Finishing Complete

- 1. FINISHING Submitted By: Shan Salah Ud Din Nabeel Shan Syed Ahsan Ali

- 2. 1 ACKNOWLEDGEMENT We are very thankful to all those people who are cooperated with us and groomed us during our Trainee program in dyeing department. Our trainee could not have been successful without guidance of these personalities. Special thanks to: Mr. Rana Shahbaz (GM) Mr. Qayyum Aslam (DGM) Mr. Kamran (Manager) Mr. Zeeshan Hashmi (Manager) Mr. Shahrukh Zaidi (Senior Assistant Manager) Mr. Tanveer Hussain (A.M) And thanks to all the Supervisors, Shift In charges, Assistant Managers and Operators of the Finishing Department.

- 3. 2 FINISHING General Overview: 1.1. Introduction: In textile sector, finishing are the processes in which knitted/weaved cloth is converted into its final shape. In which quality, GSM, width, shrinkage and skewness of the fabric is controlled and make the fabric more soft and good hand feel. 1.2. Processes: The several processes which are done in finishing; Slitting (Tube to Open) Drying Santax/Stenter Raising Compactor (Compaction) Tumble Finishing Tube to Open Form Softener Application Drying Raising Compaction

- 4. 3 Slitting: The slitting is done for achieving following functions; To convert tube form fabric into open form Used to remove excess water after dyeing Drying: Drying is defined as a process where the liquid portion of the solution is evaporated from the fabric. Following functions are performed during drying; To dry the fabric with the help of heated oil or steam To control the shrinkage of the fabric To prepare the fabric for the next subsequent process Raising: The raising is a process in which the terry form of the fabric is converted into the fleece. Basically, it gives a softy surface by removing the fluff type fibers from the cloth and pulling the fiber end to the surface. Compaction: The main objectives for doing compaction are; Control the final width, GSM, shrinkage and skewness of the fabric Upgrade the fabric hand feel and import a smooth, softy touch to the fabric Compress the fabric and reduce its thickness Removes the creases in the fabric

- 5. 4 CHAPTER 01 Slitting 1.1- Introduction: The slitting machine is used to slit/cut the tube form fabric into open form in finishing section. The machine consists of a blade and a sensor is attached to the blade which senses the needle line during slitting. In the slitting machine, the fabric is firstly passed through rope squeezer. In squeezer there are mini-paddlers that squeeze the rope and then passed it to the bucket from which the rope is passed to the de- twister. De- twister removes the twist in the rope and then passed it to the basket. There is an exhaust fan over the basket for circular dropping of the fabric and the blade for cutting the needle line of the fabric. Open form of the fabric is then passed from the padding roller, dancing roller and delivery roller. Finally the open form fabric is delivered to the next finishing process. Fig: 1.1 Slitting Machine

- 6. 5 1.1.1- Layout: 1.2- Machine Function Open the fabric from tube form Reduce the water content Apply overfeed to give some compaction. Width wise stretch the fabric. Plait the fabric. 1.3- Machine Data Brand name = CORINO Machine Commercial name = Super slit Machine Making Year (3 machines) = 2013, 2010, 2003 Rope Squeezer De- Twister Basket with Blade & Sensor De - Curling Rollers Water DippingPadders Lapping

- 7. 6 1.4- Production Plan and Machine Cleaning Control 1.4-1. Production Plan Total number of machines = 3 Slit Machine 1 = Light shades/New color/Samples Slit Machine 2 = Full - Bleach or Grey Shades Slit machine 3 = Dark Shades 1.4-2. Machine Cleaning Control Cleaning between two shades with water and air After every lot, the water used for dipping is changed Cleaning of curling rollers with air pressure to remove the dust and fluff from the rollers 1.5- Capacity and Maintenance Schedule 1.5-1. Fabric Wise Capacity per Shift Terry = 4000-5000 Kg LSF (Low Shrinkage Fleece) = 4000-5000 Kg Single (Jersey) = 3000 Kg Rib = 3500 Kg 1.5-2. Fabric Wise Capacity per Day Terry = 13.5 Ton LSF (Low Shrinkage Fleece) = 13.5 Ton Single (Jersey) = 12 Ton Rib = 12 Ton 1.6- Annual and Monthly Maintenance Schedule 1.6-1. Monthly Maintenance Schedule Check out the motor working and greases the motor parts e.g. Shaft Grease the bearings of water slitting device and driving screw for basket opening 1.6-2. Annually Maintenance Schedule Check the motor /de-twister speed and motor belts condition The blade used for cutting also changed on demand

- 8. 7 The squeezers and padders are also checked so that pressure drop not occur Change gear oil once in a year 1.7- Operation: The tube form fabric slitting is done as; Rope form fabric placed in trolley It is passed through the squeezing unit where most of liquid is extracted Then it enters the de-twister, which eliminates the tension/twist of the rope and is prepared for the slitting Then untwist form fabric is transferred to the basket. The cutting line can be controlled by means of basket rotation Then fabric passed through blade and slitting is done. Passed the fabric from de-curling rollers to removes the curls Passed the slitted fabric from padders having almost 1 bar pressure in which most of the water is squeezed After squeezing the fabric it go to the plaiter to plait on trolley

- 9. 8 1.8- Machine Construction The slitting machine is constructed on the basis of the following parameters; Lapping methods Roll-to-roll stitching according to needle line Machine speed according to fabric Quality control Loop pulling needle line 1.8-1. Lapping Methods Open form fabric is placed into trolley by using rollers moving with motor. The fabric is basically lapped one by one on the fabric surface. For this lapping, speed of the rollers is adjusted according to the fabric. 1.8-2. Roll-to-roll Stitching according to Needle Line Fabric is passed over the blade and that place is detected by sensor/camera which is called needle point of the fabric and the blade cuts the fabric from the line. Roll to roll stitching is done in invertor department where one roll is attached/stitched with the other roll so that needle line is matched by the both rollers. 1.8-3. Machine Speed According to Fabric Terry = 50-60m/min LSF (Low Shrinkage Fleece) = 40-50m/min Rib = 30m/min Jersey (Single) = 60-70m/min 1.8-4. Quality Control In quality, fabric is then checked whether the cutting is done at the needle point or there may be some kind of inaccuracy during slitting. But mostly the fabric is directly moved towards the next process and quality is checked out at the end. 1.8-5. Loop Pulling Needle Line The rollers on the machine rotate the fabric needle line in front of the blade for slitting. Basically they pull the loop needle line towards the blade. Sometimes blade pulls the needle line fabric out that is not required. That condition shows the expiry of blade.

- 10. 9 1.9- Utilities Needed Water (Washing/Cleaning purpose) Electricity Compressed air (to form the tube fabric into balloon form and for cleaning purposes) 1.10- Man Power Operators per machine required = 2 First operator is present to operate the machine Second operator/loader is present to do other work like adjustments of trolley and to check the fabric alignment to adjust the lapping methods 1.11- Safety and Fire Handling Safety and fire handling is not just the saving of accidents of peoples and M/C. It also includes the operation of M/C in proper way. The operation on the machine must be correct and according to the procedure so that there will be no chance of problem in fabric. Keep the floor clean so that there will be no slippage on floor.

- 11. 10 CHAPTER 02 Santax 2.1- Introduction Santex is used for the removal of water contained in the fabric by applying heat on the fabric. In this machine, the fabric is passed through dryer at a very low speed. Drying is done by applying steam through the dryer. During drying the total heat passed through the machine is extracted by the exhaust fan. Fig: 2.1 Santex Machine 2.2- Functions of Santex Machine To dry the fabric with the help of heat To prepare the fabric for the next finishing process To remove residual water containing in the fabric Usually trim fabric passed from this

- 12. 11 2.3- Working Principle of Dryer The machine contains two chambers. In which steam lines are passed for drying purposes. Two conveyors are placed for the movement of fabric from wet state to dryer state. Each chamber has its own steam and condensate line. These are usually 2 pass chambers. Every chamber has its own exhaust which meets with the main exhaust. We passed those fabric from santex in which usually we have no concern with shrinkage, width and GSM. The speed of the dryer depends on the temperature of the machine and the GSM of the fabric. If the machine temperature is high then machine speed is also high and the machine temperature is low than the machine speed is also low. Fig: 2.2 Schematic diagram of Santex 2.4- Machine Data Machine Name = SANTAX Model Number = CH-9555 TOBEL Making Year = 1994 Manufacturer = Switzerland

- 13. 12 2.5- Production Plan and Machine Cleaning Control Production Plan Fabric Type Temperature (o C) Speed (m/min) Single Jersey 65 30 PK 65 20-30 1*1 Rib 65-70 25 Machine Cleaning Control To clean the machine with compressed air To check and clean the conveyor belt 2.6- Man Power One operator is present to operate the machine in a correct manner. 2.7- Utilities Needed Steam Compressed Air Electricity

- 14. 13 CHAPTER 03 Stenter Machine 3.1- Introduction: Stenter is a machine that is used for drying of fabric. The main difference between santex and stenter is that in stenter we deals with many controlling parameters e.g. GSM, width and shrinkage. But santex is used for just drying purpose and only trim/strips are passes through it. The purpose of the Stenter machine is to maintain the width and GSM of the fabric and also for heat setting and it is used for applying final softener applications. Fig: 3.1 Stenter Machine 3.2- Functions of Stenter Machine: Control the width of the fabric Control the GSM of the fabric Control the Shrinkage/Skewness of the fabric Final softener applications Fabric drying

- 15. 14 3.3- Machine data There are three Stenter machines in Style Textile. Stenter-1 Brand Name = SHAOYANG NO.2T M.W Chambers = 5 Year of construction = 2003 Manufacturer = China Stenter-2 Brand Name = VIROCK Chambers = 6 Year of Construction = 2011 Manufacturer = China Stenter-3 Brand Name = EHWHA Chambers = 10 Year of Construction = 2015 Manufacturer = Korea 3.3- Production Plan Production plan of the Stenter machine is based on 1st in 1st out. Fabric which is slitted 1st is dry and compacted 1st and vice versa. Shift incharge is planned the production capacity of the shift. 3.4- Machine Cleaning Control Final machine cleaning is done in the 1st shift (7am-8am) usually. During shift, before new color (light/dark) and softener changes cleaning are usually done.

- 16. 15 If the dark shade in the machine is processed and then light shade fabric is processed cleaning must be done with water and compressed air. If we change the softener type then there is also need of cleaning before the processing of new fabric. 3.5- Capacity: Capacity of the fabric depends upon the type of fabric/color/speed. Stenter-1 (SHAOYANG) = Colored/Samples Stenter-2 (VIROCK) = White/light shades (130o C) Stenter-3 (EHWHA) = Black/Dark Shades (180o C) Fabric wise: Stenter-1 (SHAOYANG) Single Jersey = 9 Tons/day Low shrinkage fleece (LSF)/Terry = 10.5 Tons/day Stenter-2 (VIROCK) Single Jersey = 9 Tons/day Low shrinkage fleece (LSF)/Terry = 10.5 Tons/day Stenter-3 (EHWHA) Single Jersey = About 17 Tons/day Low shrinkage fleece (LSF)/Terry = 22 Tons/day 3.6- Machine Speed: Stenter-1 (SHAOYANG) Single Jersey = 25 m/min Low shrinkage fleece (LSF)/Terry = 20 m/min

- 17. 16 Stenter-2 (VIROCK) Single Jersey = 26 m/min Low shrinkage fleece (LSF)/Terry = 18 m/min Stenter-3 (EHWHA) Single Jersey = 60 m/min Low shrinkage fleece (LSF)/Terry = 35-40 m/min 3.7- Machine Construction and Operation: Solution making In solution making, concentration of softener or any other special finish that is applied to the fabric is maintained. In Stenter machine 100 liter tank is attached which has a capacity to do chemical dipping about 300 Kg fabric. Usually RGH softener is used for softener application Curling Rollers These rollers are used to remove the curls from the fabric. Over feed rollers Over feed rollers are used to maintain the GSM/Width of the fabric and it also imparts the tension towards fabric. Skewness roll function There are two rollers in the Stenter machine that is used to control the skewness of the fabric. Two type of twist are used. For Z-twist, the right roller is used to adjust the right angle of the fabric. For S-twist, the left roller is used to adjust the left angle of the fabric. Fig: 3.2 over Feed & Skewness Rollers

- 18. 17 Wheel Over Feed Brush Function It is a roller wheel that feed the fabric to the pins of Stenter machine and the brushes are used to hit the fabric into the clips. Fig: 3.3 Over Feed Brush Main over Feed It is a roller that feed all the fabric to the stenter after squeezed from the padders. Fig: 3.4 Main Over Feed Dandy Roller These are also called dancing rollers and it is used to impart the tension into the fabric for complete stretching. If there is tension in the fabric then they move up and down. Heating Chambers In heating chambers there is process of drying. Air comes from atmosphere and move in the chamber with the help of fans from top to bottom of the chamber. Heated oil is passed through

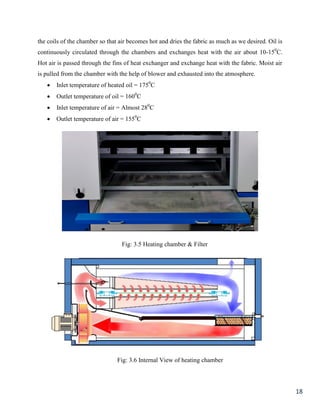

- 19. 18 the coils of the chamber so that air becomes hot and dries the fabric as much as we desired. Oil is continuously circulated through the chambers and exchanges heat with the air about 10-150 C. Hot air is passed through the fins of heat exchanger and exchange heat with the fabric. Moist air is pulled from the chamber with the help of blower and exhausted into the atmosphere. Inlet temperature of heated oil = 1750 C Outlet temperature of oil = 1600 C Inlet temperature of air = Almost 280 C Outlet temperature of air = 1550 C Fig: 3.5 Heating chamber & Filter Fig: 3.6 Internal View of heating chamber

- 20. 19 Cooling After heating chambers, there is a system of cooling of fabric. When the fabric is coming out from chambers its temperature is almost 1100 C. Temperature of the fabric is reduced to 700 C by passing it through cooled air. Air is passed through nozzles to create high velocity of air. After that fabric is passed to lapping rollers. Lapping Rollers The lapping rollers are the rollers that roll the fabric one after the other. They are also called delivery rollers. Fig: 3.7 Lapping Rollers Width Adjustment The width is adjusted by the clips of the Stenter machine because according to instructions the width plate is open and stretch the fabric until the required width is not achieved. Temperature and Speed For light/medium shades = 130o C For Dark Shades = 160o C Single Jersey = 60 m/min Low shrinkage fleece (LSF)/Terry = 35-40 m/min

- 21. 20 3.8- Operation: After slitting fabric is send to stenter machine where heat setting is applied Slit fabric is firstly passed from centric unit so that fabric position remains in the center After that its passes through different types of rollers to remove side curls. Water application is applied to fabric before softener addition and passed through padder Softener applications applied and then passed the fabric through pressurized padder to squeeze the fabric Soft fabric is then passed through over feed rollers for over feeding of the fabric in case of width/GSM adjustment Fabric is also passed through brush wheel before heat setting so that fabric is attached with the pins Fabric is then passed through dryer chambers for drying of the fabric in which oil heat is exchange with the fabric and fabric is dried After that dried fabric is passed to delivery roller Then lapped in the delivery trolley and fabric is ready for next finishing process Fig: 3.8 Fabric passage through Stenter

- 22. 21 3.9- Quality control Hand feel Shrinkage Skewness Width GSM 3.10- Man power Operator per machine = 3 1 is in the front feeding section, 2nd is on panel board and 3rd one is at the end where lapping is done. 3.11- Utilities Water Compressed Air Thermo-oil Electricity Lay out: Centric Unit De - Curling Rollers Water Dipping Padding Rollers Dancing Rollers Chemical Dipping Padding Rollers Main Over Feed Heating Chambers Cooling Zone Lapping

- 23. 22 CHAPTER 04 Raising Machine 4.1- Introduction A finishing process that raises the surface fibers of a fabric by means of passage over rapidly revolving cylinders having metal pins for raising of the fabric. Mostly, terry and LSF fabric is passed through this stage. Machine also includes some rotating brushes. Speed of rollers adjusted the amount of raising of the fabric. With different speed and direction we can get different effects. The raising effect can also be obtained by adjusting the fabric tension or by adjusting the speed and the roller rotation direction. Fig: 4.1 Raising Machine

- 24. 23 4.2- Machine Data, Production Plan & Capacity: Raising # 3 Brand Haining Model MA473D Year of Construction 2009 Max. Fabric Speed 8.12 – 16.20 m/min Capacity 4500 kg/Day Raising # 4 & 2 Brand YANCHENG ZHIDA TEXTILE MECHANICAL Model MA435H Year of Construction 2010 Max. Fabric Speed 6 – 30 m/min Capacity 7500 kg/Day

- 25. 24 Raising # 2 & 6 Brand Haining Manufacturer China Model MA8768A Year of Construction 2014 Max. Fabric Speed 10 – 30 m/min Capacity 7500 kg/Day Raising # 5 Brand TEXLINK Manufacturer China Model TRSM – 36 – 2400 Year of Construction 2015 Max. Fabric Speed 30 m/min Capacity 9000 kg/Day

- 26. 25 4.3- Machine Construction & Operation: The function of a raising machine is to produce a hairy surface on a fabric; this effect is made through a series of needles. Series of rollers that are called raising rollers are placed on a flange with circular settlement; these rollers are covered by an ordered alignment of needles. The raising rollers are divided between ―pile‖ and ―counter pile‖ raising rollers, according to the direction which the needles are plied. Fig: 4.2 Raising Machine Loop Direction: It is rotated opposite to the movement of fabric in longitudinal direction. Note: Before raising width is more and GSM is less and after raising width is less and GSM is more. Single Pass Raising/Double Pass Raising: In single passing we passed the fabric only single time on the pin rollers drum. And in double passing we passed the fabric 2 times from the same place of raiser and we need more raising in that type of case. The production is less in case of double raising.

- 27. 26 About 36 pin rollers are fixed on the drum for raising. A blower is also used to remove raised fluff out to the exhaust. It is better to pass the wet fabric through the raising machine many times (dry when processing cotton fabrics) when there is a need of power full raising and treat the fabrics in advance with softening-lubricating agents. Fig: 4.3 Raising Mechanism How does a Raising machine work? The raising rollers are rotating on their axle; both series of pile and counter pile are rotating in the same direction. The flange on which the raising rollers are fixed is also rotating on its axle. The assembly of raising rollers fixed on two side flanges is called ―main drum‖.

- 28. 27 The fabric encircles and is sliding on most of the raising drum; it enters in one point that is called fabric entry, in this point a driven roller (called tension roller) is controlling the feeding of the fabric on the main drum. The fabric leaves the main drum, pulled out by a roller called fabric speed roller, this roller in fact is controlling the sliding speed of the fabric on the main drum. 4.4- Utilities Needed: Electricity Air

- 29. 28 CHAPTER 05 Compactor 5.1- Introduction Compactor is a textile finishing machine which is designed especially for compacting 100% cotton knitted fabric like jersey, pique, LSF, rib and terry etc. as well as cotton blended fabric in rope form, changing the dimensional stability of the fabric and presenting it to plaited form. Compactor makes it to obtain top quality fabric, with minimized shrinking nature and a soft fluffy hand. Fig: 5.1 Compactor Machine 5.2- Function of Compactor: Compactor is important machine in knit fabric finishing process. There are a lot of technical works which are done by compactor machine. The works are done by compactor machine are; GSM control of the knitted fabric. For high GSM, overfeed is increased and fabric width is decreased. For low GSM, overfeed is decreased and fabric width is increased Control shrinkage Increase smoothness of fabric Heat setting is done of fabric Creases are removed

- 30. 29 5.3- Types of Compactor Machine: Compactor machines are two types. 1. Tubular compactor 2. Open compactor 5.3.1- Tabular Compactor Tubular compactor is used after hydro-extractor, de-watering and dryer. By the compactor machine, compacting is done for control the shrinkage of the fabric. Here, different types of off line quality of the fabric are measured. 5.3.2- Open Width Compactor Open compactor is used for compacting the open form fabric. Here, slitting machine is used for open the fabric from the tubular form. Open Width Compactor is suitable for open width knit fabrics to achieve exact dimensional stability and a soft feel. The machine generally consists of a feeding frame with centering device and driven scroll rollers, an equalizing stenter frame with over feed roller and brush pinning arrangement. The entry section of pin frame is provided with edge spreaders. In-Feed device, an S.S. fabricated steaming unit for uniform moistening of the fabric. The Steaming Device has stainless steel sliding shutters that allow steam to flow only as per the width of the fabric. 5.4- Production Plan & Capacity Compactor # 1 Brand LAFER Model TEXEN Year of Construction 2009 Volts 440V Capacity 4 Tons/Day Fabric Speed (LSF/Terry) 20 – 25 m/min

- 31. 30 Compactor # 2 Brand LAFER Model TEXEN Year of Construction 2009 Volts 440V Capacity 3.6 Tons/Day Fabric Speed (LSF/Terry) 20 – 25 m/min Compactor # 3 Brand LAFER Machine # KSA500 Year of Construction 2014 Volts 440V Capacity 5 Tons/Day Fabric Speed 50 m/min

- 32. 31 5.5- Machine Construction Compactor has same construction and operation as stenter has but in compactor steam is used to moist/soft the fabric for the adjustment of GSM and shrinkage. These are some different things in compactor; Steam: Steam is used in compactor having pressure 1.3 bar and the air used in compactor has 6 bar pressure. Steam is passed through nozzles and moist the passing fabric. Sheet adjustment: In compactor the final GSM is achieved through these sheets. If we compact the sheet with no overfeed then GSM is lesser. If we compact the sheet with overfeed then GSM of the fabric will increases. Speed is controlled according to the fabric type. For LSF speed is about 25m/min and for single jersey speed is more than LSF. 5.6- Quality Control Hand feel Shrinkage GSM 5.7- Man power Operator per machine = 3 5.8- Utilities Water Compressed Air Steam Electricity

- 33. 32 CHAPTER 06 Tumble 5.1- Introduction: A cloth dryer, tumble dryer, or drying machine is a powered household appliance that is used to remove moisture from a load of clothing and other textiles, usually shortly after they are washed in a washing machine. Many dryers consist of a rotating drum called a "tumbler" through which heated air is circulated to evaporate the moisture, while the tumbler is rotated to maintain air space between the articles. Using these machines may cause clothes to shrink. A simpler non-rotating machine called a "drying cabinet" may be used for delicate fabrics and other items not suitable for a tumble dryer. Fig: 6.1 Tumble dryer

- 34. 33 5.2- Tumble Operation: In this process the garment are placed (inside out) into a machine with sealed (not perforated) cylinder and application of recipe by either pumping or spraying The drum is turned for 20 min there should not be excessive dripping of chemicals from the garment. If so more tumbling time is allowed This method is being used more and more due to the fact that there is no wastage of chemicals After saturation the garments are hydro extracted tumble dry at 70°C to 10—20 % pick up moisture content The iron and steam press the garments to remove/set creases. Cure at 150—160°C for 8 - 10 min 5.3- Machine Data: Tumble Dryer Brand Two Star No. of Machines 4 Capacity 600 kg/day (Each Machine) 5.4- Utilities: Water Electricity Steam Compressed Air