Hot Water for Industry

- 2. ARMSTRONG IS A TRUSTED GLOBAL LEADER IN INSTANTANEOUS HOT WATER GENERATION, DISTRIBUTION AND PRECISION TEMPERATURE CONTROL. With in-depth knowledge and experience that spans more than a century, Armstrong understands your industry’s hot water system dynamic in ways no one else can. REGARDLESS OF THE METHOD YOU USE TO HEAT WATER, WE HAVE THE INTELLIGENT SOLUTIONS YOU NEED. Our experts will show you how to avoid scaling, improve efficiency and safety, and increase your production and yield. We can also help you satisfy global water quality standards by providing clean, safe outgoing water that meets USFDA and EU bottle water and food ingredient water standards for direct use without additional filtration. (This statement presumes USFDA and EU compliant influent water.) ARMSTRONG DOES IT ALL. We can solve your problems and prevent them with a packaged solution designed specifically for your unique parameters. We offer a full range of individual state-of-the-art products, including: water heaters, water temperature controls, hose stations, variable frequency drive (VFD) pump assemblies and ancillary accessories such as storage tanks, pressure-reducing valves and more. From a complete, fully integrated hot water system for a new facility to custom- engineering and turnkey solutions for each of your existing plants worldwide, Armstrong is your single source solution. For more information or to find an Armstrong representative in your area, visit our new, easy-to-navigate website at: armstronginternational.com/products-systems/hot-water-industry. 2 HOT WATER FOR INDUSTRY

- 3. 3

- 4. 4 HEATING WATER WITH STEAM ARMSTRONG DELIVERS GROUNDBREAKING ACCURACY, SIMPLICITY AND UNPARALLELED PERFORMANCE WITH OUR ADVANCED STEAM/WATER SOLUTION. We combined our state-of-the-art digital water temperature control technology with our instantaneous heat exchanger design to create ReadiTemp™—a revolutionary series of standard and application-customized steam/water instantaneous water heaters for any process application requiring very specific temperatures, from chilled water to temperatures as high as 212°F (100°C). FROM A SINGLE PRODUCT TO A COMPLETE, FULLY INTEGRATED SYSTEM, OUR HOT WATER SOLUTIONS FOR STEAM CAN FULFILL YOUR MOST EXACTING DEMANDS. Armstrong will help you increase production and yield, enhance safety and efficiency, and reduce energy consumption and utility costs with hot water products and solutions for steam that are tailored to your specific industry and organization. EMECH® DIGITAL CONTROL VALVE Hot water delivered immediately on demand, and maintained at precision temperatures (+/-1°F, +/-0.5°C). READITEMP™ STEAM/ WATER HOT WATER SYSTEM Advanced system with digital control technology and instantaneous heat exchanger design—shell and tube or plate and frame.

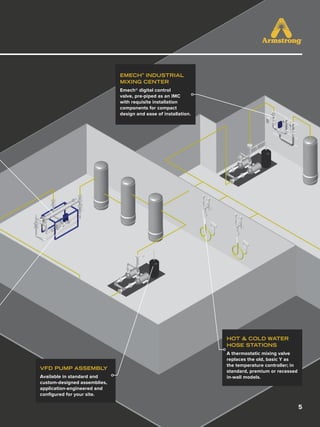

- 5. 5 EMECH® INDUSTRIAL MIXING CENTER Emech® digital control valve, pre-piped as an IMC with requisite installation components for compact design and ease of installation. HOT & COLD WATER HOSE STATIONS A thermostatic mixing valve replaces the old, basic Y as the temperature controller; in standard, premium or recessed in-wall models. VFD PUMP ASSEMBLY Available in standard and custom-designed assemblies, application-engineered and configured for your site.

- 6. UNPARALLELED QUALITY, DEPENDABILITY AND HASSLE-FREE MAINTENANCE— INSTANTANEOUS HOT WATER WITH NO STEAM REQUIRED. Our gas-fired water heater, Flo-Direct® , is more reliable, needs less maintenance, requires no permits or annual boiler inspections, and offers a lower cost of ownership. Simple in design and operation, Flo-Direct® is 99.7% efficient and 100% safe for your process, making it the ideal choice for a broad range of hot water applications, including washdown, batch production, vessel filling, tank cleaning and more. BY REMOVING STEAM FROM YOUR FACILITY, ARMSTRONG CAN HELP YOU SAVE UP TO 40% ON UTILITY COSTS AGAINST USING STEAM TO HEAT WATER. Armstrong understands the complexities of switching from steam-based hot water generation to Flo-Direct® , the most energy efficient method of hot water production on the market today. Our experts will provide you with all the engineering support needed to ensure a smooth process and turnkey installation. 6 HEATING WATER WITH GAS VFD PUMP ASSEMBLY Available in standard and custom-designed assemblies, application-engineered and configured for your site. FLO-DIRECT® GAS- FIRED WATER HEATER Instantaneous hot water at 99.7% (HHV) efficiency and precision temperatures, drinking water compliant without filtration.

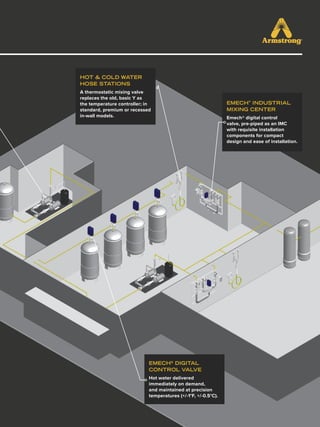

- 7. 7 EMECH® DIGITAL CONTROL VALVE Hot water delivered immediately on demand, and maintained at precision temperatures (+/-1°F, +/-0.5°C). EMECH® INDUSTRIAL MIXING CENTER Emech® digital control valve, pre-piped as an IMC with requisite installation components for compact design and ease of installation. HOT & COLD WATER HOSE STATIONS A thermostatic mixing valve replaces the old, basic Y as the temperature controller; in standard, premium or recessed in-wall models.

- 8. 8 EMECH® DIGITAL CONTROL AND INDUSTRIAL MIXING CENTER EMECH® DIGITAL CONTROL VALVES Armstrong Emech® digital control technology delivers and maintains water at precisely the desired temperature (+/-1°F, +/-0.5°C)—hot or chilled—immediately on demand. Compared to traditional mixing and control valve systems, Emech® offers a superior performance in terms of speed, precision and reduced mechanical wear. THE ADVANTAGES OF EMECH® DIGITAL CONTROL »» Reduce batch time, increase productivity— No start-up delay in reaching the set point. »» Save water and energy—No need to drain hot water while waiting to reach the set point. »» Eliminate queuing time—CIP hot water is immediately available. »» Maximize profits, minimize waste—Increased speed and accuracy eliminates inefficiencies of wasted energy and poor product quality resulting from hot water supplied above or below set point. »» Improve process set-up time—Increased operation speed compensates for system pressure variations, enabling a correct setup more quickly. »» Connects to plant BAS or DDC

- 9. 9 EMECH® INDUSTRIAL MIXING CENTER Armstrong Emech® digital control valve is pre-piped as an industrial mixing center with all the requisite installation components for compact design and ease of installation. Factory assembled for either non-recirculation or recirculation applications as standard. THE ADVANTAGES OF EMECH® IMC »» Features Emech® digital control technology »» Choose from standard assemblies (3 non-recirculated, and 3 recirculated), or customize »» Wide range of flow rates up to 644 gpm (@ 20 psi drop) »» Factory assembled with 3 connection points for non-recirculated or 5 connection points for recirculated to simplify installation »» Includes isolation valves, check valves, thermometers and pressure gauges

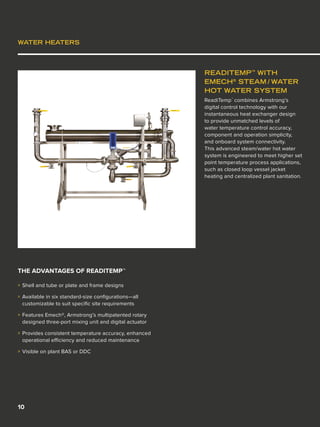

- 10. 10 WATER HEATERS READITEMP™ WITH EMECH® STEAM / WATER HOT WATER SYSTEM ReadiTemp™ combines Armstrong’s digital control technology with our instantaneous heat exchanger design to provide unmatched levels of water temperature control accuracy, component and operation simplicity, and onboard system connectivity. This advanced steam/water hot water system is engineered to meet higher set point temperature process applications, such as closed loop vessel jacket heating and centralized plant sanitation. THE ADVANTAGES OF READITEMP™ »» Shell and tube or plate and frame designs »» Available in six standard-size configurations—all customizable to suit specific site requirements »» Features Emech®, Armstrong’s multipatented rotary designed three-port mixing unit and digital actuator »» Provides consistent temperature accuracy, enhanced operational efficiency and reduced maintenance »» Visible on plant BAS or DDC

- 11. 11 FLO-DIRECT® GAS-FIRED WATER HEATER Made of stainless steel with no internal moving parts, Armstrong Flo-Direct® instantaneous water heaters are simple in design and operation. They are uniquely resistant to scale build-up, and their compact size requires minimal floor space. Flo-Direct® uses complete thermal exchange (CTE) technology, which minimizes the impact of combustion in direct contact with water and reduces these constituents to trace amounts. The result is an unparalleled level of water quality that meets USFDA and EU bottle water and food ingredient water standards for direct use without additional filtration. (This statement presumes USFDA and EU compliant influent water.) **99.7% HHV = 110.8% LHV Maximum hot water temperature out 85°C (10°F to 140°F) Suitable for use with natural gas or LPG THE ADVANTAGES OF FLO-DIRECT® »» 99.7% efficiency (HHV**) »» Utilizes practically all available energy in the gas »» Increased safety of precision temperatures »» Fast return on investment »» Fuel savings as high as 30-60% when compared to steam/water heating systems »» Heats water on demand »» Same efficiency at all demands »» Improved CO2 emissions »» Lower maintenance »» No insurance inspections required »» No specialist staff required »» Resistant to scaling »» Drinking water compliant »» No water treatment required »» 10-year warranty on body and internals »» 2-year warranty on all other components

- 12. 12 WASHDOWN ACCESSORIES Armstrong offers a full range of performance-matched accessories such as washdown hose, hose racks and reels, and spray nozzles to support and complement core engineered products. COMPONENTS VARIABLE FREQUENCY DRIVE (VFD) PUMP ASSEMBLIES Armstrong VFD Pump Assemblies team with Flo-Direct® Gas-Fired Water Heaters and our optional storage tanks at a central location to maintain flow and pressure levels at variable usage draw-off points within the hot water distribution system. Available in standard and custom-designed assemblies, our VFD Pump Packages are application-engineered and configured specifically to the needs of the installation site. The result is a complete, high efficiency, low energy consumption, hot water solution.

- 13. 13 EMERGENCY FIXTURE CONTROL Armstrong Model Z358 series thermostatic mixing valves have been designed specifically to provide temperature controlled water to emergency fixtures as detailed in ANSI Z358.1-2014. HOSE STATIONS Armstrong hot & cold water hose stations replace the older, basic mixing Y with a Thermostatic Mixing Valve (TMV) as the primary water temperature controller. Choose from standard, premium and recessed in-wall mounting models. Armstrong also offers Steamix® steam & water hose stations that will not pass live steam, even in the event of significant cold water pressure reduction or the failure of cold water supply or its primary operating component. Steamix® is available in standard, premium and stainless steel models.

- 14. 14 ON THE FOREFRONT OF TECHNOLOGY AND INNOVATION Armstrong International introduced digital water temperature control to the world and our company holds more than 50 patents on exceptional products and software. All over the world, Armstrong’s intelligent solutions are hard at work, consistently saving time, money and energy for some of the largest, most efficient companies in your industry.

- 15. 15

- 16. Bulletin-434 Printed in U.S.A.- 10/16