Air Sealing and Ventilation Improvements for Multifamily Buildings - Fitzgerald and Bohac

- 1. Air sealing and ventilation improvements for multifamily buildings March 2, 2012 Jim Fitzgerald Dave Bohac Center for Energy and Environment Better Buildings: Better Business Conference

- 2. Better air quality through sealing leaks between units and ventilation improvements What causes problems? Air leakage & air flow rate measurements • 6 building CEE study Air sealing and ventilation case studies Maybe save energy too

- 3. What causes problems? Sometimes people smoke (and cook and ??)

- 4. Convert to smoke-free building Association of Nonsmokers - Minnesota http://www.mnsmokefreehousing.org/ 500+ smoke-free apartment buildings listed in Minnesota

- 5. Owners – cooking odors are worst problem What type of odor or contaminant is the most common source of objectionable air in buildings you manage? 0% 5% 10% 15% 20% 25% 30% 35% 40% 45% 50% cooking odors tobacco odors other none don't know

- 6. How big are air flows between units? Pacific Northwest: • Building average – 13 to 26% air from other units • Individual units – as high as 35% NJ mid-rise: 4th floor – 22% from other units West Coast: 4% air from adjoining units Francisco & Palmiter (1994) Harrje et al (1988) Feustal & Diamond (1988) Multizone tracer gas measurements

- 7. How big are air leaks between units? Minnesota: Modera et al. (1986) • 52% air leaks between units • 1900’s low-rise masonry Chicago: Diamond et al. (1986) • Similar results to Minnesota • 1900’s low-rise Sweden: Levin (1988) • 12 to 36% air leaks between units • 3 Swedish apartment buildings Blower door air leakage tests

- 8. What are the driving forces to move air into and though buildings?

- 9. What are the driving forces? Winter Stack Effect Taller Building => Bigger Effect In at the bottom and out the top

- 10. What are the driving forces? Wind Effect In on windward side and out on leeward side Taller Building => Bigger Effect

- 11. Mechanical ventilation is required by code: bathrooms, corridors & some kitchens Exhaust ventilation => draws air into an apartment Flow imbalances can also cause air to move from one apartment to another What are the driving forces? Mechanical System Effect

- 12. Does it help for a smoker in a lower floor unit to open a window? Not upstairs neighbor Pressure in smoker’s unit will be about the same as outside, which increases pressure to upstairs and increases flow from smoker’s unit to upstairs

- 13. In at the bottom and out the top Anyway it can! Gaps in walls, floors, mechanical chases Some are accessible and others too diffuse or inaccessible for sealing How does the air travel between units?

- 14. Gaps around sink plumbing Most openings are small and diffuse

- 16. Chemical smoke moves out of baseboard leak Clear acrylic caulk required plus moving bookcases, etc

- 19. Gaps around bath fan Bathroom exhaust fans

- 20. Leaky (2.5 si) Tight (0.1 si) Recessed Light Fixtures

- 21. Hidden high rise chases = large uncontrolled flows

- 23. Can practical air sealing and ventilation treatments reduce secondhand smoke (SHS) transfer? 6 dissimilar buildings common to local multifamily building types This research project was funded in part by ClearWay Minnesota, … funded by proceeds from the Minnesota tobacco settlement. These findings are solely the responsibility of the authors and do not necessarily represent the official views of ClearWay Minnesota.

- 24. General approach to reduce odor transport between apartments and improve air quality Ventilate the source • Capture source before transported Reduce transport between apartments • Seal building leaks • Reduce driving force - pressure difference Ventilate receiver’s apartment

- 25. General approach to reduce odor transport between apartments and improve air quality Ventilate Seal Ventilate

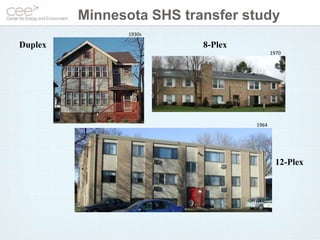

- 26. Duplex 8-Plex 12-Plex 1930s 1970 1964 Minnesota SHS transfer study

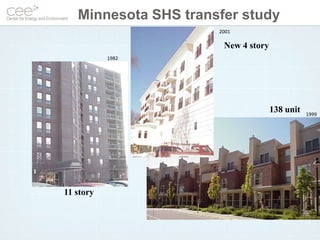

- 27. New 4 story 138 unit 11 story 1982 2001 1999 Minnesota SHS transfer study

- 28. Page 28 Quantify – building tests Before and after fan pressurization tests • Total “effective leakage area” of apartment • Fraction of leakage area to outside and to other units

- 29. Guarded Zone Multiple Fan Air Leakage Test Up to 6 tests per unit Test 1 Test 2 Unit A Unit B Unit C Unit A Unit B Unit C QB1 QA2 QB2 Common Area Common Area Q50 B total = QB1 Q50 B to A = QB1 - QB2 Test 3 Test 4 Unit A Unit B Unit C Unit A Unit B Unit C QB3 QC3 QB4 QComm4 Common Area Common Area Q50 B to C = QB1 - QB3 Q50 B exterior = QB4 Fan Fan Fan Fan Fan Fan Fan Test 1 Test 2 Unit A Unit B Unit C Unit A Unit B Unit C QB1 QA2 QB2 Common Area Common Area Q50 B total = QB1 Q50 B to A = QB1 - QB2 Test 3 Test 4 Unit A Unit B Unit C Unit A Unit B Unit C QB3 QC3 QB4 QComm4 Common Area Common Area Q50 B to C = QB1 - QB3 Q50 B exterior = QB4 Fan Fan Fan Fan Fan Fan Fan Test 1 Test 2 Unit A Unit B Unit C Unit A Unit B Unit C QB1 QA2 QB2 Common Area Common Area Q50 B total = QB1 Q50 B to A = QB1 - QB2 Test 3 Test 4 Unit A Unit B Unit C Unit A Unit B Unit C QB3 QC3 QB4 QComm4 Common Area Common Area Q50 B to C = QB1 - QB3 Q50 B exterior = QB4 Fan Fan Fan Fan Fan Fan Fan Test 1 Test 2 Unit A Unit B Unit C Unit A Unit B Unit C QB1 QA2 QB2 Common Area Common Area Q50 B total = QB1 Q50 B to A = QB1 - QB2 Test 3 Test 4 Unit A Unit B Unit C Unit A Unit B Unit C QB3 QC3 QB4 QComm4 Common Area Common Area Q50 B to C = QB1 - QB3 Q50 B exterior = QB4 Fan Fan Fan Fan Fan Fan Fan 1: Total Leakage 2: 1 – 2= Leak to Right 3: 1 – 3= Leak to Left 4: 1 – 4= Leak to Out

- 30. Page 30 Quantify – building tests Before and after fan pressurization tests • Total “effective leakage area” of apartment • Fraction of leakage area to outside and to other units Before and after tracer gas tests • Week long average tests • Passive perfluorocarbon tracers • Nicotine • Particles Measure exhaust ventilation flow Measure before/after treatments Up to 7 units per building

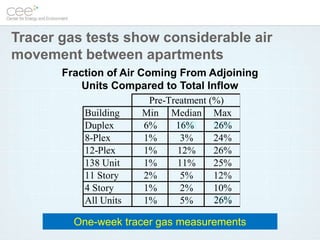

- 31. Tracer gas tests show considerable air movement between apartments Fraction of Air Coming From Adjoining Units Compared to Total Inflow Building Min Median Max Min Median Duplex 6% 35% 65% 8-Plex 1% 3% 24% 12-Plex 1% 12% 26% 138 Unit 1% 11% 25% 1% 7% 11 Story 2% 5% 12% 1% 2% 4 Story 1% 2% 10% 0% 2% All Units 1% 5% 65% 0% 3% Pre-Treatment (%) After Sealing (% 26%16% 26% One-week tracer gas measurements

- 32. Range Median Top-floor units: 2 to 26% 16% Mid-floor units: 1 to 20% 5% Lowest-floor units: 1 to 4% 2% How does the fraction vary by floor? Fraction of Air Coming From Adjoining Units Compared to Total Inflow One-week tracer gas measurements

- 33. Total air leakage of individual units Min Median Max Min Median Max Min Median Max < 1.25 2,101 2,368 2,636 115 130 145 3.16 3.56 3.97 0% 837 1,008 1,031 46 55 57 1.93 2.04 2.46 0% 731 917 1,318 40 50 72 1.61 2.02 2.90 0% 390 665 754 21 37 41 0.86 1.01 2.06 88% 376 454 958 21 25 53 0.57 0.76 2.14 86% 921 1,156 1,559 51 63 86 1.05 1.85 2.30 14% 376 861 2,636 21 47 145 0.57 1.66 3.97 22% NELA (si/100 sf)Ref. Flow Rate(cfm50) ELA (si) Building Min Median Max Min Median Max Min Duplex 2,101 2,368 2,636 115 130 145 3.16 8 Plex 837 1,008 1,031 46 55 57 1.93 12 Plex 731 917 1,318 40 50 72 1.61 138 Unit 390 665 754 21 37 41 0.86 11 Story 376 454 958 21 25 53 0.57 4 Story 921 1,156 1,559 51 63 86 1.05 All Buildings 376 861 2,636 21 47 145 0.57 Ref. Flow Rate(cfm50) ELA (si) LEED Green Building Rating system for MF SHS control requires ELA divided by wall & floor & ceiling area to be less than 1.25 si/100 sf ELA – equivalent leakage area, reference 4Pa & coef. = 1 (1999) (1982) (2001) Blower door air leakage tests

- 34. Fraction of air leakage to adjacent units Total Building ELA (si) ELA (si) (%) Duplex 130 26 20% 8 Plex1 55 28 59% 12 Plex1 50 28 57% 138 Unit 37 5 16% 11 Story 25 8 26% 4 Story 64 All Buildings 47 9 27% 1 - leakage to adjacent units includes leakage to common area To Adjacent Units Blower door air leakage tests

- 35. Leakage Area of Individual Units 712 34 1.8 612 28 1.1 514 512 510 28 1.3 24 0.5 33 2.5 1.1 4.4 414 412 410 34 2.4 22 0.1 53 1.0 2.3 4.2 314 312 310 21 3.0 25 1.3 33 1.2 212 23 Elevator 11 Story Building

- 37. General approach to reduce odor transport between apartments and improve air quality Ventilate Seal Ventilate

- 38. Air sealing treatments Focus on leaks between units (not exterior) Seal as much is practical – 3 to 8 hours/unit. Average cost of about $700/unit Blower door test to monitor total leakage Use visual/smoke puffer diagnostics sometimes aided by blower door. Tried IR in limited cases

- 39. Total and shared leakage CFM50/unit Existing After Treatments Total Shared Total Shared Duplex 2409 466 1881 601 8-plex 1032 475 916 307 12-plex 918 507 769 247 138 unit 641 90 639 88 New 4 story 1150 25 900 20 11 story 556 120 417 108 Blower door air leakage tests

- 40. Modest overall reductions in leakage between apartment units – but some were significant Range Median Duplex: small change 8-plex: 21 to 44% 35% 12-plex: 14 to 70% 55% New 138-unit: 0 to 23% small change New 4-story: 0 to 20% 11-story: 0 to 56% 23% Blower door air leakage tests

- 41. Mechanical ventilation observations Often provided only by occupant-operated (highly intermittent-typically off) bath fans Many bath fans are better noise-generators than air movers, even when new Apartment bath fans are not maintained (corrosion, dirt) Apartment exhaust flows are rarely balanced

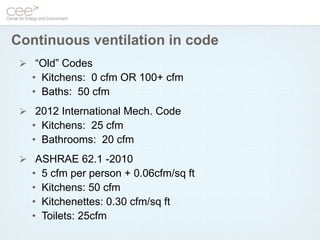

- 42. Continuous ventilation in code “Old” Codes • Kitchens: 0 cfm OR 100+ cfm • Baths: 50 cfm 2012 International Mech. Code • Kitchens: 25 cfm • Bathrooms: 20 cfm ASHRAE 62.1 -2010 • 5 cfm per person + 0.06cfm/sq ft • Kitchens: 50 cfm • Kitchenettes: 0.30 cfm/sq ft • Toilets: 25cfm

- 43. Corridor supply choices Minimum 0.05 cfm/sq ft corridor area (IBC) Minimum 0.06 cfm/sq ft corridor area ASHRAE 62.1-2010 Supply all ventilation to corridor & exhaust from units Original design flow (typically higher) Confirm with local code official

- 44. Ventilation treatments – for study Install effective (and quiet) exhaust fans with capacity of at least 30 to 45cfm Convert intermittent exhaust to continuous exhaust Balance exhaust air flows to reduce ventilation driving force between units

- 45. Ventilation treatments Quiet, Continuous Ventilation Constant Air Regulator Quiet Ceiling Exhaust Multi-point

- 46. Ventilation rate increased substantially 60% Increase*only one unit with added fan Existing After Treatments Duplex: 28 (12 to 43) 43 (35 to 50) 8-plex: 38 (19 to 58) 50 (26 to 79) 12-plex: 38 (23 to 75) 73 (57 to 157) New 138-unit: 26 (15 to 47) 41 (31 to 53) 11-story: 28 (18 to 79) 69 (45 to 124) 4-story*: 45 (26 to 61) 48 (22 to 88) Average 34 54 Median Ventilation Rate (cfm) min to max One-week tracer gas measurements

- 47. Cleaner air, same transfer rate Original ventilation system may be a direct path for smoke transfer (11 story, 138 unit, 4 story ducts) More smoke is captured near source Dilution reduces concentration in nonsmoker’s or receiver’s unit

- 48. Effect of Treatments: Air Transfer Fraction of Incoming Air From Adjoining Units Existing After Treatments Top-floor: 16% (2 to 26%) 13% (0 to 42%) Mid-floor: 5% (1 to 20%) 2% (0 to 12%) Lowest-floor: 2% (1 to 4%) 7% (1 to 19%) One-week tracer gas measurements

- 49. Effect of treatments 65% of the units had decreased air transfer 60% increase in ventilation rate 80% of tenants: SHS drift was less frequent and less severe

- 51. 8-Plex: balance ventilation & air seal Rooftop fan serves 4 units

- 52. 47 28 32 53 26 17 9 32 Uneven exhaust flow rates cause pressure difference & air flow between units Before Apartment exhaust flow rates Powered roof ventilator 8 plex

- 53. 25 26 28 26 23 26 27 24 47 28 32 53 26 17 9 32 Uneven exhaust flow rates cause pressure difference & air flow between units Before After 6 6 3 2 Added Powered roof ventilator Apartment exhaust flow rates Balanced exhaust flow rates reduces driving forces

- 54. Page 54 Open between tubs Neighbor’s bathtub Why do our clothes smell like smoke?

- 55. Easy air flow is possible through framing around pipes, etc

- 56. Page 56 Is better good enough? Unit #3 contaminants in unit #7 decreased by factor of five Fraction of air from unit #3 to #7 reduced from 11% to 6% Unit #3 ventilation rate increased 158% Marked reduction of SHS odors per tenants Will owners pay for it? Who can do the work?

- 57. Page 57 Ongoing Success: 67 Buildings in Condo Complex of Tested 8-plex Condo Maintenance team trained to respond to smoke complaints in additional buildings. Smoker is back-charged for repair costs 20 additional units have been completed to date 15 more units are scheduled Huge improvement in livability Common areas air quality improved

- 58. Page 58 Details of Ongoing work Typical complaint has smoker on lower level with fan off and large bypasses venting smoke into chases. Non-smoker on upper level often had higher exhaust fan flows which increased airflow from chase into unit. Stack effect enhances this flow in winter. Seal major bypasses, 1-4 person hours Ventilation modifications • Nonsmoker: replace fan damper with CAR • Smoker: remove fan damper and omit CAR for higher capture. • Typical flows are 25cfm in nonsmoker and 75cfm in smoker’s unit. Existing Conditions Practical & Effective Work

- 59. Page 59 High rise case study: seal hidden shafts & rooftop exhaust ventilation

- 60. Hidden chase openings often difficult to access

- 61. Add mineral wool fire-safing to high rise shaft openings

- 62. Seal with listed fire barrier

- 63. Page 63 PRV fan on roof – top of vent chase Vent chase Operable register

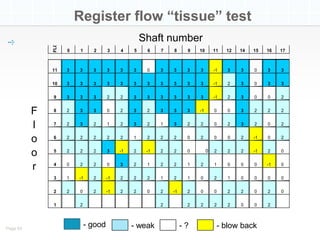

- 64. Page 64 FLOOR 0 1 2 3 4 5 6 7 8 9 10 11 12 14 15 16 17 11 3 3 3 3 3 3 0 3 3 3 3 -1 3 3 0 3 3 10 3 3 3 3 3 3 3 3 3 3 3 -1 2 3 0 3 3 9 3 3 3 2 2 3 3 3 3 3 3 -1 2 3 0 0 2 8 2 3 3 0 2 3 2 3 3 3 -1 0 0 3 2 2 2 7 2 3 2 1 2 3 2 1 3 2 2 0 2 3 2 0 2 6 2 2 2 2 2 1 2 2 2 0 2 0 0 2 -1 0 2 5 2 2 2 3 -1 2 -1 2 2 0 0 2 2 2 -1 2 0 4 0 2 2 0 3 2 1 2 2 1 2 1 0 0 0 -1 0 3 1 -1 2 -1 2 2 2 1 2 1 0 2 1 0 0 0 0 2 2 0 2 -1 2 2 0 2 -1 2 0 0 2 2 0 2 0 1 2 2 2 2 2 2 0 0 2 Unit Number Register flow “tissue” test - good - weak - ? - blow back Shaft number F l o o r

- 65. Page 65 Floor Press Flow Notes 11 -74 28 10 -45 27 9 -15 14 8 -10.8 14 7 -9.5 10 6 na 5 +1.2 + stinks 4 +0.1 + smoker 3 +0.3 + stinks 2 -2.8 4 1 -5.3 8 Flow box measurement

- 66. Page 66 Obstructions: undersized floor cutout full-sized subduct Concrete floor Bathroom vent sub duct The 144 sq. in. shaft area only has 32 sq. in. for air flow. c Vent chase: 12” X 12” = 144 Sq. in. 8 x 8 cutout

- 67. Page 67 Obstructions: undersized floor cutout full-sized subduct Vent chase: 12” X 12” = 144 Sq. in. Concrete floor Bathroom sub duct – replaced with 3” for more flow. The 144 in2 shaft only has 32 in2 for air flow 8 x 8 cutout

- 68. Page 68 Drywall joints open

- 69. Page 69 Total: 506 cfm From units: 93 cfm Leaks: 413 cfm No flow from lower 5 floors Fan & register flow measurements

- 70. Page 70 Ventilation system problems Restrictions cause most air to be drawn from upper apartments Duct leaks • Air drawn from unknown sources • Lower units no or reverse flow Operable registers – occupant “balancing” • No flow when closed • Too high when open

- 71. Page 71 Ventilation system solutions Reduce duct restrictions: 3” sub ducts to upper 3 floors Seal ductwork with Aeroseal technology Install constant air regulators or designed orifice plates at registers Test and adjust fan flow to required duct pressure Thanks to Don Stevens for advising us of subduct code issue Target: equal flow from all units

- 72. Page 72 Remove restriction and provide 3” subducts for top 3 floors Code: fire damper or sheet metal sub duct extending 22” above fan inlet

- 73. Page 73 Aeroseal required for fan draw to reach lower units Before After Total: 506 279 cfm From units: 93 221 cfm Leaks: 413 58 cfm Targets leaks

- 74. Page 74 Option used for test: 3” opening sized to exact flow rate Remove dampers, balance register flow First option : “self-adjusting” constant air regulator “CAR” Production option: fixed orifices – more to come

- 75. Page 75 Floor Before After Press Flow Press Flow 11 -74 28 -75 21 10 -45 27 -65 20 9 -15 14 -63 20 8 -10.8 14 -56 20 7 -9.5 10 -52 20 6 na -49 20 5 +1.2 + -42 20 4 +0.1 + -42 20 3 +0.3 + -42 20 2 -2.8 4 -42 20 1 -5.3 8 -44 20 Treatments Subducts Aeroseal Orifice plates Fan adjustment Even flow after upgrades Outcomes Required ventilation for all Save 227cfm ($250 - $500/year) Reduce unit/unit flow – smoke drift 17 fans ~ $4k - $8k

- 76. Page 76 Keep control fans on Aethelometer Measurement of ETS Particle Concentration in Nonsmoker's Apartment -2 0 2 4 6 8 10 12 11/28 11/29 11/30 12/1 12/2 12/3 12/4 12/5 12/6 ETSParticleConcentration(mg/m3 ) Instrument precision ETS odors logged by resident Kitchen shaft central exhaust fan turned off at midnight SHS odor threshold Secondhand smoke monitored in 11th floor unit SHS logged by resident

- 77. From research to production: current options Spray seal ducts with mastic & seal fan curbs Orifice restrictors Efficient fan Clean or remove blockages

- 78. Current options Spray sealing with mastic

- 79. Fan not connected - curb open Current options: curb leakage Total flow: 174 cfm From units: 30 cfm Airflow from building shafts not exhaust grilles

- 80. Current options: stop curb leakage Sealed Total flow: 126 cfm From units: 120 cfm

- 81. Current options CARs failures: How soon? How often? After 9 years – 1 in 3 plugged Dust buildup in 9 months Adjustment holes

- 82. Current options Fixed orifices Not prone to foul Can be cleaned Durable Sized for flow at target pressure Mass - produced, low cost Allow lower operating pressure (reduced duct leakage, & fan power) 2 11/2 11/4 1

- 83. Current options Fixed orifices – flow rate guideline Inside Diameter (in) Pressure, in wc (Pa) Nominal Actual 0.15 (36) 0.2 (50) 0.25 (62) 0.36 (90) 0.5 (124) 0.75 (186) 2 2.45 36 40 44 54 1.5 1.97 21 24 28 34 39 48 1.25 1.73 18 21 26 29 36 1 1.37 16 18 22 # stories* 3 to 7 5 to 10 6 to 12 9 to 18 12 to 25 to 25 *- building size for Minneapolis climate (20F average outside temp)

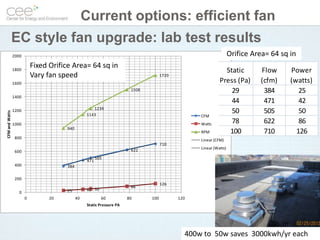

- 84. Current options: efficient fan 384 471 505 622 710 25 42 50 86 126 940 1143 1234 1508 1720 0 200 400 600 800 1000 1200 1400 1600 1800 2000 0 20 40 60 80 100 120 CFMandWatts Static Pressure PA CFM Watts RPM Linear (CFM) Linear (Watts) EC style fan upgrade: lab test results C 9" diam test Static Press (Pa) Flow (cfm) Power (watts) 63.6 in2 inlet area 29 384 25 (13 inlets 2.45 in) 44 471 42 (21 inlets 1.97 in) 50 505 50 (27 inlets 1.73 in) 78 622 86 (43 inlets 1.37 in) 100 710 126 Orifice Area= 64 sq in Fixed Orifice Area= 64 sq in Vary fan speed 400w to 50w saves 3000kwh/yr each

- 85. Exhaust grille on 12 story looks OK Current options: blockages

- 86. Current options: blockages Exhaust fan runs but DP low/high Fan intake 20.9Pa too low for flow needed Fan outlet 221Pa to exterior grille (side with resistance) Check pressures

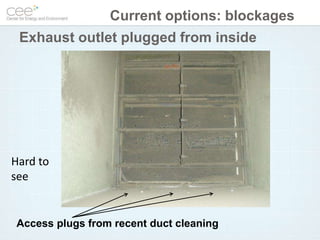

- 87. Current options: blockages Access plugs from recent duct cleaning Exhaust outlet plugged from inside Hard to see

- 88. Dirt obstructs flow: clean & adjust fan down Current options: blockages As found: 609 cfm After: 2,338cfm Design flow: 1,780 cfm

- 89. Fan stops damper from opening Current options: blockages

- 90. 300 inspected – 1 in 4 plugged Current options: supply blockages

- 91. Exterior screen is clear. Hidden screen is forgotten Current options: supply blockages Pressure across grille 0.9 in wc (221Pa) Inspection: 18 of 46 Corridor supply intakes obstructed

- 92. Nobody can keep this clean: remove hidden screens Current options: supply blockages

- 93. 138 unit: little unit to unit leakage

- 94. Meets LEED leakage guideline Occupants still complain of smoke transfer 324 323 322 321 601 9 17 574 3 622 +/-1 +/-13 +/-3 1 44 224 +/-7 223 222 +/-4 221 21 688 71 33 661 65 654 +/-7 +/-4 28 -4 2 64 124 +/-14 Guest +/-12 123 +/-15 122 +/-12 121 609 35 390 37 606 51 664 93 683 +/-8 +/-2 +/-8 Guarded-Zone Measured Air Leakage Rates 734 680 -13 +/-11 Oaks: Pre-Treatment unit # total leakage unit/unit leakage leakage precision (cfm50) Smoker Non- smoker

- 95. Vent blocked: view inside smoker’s fan duct in attic

- 96. Vent blocked: roof damper frozen shut on same fan

- 97. CARs in fan duct in attic, smokers open for higher flow

- 98. Post treatment fan flows Unit Flow (cfm) Unit Flow (cfm) Unit Flow (cfm) 323 24 322 25 224 21 223 20 222 22 Guest 26 123 28 122 20Smoker

- 99. 4 Story: duct leakage in ceiling joist space

- 100. All leakage into joist space

- 101. Aeroseal ducts in joist space

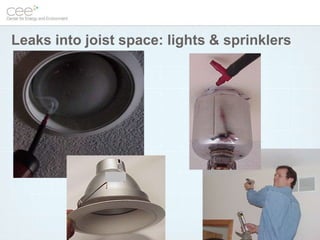

- 102. Leaks into joist space: lights & sprinklers

- 103. New continuous duty fan in kitchen: source of odor complaint

- 104. Continuous at 40cfm. Installer sets high speed: 75, 160, or 390 cfm Less than 20 watts at low speed Continuous ventilation with kitchen hood in 1 unit

- 105. Duct seal side-benefit Backdraft potential reduced by Aeroseal -4.5 pa before -1.5pa after 80%-ID furnace both into B vent natural draft water heater Door closed dryer+ AC fan on in 1 unit

- 106. Recommendations Ventilate - source Seal - between Ventilate - receiver

- 107. Recommendations: ventilation Moderate/continuous/quiet – better than intermittent Central exhaust: orifice, seal ducts, replace or adjust fan Check for blockages and leaks

- 108. Recommendations: air sealing Seal between units Large, accessible leaks (unoccupied or new is better) Includes ducts and mechanical/plumbing chases Improvement possible – can not eliminate transfer

- 109. In at the bottom and out the top Additional slides

- 110. Additional Information Canada Mortgage and Housing Corporation Fact Sheet: Solving Odour Transfer Problems in Your Apartment http://www.cmhc.ca/en/co/reho/reho_002.cfm

- 111. Fan not connected - curb open Current options: curb leakage Total flow: 174 cfm From units: 30 cfm Airflow from building shafts not unit exhaust grilles

- 112. Current options: stop curb leakage Sealed Total flow: 126 cfm From units: 120 cfm

- 113. 2-part Foam Seals Plumbing Chase Stop Vertical Air Transfer In Plumbing Wall Patched, primed Inject Foam Along Top of Wall 12-plex Shared leakage reduced about 50% from 507 to 247 cfm50

- 114. Kitchen option for cooking source In different project after work Cooking moisture was an issue in 15% of units Continuous kitchen fan option needed VenMar developed (UL) a quiet continuous range hood

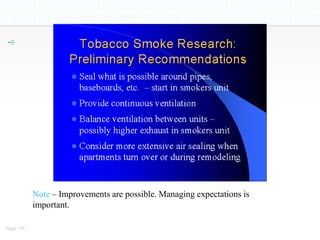

- 115. Page 115 Note – Improvements are possible. Managing expectations is important.

- 116. Page 116 What does this cost, who pays, who can do it? •Licensed mechanical contractor required for all duct alterations. •Aeroseal franchisee required for duct sealing. (Maint. prep ok) •Performance contractor/ consultant for design, balancing, QC •$300 per unit or $3,200 for 1 shaft minimum, $5,000 for 2 shafts •Changes to the building are an Association responsibility. •Airsealing in unit is responsibility of individual condo owner

- 117. Page 117 Individual supply and very low leakage required for best control If an occupant opens a window to let smoke out air can come in and blow smoke into adjacent units. At 30F we measured a lower unit change pressure from from -0.7pa to hall to +24pa to hall by opening 1 window. Some flow still came in from under the kitchen kickboard @+2pa to hall. The occupant complained about intermittent smoke. Total air leakage down to 283cfm50 after work. Some individuals may not tolerate any smoke transfer, a large improvement may not be enough.

Editor's Notes

- Probably the more appropriate title of this presentation is “how to achieve better air quality by sealing leaks between units and improving ventilation. Our focus is not necessarily on reducing energy, but what can be done to improve air quality in MF buildings. So we’ll talk about what the sources of contaminants are, how they get between units, what others have found regarding air leakage and air flows between units and then we’ll present information from our 6 building study in Minnesota.

- So do you think the person in this apartment smoked a little bit? It’s either that or a lot of fired food. Secondhand smoke drift between units is one of the most significant sources of concern in apartment buildings and condos.

- You could get rid of one of the SHS problem by converting the building to be smoke-free. There has been a strong effort in Minnesota and the “Live Smoke Free” program now has more than 500 smoke-free apartment buildings in Minnesota listed on their web site. They have a nice page that allows people to search for buildings in their area. They also have information for owners regarding steps to making their building smoke-free.

- Survey of apartment owners indicates that cooking is the most common source of complaints. So even if a building goes smoke-free, you still have to deal with cooking and other odors that are transferred between units. Also, want to provide adequate ventilation in each unit to keep them fresh.

- The cause of the problems are not just the sources, but that air and odors travel between units. You can see in these three studies with tracer gas measurements in apartments across the country that up to 35% of an apartment’s air comes from their neighbors.

- Other studies that have looked at the leakage in apartment buildings have found 50% or more of the total leakage is to other apartments or to the common area.

- So why is it that apartments share their air and their odors and other contaminants with their neighbors? What are the driving forces?

- Just a little building science 101 here. In colder climates the main driving force is the stack effect. You have warm air in the building and colder air outside. Just like a hot air balloon, hotter air rises. In this case this tends to cause air to enter the building on the lower floors and exit out the top. This effect gets bigger with taller buildings, so it can be a big issue for taller MF buildings. That is unless the floors are air sealed or isolated from each other – and that doesn’t happen often.

- The wind effect on buildings is pretty obvious. Air tends to enter on the windward side and leave on the downwind side. It is important to note that wind speeds are higher farther from the ground, so wind pressures are greater for the upper level of taller MF buildings.

- The third effect is the mechanical system effect and sometimes that isn’t discussed much for single family houses. This is the imbalance of air flow in apartments. In most cases this occurs when there is more exhaust ventilation in one unit than an adjacent unit. Now in some buildings it makes sense to do this. Say for instance you have a pool attached to a school. You don’t want the chlorine smell from the pool to get into the school, so you run extra exhaust in the pool area which causes the pool to be at a negative pressure relative to the school and air flows from the school to the pool – not the other way around. Unfortunately, this same effect happens in MF buildings. Someone doesn’t like their neighbor’s cooking or smoking, so they turn on their bath fan. Unfortunately, that typically causes more air and odor to move into their unit. So turning on an exhaust fan has the exact opposite of the desired effect.

- Sometimes smokers can be proactive. We’ve had buildings where the smoker got tired of their neighbor’s complaints so they opened a window when they smoked. Do you think that helps? Well on a cold day it probably helps the person in the unit below, but it doesn’t help their upstairs neighbor. When you open a window it causes the pressure to be about the same as outside which only increases the pressure difference from the smoker to the upper unit and produces more air flow (and odor) to the upper unit. Something to think about – another case where you intuition of what should help actually does not.

- Of course you not only need the driving force, but also the pathways. For people that haven’t been involved in air sealing, the initial response can be – how does the air get from my unit to theirs? Solid floor no obvious leaks. But there are always leaks.

- Unfortunately, most are small and spread out around the unit – access of occupied units can be a problem.

- Baseboards or under walls can be an issue. 1/32” crack doesn’t seem like much but multiply that by 3’ and you have a 1 square inch leak. Multiply by 30’ and you have 10 sq inches.

- Not sure if you want this slide here

- Not sure if you want this slide here

- Add unit ERV/HRV as per Gord Cooke Stack vents

- Put these 3 slides in with the LakeShore case study?