Flarenet

- 1. ASPEN FLARE SYSTEM ANALYZER/ FLARENET By GAUTHAM S Process Engineer

- 2. Simulation It is the process of examination of a problem not by subjecting a direct experimentation but by a software capable of producing the results under certain caveats. SOFTWARES AVAILABLE Aspen Hysys, Aspen Plus, Unisim, Pro II, Flarenet, Pipesim, Pipenet, etc

- 3. Selection of Simulator • The different simulator available are Aspen HYSYS, Aspen Plus, Unisim, PRO II, etc., • VB, the liquid molar volume at the boiling point TB, for Water is wrong in the Aspen Plus databank PURE10. In PURE10, the value of VB in CC/MOL is 1401.38; however, the value should be 18.5064 CC/MOL. This property VB used in some transport properties, viscosity, diffusion coefficient like Wilke Chang model. It will not effect liquid density calculations • The knowledge of limitations of different simulators is necessary to choose the effective simulator.

- 4. Flare Scheme Simulation • Aspen Flare System Analyzer is a software to simulate the flare system network. • It was previously called Flarenet.

- 5. Basis of Simulating a Flare Network Scheme • Define the Composition • Define the Flare Network • Define the Sources • Define the Scenarios

- 6. Define the Flare Network • It involves the routing of the flare network. • The header, pipes, vessel and associated fittings involved will be taken into account. It is incomplete without the addition of the sources

- 7. Define the Sources • The various sources are Control Valves Pressure Safety Valves Blow down Valves with Restriction Orifice • To define the sources, we need the following PSV SIZING DATA Process Simulation (HYSYS File) Depressuring Calculation

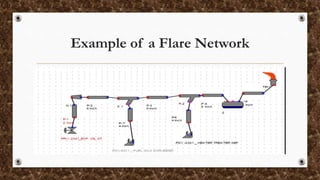

- 8. Example of a Flare Network

- 9. Define the Scenarios • The one default scenario is when all relief devices go mayhem • The others can be Blocked Discharge, Power failure, Control Valve failure Emergency Blowdown etc.,

- 10. Outcome of Flare Scheme Simulation • The pipes such as flare header size can be designed and verified as per API recommended practice. • Calculations involving MACH No / Velocity /Pressure drop /Noise limit can also be designed and verified as per API Standards.

- 11. Flare Simulation Development Methodology • Flare composition and Molecular Weight • Inlet pressure and temperature at Control Valves • PSV governing cases and their respective orifice size • Dimensions of pipes, vessels and associated fittings involved • Client specification on Flare system • Flare Network Scheme

- 12. Flare Simulation Report • Introduction - Background & Objectives • Basis of Simulation Study - Scope of the study - Reference documents - Test run review for different Scenarios • Results of the simulation study - Quality of test run simulations - Alternative Sizing or Rating results - Robustness of the design - Conclusion

- 13. THANK YOU