Knitting

- 2. Knitting • Knitting is a process of manufacturing a fabric by inter looping of yarns. • Knitting is the second most important method of fabric formation. • It can be defined as a needle technique of fabric formation, in which, with the help of knitting needles , loops are formed to make a fabric or garment. • Fabric can be formed by hand or machine knitting , but the basic principle remains exactly the same i.e. pulling a new loop through the old loop. • Knitted Fabric are popular for their shape fitting property, soft handle, bulkier nature and high extension at low tension.

- 3. Development of Knitting • The word knitting is derived from the Sanskrit word Nahyati. According to the textile history, it is said that finger knitting started since 1000 BC. In finger knitting, the fabric was produced on the hand using the fingers. The looping was done on the fingers. The fabric was produced by removing a new loop through an old loop. • Since the fabric produced on the hand was smaller in width the peg knitting was introduced. The finger knitting had only 4 loops in width but in peg knitting more numbers of loops was possible. According to the width of the fabric the number of pegs was decided. • Hand knitting with 2 pins was practiced since 256 AD. The knitted fabrics were prepared with the help of 2 pins. In about 5th century AD an oldest knitted article (sock) was seen. • Reverent William Lee, in 1589 a resident of England invented the first knitting machine with bearded needle. The gauge of the machine was 8npi and afterwards it was made upto 20npi. The machine had a potential of knitting 10 times more than hand knitting with two pins. Further many more warp and weft machines were developed but the principle remained the same. • In the 18th century , rib knitting machine, warp knitting machines and circular knitting frame was invented • In the 19th century, latch needle, compound needle, fashioning mechanism, seamless heal and toe i.e. sock, flat knitting machine, interlock knitting were invented all over the world. • In the 20th century, double cylinder circular machine, electronic needle selection, relanit principle, Pizo electronic jacquard etc were invented

- 4. Types of Knits Knitted fabrics Weft Knitting Single jersey Purl Rib Interlock Warp knitting Tricot Raschel

- 5. Classification of Knitting Knitting is primarily classified as weft knitting and warp knitting. This classification is based on the direction of movement of yarn with respect to the direction of fabric formation

- 6. Classification of Knitting Weft Knitting Warp Knitting

- 7. Warp Knitting In case the yarns run in length direction, i.e. the direction of fabric formation during knitting, the process is called warp knitting. The yarns inside the knitted fabrics are just like the warp yarns in woven fabrics Such knitted fabrics are called warp knitted fabrics, and the machine which produces such fabric is known as warp knitting machine.

- 8. Warp Kitting • Tricot • Raschel

- 9. Weft Knitting If the yarns run in the width or crosswise direction with reference to the direction of fabric formation during knitting, then the process of knitting is called weft knitting.

- 10. Needle loop • basic unit of knitted structure. • consists of a head (H) and two side limbs or legs (L). • At the base of each leg is a foot (F), which meshes through the head of the loop formed at the previous knitting cycle • The yarn passes from the foot of one loop into the foot and leg of the next loop formed by it

- 11. Applications of Knitted Fabrics • Sportswear(conformity, flexibility) • Casual wear (comfort) • Dress wear • Technical textiles application

- 12. Advantages of Knitting • Fabric can be produced from minimum number of yarns, even only one yarn • Loop size can be varied to a wide extent and that too very easily. • The extensibility and stability of the knitted fabric can be engineered • Wastage of yarn during conversion of yarn into fabric by knitting is negligible.

- 13. Advantages of Knitting • The desired porosity or compactness of the fabric can be achieved easily. • The extensibility and stability of the knitted fabric can be engineered.

- 14. Comparison of woven and Knitted fabric Knitting is comparatively economical(no need of preparation of yarn) and faster process to convert yarn into fabric or even into direct apparels ,

- 15. Woven vs. knitted Woven • Produce by interlacing of yarn • Set of yarn is required for warp and weft • Elasticity and stretch ability is poor • Dimensionality stable • More durable • Less moisture absorption Knitted • Produce by interloping of yarn • Minimum one yarn is required • Good elasticity and stretch ability • Dimensionally not stable • Less durable • Wicking and moisture property is better

- 16. Woven vs knitted • Good drape property • Less crease resistant property • Air permeability property is poor • Tensile and Tear strength can be checked • Poor drape property • Good crease resistant and no need of ironing • Excellent air permeability • Fabric is comparatively strong and Durable • Bursting strength check rather than tensile strength

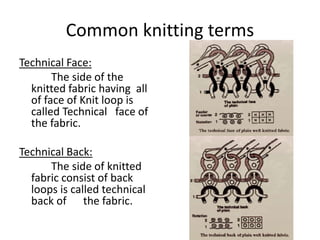

- 17. Common knitting terms Technical Face: The side of the knitted fabric having all of face of Knit loop is called Technical face of the fabric. Technical Back: The side of knitted fabric consist of back loops is called technical back of the fabric.

- 18. Common knitting terms Fabric Weight : Followings units are provided for fabric weight. Grams per meter Square (g/m2) GSM = weight in (g) / Area ( length cm * width cm)*10000 Ounces per Square Yard (Oz/Yd2) Ounces to GSM = Ozs / Yd2 *33.906

- 19. Common Knitting terms • Stitch Length :- the stitch length is one of the most important factor controlling the properties of knitted fabrics. The stitch length , measured in millimeter is the length of the yarn in the knitted loop. Generally longer the stitch length, the more open and lighter the fabric. • Stitch density :- Stitch density is a term frequently used in knitting and represents the total number of needles loop in a given area. Stitch density is the product of Courses and Wales per unit length and is measured in units of loops per square centimeter.

- 20. Common Knitting terms • Wales :- A wale is a vertical column of loops produced by the same needle knitting at successive knitting cycles. The number of Wales determine the width of the fabric and they are measured in units of Wales per centimeter. • Courses :- Courses are rows of loops across the width of the fabric produced by adjacent needles during the same knitting cycle and are measured in units of courses per centimeter. The courses determine the length of the fabrics