface Figure Weaves – Clipped Spot

- 38. +Surface Figure Weaves: Clipped Spot – Dotted Swiss

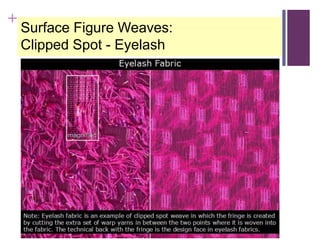

- 39. + Surface Figure Weaves: Clipped Spot - Eyelash

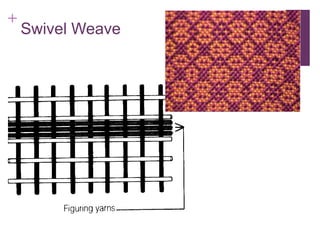

- 40. + Swivel Weave

- 41. + Pile Weaves 3-dimensional structures Weaving an extra set of warp or filling yarns into the ground yarns Makes loops or cut ends on the surface Woven cut pile example:

- 42. + Warp- and Weft-Pile Fabrics Warp pile: extra set of warp yarns form the pile Filling/weft pile: extra set of filling yarns form the pile

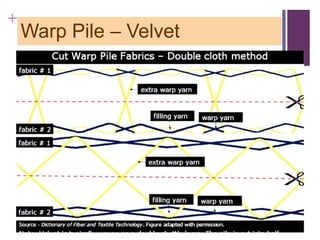

- 43. + PILE FABRIC Warp pile fabrics. Double Cloth Method: Velvet Over-the-wire Method: Terry cloth Friezé Weft or Filling Pile Velveteen Corduroy Used in: Outerwear Lining of coats, gloves, and boots Carpets, upholstery, bedspreads Absorbent towels and washcloths Stuffed Toys

- 44. Warp Pile - Velvet – Double Cloth Method

- 45. + Warp Pile – Velvet

- 46. + Warp Pile – Velvet

- 47. + Warp Pile – Velvet

- 48. + Warp Pile - Panne Velvet

- 49. + Warp Pile - Devore Velvet

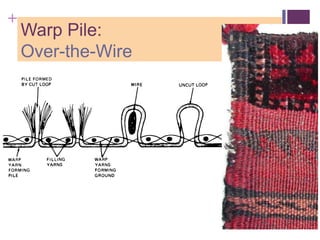

- 50. + Warp Pile: Over-the-Wire

- 51. + Warp Pile -Over-the-wire: Loops are very regular and in rows

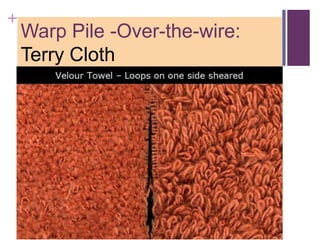

- 52. + Warp Pile - Over-the-wire: Terry Cloth Uncut pile fabrics manufactured with an extra set of warp yarns to create the loop by slack-tension method. Terry toweling quality, cost, and durability depend on weave type (plain or twill), count of base cloth, and loop characteristics. Terry cloth has pile on both sides of the fabric. Some fabrics have pile on the face side only. In velour (e.g., towels, robes), the loops are sheared on one or both sides to enhance appearance and softness.

- 53. + Warp Pile -Over-the-wire: Terry Cloth

- 54. + Warp Pile -Over-the-wire: Terry Cloth

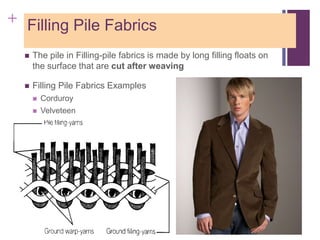

- 55. + Filling Pile Fabrics The pile in Filling-pile fabrics is made by long filling floats on the surface that are cut after weaving Filling Pile Fabrics Examples Corduroy Velveteen

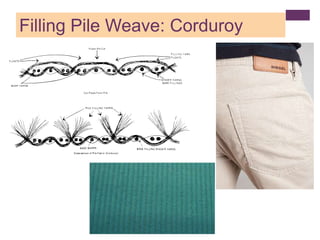

- 56. + Filling Pile Weave - Corduroy Theextra set of filling yarns forms floats (similar to velveteen). The floats are cut to create the pile in parallel lines along the length of the fabric.

- 57. Filling Pile Weave: Corduroy

- 58. + Filling Pile Weaves - Corduroy Ridges or cords, known as wales, along the length of the fabric Described by: Number of wales per inch, e.g. 8 wale,10 wale,16 wale. The higher the number of wales, the finer the fabric. Width of the wales.e.g,wide wale,pinwale, and featherwale.

- 59. + Filling Pile Weaves - Corduroy

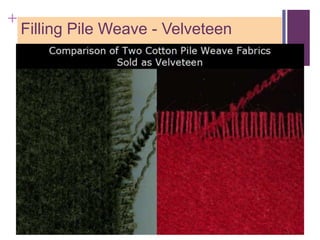

- 60. Filling Pile Weave: Velveteen Filling Yarns

- 61. + Filling Pile Weaves - Velveteen Velveteen fabrics are woven with an extra set of spun yarns.

- 62. + Filling Pile Weave – Cotton Velveteen

- 63. + Filling Pile Weave - Velveteen

- 64. + Warp Pile-like (faux pile) Surfaces by Other Methods Tufted Flocked surfaces

- 65. Tufting

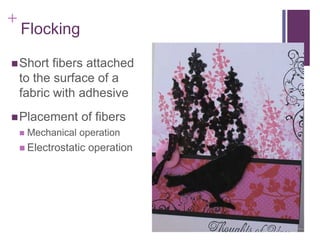

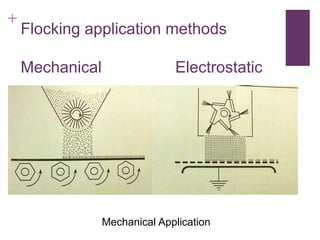

- 66. + Flocking Short fibers attached to the surface of a fabric with adhesive Placement of fibers Mechanical operation Electrostatic operation

- 67. + Flocking application methods Mechanical Electrostatic Mechanical Application

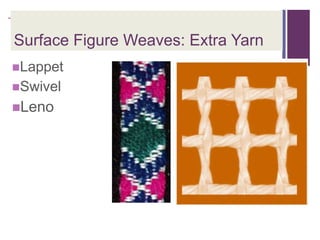

- 68. + Surface Figure Weaves: Extra Yarn Lappet Swivel Leno

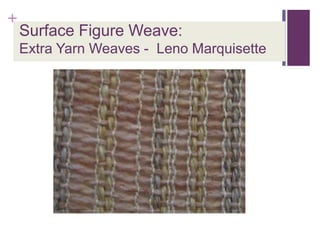

- 69. +Surface Figure Weaves: Leno Weave Extra Yarn - Leno Looking at Leno: Yarns are crossed and that one yarn of the pair is always above the other. Together they wrap the perpendicular yarn. Fabric names: Marquisette - Mosquito netting Casement fabrics used for window treatments

- 70. +Surface Figure Weave: Extra Yarn Weaves - Leno

- 71. +Surface Figure Weave: Leno Weave Extra Yarn Weaves - Leno

- 72. + Surface Figure Weave: Extra Yarn Weaves - Leno Marquisette

- 73. + Momie or Crepe Weave Gives a pebble-like surface that looks like a true crepe Presents no “wale” or other distinct weave effect but gives the cloth the appearance of being sprinkled with small spots (pebbles)

- 74. + Momie or Crepe Weave Random interlacing of warp and filling yarns that results in an irregular surface. Produced using a dobby attachment. The pebbly surface of the fabric is due to distortion of the weave by the over- twisted crepe yarns that shift once tension during weaving is released. True crepe is produced with crepe yarns (very high twist) in the warp and/or filling direction of plain or satin weave fabrics. Crepe weave is used instead of true crepe to reduce cost.

- 75. + Momie or Crepe Weaves Granite Weave Crepe Weave (any fiber can be used to make a crepe weave) Sand Crepe – medium-heavy weight fabric; repeat pattern of 16:16; no float is greater than 2 yarns in length Granite Cloth – momie weave based on a satin weave; even-sided fabric; no long floats, no twill effect Moss Crepe – combines high twist crepe yarns and crepe weave Bark Cloth – heavyweight momie-weave; found in furnishings; rough texture – tree bark

- 76. + Fancy Weave Warp Pile: Double Cloth

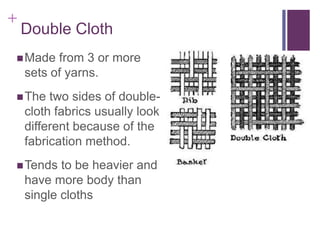

- 77. + Double Cloth Made from 3 or more sets of yarns. The two sides of double- cloth fabrics usually look different because of the fabrication method. Tends to be heavier and have more body than single cloths

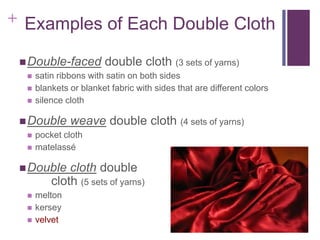

- 78. + Examples of Each Double Cloth Double-faced double cloth (3 sets of yarns) satin ribbons with satin on both sides blankets or blanket fabric with sides that are different colors silence cloth Double weave double cloth (4 sets of yarns) pocket cloth matelassé Double cloth double cloth (5 sets of yarns) melton kersey velvet

- 79. + Double Cloth: Pocket Cloth

- 80. +

- 81. + Double Weave Double Cloth: Matlasse

- 82. + Double Weave Double Cloth: Matelassé

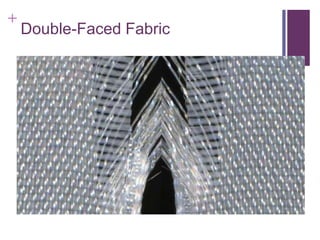

- 83. + Double Faced Double Cloth Weaves Double faced fabric is constructed with three sets of yarns. The combination can be either two warp sets and one filling set, or vice versa. Examples: Double-sided satin ribbon, Double georgette

- 84. + Double-Faced Fabric

- 85. + DOUBLE WEAVE

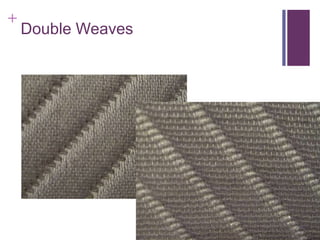

- 86. + Double Weaves Reverse Face

- 87. Back Front

- 88. + Double Weaves

- 89. + Double Weaves

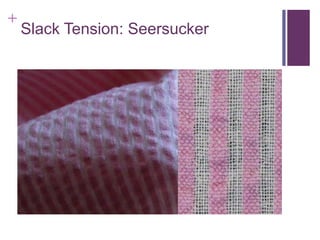

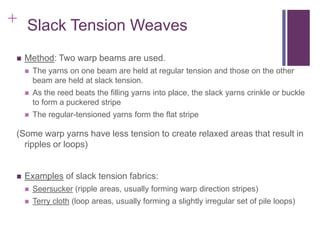

- 90. + Slack-tension Weave Sections of warp yarns have reduced tension. Results in bands or stripes of slightly puckered areas. Because the puckering is woven into the fabric, the pucker cannot be flattened. Seersucker fabrics are relatively more expensive to produce as the fabrics are woven at a slower speed.

- 91. + Slack Tension: Seersucker

- 92. + Slack Tension Weaves Method: Two warp beams are used. The yarns on one beam are held at regular tension and those on the other beam are held at slack tension. As the reed beats the filling yarns into place, the slack yarns crinkle or buckle to form a puckered stripe The regular-tensioned yarns form the flat stripe (Some warp yarns have less tension to create relaxed areas that result in ripples or loops) Examples of slack tension fabrics: Seersucker (ripple areas, usually forming warp direction stripes) Terry cloth (loop areas, usually forming a slightly irregular set of pile loops)

- 93. Regular tension areas Seersucker Slack tension areas

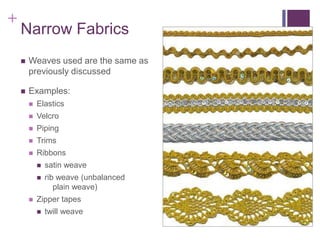

- 94. + Narrow Fabrics Weaves used are the same as previously discussed Examples: Elastics Velcro Piping Trims Ribbons satin weave rib weave (unbalanced plain weave) Zipper tapes twill weave

- 95. + Questions ??? ??? ???

Editor's Notes

- More involved than that for basic weavesFabric costs are higherFabric may have a more specialized applicationTechniques used to create fancy fabrics vary in complexity & influence:Fabric CostServiceabilityExpensiveAttractiveDurability variesCare varies

- Figure, or novelty weaves: combinations of basic weaves that do not require extra warp or filling yarns to create a design. Surface figure weaves: require extra warp and/or filling yarns to create a design. Extra yarns are inserted during weaving. Pile weaves: require extra warp or filling yarns to form the pile created during weaving. Double cloth: requires three or more sets of yarns to form different effects on the face and back; includes double cloth, double weave, and double-faced fabrics. Leno weave: crosses two or more warp yarns to hold the filling yarn in position. Crepe weave: a texture is created by random interlacing of warp and filling yarns. Slack-tension weave: bands or stripes of slightly puckered areas are created by reducing the tension on yarns that are puckered. Figure Weaves Figure, or novelty weave, is "a woven construction that is a variation or combination of basic weaves - plain, satin, and twill.“* Figure weaves include dobby, jacquard, and piqué. o Dobbyandjacquardaremorecommon. No extra warp or filling yarns are used to create a design.

- Figure, or novelty weave, is "a woven construction that is a Variation or combination of basic weaves - plain, satin, and twill.“* Figure weaves include dobby, jacquard, and piqué. Dobby and jacquard are more common. No extra warp or filling yarns are used to create a design. A variety of designs and textures are created by varying the fiber or yarn. o Simple designs require less yarn manipulation and can be made on on a standard harnessed loom with a dobby attachment to raise and lower a limited number of yarns. o Complicateddesignsrequireajacquardweavingprocessin which individual warp yarns can be controlled. *Source - Dictionary of Fiber and Textile Technology JacquardDamaskTapestry

- Jacquard weaves are figure weaves with large repeats or non- repeating designs with curves. They contain more than 25 yarn interlacing arrangements before the design repeats. Each yarn is controlled independently to create intricate designs. Originally, punched cards were used to raise the warp yarns to create a design; it was very labor intensive making intricate designs and expensive to produce. Today, computer controlled jacquard systems are used raise the warp yarns, thereby drastically reducing manufacturing costs.

- Jacquard weaves are figure weaves with large repeats or non- repeating designs with curves. They contain more than 25 yarn interlacing arrangements before the design repeats. Each yarn is controlled independently to create intricate designs. Originally, punched cards were used to raise the warp yarns to create a design; it was very labor intensive making intricate designs and expensive to produce. Today, computer controlled jacquard systems are used raise the warp yarns, thereby drastically reducing manufacturing costs.

- he Cloth of St Gereon is a mural tapestry of a repeat pattern with a decorative motif in seven colorsof a bull being attacked by a griffin, a fantastic creature with the body of a lion and the head and wings of an eagle.[1][2] The Cloth of St Gereon is the oldest known European tapestry still existing, dating to the early 11th century.[3][4][5][6][7] A number of European museums hold sections of the original cloth, which was cut into fragments in the 19th century.

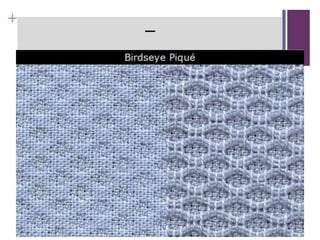

- Have raised areas visible on the fabric face and loosely woven floats on the fabric back. Stuffer yarns make the raised areas more prominent and contribute to fabric weight and bulk. They are laid between the warp and filling yarns, but not woven into the fabric. They can be pulled without affecting the integrity of the fabric. Most piqués are woven with a dobby attachment. Jacquard looms are used to produce more complicated designs. o Examples:widewalepiqué,pinwalepiqué,bedfordcord, birdseye piqué, and bullseye piqué.

- Have raised areas visible on the fabric face and loosely woven floats on the fabric back. Stuffer yarns make the raised areas more prominent and contribute to fabric weight and bulk. They are laid between the warp and filling yarns, but not woven into the fabric. They can be pulled without affecting the integrity of the fabric. Most piqués are woven with a dobby attachment. Jacquard looms are used to produce more complicated designs. o Examples:widewalepiqué,pinwalepiqué,bedfordcord, birdseye piqué, and bullseye piqué.

- Have raised areas visible on the fabric face and loosely woven floats on the fabric back. Stuffer yarns make the raised areas more prominent and contribute to fabric weight and bulk. They are laid between the warp and filling yarns, but not woven into the fabric. They can be pulled without affecting the integrity of the fabric. Most piqués are woven with a dobby attachment. Jacquard looms are used to produce more complicated designs. o Examples:widewalepiqué,pinwalepiqué,bedfordcord, birdseye piqué, and bullseye piqué.

- – this limits the complexity of designs (less than 25 different arrangements of warp yarns to complete one repeat designDobby weaves have small, simple geometric designs with straight lines in at least one direction. They have fewer than 25 yarn interlacing arrangements before the design repeats. Dobby weaves are created with a dobby attachment that selectively raises and lowers the yarns to create the design. The design motif may be spaced out on a plain, twill, or satin background. The design motif may be an “allover design;” examples include waffle weave and huck/huckaback. face back face back

- In some fabrics (mostly apparel), the floating yarns are very short as the motifs are close together. In upholstery fabrics, where the back of the fabric is coated, long floating yarns are left uncut to enhance fabric durability (uncut yarns resist snagging).

- In clipped or cut spot weave, the floating yarns are cut between motifs, forming a fringe. Fringe generally appears on the back of the fabric; fringe can appear on the face of the fabric for design purposes.

- In clipped or cut spot weave, the floating yarns are cut between motifs, forming a fringe. Fringe generally appears on the back of the fabric; fringe can appear on the face of the fabric for design purposes.

- Note: Loops have been pulled to show the base fabric on side A. Notice that nothing happens to loops on side B when the loops on side A are pulled. This is because different sets of warp yarns are used to produce loops on the two sides of the fabric.

- Note: Loops have been pulled to show the base fabric on side A. Notice that nothing happens to loops on side B when the loops on side A are pulled. This is because different sets of warp yarns are used to produce loops on the two sides of the fabric.

- Pile is pressed in one direction.

- Leno weave fabrics are produced by crossing pairs of warp yarns (or sets of warp yarns) prior to inserting the filling (or set of filling yarns) through the shed during weaving. The warp yarns form a figure 8 around the filling yarns as they cross over to hold the filling yarns in place. Leno weave is used to produce open construction fabrics. Leno weave is combined with other types of weaves to create interesting designs. Leno weave is used for curtains, apparel, vegetable sacks (onions, potatoes), carpet backing (Action Bac®), and industrial applications.

- The puckered look can also be produced at a lower cost by application of chemicals such as caustic soda to shrink the stripes after the fabric has been woven (information included in the section on Finishing).