Ferrocement

- 2. INTRODUCTION Definition “Ferro cement is a type of thin wall reinforced concrete, commonly constructed of hydraulic cement mortar, reinforced with closely spaced layers of continuous and relatively small size wire mesh. The mesh may be made of metallic or other suitable material. • It is a strong, low-cost, long-lasting building material made from a wire reinforced mixture of sand, water, and cement. • Uses for Ferro-cement are walls, floors, and roofs, underground structures, underground water tanks, water control devices, retaining walls, stairways built over adobe blocks, etc.. • A ferro-cement structure is usually 2-5 cm (3/4"-1 3/4") thick--- much thinner and lighter than poured concrete structures. Because it has wire reinforcing distributed throughout the structure, ferrocement structures have much greater tensile strength and flexibility than ordinary concrete. FERROCEMENT

- 3. INTRODUCTION History •The term "ferrocement" was given to this product by its inventor in France, Joseph Monier. At the time, (1850's) he wanted to create urns, planters, and cisterns without the expense of kiln firing. In 1875 he created the first steel and concrete bridge. •The outer layer was sculpted in its wet state to mimic rustic logs, thereby also introducing Faux Bois( false wood- wood or wood grains in various media) concrete into practice. •Recent trends have "ferrocement" being referred to as ferro concrete or reinforced concrete to better describe the end product instead of its components. By understanding that aggregates mixed with Portland cement form concrete, but many things can be called cement, it is hoped this may avoid the confusion of many compounds or techniques that are not ferro concrete. FERROCEMENT

- 4. MATERIAL SPECIFICATION. SPECIFICATION FERROCEMENT SPECIFICATION •Cement mortar mix. •Skeleton steel. •Steel mesh reinforcement or Fibre-reinforced polymeric meshes.

- 5. MATERIAL SPECIFICATION. SPECIFICATION FERROCEMENT CEMENT MORTAR MIX CEMENT • Ordinary Portland cement is used for normal applications. • Recommended cement quantity is 500 – 600 kg per cubic meter. • Lower cement consumption will result into reduction in strength and increase permeability. SAND • Ordinary river sand free of any organic matter should be used. • Sand should be strong, impermeable and capable of producing sufficiently strong mix with as low water/cement ratio as possible. • Allowable maximum grain size is 2.36mm. • Fineness modulus should be between 2.5 – 3.0.

- 6. MATERIAL SPECIFICATION. SPECIFICATION FERROCEMENT WATER • Water is required for producing workable mix and hydration of cement. ADMIXTURES • Used to improve workability and to reduce water/cement ratio. • Air entraining agents should not be used.

- 7. MATERIAL SPECIFICATION. SPECIFICATION FERROCEMENT SKELETON STEEL •Forms the skeleton of the structure. •3 to 8 mm steel rods are used. •Used in the form of tied reinforcement or welded wire fabric •Used to impart structural strength in case of boats, barges etc •Reinforcement should be free from dust, rust and other impurities

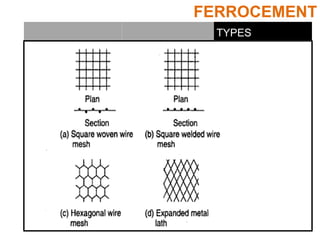

- 8. MATERIAL SPECIFICATION. SPECIFICATION FERROCEMENT STEEL MESH REINFORCEMENT •MS wires of 2 – 6mm dia. at 100 – 150 mm interval in a grid form. • Wire meshes: Woven mesh(GI / MS of 1 – 1.5mm dia. at 10 – 20mm in a grid form) Chicken mesh (GI hexagonal mesh of 10 – 20mm made of wire of 0.5 – 1mm dia.). •Welded wire mesh has hexagonal or rectangular openings. •Expanded metal mesh (Diamond shaped openings of 20 – 25mm). Concrete does not dry; it becomes strong chemically, in 28 moist days. If concrete dries before this period it will not reach maximum strength.

- 13. OTHER FERROCEMENT CONSTRUCTION METHODS FOR FERRO CEMENT •Skeletal Armature Method •Closed Mould Method •Integral Mould Method •Open Mould Method

- 14. OTHER FERROCEMENT CONSTRUCTION METHODS FOR FERRO CEMENT Skeletal Armature Method

- 15. OTHER FERROCEMENT CONSTRUCTION METHODS FOR FERRO CEMENT Close Mould Method

- 16. OTHER FERROCEMENT CONSTRUCTION METHODS FOR FERRO CEMENT Integral Mould Method

- 17. OTHER FERROCEMENT CONSTRUCTION METHODS FOR FERRO CEMENT Open Mould Method

- 18. APPLICATIONS FERROCEMENT Residential buildings •Houses •community centers •precast housing elements •corrugated roofing sheets •wall panels

- 22. APPLICATIONS FERROCEMENT •Marine applications •Water supply and sanitation •Agricultural •Residential buildings •Renewable energy •Other structures

- 24. APPLICATIONS FERROCEMENT Water supply and sanitation •Water tanks •Sedimentation tanks •Swimming pool linings •Well casings •Septic tanks

- 25. APPLICATIONS FERROCEMENT Agricultural •Grain storage bins •Silos •Canal linings •Pipes •Shells for fish and poultry farms

- 26. APPLICATIONS FERROCEMENT Renewable energy •Biogas digesters •biogas holders •Incinerators •panels for solar energy collectors

- 27. APPLICATIONS FERROCEMENT Other structures •Bus shelters •industrial shelters •pedestrian bridges •skateboard rings •sculptures