Manaav sadhna, Ahmedabad

- 1. AIM OF THE PROJECT To Serve The Underpriviledged By Seeing The God In Every Individual(manav), Mere Service Is Transferred Into Worship(sadhna). CONTEXT RAMAPIR NO TEKRO It Is The Largest Slum Area Of Ahmedabad Which Consists Of people from Schedulded Castes Around Gujarat And Potter Families Of Rajasthan. It Faces All The Evils Of The Existence Such As Health Issues,Backward Traditions, Illiteracy Etc Manaav sadhna chose to work with the tekro because of its proximity to Gandhi Ashram. Lack of education and Employment opportunity are the core causes of many problems in the Tekro AHMEDABAD ROLE OF THE ACTIVITY CENTRE The Multi Purpose Activity Centre Serves As An Informal School For Young Childrens, Provides Evening Education For Adults And Serves As A Training Centre And Activity Workshop For Manufacturing Of Craft Based Products By Women And Elderly INTRODUCTION ARCHITECT- YATIN PANDYA SITE AREA- 1200SQM

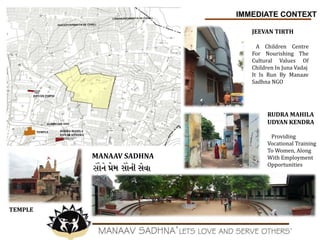

- 2. IMMEDIATE CONTEXT RUDRA MAHILA UDYAN KENDRA Providing Vocational Training To Women, Along With Employment Opportunities JEEVAN TIRTH A Children Centre For Nourishing The Cultural Values Of Children In Juna Vadaj It Is Run By Manaav Sadhna NGO TEMPLE MANAAV SADHNA JEEVAN TIRTH RUDRA MAHILA UDYAN KENDRA TEMPLE

- 3. ARCHITECTURAL PLANS GROUND FLOOR PLANFIRST FLOOR PLAN 1. ENTRY 2. ADMIN 3. STORE-ROOM 4. TOILET 5. CLASSROM 6. LIBRARY 7. KITCHEN 8. DINNING AND WASH AREA 9. DENTAL CLINIC 10. SITTING 11. MEDITATION SPACE 12. COURTYARD 5 5 5 5 5 5 2 2 3 3 11 9 7 10 12 1 6 13 DAY CARE 14 GYM 15 ANGANWADI 5 5 14 13 12 3 N

- 4. SECTIONSDESIGN CONCERNS : Non Polluting Environment, Economic Empowerment And Affordable Built Forms Are The Three Key Dimensions Of This Initative. The Project Is An Outcome Of Three Years Of Empirical Research At The Vastu Shilpa Foundation For Studies An Research In Environmental Design With The Goal Of Converting Municipal Waste From Domestic Sector Into Building Components. The Project Also Demonstrates That Building Can Become An Economic Activity, Empowering People. SECTION – AA’ SECTION – BB’ SECTION – CC’N

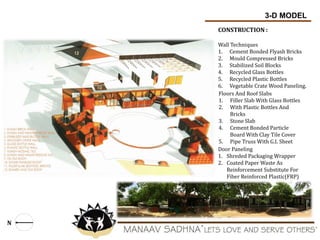

- 5. 3-D MODEL CONSTRUCTION : Wall Techniques 1. Cement Bonded Flyash Bricks 2. Mould Compressed Bricks 3. Stabilized Soil Blocks 4. Recycled Glass Bottles 5. Recycled Plastic Bottles 6. Vegetable Crate Wood Paneling. Floors And Roof Slabs 1. Filler Slab With Glass Bottles 2. With Plastic Bottles And Bricks 3. Stone Slab 4. Cement Bonded Particle Board With Clay Tile Cover 5. Pipe Truss With G.I. Sheet Door Paneling 1. Shreded Packaging Wrapper 2. Coated Paper Waste As Reinforcement Substitute For Fiber Reinforced Plastic(FRP) N

- 6. ANALYSIS Training centre 73% Library 12% Dental 7% Meditation place 4% Kitchen 4% INTER-RELATIONSHIP It Has The Radial Organization A Radial Organization Combines Elements Of Both Central And Linear Organization Here All The Spaces Tend To Open At The Central Court The Courtyard Acts As A Multipurpose Space Where Children’s Dance And Play Various Outdoor Games. Many Cultural Programme’s Are Conducted Here Ahmedabad Has The Hot And Dry Climate. All The Spaces Are Oriented Towards The Windward Side Facing The Open Court For The Ease In Cross Ventilation CLIMATE LOWER LEVEL PLAN GYM 26% ANGANWAADI 21% DRAWING CLASS 13% DAY CARE 31% TOILETS 9% PROGRAMME UPPER LEVEL PLAN SERVICES DENTAL CLINIC TEMPLE ADMIN OFFICE KITCHEN LIBRARY TRAINING CENTRE AANGAN WADI GYM SERVICES SPATIAL ORGANIZATION N

- 7. AREA ANALYSIS BUILT- OPEN OPEN, SEMI-OPEN AND CLOSE UPPER LEVEL PLAN LOWER LEVEL PLAN Semi Open Spaces Acts As A Good Transition From Open Spaces To Closed Space. Due To Hot And Humid Climate Users Mostly Prefer To Use This Semi-open Spaces. 73% 27%34% 66% BUILT UP OPEN 30% 12% 58% 71% 12% 17% CLOSE SEMI-OPEN OPEN N

- 8. ANALYSIS INTAKE OF LIGHT HOT AIR ENTERS FROM SMALLER OPENING AND GET COOLED KEEPING THE INSIDES COOL CIRCULATION CLIMATIC RESPONSE

- 9. MATERIALS • Materials: • Fly Ash, Water Residue, Cement, Gypsum, Lime, River Sand PROCESS: • All The Required Ingredients Are Measured By Weight And Mixed Properly • The Water Content Is To Be Maintained. • The Slurry Is Poured In A Mould And The Mould Is Placed In The Brick Making Machine And Subjected To Vibration. • Proper Pressure Is Applied To Achieve Shape And Size. WALL TYPE 1- WASTE RESIDUE BRICK WALL TYPE 2- FLYASH BRICK Materials: • Fly Ash, Cement PROCESS: • All The Required Ingredients Are Measured By Weight And Are Mixed Properly. • The Mixed Slurry Is Poured In The Mould. • Here The Bricks Are Laid On Edge In Rat Trap Bond. It Saves Are 25% Of Brick Consumption Than Flemish Bonded Masonry WALL TYPE 2-SOIL BLOCK Materials: Soil, Cement, Sand, Water

- 10. MATERIALS Materials: Glass Bottle, Flyash, Cement Mortar Skill/ Machine: Masonry Composition: 1:3 Cement Sand Cost Component: Glass Bottle -2rs/Bottle+labour Charges PROCESS • Empty Bottles Are Cleaned Of Labels. • A Mockup Of Bottle Arrangement Is Done In Desired Pattern On Ground Without Cement Mortar. • Bottles Are Laid In Horizontal Courses Over Cement Mortar Bed. • Deep Groove Pointing Is Done. Materials: Plastic bottle, Flyash, Cement mortar Skill/Machine: Masonry Composition: 1:3Cement Sand Cost Component: Plastic bottle- 1Rs/bottle+labour charges PROCESS • Empty bottles are cleaned. • Bottles are filled full of flyash or waste residue. • Bottles are laid in horizontal courses over a cement mortar bed. • Deep groove pointing is done

- 11. MATERIALS Materials : Resin, cobalt, glass fibre matt. Skill/ Machine: Masonry Composition: 96.5% resin, 1.5% cobalt, 2% catalyst Cost Component: FRP Panel Per sqft = Rs. 30- 40* PROCESS • Plastic Wrappers Are Cleaned With Scissors Cut Into Fine Shreds. • On A Clean Sheet Of Plastic A Glass Fibre Matt Is Laid. • Shreds Are Laid Over It And Then Covered By Another Matt. • Mixture Of Polymer Resin Catalyst And Stabilizer Is Applied Over The Matt. • In Half An Hour The Polymer Is Set And Plastic Sheet Is Removed And FRP Sheet Is Ready To Use. Materials : steel frame, cycle spare-parts. Process • Doors Are Made Up Of Steel Frame And Recomposed Metal Parts As Infill. • The Diverse Parts Of Broken Bicycles And Used Rotary Blades Of Stone Cutter Etc Are Creatively Composed Which Not Only Is Like A Grill To Door’s Shutters But Creates Dynamic Backdrop To The Space.

- 12. MATERIALS MATERIAL • MS box section • Cement bonded particle board • Country tile MATERIAL • Corrugated Galvanized iron sheets • Mud mortar • Country tile • Steel tubes MATERIAL • Fiber Recycle Plastic(FRP) • Rugs MATERIAL • Glass Bottle • Plastic Bottel • Fly Ash Brick • Mild Steel Reinforcement Bar • 1:2:4 Cement Concrete

- 13. MATERIALS C E I L I N G FLOOR- CONSTRUCTION SITE WASTE AND INLAY