Lime

- 3. LimeLime

- 4. LimeLime • Lime has been used as a cementing material since times immemorial. • Many past structures are still in good shape, which were constructed using lime as a binding material. • But in recent times cement has replaced the use of lime to a great extend. • No doubt cement is remarkable material yet lime mortars have some good properties e.g. good workability and plasticity, less shrinkage on drying, durability etc. • Lime is cheaper too and is locally available.

- 5. Classification of LimeClassification of Lime Limes are usually divided into three classes: • Fat, rich, pure, high calcium or white lime • Poor or lean lime • Hydraulic lime - Feebly hydraulic lime - Moderately hydraulic lime - Eminently hydraulic lime

- 6. Fat, rich, pure, high calcium or white limeFat, rich, pure, high calcium or white lime • It has high calcium oxide content. It contains about 93% of calcium oxide and 5% impurities in the form of clay. • Setting and hardening depend upon absorption of carbon dioxide from atmosphere. • It is obtained by calcining the purest available calcium carbonate. CaCO3 → CaO + CO2

- 10. • Addition of water breaks up lumps of quick lime to powder, gives out considerable head and swells to two to three times of original volume giving fat lime. • It is slow in setting. • Used for plastering and white washing. • Not suitable for mortar because of poor strength and slow hardening.

- 11. Poor or lean timePoor or lean time • It contains more than 5% of clayey impurities because of which it takes longer to slake than fat lime. • It sets and hardens slowly. • It is used both for plaster and lime mortar.

- 12. Hydraulic LimeHydraulic Lime • This type of lime sets under water, hence called Hydraulic Lime. • It is used building works where strength is required. • On calcination, carbon dioxide escapes leaving behind quick lime which reacts with silica and alumina.

- 13. Three sub-division of Hydraulic LimeThree sub-division of Hydraulic Lime • Feebly Hydraulic Lime: It contains less than 15% silica and alumina. • Moderately Hydraulic Lime: It contains 15 to 25 percent silica and alumina. It gives the stronger mortar than feebly hydraulic lime and suitable for good class masonry. • Eminently Hydraulic Lime: Its composition is very similar to Ordinary Portland Cement. It contains 25 to 30 percent silica and alumina. It must be very finely ground and screened before use otherwise the coarser particles are likely to slake after use.

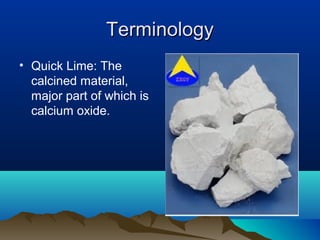

- 14. TerminologyTerminology • Quick Lime: The calcined material, major part of which is calcium oxide.

- 15. Hydraulic LimeHydraulic Lime • Lime containing small quantities of silica and alumina.

- 16. Hydrated LimeHydrated Lime • A dry powder obtained on treating quick lime with sufficient water to satisfy its chemical affinity with water under the condition of its hydration.

- 17. Lump LimeLump Lime • Quick lime as it comes from kiln.

- 18. Manufacture of LimeManufacture of Lime • Fat lime is obtained by burning lime stones which are the purest forms of calcium carbonate. • Whereas the hydraulic lime is obtained by burning Kankar. • Hydraulicity of lime obtained from kankar is because of presence of clay in it.

- 19. Kankar is of two types: 1. Nodular Kankar: It is found either on the surface or a few feet below surface in alluvial soils. Kankar found below the soil has better hydraulic properties than those of the one found on surface. Nodular kankar is far superior to block or quarried kankar because of its better hydraulic properties, better weathering properties and easier collection.

- 20. 2. Quarried or block kankar: It is found in blocks a few feet below ground or on or near the banks of rivers or their tributaries. Blocks are generally 5 to 30 cm thick.

- 21. Principal Stages in LimePrincipal Stages in Lime ManufacturingManufacturing • Calcination or burning • Hydration or slacking

- 22. Lime BurningLime Burning Like bricks, lime stones too are burnt in either clamps or kilns.

- 23. Clamp BurningClamp Burning • Quantity is so small to spend much for setting of kiln. • On clear surface about 5 m in diameter alternate layers of broken lime stones and fuel are laid. • The inward sloped sides are plastered with mud to stop the loss of heat. • The clamp is then fired at the bottom. • Disappearance of blue flames at top is an indication of the burning of lime having completed. • After the burning and cooling of clamp, pieces of quick lime are hand picked. • The clamp burning is uneconomical because of more fuel consumption. • Also the quick lime carries an admixture of ash.

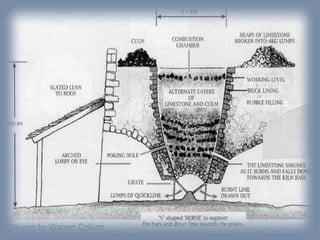

- 24. Kiln BurningKiln Burning • Quantity of lime to be obtained is large then permanent structures of kilns are constructed. • Kilns could be either of the intermittent type or the continuous.

- 25. Intermittent Kiln (Country Kiln)Intermittent Kiln (Country Kiln) • Fuel is not in contact with the lime. • Big pieces of lime are used to make a sort of arch on which smaller pieces of lime stones are loaded. • Burning should be gradual so that the stones forming the arch do not get split. • It takes normally two days to burn and one day to cool.

- 26. Continuous KilnContinuous Kiln • Commonly used. • Top should be covered over with mud leaving a hole 0.5 meter in dia in the center. • Burning proceeds continuously and the kiln is not allowed to cool down. • Burnt material is drawn out daily and fresh charge of stone and fuel is added from top. • Overburnt pieces are discarded whereas under- burnt ones are reloaded into kiln. • Remaining material is slacked or ground in a mill.

- 27. Artificial Hydraulic LimeArtificial Hydraulic Lime • Where good hydraulic lime stone is not available hydraulic limes stone can be manufactured artificially. • The quick lime is slacked and required quantity of clay is then mixed to get the same composition as that of good hydraulic lime stone. • It is then made into balls, dried and burnt in kilns. • Burnt balls are then ground dry to get artificial hydraulic lime.

- 28. Slaking of LImeSlaking of LIme • Quick lime should be slaked as soon as possible otherwise it may change its properties due absorption of moisture and carbon dioxide from the atmosphere. • If, however, delay is unavoidable then the lumps of quicklime should be stored in heaps. • The heaps should be covered to minimize direct atmosphere contact.

- 29. Methods of SlakingMethods of Slaking • Platform Slaking • Tank Slaking

- 30. Platform SlakingPlatform Slaking • Water is sprinkled in small quantities through rose cans over lumps of quicklime spread in 15cm thick layer on a water tight masonry platform until the lumps break into fine powder. • The stuff is periodically turned over. • The stuff is left over to allow the process of slaking to continue for 24 hours. The slaked lime is then screened through sieves.

- 31. Tank SlakingTank Slaking • This method is done when the slaked lime is needed in the form of putty.

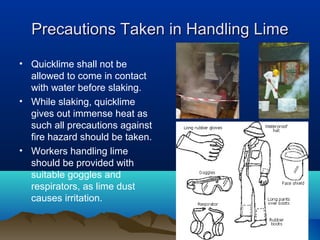

- 32. Precautions Taken in Handling LimePrecautions Taken in Handling Lime • Quicklime shall not be allowed to come in contact with water before slaking. • While slaking, quicklime gives out immense heat as such all precautions against fire hazard should be taken. • Workers handling lime should be provided with suitable goggles and respirators, as lime dust causes irritation.

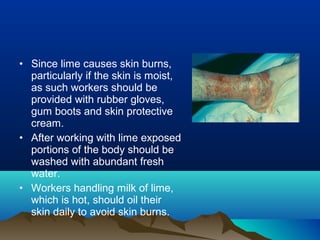

- 33. • Since lime causes skin burns, particularly if the skin is moist, as such workers should be provided with rubber gloves, gum boots and skin protective cream. • After working with lime exposed portions of the body should be washed with abundant fresh water. • Workers handling milk of lime, which is hot, should oil their skin daily to avoid skin burns.