Fly ash

- 1. FLY ASH Gayatri Pande. Manjari Yengde. SDMCA.

- 2. • Fly ash, also known as "pulverised fuel ash" it is a coal combustion product composed of fine particles that are driven out of the boiler with the flue gases. Ash that falls in the bottom of the boiler is called bottom ash.

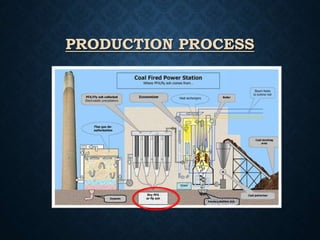

- 3. PRODUCTION • Fly ash is one of the residues created during the combustion of coal in coal-fired power plants. • Fine particles rise with flue gasses and are collected with filter bags or electrostatic precipitators • Fly ash is a waste by-product material that must be disposed of or recycled • 131 million tons of fly ash are produced annual by 460 coal- fired power plants in the U.S. alone.

- 5. CHEMICAL COMPOSITION • Because fly ash is a by-product material chemical constituents can vary considerably but all fly includes: • Silicon Dioxide (SiO2) • Calcium Oxide (CaO) also known as Lime • Iron (III) Oxide (FeO2) • Aluminum Oxide (Al2O3) • Depending on source coal may include on or more toxic chemicals in trace amounts: • Arsenic, Beryllium, Boron, Cadmium, Chromium, Cobalt, Lead, Manganese, Mercury, Molybdenum, Selenium, Strontium, Thallium, and Vanadium.

- 6. CLASSES • ASTM C618 Defines two classes of fly ash: • Class C • Class F • ASTM C618 requirements: • Loss of Ignition (LOI) < 4% • 75% of ash must have fineness of 45 µm or less • Primary difference between Class C and Class F fly ash is the amount of the amount of calcium, silica, alumina, and iron content in the ash

- 7. CLASS C • Produced from burning younger lignite and subbituminous coal • Higher concentration of alkali and sulfate • Contains more than 20% lime • Self-cementing properties • Does not require activator • Does not require air entrainer • Not for use in high sulfate conditions • Primarily residential construction • Limited to low fly ash content concrete mixes

- 8. CLASS F • Produced from burning harder, older anthracite and bituminous coal. • Contains less than 20% lime • Requires cementing agent like PC, quick lime, hydrated lime • Used in high sulfate exposure conditions • Addition of air entrainer needed • Used for structural concretes, HP concretes, high sulfate exposure concretes • Useful in high fly ash content concrete mixes

- 9. RECYCLED FLY ASH USE

- 10. DISPOSAL • In the past fly ash produced from coal power plants was simply entrained in flue gasses and released into the environment. Now in the U.S., EPA regulations requires greater than 99% of total fly ash produced in a plant to be captured and either stored, recycled, or disposed. • Worldwide, more than 65% of fly ash produced in the world is disposed of in landfills or ash ponds. • In India alone fly ash landfills comprise 40,000 acres of land.

- 11. FLY ASH LANDFILL

- 12. FLY ASH USES • Portland Cement and Grout • Brick and CMU • Embankment/ Structural Fill and Mine Reclamation • Road Subbase • Soil Stabilization • Flowable Fills (CLSM) • Waste Stabilization and Solidification • Raw Feed for Cement Clinkers • Aggregate • Ashphaltic Concrete Mineral Filler • Numerous Agricultural Applications

- 13. CLASS C VS. CLASS F FLY ASH CONCRETES • 1. Class C fly ash is typically not as effective as Class F fly ash in mitigation of ASR. • 2. Class C will generate more heat of hydration than Class F. • 3. Class C will generally not be as resistant to sulfate attack. ASTM C 618 prohibits the use of Class C in high sulfate exposure environments • 4. Class C will generate more strength at early ages than Class F. • Generally Class F can be used for high fly ash content concretes (up to 40% of C.M.) whereas Class C is used in low fly ash content concretes

- 14. FLY ASH BRICKS • Fly ash bricks are durable, have low water absorption, less consumption of mortar, and are economical/eco- friendly. • Fly ash bricks can have up to three times the strength of conventional bricks • Fly ash bricks can utilize up to 50% Class C fly ash. • Fly ash brick production can reduce the embodied energy of masonry construction by up to 90%.

- 15. FLOWABLE FILL • Flowable fill is used as a self-leveling, self compacting backfill material that replaces compacted soils or granular fill. • The strength of the flowable fill varies from 50 to 1,200 lbf/in². • Fly ash generally supplements the Portland cement in greater volume than fly ash concretes it also acts as a mineral filler. • Mainly used in place of concrete to reduce dead loads and allow for future excavation if necessary. • The fine particulate of the fly ash acts as ball bearings allowing it to flow freely. • Generally Class C fly ash is used for flowable fill.

- 16. SOIL STABILIZATION • Soil stabilization is the permanent physical and chemical alteration of soils to enhance their properties. • Using fly ash as a soil stabilization can increase shear strength, control the shrink-swell properties of the soil, and improve the load bearing capacity. • Benefits include higher resistance (R) values, reduction in plasticity, lower permeability, and elimination of excavation.

- 17. SOIL STABILIZATION • A sheep’s foot roller is commonly used to add the fly ash to the soil. • Also specialized equipment can be utilized to pump fly ash or other stabilizers into the soil. • Class C fly ash is used in soil stabilization