Heat Exchanger

- 1. . Introduction to HEAT EXCHANGERS Joy Mukherjee

- 2. What is a Heat Exchanger? A heat exchanger is a device which transfers heat from one medium to another.

- 4. Types of HE q Double-pipe exchanger q Shell and tube exchangers q Plate and frame exchangers q Plate-fin exchangers. q Spiral heat exchangers. q Air cooled heat exchangers q Agitated vessels. q Fired heaters.

- 5. Based on transfer process qIndirect Contact – Shell & Tube Heat Exchangers qDirect Contact – Cooling Towers qGas-Liquid exchangers qLiquid-Liquid exchangers qGas-Gas heat exchangers Based on phase of fluids

- 6. Based on construction q Tubular § Double pipe heat exchanger § Shell and tube heat exchangers § Spiral heat exchangers q Plate-type § Plate and frame heat exchangers § Spiral plate heat exchangers q Extended Surface § Plate-fin exchanger § Tube-fin exchanger

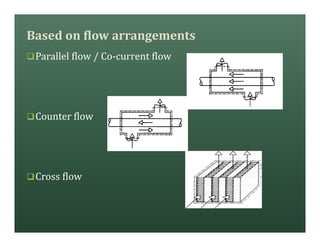

- 7. Based on flow arrangements qParallel flow / Co-current flow qCounter flow qCross flow

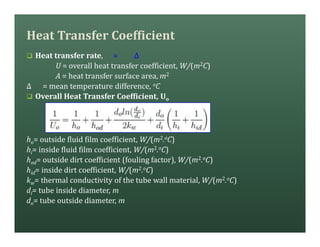

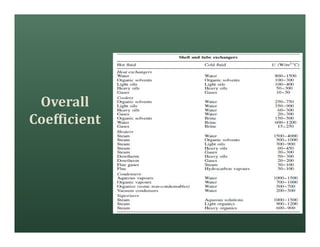

- 8. Heat Transfer Coefficient q Heat transfer rate, = ∆ U = overall heat transfer coefficient, W/(m2C) A = heat transfer surface area, m2 ∆ = mean temperature difference, oC q Overall Heat Transfer Coefficient, Uo ho= outside fluid film coefficient, W/(m2.oC) hi= inside fluid film coefficient, W/(m2.oC) hod= outside dirt coefficient (fouling factor), W/(m2.oC) hid= inside dirt coefficient, W/(m2.oC) kw= thermal conductivity of the tube wall material, W/(m2.oC) di= tube inside diameter, m do= tube outside diameter, m

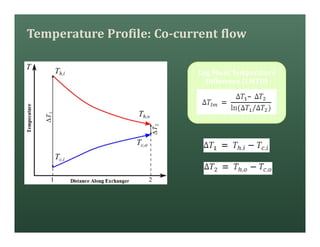

- 9. Temperature Profile: Co-current flow Log Mean Temperature Difference (LMTD)

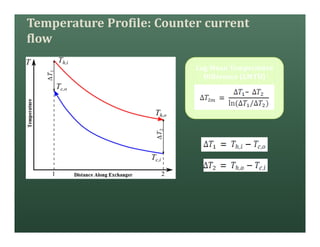

- 10. Temperature Profile: Counter current flow Log Mean Temperature Difference (LMTD)

- 11. Temperature Correction Factor (Ft) q Mean temperature difference, ∆ ∆ = ∆ qFt depends on R & S = − − = − −

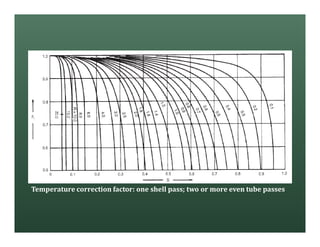

- 12. Temperature correction factor: one shell pass; two or more even tube passes

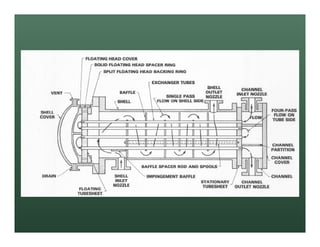

- 15. Components of a STHE q Shell q Shell cover q Tubes q Channel q Channel Cover q Tube sheet q Baffles q Floating-Head Cover q Nozzles q Tie-Rods & Spacers q Pass Partition Plates q Impingement Plates q Sealing Strips & Sealing Rods

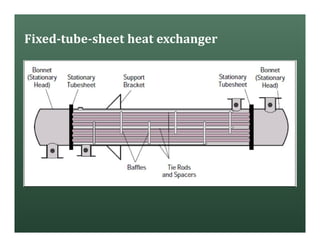

- 16. Classification by Construction Fixed-tube-sheet heat exchanger qHas straight tubes secured at both ends to tube-sheets welded to the shell qLow cost, simplest construction. qBundle is "fixed" to the shell so outside of the tubes cannot be cleaned mechanically. qApplication is limited to clean services on the shell side

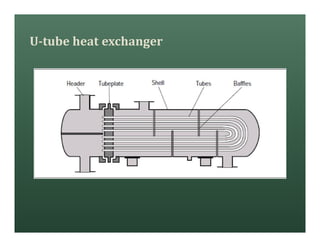

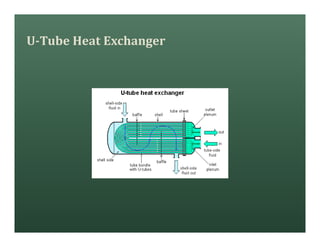

- 18. U-tube heat exchanger q Tubes are bent in the shape of a U q Only one tube-sheet q Bending of tubes adds to the cost q Tube bundle is removable, outside of tubes can be cleaned. q Because of the U-bend, inside of the tubes can’t be cleaned mechanically q Can’t be used for dirty fluids inside tubes.

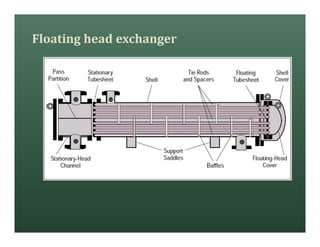

- 20. Floating head exchanger qMost versatile and costliest. qOne tube-sheet is fixed relative to the shell, and the other is free to “float” within the shell. qCleaning of both the insides and outsides of the tubes qCan be used for services where both the shell-side and the tube-side fluids are dirty Widely used in Petroleum Industry

- 23. Straight-Tube ( 1-Pass )

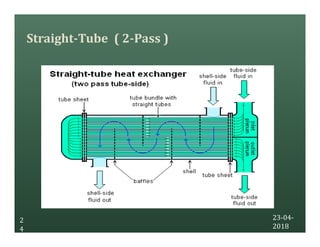

- 24. Straight-Tube ( 2-Pass ) 23-04- 2018 2 4

- 25. Transportation of Heat Exchanger

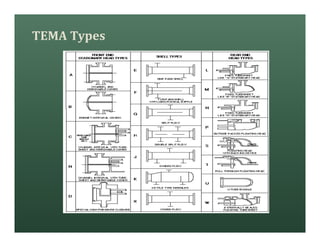

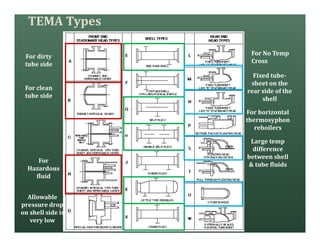

- 26. TEMA Types

- 27. For dirty tube side For clean tube side For Hazardous fluid For horizontal thermosyphon reboilers For No Temp Cross Large temp difference between shell & tube fluids Allowable pressure drop on shell side is very low Fixed tube- sheet on the rear side of the shell TEMA Types

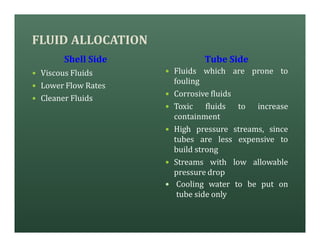

- 28. FLUID ALLOCATION Shell Side Tube Side — Viscous Fluids — Lower Flow Rates — Cleaner Fluids — Fluids which are prone to fouling — Corrosive fluids — Toxic fluids to increase containment — High pressure streams, since tubes are less expensive to build strong — Streams with low allowable pressure drop — Cooling water to be put on tube side only

- 29. Tubes Tubes should be able to withstand: § Operating temperature and pressure on both sides § Thermal stresses due to the differential thermal expansion between the shell and the tube bundle § Corrosive nature of both the shell-side and the tube-side fluids Ø TUBE PITCH RATIO: Min 1.25 times of tube OD 1.333 times of tube OD 1.5 times of tube OD Ø TUBE PASS: Based on pressure drop & velocity limit on tube side

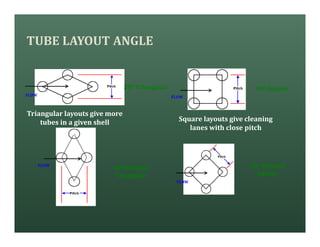

- 30. TUBE LAYOUT ANGLE 30o FLOW 90o FLOW 45o FLOW 60o FLOW 30o Triangular 60o Rotated Triangular 45o Rotated Square 90o Square Triangular layouts give more tubes in a given shell Square layouts give cleaning lanes with close pitch

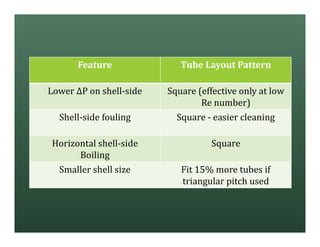

- 31. Feature Tube Layout Pattern Lower ΔP on shell-side Square (effective only at low Re number) Shell-side fouling Square - easier cleaning Horizontal shell-side Boiling Square Smaller shell size Fit 15% more tubes if triangular pitch used

- 32. Tube pitch qShortest distance between two adjacent tubes. qTEMA specifies a minimum tube pitch of 1.25*(OD) qMinimum tube pitch leads to smallest shell diameter for a given number of tubes. qTo reduce shell-side pressure drop, the tube pitch may be increased to a higher value.

- 33. Tube-sheet q Barrier between shell-side and tube-side fluids. q Mostly circular with uniform pattern of drilled holes. q Tubes are attached to tube-sheet

- 34. Tie rods and spacers Tie rods and spacers are used for: q holding the baffle assembly together q maintaining the selected baffle spacing qhelp the bundle to slide out from the shell qCan also be used as tie rods to hold the bundle in position. Sliding strips

- 35. Sealing strips and Seal rods qSealing strips prevent shell side fluid from bypassing the bundle. qSealing strips block the resulting large open area at top or bottom of the shell. qSeal rods are also used to control the leakage streams.

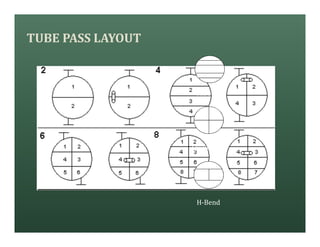

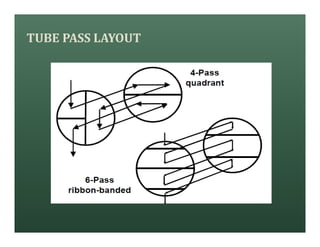

- 37. TUBE PASS LAYOUT

- 38. TYPES OF BAFFLES qSegmental type; § Single – horizontal & vertical § Double § Triple § No-Tubes in Window (NTIW) qOrifice type qDisc and doughnut type qRod type qImpingement type qLongitudinal (pass partitions)

- 39. TYPES OF BAFFLES

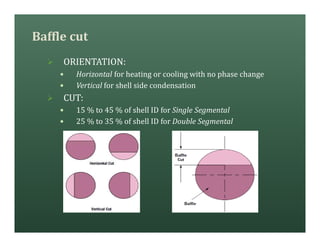

- 40. Ø ORIENTATION: — Horizontal for heating or cooling with no phase change — Vertical for shell side condensation Ø CUT: — 15 % to 45 % of shell ID for Single Segmental — 25 % to 35 % of shell ID for Double Segmental Baffle cut

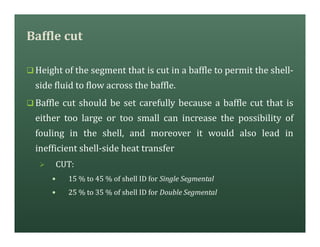

- 41. Baffle cut q Height of the segment that is cut in a baffle to permit the shell- side fluid to flow across the baffle. q Baffle cut should be set carefully because a baffle cut that is either too large or too small can increase the possibility of fouling in the shell, and moreover it would also lead in inefficient shell-side heat transfer Ø CUT: — 15 % to 45 % of shell ID for Single Segmental — 25 % to 35 % of shell ID for Double Segmental

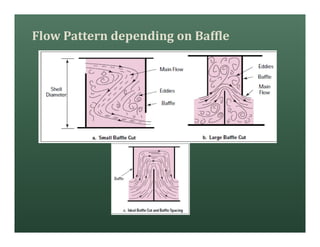

- 42. Flow Pattern depending on Baffle

- 43. Baffle/ Nozzle orientation q The orientation of the baffle cut is important for heat exchanger installed horizontally. Ø When the shell side heat transfer is sensible heating or cooling with no phase change, the baffle cut should be horizontal. Ø For shell side condensation, the baffle cut for segmental baffles is vertical. Ø For shell side boiling, the baffle cut may be either vertical or horizontal depending on the service. q Positioning of inlet/ outlet nozzle is also important for the proper functioning of exchangers. Ø In cooling water services, the inlet nozzle should be at the bottom and outlet nozzle should be at the top. Ø For condensing services exit should be from the bottom nozzle.

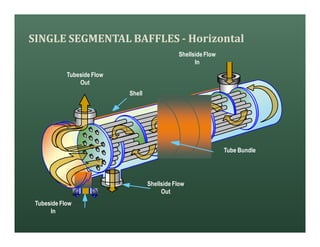

- 44. Shellside Flow Out Tubeside Flow In Tubeside Flow Out Shell Tube Bundle Shellside Flow In SINGLE SEGMENTAL BAFFLES - Horizontal

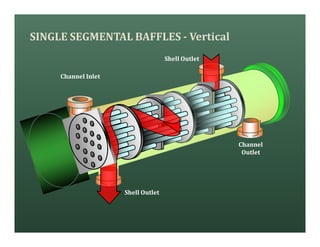

- 45. Shell Outlet Channel Inlet Channel Outlet Shell Outlet SINGLE SEGMENTAL BAFFLES - Vertical

- 46. Shell Outlet Shell Inlet DOUBLE SEGMENTAL TRANSVERSE BAFFLES

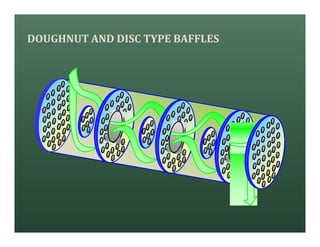

- 47. DOUGHNUT AND DISC TYPE BAFFLES

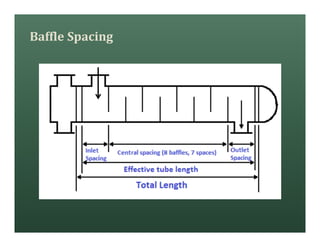

- 48. Baffle Spacing qBaffle spacing is the longitudinal or centreline-to- centreline distance between adjacent baffles. qAccording to TEMA, the minimum baffle spacing should be one-fifth of the shell inside diameter or 2 in., whichever is greater. qThe maximum baffle spacing is the shell inside diameter.

- 49. Baffle Spacing

- 50. Impingement devices q Impingement rod, Impingement plate, Nozzle Impingement baffle are the various devices used in heat exchangers to trim down the effects of high velocity at entry nozzles over tube bundle.

- 51. TUBE-PROBLEMS • Scaling of inside/outside of the tube surface • Blockage of tube passage • By passing across the baffle • Puncture in the tube • Leakage through the tube to tube-sheet • Leakage through gasketted joint of floating head

- 52. Bypass & Leakage streams: TINKER FLOW MODEL Ø B stream: Main heat transfer stream, follows a path around baffles and through tube bundle Ø A stream: Leakage stream, flowing through clearance between tubes and holes in baffles Ø C stream: Tube bundle bypass stream in the gap between the tube bundle and shell wall Ø E stream: Leakage stream between baffle edge and shell wall Ø F stream: Bypass stream in flow channel partitions due to omissions of tubes in tube pass partitions.

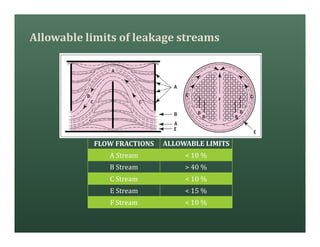

- 53. FLOW FRACTIONS ALLOWABLE LIMITS A Stream < 10 % B Stream > 40 % C Stream < 10 % E Stream < 15 % F Stream < 10 % Allowable limits of leakage streams

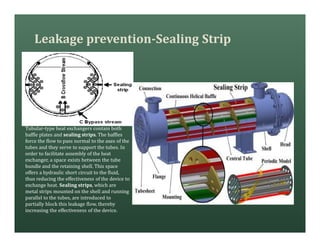

- 54. Leakage prevention-Sealing Strip Tubular-type heat exchangers contain both baffle plates and sealing strips. The baffles force the flow to pass normal to the axes of the tubes and they serve to support the tubes. In order to facilitate assembly of the heat exchanger, a space exists between the tube bundle and the retaining shell. This space offers a hydraulic short circuit to the fluid, thus reducing the effectiveness of the device to exchange heat. Sealing strips, which are metal strips mounted on the shell and running parallel to the tubes, are introduced to partially block this leakage flow, thereby increasing the effectiveness of the device.

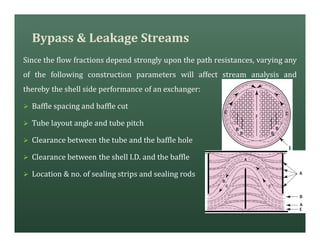

- 55. Bypass & Leakage Streams Since the flow fractions depend strongly upon the path resistances, varying any of the following construction parameters will affect stream analysis and thereby the shell side performance of an exchanger: Ø Baffle spacing and baffle cut Ø Tube layout angle and tube pitch Ø Clearance between the tube and the baffle hole Ø Clearance between the shell I.D. and the baffle Ø Location & no. of sealing strips and sealing rods

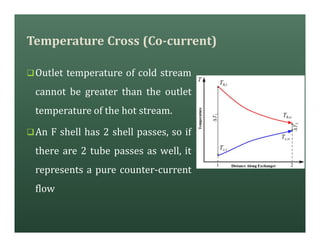

- 56. Temperature Cross (Co-current) qOutlet temperature of cold stream cannot be greater than the outlet temperature of the hot stream. qAn F shell has 2 shell passes, so if there are 2 tube passes as well, it represents a pure counter-current flow

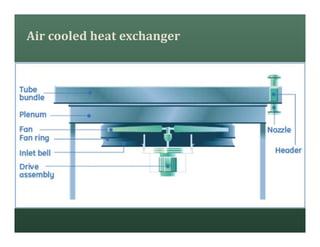

- 57. Air cooled heat exchanger

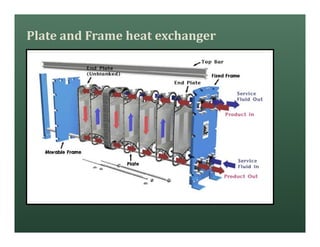

- 58. Plate and Frame heat exchanger

- 59. Spiral heat exchanger Ideal for handling fouling fluids, viscous media, slurries, sewage sludge, and other dirty process fluids and effluents with suspended solids or fibres.

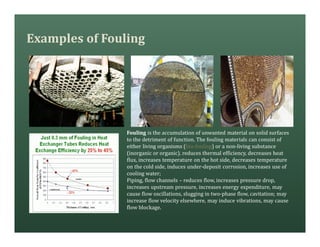

- 60. Examples of Fouling Fouling is the accumulation of unwanted material on solid surfaces to the detriment of function. The fouling materials can consist of either living organisms (bio-fouling) or a non-living substance (inorganic or organic). reduces thermal efficiency, decreases heat flux, increases temperature on the hot side, decreases temperature on the cold side, induces under-deposit corrosion, increases use of cooling water; Piping, flow channels – reduces flow, increases pressure drop, increases upstream pressure, increases energy expenditure, may cause flow oscillations, slugging in two-phase flow, cavitation; may increase flow velocity elsewhere, may induce vibrations, may cause flow blockage.

- 61. Aims of Thermal Design 1. Achieve the specified duty at minimum overall cost 2. To achieve high heat transfer coefficient within allowable pressure drops. 3. 10-20 % Overdesign margin (design safety) 4. Pressure drops should be in limits 5. To keep fluid velocities in limit 6. To keep shell side flow fractions in limit

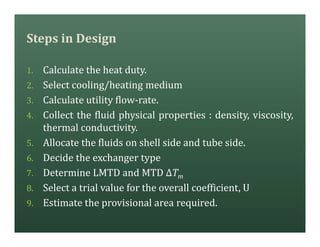

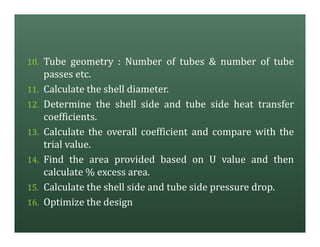

- 63. Steps in Design 1. Calculate the heat duty. 2. Select cooling/heating medium 3. Calculate utility flow-rate. 4. Collect the fluid physical properties : density, viscosity, thermal conductivity. 5. Allocate the fluids on shell side and tube side. 6. Decide the exchanger type 7. Determine LMTD and MTD ΔTm 8. Select a trial value for the overall coefficient, U 9. Estimate the provisional area required.

- 64. 10. Tube geometry : Number of tubes & number of tube passes etc. 11. Calculate the shell diameter. 12. Determine the shell side and tube side heat transfer coefficients. 13. Calculate the overall coefficient and compare with the trial value. 14. Find the area provided based on U value and then calculate % excess area. 15. Calculate the shell side and tube side pressure drop. 16. Optimize the design

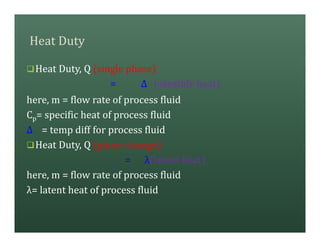

- 65. Heat Duty qHeat Duty, Q (single phase) = ∆ (sensible heat) here, m = flow rate of process fluid Cp= specific heat of process fluid ∆ = temp diff for process fluid qHeat Duty, Q (phase change) = λ(latent heat) here, m = flow rate of process fluid λ= latent heat of process fluid

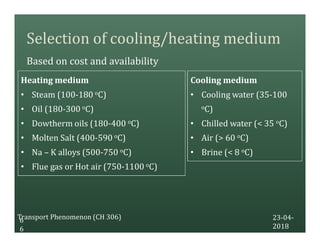

- 66. Selection of cooling/heating medium Based on cost and availability 23-04- 2018 Transport Phenomenon (CH 306)6 6 Cooling medium • Cooling water (35-100 oC) • Chilled water (< 35 oC) • Air (> 60 oC) • Brine (< 8 oC) Heating medium • Steam (100-180 oC) • Oil (180-300 oC) • Dowtherm oils (180-400 oC) • Molten Salt (400-590 oC) • Na – K alloys (500-750 oC) • Flue gas or Hot air (750-1100 oC)

- 67. Utility Flow rate qUtility flow rate, mw = ∆ Here, m = flow rate of utility Cpw= specific heat of utility ∆ = temp diff for utility

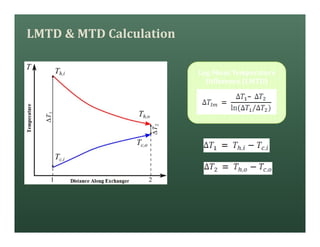

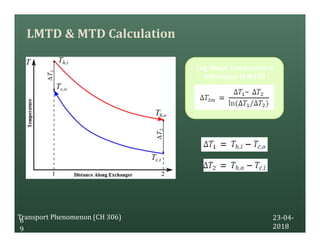

- 68. LMTD & MTD Calculation Log Mean Temperature Difference (LMTD)

- 69. LMTD & MTD Calculation 23-04- 2018 Transport Phenomenon (CH 306)6 9 Log Mean Temperature Difference (LMTD)

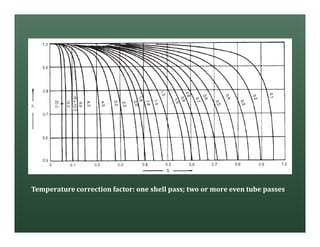

- 70. Temperature Correction Factor (Ft) q Mean temperature difference, ∆ ∆ = ∆ qFt depends on R & S = − − = − −

- 71. Temperature correction factor: one shell pass; two or more even tube passes

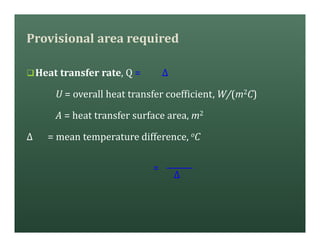

- 73. Provisional area required qHeat transfer rate, Q = ∆ U = overall heat transfer coefficient, W/(m2C) A = heat transfer surface area, m2 ∆ = mean temperature difference, oC = ∆

- 74. Number of tubes = Here, Nt= No. of tubes do= tube o.d. L= Tube length qDecide the number of passes & tube layout, pitch

- 75. § To avoid fouling, tube velocity is kept between 1-2 m/s § At 2 and 4 passes, tube velocity is less than 1 m/s § At 8 passes, tube velocity is more than 2 m/s § Number of passes = 6 0 0.5 1 1.5 2 2.5 2 4 6 8 TubeSideVelocity,m/s No. of Passes Tube Passes vs Tube Side Velocity 1.35 m/s

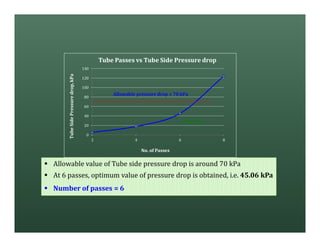

- 76. § Allowable value of Tube side pressure drop is around 70 kPa § At 6 passes, optimum value of pressure drop is obtained, i.e. 45.06 kPa § Number of passes = 6 0 20 40 60 80 100 120 140 2 4 6 8 TubeSidePressuredrop,kPa No. of Passes Tube Passes vs Tube Side Pressure drop 45.06 kPa Allowable pressure drop = 70 kPa

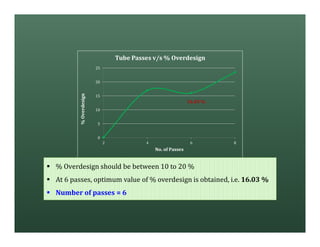

- 77. 0 5 10 15 20 25 2 4 6 8 %Overdesign No. of Passes Tube Passes v/s % Overdesign 16.03 % § % Overdesign should be between 10 to 20 % § At 6 passes, optimum value of % overdesign is obtained, i.e. 16.03 % § Number of passes = 6

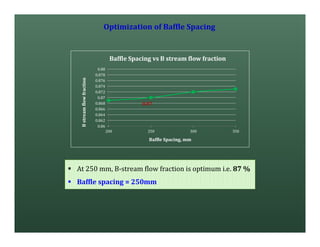

- 78. Optimization of Baffle Spacing § At 250 mm, B-stream flow fraction is optimum i.e. 87 % § Baffle spacing = 250mm 0.86 0.862 0.864 0.866 0.868 0.87 0.872 0.874 0.876 0.878 0.88 200 250 300 350 Bstreamflowfraction Baffle Spacing, mm Baffle Spacing vs B stream flow fraction 0.87

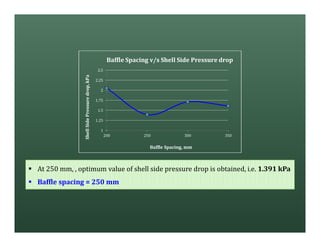

- 79. 1 1.25 1.5 1.75 2 2.25 2.5 200 250 300 350 ShellSidePressuredrop,kPa Baffle Spacing, mm Baffle Spacing v/s Shell Side Pressure drop § At 250 mm, , optimum value of shell side pressure drop is obtained, i.e. 1.391 kPa § Baffle spacing = 250 mm

- 80. 10 12 14 16 18 20 22 200 250 300 350 %Overdesign Baffle Spacing, mm Baffle Spacing vs % Overdesign 16.03 % § % Overdesign should be between 10 to 20 % § At 250 mm, optimum value of % overdesign is obtained, i.e. 16.03 % § Baffle spacing = 250 mm

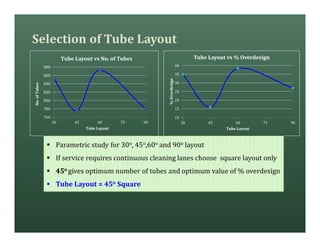

- 81. 760 780 800 820 840 860 880 30 45 60 75 90 No.ofTubes Tube Layout Tube Layout vs No. of Tubes Selection of Tube Layout 10 15 20 25 30 35 40 30 45 60 75 90 %Overdesign Tube Layout Tube Layout vs % Overdesign § Parametric study for 30o, 45o,60o and 90o layout § If service requires continuous cleaning lanes choose square layout only § 45o gives optimum number of tubes and optimum value of % overdesign § Tube Layout = 45o Square

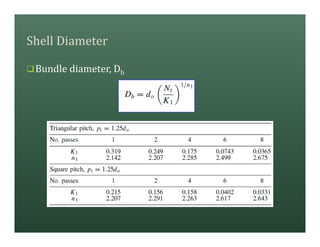

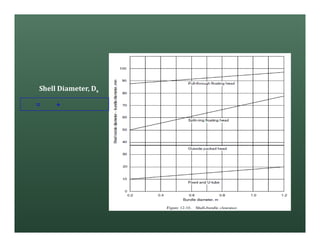

- 83. = + Shell Diameter, Ds

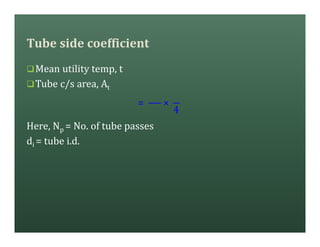

- 84. Tube side coefficient qMean utility temp, t qTube c/s area, At = × 4 Here, Np = No. of tube passes di = tube i.d.

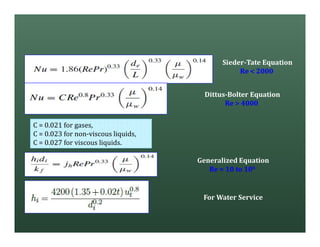

- 85. Sieder-Tate Equation Re < 2000 Dittus-Bolter Equation Re > 4000 Generalized Equation Re = 10 to 106 For Water Service C = 0.021 for gases, C = 0.023 for non-viscous liquids, C = 0.027 for viscous liquids.

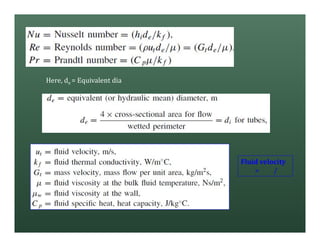

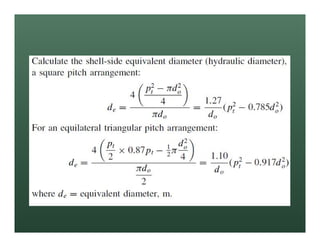

- 86. Here, de = Equivalent dia Fluid velocity = /

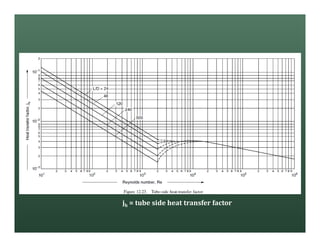

- 87. jh = tube side heat transfer factor

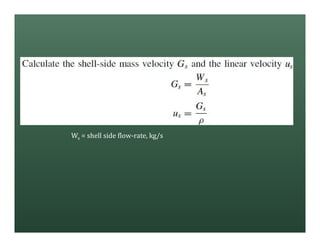

- 88. Shell Side Coefficient qChoose baffle spacing, lB and tube pitch, pt q1/5th of the shell dia or 2 in., whichever is greater qCross-flow area Here, lB is baffle spacing, m. qCalculate mean temperature qDecide baffle cut % (start with 25%)

- 89. Ws = shell side flow-rate, kg/s

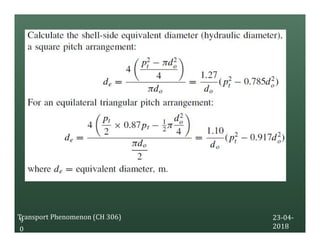

- 90. 23-04- 2018 Transport Phenomenon (CH 306)9 0

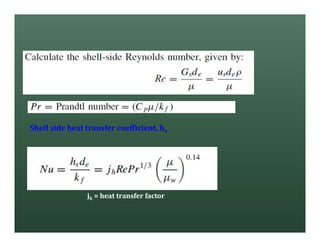

- 91. Shell side heat transfer coefficient, hs jh = heat transfer factor

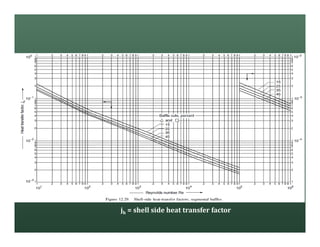

- 92. jh = shell side heat transfer factor

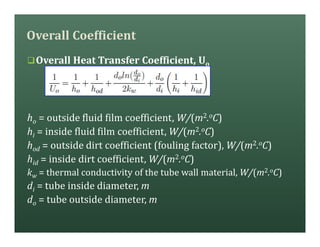

- 93. Overall Coefficient qOverall Heat Transfer Coefficient, Uo ho = outside fluid film coefficient, W/(m2.oC) hi = inside fluid film coefficient, W/(m2.oC) hod = outside dirt coefficient (fouling factor), W/(m2.oC) hid = inside dirt coefficient, W/(m2.oC) kw = thermal conductivity of the tube wall material, W/(m2.oC) di = tube inside diameter, m do = tube outside diameter, m

- 94. Dirt factor / Dirt coefficient /Fouling factor

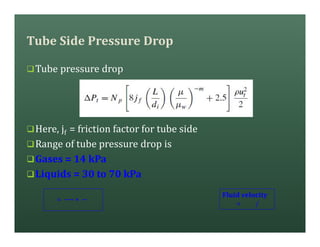

- 95. Tube Side Pressure Drop qTube pressure drop qHere, jf = friction factor for tube side qRange of tube pressure drop is qGases = 14 kPa qLiquids = 30 to 70 kPa = × Fluid velocity = /

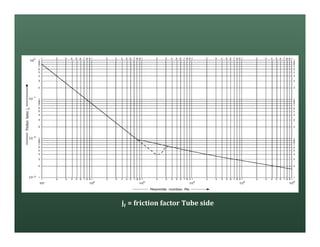

- 96. jf = friction factor Tube side

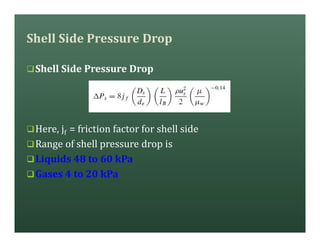

- 97. Shell Side Pressure Drop qShell Side Pressure Drop qHere, jf = friction factor for shell side qRange of shell pressure drop is qLiquids 48 to 60 kPa qGases 4 to 20 kPa

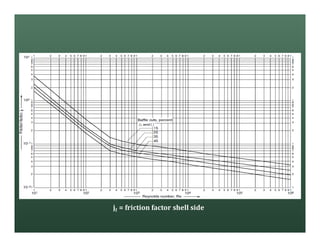

- 98. jf = friction factor shell side

- 99. To Reduce Tube Side Pressure Drop qTube pressure drop ØDecrease number of tube passes ØIncrease tube diameter ØDecrease tube length ØIncrease number of tubes & hence increase shell diameter = × Fluid velocity = /

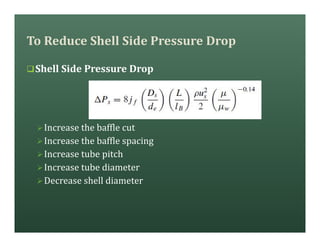

- 100. To Reduce Shell Side Pressure Drop qShell Side Pressure Drop ØIncrease the baffle cut ØIncrease the baffle spacing ØIncrease tube pitch ØIncrease tube diameter ØDecrease shell diameter