Metal Cladding - Quinta Metalica in English

- 1. 1 Pasión por los revestimientos METAL CLADDINGS Co nd en sa do re s A. A. io ar rn ce • Lu io ar rn ce Lu

- 3. 3 Summary Contents Página Concept´s Presentation 4 The metals 6 Titanium 7 Copper 8 Zinc 10 Stainless Steel 12 Lead 13 Sistems of metalic claddings Standing seam for roofs 14 Standing seam for facades 15 Shingle system for facades 16 Facade pannels 17 Roofs QUINTA METÁLICA® 18 ® Facades QUINTA METÁLICA 20 Special Facades 22 QUINTA METÁLICA The company. Certifications 23 Installation Service 24 Technical Assistance 25 Resources 26 Technical information for Arquitects The metals,properties and characteristics 27 Double standing seam, shingles systen 28 Slot in panels, cassetes 29

- 4. 4 CONCEPT´S PRESENTATION We talk about roofs and facades made out of nobles metals, and in most of the cases, installed by seaming technique. The fixations are not visible, the joins are discrete, and most of the details are hand made. We are talking about fit tailored systems for each project. The necessary techniques to make these types of claddings were developed in Central Europe some centuries ago. The combination of quite ductile metals and noble metals in combination with seams technique,, has proved to be a quite attractive, effective and durable solution. Quinta Metálica has born to offer architects and main constructors worldwide, the chance to employ this same solution for the claddings of their projects. We hope you enjoy some of the projects we have participate and to expect to help you to choose one of our solutions.

- 5. 5 Here are some of the reasons that have moved the architects and the promoters to use these types of solutions : • Atrractive and Natural surfaces • Possibility to adapt to any type of geometry and any kind of project • Buildings stand out most with them • Metals have a natural weathering process • Long durability • Light heavy solution for large roofs • Competitive price • No maintenance or cleaning needed

- 6. 6 THE METALS Unless the lead, rest of metals are in strictly accordance to Common Characteristics a sustainable construction , as all of them are recyclable at any time, are not toxic nor for the environmental nor for the The metals we work with in Quinta Metálica are mostly human being, require low energy consumption for their noble metals. They have natural surfaces that react to the production and are coming from large disposals resources. weather exposure, creating and forming in each case their own particular patina. This gives special textures and unique colours to the buildings where they are installed, typical of a natural metal, offering a range of sensations of quality and warmth that any other painted metals are able to give.. They are extremely durable and will protect the buildings where are installed during decades without any kind of maintenance or cleaning .

- 7. 7 TITANIUM It has become quite famous due to its use by architects like Frank O’Gehry and one of his famous Project the Guggenheim Museum in Bilbao, the titanium is the best metal employed by Quinta Metálica. Quite light, very strong and exceptionally resistance against corrosion, it creates the difference in the building where it has been used.. In the seaming technique it is normally used thinner thicknesses compared to copper or zinc (0,4mm instead of 0,6 o 0,8mm) and this gives the typical water undulation in the facades. These facades have quite movement and provides own life to the façade that it last all over its life.

- 8. 8 COPPER Copper is quite well known due to its typical blue-green patina which is created in all copper claddings. Copper is one of the natural metal that has its own colour. This typical orange salmon pink colour , turns quite fast to brownish tones and it loose its typical brilliant aspect of the surface. These colours are established and changes progressively to a darker brownish tones. This is the typical final colour in some facades or in areas protected against rain water, but copper installed in a roof will develops all over the years the typical turkish blue – greenish patina..

- 9. 9 Besides the natural copper, there are other surfaces made out of copper installed by Quinta Metálica : • Pre oxided brown copper. It comes from the production with the typical brown tone of copper after some months of natural weathering. • Pre patinated copper. It comes from the production with the real patina copper making this material specially used to have the cladding with green bluish aspect from the beginning.. • Tinned copper. This is a hot dip tinned strip of copper that gives a matt grey surface keeping main characteristics of copper.. There are some other copper alloys in the market that offer more possibilities of surface aspects . In this case we make special mention to the brass – alloy of copper and zinc , and the copper – aluminium alloy that gives a yellowish aspect similar to gold. All these types of materials are installed practically in the same way as natural copper and all of them has long lifetime over 100 years without any need of maintenance or cleaning. All of them are suitable to be used in sea side areas or industrial areas, where its exceptional well resistance to corrosion is specially recommended.

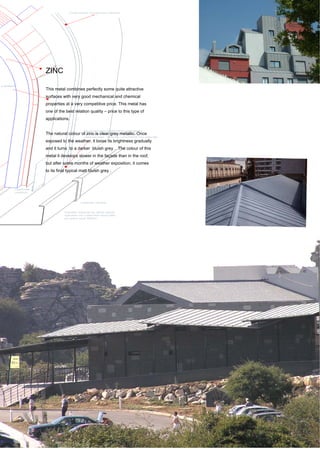

- 10. 10 ZINC This metal combines perfectly some quite attractive surfaces with very good mechanical and chemical properties at a very competitive price. This metal has one of the best relation quality – price to this type of applications. The natural colour of zinc is clear grey metallic. Once exposed to the weather, it loose its brightness gradually and it turns to a darker bluish grey . The colour of this metal it develops slower in the façade than in the roof, but after some months of weather exposition, it comes to its final typical matt bluish grey .

- 11. 11 There ares some other tones of zinc we install : • The most popular is the prepatinaed clear grey. This is the colour that zinc will have after some months of weather exposition. This tone is quite stable and without remarkable changes both in facade and in the roof.. This surface transmits lightness and modernity and is mostly used in facades more than in roofs.. • It exists another prepatined zinc, much more darker than the other one, which is almost dark as anthracite. Its combines quite well with slate and some other natural materials. • Another type of surfaces to be added to these prepatinated. We refer to the pigmet zinc , which are prepatinated materials with blue, red and green tints . These colours keep the natural metallic texture aspect of zinc, but giving new chances to play with new aspects of the metallic claddings. The system of installation of these pre patinated materials is exactly the same as the used in natural zinc.

- 12. 12 Stainless Steel Stainless Steel could be easily recognized at first sight. It has such a high resistance corrosion properties that almost does not change its aspect from the initial estate. This gives an unique view of solidity and integrity, providing aspect of unlimited material. There are basically two types of surfaces: • Glossy matt • Brilliant Glossy matt is normally installed with double standing seam techniques in roofs, while brilliant surface is normally installed in panels systems in facades..

- 13. 13 Lead New lead material has an aspect of clear metallic grey, similar to natural zinc. Once exposed to atmosphere, it loose this brilliance gradually and it turns into a matt darker grey aspect. Colour changes in facades are bit slower than in roofs, but approximately after two years, it becomes more homogeneous and it reach its maturity patination process.. Compared to any other metal, lead does not present any kina of waves or undulations in the sheet, due to its excellent adaptation to its base ( this is also helped due to its high specific weight and its almost non existing mechanical resistance ). This provides a quite solid and contudent visual aspect. Its extreme ductility and malleability, makes this metal able to cover any kind of support easily.

- 14. 14 ROOFING AND WALL CLADDING SYSTEMS Standing seam for roofs Seaming process The double standing seam system us perfectly valid for flat roofs, pitched roofs ,curved roofs or irregular roofs . This is a quite versatile system that has proved its validity during centuries in those countries where these systems are traditionally used. This system covers the roof seaming longitudinally the sheets , joining and folding one sheet to the other, creating a waterproof seal and non visible fixations.. Its aspect is discreet, creating fine parallel lines every half meter approximately, that longs all over from ridge to the eave. It provides directionality and lightness to the covering. With this system, we reach the goal of reinforced this sensation, by using fine and appropriate details and flashings , also in the junctions with other existing materials in the roof. Angle seam On top of this , these flashings and unions allow metal to keep its regular thermal expansion due to variation of the different weather conditions they are exposed to. This is a must in order to secure a guarantee a long life for the coating. Quinta Metálica employs the same details Double standing seam developed and tested all over centuries in countries with finished. long tradition metal use , such as Germany, Belgium, France or U.K , in order to make sure that metal roofs could expand and dilate because of thermal changes.

- 15. 15 Standing seam for facades Seam procees Standing seam for facade is quite similar to the one employed by Quinta Metalica for the standing seam in roofs. This is a system that covers the facade by welting the sheets between them in the longitudinal way, creating a waterproof joint with hidden fixations. Direction of installation is from the bottom to the top. Direction of the joint could be horizontal or vertical, but could be also be done with a particular angle if the project requires it. The longitudinal joints, creates a clear fine lines that are created all along the facade. Due to the shadow effect , this aspect is much more visible in the horizontal joints than in the vertical ones. These joints are separated every half meter approximately. This transmits lot of directionality to the facade and give particular properties to the facade. In order that the façade is well organized and aspect is ordered, is quite important that joints are in line with the location of the windows or any other holes of the façade. Quinta Metálica gives the necessary technical support to provide the correct lay out of the facade. It is possible to make any kind of combination with different types of heights of sheets. Quinta Metálica will provide the best advisory and will propose best solution for each material.

- 16. 16 Shingles system for facades Proceso de enganchado The shingle pannels system is also known as fish-scale. This is the most flexible system , as far as the joins and material could be adapted to any kind of geometry. It could be also applied in roofs with minimum pith of 35º. The join is the same all over the facade , and could create same lines in both senses, horizontal and vertical. Installation direction could be done in any sense, but normally is in horizontal, vertical or at 45º. The joins create quite discrete and fine lines in the façade , in both senses , and could be placed from half a meter up to two meters, depending on the final aspect expected . It exists many possible combinations in order to reach architect’s expectative. The correct result of this type of facade, requires perfect combination with the aluminium or wooden carpentry.

- 17. 17 Proceso de enganchado Facade pannels This system provides a particular aspect to the facade, with panel systems with particular trace between them. The direction of the trace could be horizontal or vertical, and the architect could play with different widths to give different aspect to the façade. Installation of panels is by a inserting one panel with the other using the particular profile on them. Fixation is not visible . Way of installation is starting from the top part going down to the bottom part of the facade, or from one side to another depending on the direction of the trace. This system usually is not able for curved facades. The longitudinal joins create fine or strong lines over the facade, depending on the previous idea of architects. This solution transmit strongness and order to the facade, specially in the darker colours.

- 18. 18 QUINTA METALICA ROOFS Our metallic roofs are long lasting life , not only because of the metals used, but also for the installation system. Besides this, no need of any maintenance, no cleaning Different types of roof system and free of problems. We consider all details in all our installations and every step is strongly controlled according to the certified Management Quality system ISO9001. These types of roofs are made out of different layers, and each one, has its own function and utility. Non ventilated roof. Zinc over • Outside metal layer : protects and secures the ventilation membrane over Word sandwich panel impermeability and provides final esthetical to the building. • Separation layer or ventilation membrane : helps the thermal expansion of the metals, reinforce the impermeability, could avoid condensations, and could absorb small irregularities on the direct substrate . It provides a microventilation to the internal face of the metal layer. • Direct support : provides the support of the metal Non ventilated roof. Zinc over and its fixations base, and it resists wind, snow, ventilation membrane , solid thermal insulation and profiled steel sheet. and heavy rain pressure. • Ventilation chamber: this is employed in the ventilated roofs . This system fully avoids the condensation and disperse temperature of the roof. • Thermal insulation : protects from the exterior temperatures • Vapour barrier : avoids condensation in the non ventilated roofs. Ventilated roof. Zinc over ventilated membrane, chipboard with battens with thermal insulation between battens.

- 19. 19 Before starting the installations, we draw the roof in autocad in order to establish its correct bonding. It is strongly recommended to take real measures of the base support in order to secure correct measures. Metallic roofs in most of the cases, are installed by the Qunta Metalica Double Standing Seam system. This system is water proof from 7º of pitch , During installation we pay special attention to the follwoing points : • Roof and metal should have coorect thermal expansion • Flashings should be carefully treated • Same solution for the whole roof • The bonding of sheets should be aesthetical correct. • Metal should be free of cracks, hints or marks and must be as plain as possible. • Global final aspect should be in accordance to the general aspect o the project . Besides this, we guarantee the impermeability of the roof and its protection and long lasting life over decades.

- 20. 20 QUINTA METÁLICA FACADES Quinta Metálica Facades will provide excellence to the Project As in the roofs, our facades are made out of different layers, and all of them are carefully designed, planned and executed with its own function . However, in facades we are not limited individually for each building . to the double standing seam, as it exists other façade systems that could be used that provide more technical and aesthetical Most of the sheets, are previously produced and profiled in chances.. our plant, so we make sure that are not manipulated at the building site and are installed following the installation plan previously designed. Example of facades Ventilated facade. Zinc with membrane ventilation over profiled sheets with insulation. Non ventilated facade. Copper over Ventilated Facade. Copper fixed to Z Ventialted Facade : zinc with underlay layer, insulation, fixed to a profile, fixed to the supporting layer. ventilation membrane, chipboard, concrete support omega profiles, insulation between them, fixed to the base support.

- 21. 21 When we designed a facade, we always try to make sure that the metal cladding is fully integrated, in a natural way, with the rest of facade elements ( metallic windows, doors, balconies, etc). This could only be achieved by making previous design and plan of the front elevation of the roof , and adapting the dimensions of sheets to the metallic carpentry , that should be fully integrated with the metal cladding . During production process of the metal, that is , the slitting, profiling, bending and transport to the building site, we always take care of : • Correct ending free of hits, marks or scratches • Secure correct thermal expansion of metal • Corners, endings and unions with other metals should be clean and well executed. • Metal sheets should be as plain as possible

- 22. 22 SPECIAL FACADES We also provide to the market , full support for the architects for their projects with new metal endings. This includes facades with perforated, expanded or punched finishing, that could be obtain with any kind of metal. This is an increase tendency, and Quinta Metalica has been chosen to execute these type of jobs in many projects. The combination of high quality metals with flexible and improved cladding systems, are suitable to provide unexpected results to the buildings they are installed in, and are able to change totally transform the final impact of their visual and aesthetic aspect .

- 23. 23 QUINTA METÁLICA The company Certifications Pasión por los revestimientos. This is our identitie leit- We are fully convinced in Quinta Metálica that quality motiv with means passion for claddings. This is what we should be a must in all our activity and is the only way to like to do, and this is where we are strongly specialized. We create a difference in the market. Because of this, we basically use the materials shown , but we in fact deal with obtain the ISO9001 certificate that certifies that our Quality any type of metal and systems. Control Management is in strict accordance to this international certification. We work all over the world and we have more than 300 projects installed. Besides this, and due to our commitment with all environmental issues that should be fully respected and Our human force is our main force, where more than followed in all kind of activity and service. Based on this, we seventy persons are exclusively dedicated to this type of also obtain the ISO14001 certification that confirms that our activity and to continuously improved our presence and Environmental Management System fully follows this quality service in the market. specification . We can offer the complete construction solution for each Project and we manage from the base structural support up to the exterior and final metal cladding..

- 24. 24 The installation Service Quinta Metálica has as main objective to offer to our customers a high quality service in the supply and installation of metal claddings. We prefabricated our materials before the installation whenever is possible and we deliver to the building site materials already profiled and bended. To achieve this, we normally follow this procedure steps : 1. Measurement at the building site , basically the base support in order to make sure metal will fit to this base. 2. Drawing of the façade in AutoCAD . 3. Bonding of the metal according to the drawings. 4. Once the bonding is approved, we sent the production order to our plant in order to profile and send sheets to the building site. Packaging of the material to avoid any damages during transport. 5. Installation of the metal sheets and flashings according to the installation instruction prepared by the technical department. This way of procedure and philosophy, is what we called “ the Quinta Metálica system” , in accordance to the ISO 9001 certificate.

- 25. 25 Resources Human Force Our human force and installors are correclty trained to clad any type of surface. This installors have passed their own trainee period and are organized in different categories depending on its spcialization skills and knowledge. This installation tema is supported by a technical back office which is in direct contact with them and customers to obtain the best results. Machinery Quinta Metálica has its own completely equipped production plant. We have specialized machines fabricated in Germany, Austria and Switzerland which are the most traditional countries using these type of systems.

- 26. 26 Pasión por los revestimientos