kiln burning and kiln burner system for clinker

- 2. Burning Equipment of Cement Plant

- 3. Scope of supply ROTARY KILN FIRING EQUIPMENT 1 + 1 Novaflam burner for heavy oil firing 1 MY skid heavy oil regulating valve train 1 Primary air fan 1 Stand-by air fan (supply by SINOMA) 1 Emergency cooling air fan specification 1 Gas electric igniter

- 4. PRECALCINER FIRING EQUIPMENT 4 + 2 Calciner burners for oil firing 1 MY skid heavy oil valve train for flow regulation and measuring 4 skid heavy oil valve train

- 5. FUEL OIL HEATING SYSTEM 1 loop low pressure regulating set for oil 2 Duplex pumps of oil high pressure pump 2 Heaters for heavy oil 4 Electrical heaters for heavy oil Thermal oil storage : tank & 2 filling pumps Thermal oil circulation : 2 circulating pumps, 1 Expansion tank 2 Thermal oil boiler with control cabinet

- 6. PUMPING ROOM (storage area) 2 circulating pumps for heavy oil low pressure loop 2 transfer pumps for power plant 2 + 1 booster pumps for diesel oil low pressure loop

- 7. 36 MW HOT GAS GENERATOR 1 Hot gas generator Diesel oil / HFO firing 1 ZV2 skid fuel oil valve train for flow regulation and measuring 1 ZV2 oil gun with tips 2 HP pumps 1 electrical heater for heavy fuel oil 1 control cabinet

- 9. Air circuits burner kiln

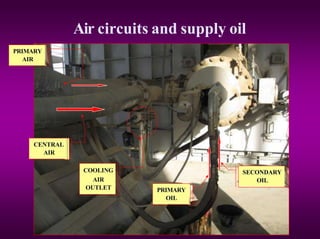

- 10. Air circuits and supply oil - TO BE COMPLETED DURING COMMISSIONING - CENTRAL AIR PRIMARY AIR COOLING AIR OUTLET PRIMARY OIL SECONDARY OIL

- 11. Burner tip - TO BE COMPLETED DURING COMMISSIONING - Primary air Central air Width air

- 12. Tip Novaflam Gun heavy oil Central air Primary air channel Igniter gas

- 13. Connecting heavy oil and gas burner Supply primary air Igniter gas Supply gas igniter Supply air igniter Supply primary heavy oil Supply secondary heavy oil Cooling air jacket gun oil

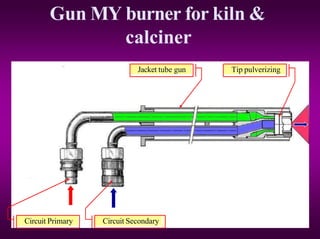

- 14. Gun MY burner for kiln & calciner Circuit Primary Circuit Secondary Tip pulverizing Jacket tube gun

- 15. Gun MY for burner Circuit Primary Circuit Secondary Spray plate Atomizer 1 Atomizer 2 Cap Jacket tube

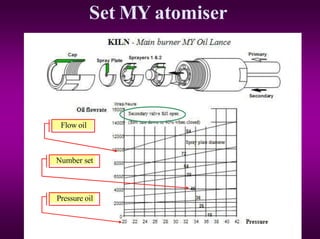

- 16. Set MY atomiser Flow oil Pressure oil Number set

- 17. Atomizer MY Ring inlet primary flow heavy oil Inlet secondary flow heavy oil Atomizer : 1 Atomizer : 2

- 18. Set atomizer MY Spray plate Spray plate Atomizer : 2 Atomizer : 1 Outlet heavy oil

- 19. Igniter gas Ionisation electrode Ignition electrode Tip igniter Injector gas Flame gas igniter

- 20. Igniter gas Electrode detection of flame Electrode ignition Detector flame Level detection flame Light control Light flame OK Light red transformer in progress Transformer ignition

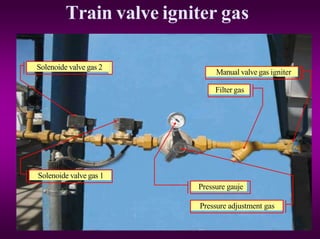

- 21. Train valve igniter gas Filter gas Pressure adjustment gas Solenoide valve gas 1 Solenoide valve gas 2 Pressure gauje Manual valve gas igniter

- 22. Igniter gas Transformer Detector flame Electrode ignition Electrode detection of flame Supply gas Connector electric Injector gas Supply air Adjustment : 3 ~ 4 mm

- 23. Cabinet igniter gas Button stop igniter Button start igniter Ligth authorized start Ligth ignitor fault Button fault acknowledg

- 24. Flame shape adjustment Indication position tip Flame shape Boolt of block

- 25. Ajustment flame burner kiln

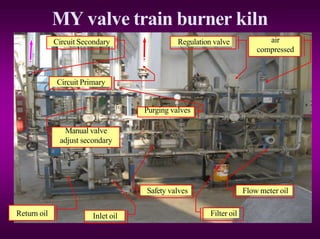

- 26. MY valve train burner kiln Flow meter oil Circuit Secondary Circuit Primary Safety valves Regulation valve Inlet oil Return oil Manual valve adjust secondary Filter oil air compressed Purging valves

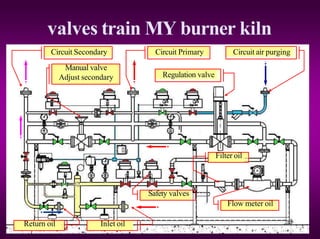

- 27. valves train MY burner kiln Flow meter oil Circuit Primary Circuit Secondary Circuit air purging Safety valves Regulation valve Manual valve Adjust secondary Inlet oil Return oil Filter oil

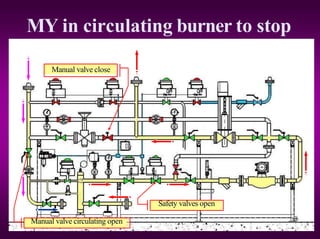

- 28. MY in circulating burner to stop Manual valve circulating open Manual valve close Safety valves open

- 29. MY burner to stop Circuit Primary Circuit Secondary air compressed Return heavy oil Inlet heavy oil Safety valves close

- 30. valve train MY in operating Flow meter oil Circuit Primary Circuit Secondary Circuit air purging Safety valves open Regulation valve Manual valve adjust secondary Circulating valve close

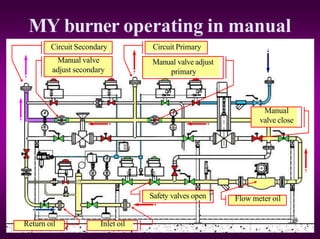

- 31. MY burner operating in manual Flow meter oil Circuit Primary Circuit Secondary Safety valves open Manual valve adjust primary Manual valve adjust secondary Inlet oil Return oil Manual valve close

- 32. MY in purging burner to stop Primary in purging Secondary in purging Supply air purging Safety valves close Valves purging open

- 33. Primary & cooling air fans kiln Emergency air fan Primary air fan Automatic valve emergency circuit air Automatic valve primary circuit air Primary Stand-by air fan

- 34. Primary air line : normal operation Valve close Automatic valve open Primary air fan run Emergency air fan stop Manual valve axial Manual valve radial Central air

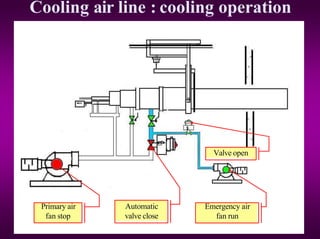

- 35. Cooling air line : cooling operation Primary air fan stop Emergency air fan run Automatic valve close Valve open

- 36. Calciner equipment 4 + 2 Calciner burners for heavy oil 1 MY heavy oil valve train 4 skid heavy oil valve train

- 37. Burner calciner Circuit Central air Manuel valve primary air Gun oil Circuit Primary air Manuel valve central air

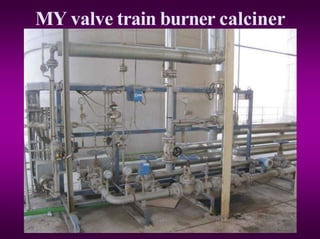

- 38. MY valve train burner calciner

- 39. Primary air fan burner calciner

- 40. valve train MY Calciner

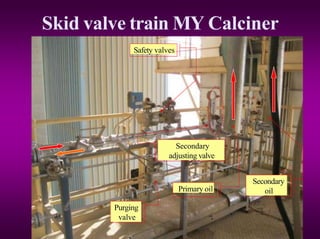

- 41. Skid valve train MY Calciner Purging valve Safety valves Primary oil Secondary oil Secondary adjusting valve

- 42. FUEL OIL LINE

- 43. Circulating pumps heavy oil Booster pump heavy oil From HFO thank To boiler house end loop

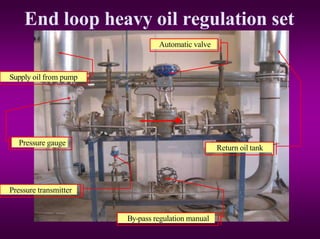

- 44. End loop heavy oil regulation set Automatic valve Pressure transmitter By-pass regulation manual Supply oil from pump Return oil tank Pressure gauge

- 45. Regulation circulating loop heavy oil Return oil to tank Pressure loop oil Automatic regulation valve By-pass valve close Supply oil Pressure transmetter

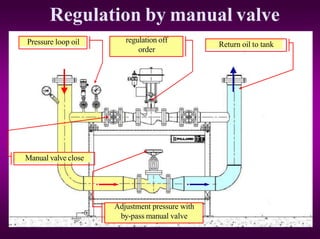

- 46. Regulation by manual valve Return oil to tank Pressure loop oil regulation off order Adjustment pressure with by-pass manual valve Manual valve close

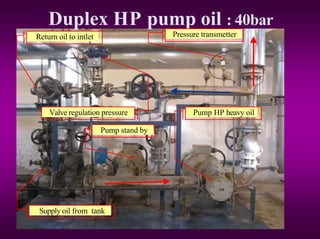

- 47. Duplex HP pump oil : 40bar Valve regulation pressure Pump HP heavy oil Pump stand by Pressure transmetter Return oil to intlet Supply oil from tank

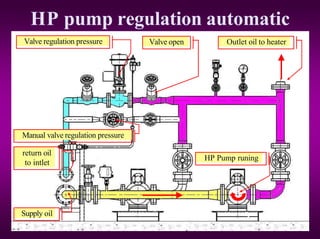

- 48. HP pump regulation automatic Valve regulation pressure Manual valve regulation pressure Valve open Outlet oil to heater Supply oil return oil to intlet HP Pump runing

- 49. HP pump regulation manual Valve regulation pressure Manual valve regulation pressure Valve close Outlet oil to burner Valve open Supply oil return oil to intlet HP Pump runing

- 50. Thermal oil line

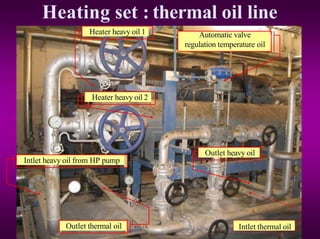

- 51. Heating set : thermal oil line Automatic valve regulation temperature oil Outlet thermal oil Valve by pass close Inlet thermal oil Heater heavy oil Outlet heavy oil Intlet Heavy oil

- 52. Heating set : thermal oil line Automatic valve regulation temperature oil Outlet thermal oil Intlet heavy oil from HP pump Heater heavy oil 1 Outlet heavy oil Heater heavy oil 2 Intlet thermal oil

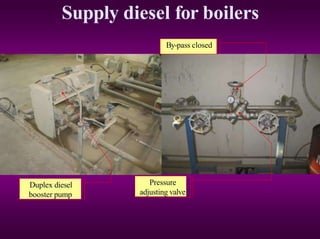

- 53. Supply diesel for boilers Duplex diesel booster pump By-pass closed Pressure adjusting valve

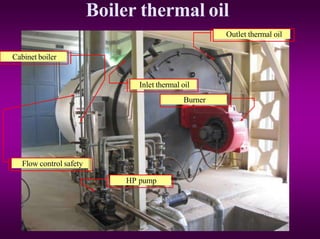

- 54. Boiler thermal oil Cabinet boiler Flow control safety Burner Outlet thermal oil Inlet thermal oil HP pump

- 55. Boiler control panel Pressure gauje outlet Pressure gauje inlet Control flow thermal oil 2 Control flow thermal oil 1 Adjust value thermal oil cold > 0.07 bar Adjust value thermal oil hot > 0.27 bar Control flow thermal oil 3

- 56. Boiler electric panel Controler temperature thermal oil Light safety fault boiler Light operating boiler Selector diesel or heavy oil

- 57. Thermal oil circulation pump Valve purging Pump circulating 1 Filter thermal oil Pump circulating 2 Drain valve filter

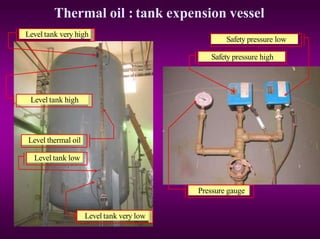

- 58. Thermal oil : tank expension vessel Pressure gauge Level tank very high Safety pressure high Safety pressure low Level tank low Level tank very low Level thermal oil Level tank high

- 59. Filling pump thermal oil Valve outlet tank Valve filling plant Filter Pump filling Valve inlet tank

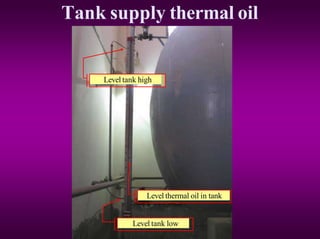

- 60. Tank supply thermal oil Level tank high Level tank low Level thermal oil in tank

- 61. Supply thermal oil in starting Manual valve by pass open Kiln supply Heater supply Tank supply Tracing supply Purge oil Temperature gauje Pressure gauje

- 62. Supply thermal oil in operating supply thermal oil from boiler Manual valve by pass close Kiln return Return thermal oil to pump Heater return Tank return Tracing return

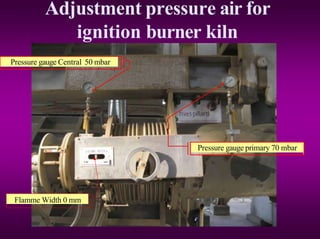

- 64. Adjustment pressure air for ignition burner kiln Pressure gauge primary 70 mbar Pressure gauge Central 50 mbar Flamme Width 0 mm

- 65. Adjustment valves air before ignition burner kiln Manual valve central 50 mbar Manual valve primary 70 mbar Cooling air oil gun 50% Air Ignitor gas adjusting during commissioning

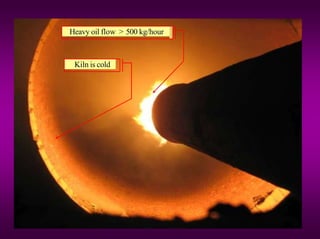

- 66. Heavy oil flow > 500 kg/hour Kiln is cold

- 67. Adjustment pressure air for burner in product Pressure gauge Primary >160 mbar Flamme Width + 15 mm Pressure gauge Central >100 mbar Central position 10 mm

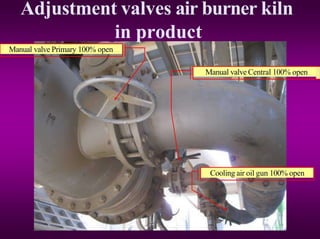

- 68. Adjustment valves air burner kiln in product Manual valve Central 100% open Manual valve Primary 100% open Cooling air oil gun 100% open

- 69. Heavy oil flow > 8500kg/hour Kiln is hot Kiln in product Secondary air is > 1000 °C

- 70. The End thank you for attention, please ask your question?