Steels as building material

- 2. STEEL Steel is an alloy of iron and carbon with very tiny amount of other metals to give it a particular property. Iron ore is melted on high temperature in furnace and then alloyed with carbon to make steel. The carbon content of steel varies from 0.1% to not more than 1.7%. The quantity of carbon has profound effect on the physical properties of steel due to the quality of carbon to crystallize as per proportion of carbon and iron. The carbon content based on % has following effects on properties of steel • Less %age of carbon increase ductility, increase ease of welding • Increase %age of carbon increases tensile strength, increase hardness, increase ease of casting.

- 3. MANUFACTURE OF STEEL The Production of steel involves a number of sequenced operation; The key stages are as follows 1. Manufacture of Pig Iron: The raw material for production used are iron ore, coke and lime stone. It is made in blast furnace. The produced iron 90 to 95% pure with sulphur, phosphorus, manganese and silicon as impurities and a carbon content of 4 to 5%; which is then directly transported to steel convertor. 2. Steel-Making: there are two methods for steel making in which further impurities are removed and alloying components are added. The two methods include i. Basic Oxygen Process and Electric Arc Process. 3. Casting: The molten metal is now casted into ingots & also into continuous billets and slabs which are then cut into appropriate length as required.

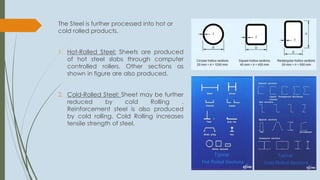

- 4. The Steel is further processed into hot or cold rolled products. 1. Hot-Rolled Steel: Sheets are produced of hot steel slabs through computer controlled rollers. Other sections as shown in figure are also produced. 2. Cold-Rolled Steel: Sheet may be further reduced by cold Rolling . Reinforcement steel is also produced by cold rolling. Cold Rolling increases tensile strength of steel.

- 5. Two kind of iron are produced from pig iron; one with high carbon content and the other with low Wrought Iron: Wrought contains only .02% of the carbon. It is fibrous in nature and possess a high melting point of about 1540 C. Due to this it cannot be welded. It has greater resistance to corrosion. It is also been used in ornamental work due to this property. Cast Iron: 2% of carbon content is present in Cast Iron. It has melting point of about 1130 C. It has high fluidity when molten. Due to its fluidity it can be casted into more complex shapes.

- 6. CATEGORIES OF STEEL Different types of steel are produced according to the properties required for their application, and various grading systems are used to distinguish steels based on these properties. According to the American Iron & Steel Institute (AISI), steels can be broadly categorized into three groups based on their Chemical Composition: 1. Carbon Steel: Carbon content of steel ranges from 0.05% to 1.7%. It can be further categories in to 3 categories: a. Low Carbon Steel (0.05% to 0.15%) b. Mild Steel (0.15% t0 o.25%). (These two are relatively soft and can subjected to extensive cold working) c. Medium Carbon Steel (0.25 to 0.5%) d. High Carbon (0.5 to 0.9%) Carbon Tools Steel (0.9% to 1.7%) 2. Steel Alloy: In order to manipulate properties of steel like corrosion resistance, weldability etc., different metals are alloyed with steel for e.g. Nickel, Zinc etc. 3. Tool Steel: Tool steels contain tungsten, molybdenum, cobalt and vanadium in varying quantities to increase heat resistance and durability, making them ideal for cutting and drilling equipment.

- 7. A Wide range of steel is available in the market depending on the carbon content, various heat treatments, alloying components and coatings over it. STRUCTURAL STEEL But Structural Steel should have carbon content from 0.16% to 0.25%. Structural steel are usually normalized by natural cooling in air after hot rolling process. The S275 grade steel is mostly used for smaller beams, angles etc. while Grade S355 is used usually for larger beams, columns and hollow section. Steel Sections can be bent also ; generally smaller sections can be bent to smaller radii as compared to larger sections. But heavier-gauge can be bent to smaller radii as compared to thin gauge. Its done through cold bending process which hardens the steel but without loosing its performance as structural steel. BI-STEEL PANELS: Bi-Steel Panels are two steel plates that are held a part with an array of welded steel bar connections. Concrete is poured in between the void space. This combination acts as RCC. It can be 2m wide and 18 m High. Its thickness varies from 200 to 700 mm. these panels are applicable in construction of shear walls, load bearing walls, core walls. This material ideally suited for blast protection

- 8. FIRE PROTECTION OF STRUCTURAL STEEL There are two approaches to deal with the fire protection of structural steel that is traditional way by using coatings and the other is fire engineering 1. Applied Protection to Structural Steel a. Intumescent coating: The thin film coating provide protection up to 120 minutes and it does not affect the aesthetic of exposed steel. It has full range of colors that can be applied with brush, roller or spray in three standard finishes basic, normal decorative and high decorative. b. Sprayed Coatings: it gives up to 240 minutes fire protection while applied directly to steel. It usually consist of vermiculite cement or mineral-fiber cement. It is highly textured but relatively cheap. c. Boarded Systems: it gives protection from 30 minutes to 240 minutes usually based on thickness of the board. The are directly screwed to the structural system. And is made of vermiculite or other mineral fiber with cement along with gypsum or calcium silicate as binding material. d. Masonry & Concrete: Structural concrete is fully encased with masonry or light weight RCC. e. Water filled Systems: Water is filled in the hollow sections of steel.

- 9. 2. Fire Engineering: The heating rate of a structural steel depends upon the severity of fire and degree of exposure of the steel. Fire engineering calculate the severity of fire based upon the ventilation ratio, thermal characteristics and then predicts the temperature rises within the structural steel based on exposure. The stability of the structural member can be predicted. From these calculations it is predicted if additional fire protection would be required or not.

- 10. STEEL ALLOYS Weathering Steel: Weathering steels are structural steels that are alloyed with the small proportion of copper. Its commercial name is corten. It can be used in cladding as well. It should be carefully detailed when used particularly with glass or Concrete as it can cause serious staining issues when rain water impinges on other material after running down through it. Its not appropriate for use in marine environment. It prevents the rust to deeply penetrate inside the structural member. STAINLESS STEEL The standard alloy used in construction have 18% chromium and 10% nickel or 17 % chromium and 12 % nickel depending upon the grade of steel. The corrosion resistance of material is due to the presence of chromium that reacts with the oxygen to from chromium oxide that immediately heals the scratches. It is available in hollow and light sections. It can be used for cladding (roofing, exterior/ interior)