Green Belt Project Storyboard Template Example

- 1. Lunch Order Cycle Time Project Storyboard Bahama Bistro Example Visit GoLeanSixSigma.com for more Lean Six Sigma Resources

- 3. Key Words (Specific to Bahama Bistro) • Order Lead Time: Total cycle time from the moment the customer places their order to the moment they receive their food. • Lunch Time: Key lunch ordering hours from 11am to 2pm • Customers: Business people and vacationers • Packaging Process: All tasks related to placing food into take-out containers, selecting utensils, napkins and condiments and then placing them all into a bag • Stock Items: All raw food items and food packaging items • Condiments: Mini-bottles of hot sauce, limes, salt and pepper

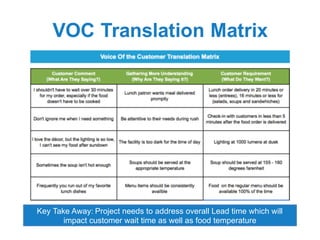

- 5. VOC Translation Matrix Key Take Away: Project needs to address overall Lead time which will impact customer wait time as well as food temperature

- 6. SIPOC – Lunch Order to Delivery Key Take Away: The scope of this project goes from the point of receiving the lunch order to the point at which food is delivered or picked up

- 7. “As Is” Spaghetti Map Key Take Away: Prep area setup leads to a lot of wasted motion

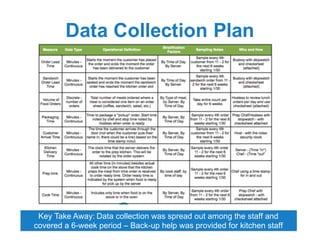

- 8. Data Collection Plan Key Take Away: Data collection was spread out among the staff and covered a 6-week period – Back-up help was provided for kitchen staff

- 9. Baseline Data –Lead Time Key Take Away: The baseline shows that for many orders, both the Order Lead Time and the Sandwich Order Lead time were well beyond the requirement. Order Lead Time Sandwich Order Lead Time

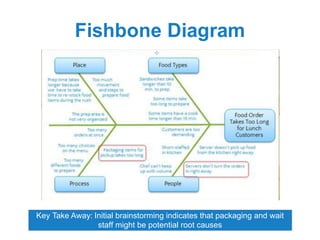

- 10. Fishbone Diagram Key Take Away: Initial brainstorming indicates that packaging and wait staff might be potential root causes

- 11. 5 Whys Key Take Away: Root Cause Analysis will focus on verifying how much packing layout and wait staff habits are impacting Order Lean Time

- 12. Process Analysis Key Take Away: The majority of the steps are non- value adding or non- value-adding but required – lots of opportunity to remove waste

- 13. Hypothesis Confirmations Key Take Away: Data shows sandwich prep takes up to 13 min., cook times are <20 min., prep area is issue & servers don’t delay orders Histogram of Sandwich Prep Time Histogram of Cooking Time

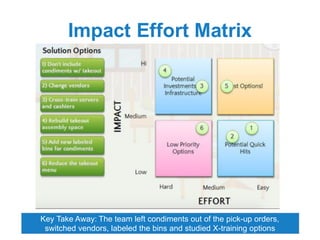

- 14. Impact Effort Matrix Key Take Away: The team left condiments out of the pick-up orders, switched vendors, labeled the bins and studied X-training options

- 15. Risk Management Key Take Away: Having the vendor call to confirm quantities would lead to lower risk of running out of key menu items

- 16. To Be Spaghetti Map Key Take Away: New layout reduces waste of motion and cuts process time in half

- 17. Before & After Time Data Key Take Away: Implemented solutions significantly decreased both Sandwich and Order Lead Time Order Lead Time – Before and After Sandwich Order Lead Time – Before and After

- 18. Monitoring & Response Plan Key Take Away: The monitoring plan factors in both the leading indicators of packaging and prep time along with the project “Y” of Order Lead Time

- 19. Innovation Transfer Opportunities Key Take Away: Most of the improvements can be immediately transferred to other bistro locations for immediate time savings

Editor's Notes

- VO – The Monitoring plan should be meaningful and manageable. Collecting too many measure for a monitoring plan may discourage employees from doing it.