Modernizing Your HMI

- 1. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 1Rockwell Automation TechED 2017 @ROKTechED #ROKTechED

- 2. Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 2Rockwell Automation TechED 2017 @ROKTechED #ROKTechED PUBLIC Modernizing your HMI Bringing data to life through Visualization

- 3. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 4Rockwell Automation TechED 2017 @ROKTechED #ROKTechED HMI’s Evolving Role IT and OT Convergence HMI is the central point for decision making in the manufacturing and industrial space. Flexible Manufacturing Emerging Technologies

- 4. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 5Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Key Benefits HMI Modernization Help convert your hidden data into relevant and timely information Reduced design and commissioning time Improved uptime and productivity More detailed and accurate alarm information Improved visualization and ease of use Anytime, anywhere information availability From merely providing plant data on a mobile device, HMI now delivers real-time data and actionable insights to operators. The consequent benefits, such as lower plant operation costs, higher process efficiency and greater energy efficiency, will power the adoption of HMI solutions1 “ 1. Convergence of Industries Marks New Era in Global Human Machine Interface Market, Frost & Sullivan ”

- 5. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 6Rockwell Automation TechED 2017 @ROKTechED #ROKTechED A View for Every Manufacturing Scenario FactoryTalk® View Machine Edition Studio 5000 View Designer ® Machine-Level HMI • PanelView™ Plus • Compact and Standard • PanelView™ 5000 FactoryTalk® View Site Edition Scalable, Distributed PC Based HMI FactoryTalk® ViewPoint Web-Based HMI • Industrial Computers • Non-Industrial Computers • Monitors • Add-on for Machine Edition and Site Edition • Access HMI screens from a web browser

- 6. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 7Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Visualization Hardware Portfolio overview and positioning PanelView 800 MobileView PanelView™ Plus 7 Performance PanelView™ 5500 (future state position) Optimized for compatibility with Micro800® and MicroLogix™ controller Design and configure with CCW Panel-mount display devices Connectivity to L1 controllers Runs FactoryTalk® View Studio Machine Edition software Closed-platform provides a robust machine interface Ethernet communication Mobile Enabled Runs Studio 5000 for enhanced integration with Logix Reduced development time Scalable vector graphics Advanced animation Logix based alarms Ethernet communication Runs FactoryTalk® View Site Edition Software Open-platform flexibility of Windows® operating systems Industrial and extreme environment options available Scalable performance options and form factors to meet a wide variety of applications Increasing features & performance Industrial Computers PanelView™ Plus 7 Standard

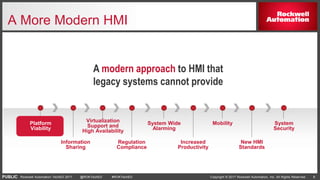

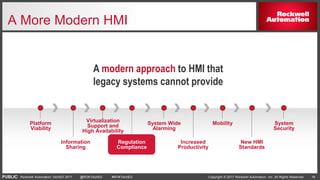

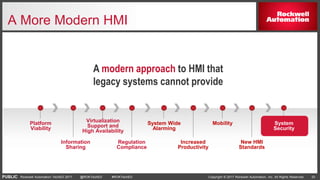

- 7. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 8Rockwell Automation TechED 2017 @ROKTechED #ROKTechED A More Modern HMI Increased Productivity Platform Viability A modern approach to HMI that legacy systems cannot provide Regulation Compliance Virtualization Support and High Availability New HMI Standards MobilitySystem Wide Alarming Information Sharing System Security

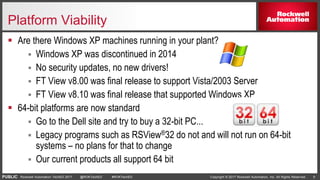

- 8. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 9Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Platform Viability Are there Windows XP machines running in your plant? Windows XP was discontinued in 2014 No security updates, no new drivers! FT View v8.00 was final release to support Vista/2003 Server FT View v8.10 was final release that supported Windows XP 64-bit platforms are now standard Go to the Dell site and try to buy a 32-bit PC... Legacy programs such as RSView®32 do not and will not run on 64-bit systems – no plans for that to change Our current products all support 64 bit

- 9. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 10Rockwell Automation TechED 2017 @ROKTechED #ROKTechED A More Modern HMI Increased Productivity Platform Viability A modern approach to HMI that legacy systems cannot provide Regulation Compliance Virtualization Support and High Availability New HMI Standards MobilitySystem Wide Alarming Information Sharing System Security

- 10. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 11Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Common Services FactoryTalk® Services Platform ACTIVATION DIRECTORY Common software license management for all FactoryTalk® products Common address lookup of resources that are shared among FactoryTalk® enabled products SECURITY DIAGNOSTICS Common security authority for all FactoryTalk® components in the system Common diagnostic messaging sub-system across all FactoryTalk® products AUDIT LIVE DATA Comprehensive record of any changes made to the manufacturing system Enterprise-wide access to real-time manufacturing data ALARMS & EVENTS Enterprise-wide notification to real-time alarms and events that require action

- 11. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 12Rockwell Automation TechED 2017 @ROKTechED #ROKTechED HMI Enabled with Information FactoryTalk Directory FactoryTalk View SE FactoryTalk Alarms and Events RSLinx Enterprise Historian VantagePoint Metrics Historian KPI’s OEE

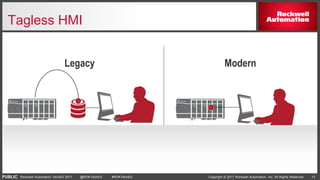

- 12. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 13Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Tagless HMI Legacy Modern

- 13. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 14Rockwell Automation TechED 2017 @ROKTechED #ROKTechED A More Modern HMI Increased Productivity Platform Viability A modern approach to HMI that legacy systems cannot provide Regulation Compliance Virtualization Support and High Availability New HMI Standards MobilitySystem Wide Alarming Information Sharing System Security

- 14. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 15Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Virtualization Break the chain between hardware and software Control system independenceExtends the hardware lifecycle THE VALUE Easy distribution of best practices Eliminating under-utilized servers improves operational efficiency Minimizes lost revenue from downtime

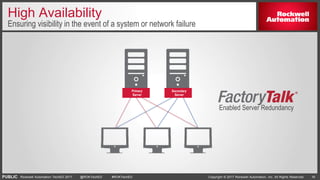

- 15. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 16Rockwell Automation TechED 2017 @ROKTechED #ROKTechED High Availability Ensuring visibility in the event of a system or network failure Primary Server Secondary Server Enabled Server Redundancy

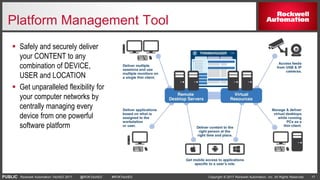

- 16. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 17Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Platform Management Tool Safely and securely deliver your CONTENT to any combination of DEVICE, USER and LOCATION Get unparalleled flexibility for your computer networks by centrally managing every device from one powerful software platform

- 17. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 18Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Benefits of the ThinManager® Platform Total Cost of Ownership. ThinManager®… Increases Productivity (centrally manage users and devices with a simple easy-to-use interface) Increases Visualization (customize multiple monitors and virtual screens) Increases Security (no locally stored data, content delivered based on role and/or location) Provides Location-Based Mobility (exclusive mobile security) Decreases Maintenance Costs 18 PRODUCTIVITY VISUALIZATION SECURITY MOBILITY

- 18. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 19Rockwell Automation TechED 2017 @ROKTechED #ROKTechED A More Modern HMI Increased Productivity Platform Viability A modern approach to HMI that legacy systems cannot provide Regulation Compliance Virtualization Support and High Availability New HMI Standards MobilitySystem Wide Alarming Information Sharing System Security

- 19. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 20Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Audit Trail & Regulatory Compliance CAPTURE Who, What, When, Where and Why

- 20. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 21Rockwell Automation TechED 2017 @ROKTechED #ROKTechED A More Modern HMI Increased Productivity Platform Viability A modern approach to HMI that legacy systems cannot provide Regulation Compliance Virtualization Support and High Availability New HMI Standards MobilitySystem Wide Alarming Information Sharing System Security

- 21. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 22Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Alarming CENTRALIZED ALARM MANAGEMENT Alarm state can be managed in one place Reduction in network traffic through “publishing” technology Improved time stamp accuracy No alarm information loss in the event of HMI outage No HMI tag duplication required, alarm instruction or tags directly A single, consistent shared alarm generation and response mechanism On the fly changes to alarming tags are automatically updated in HMI

- 22. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 23Rockwell Automation TechED 2017 @ROKTechED #ROKTechED FactoryTalk Alarms and Events The server captures all of the controller events and sends notification to connected clients The controller detects alarm conditions and triggers alarm events. Alarms are buffered in the controller and show on the display in the right order with accurate time stamps. ACCURATE Time Stamps Alarms and Events DEVICE-BASED ALARMS Uses alarm instructions in a Logix Controller TAG-BASED ALARMS Software-based alarm servers poll data tags for alarm conditions We’ve got a problem… I’m on It! We’ve got a problem… I’m on it!

- 23. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 24Rockwell Automation TechED 2017 @ROKTechED #ROKTechED A more modern HMI Increased Productivity Platform Viability A modern approach to HMI that legacy systems cannot provide Regulation Compliance Virtualization Support and High Availability New HMI Standards MobilitySystem Wide Alarming Information Sharing System Security

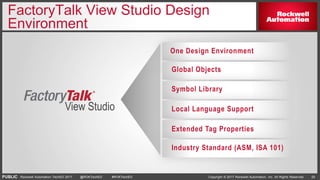

- 24. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 25Rockwell Automation TechED 2017 @ROKTechED #ROKTechED FactoryTalk View Studio Design Environment One Design Environment Global Objects Symbol Library Local Language Support Extended Tag Properties Industry Standard (ASM, ISA 101) View Studio

- 25. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 26Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Studio 5000® Design Environment Optimized Logix Integration Extended Tag Properties Logix Based Alarms Scalable Vector Graphics Advanced Diagnostics Built in Navigation Menus

- 26. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 27Rockwell Automation TechED 2017 @ROKTechED #ROKTechED A More Modern HMI Increased Productivity Platform Viability A modern approach to HMI that legacy systems cannot provide Regulation Compliance Virtualization Support and High Availability New HMI Standards MobilitySystem Wide Alarming Information Sharing System Security

- 27. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 29Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Mobility at a Glance Anytime, anywhere information availability on a device of your choice! MobileView PanelView™ Plus ViewPoint/VNC Server Operator ViewPoint Clients (Web/Mobile) ViewPoint Server Plant Manager

- 28. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 30Rockwell Automation TechED 2017 @ROKTechED #ROKTechED A More Modern HMI Increased Productivity Platform Viability A modern approach to HMI that legacy systems cannot provide Regulation Compliance Virtualization Support and High Availability New HMI Standards MobilitySystem Wide Alarming Information Sharing System Security

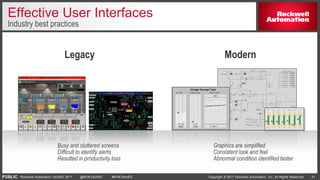

- 29. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 31Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Effective User Interfaces Industry best practices Legacy Modern Busy and cluttered screens Difficult to identify alerts Resulted in productivity loss Graphics are simplified Consistent look and feel Abnormal condition identified faster

- 30. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 33Rockwell Automation TechED 2017 @ROKTechED #ROKTechED A More Modern HMI Increased Productivity Platform Viability A modern approach to HMI that legacy systems cannot provide Regulation Compliance Virtualization Support and High Availability New HMI Standards MobilitySystem Wide Alarming Information Sharing System Security

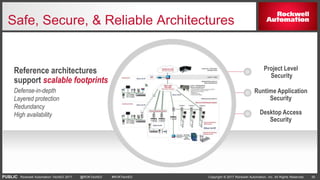

- 31. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 35Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Desktop Access Security Runtime Application Security Project Level Security Safe, Secure, & Reliable Architectures Reference architectures support scalable footprints Defense-in-depth Layered protection Redundancy High availability

- 32. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 36Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Integrated Approach to Control and HMI Help convert your hidden data into relevant and timely information The Mechanics

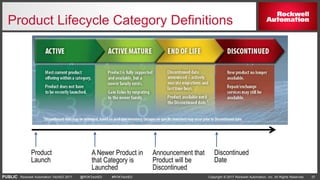

- 33. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 37Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Product Lifecycle Category Definitions Product Launch A Newer Product in that Category is Launched Announcement that Product will be Discontinued Discontinued Date

- 34. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 38Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Product Lifecycle Status Search www.rockwellautomation.com/legacy

- 35. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 39Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Things to Consider Modern HMI platforms – operating system / PC replacement Configuration sharing for security, alarms, activation and messaging Integration of HMI with information - historian, OEE, system auditing, reporting Implementation of new technologies such as mobility and virtualization Add platform management tool Requirements for regulated environments

- 36. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 40Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Things to Consider Controller being connected to Network connection Development environment / runtime Features Environment Number of screens needed Project scope Thick / thin clients

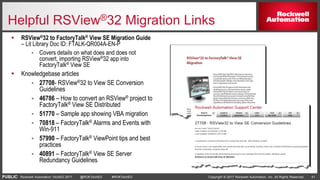

- 37. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 41Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Helpful RSView®32 Migration Links RSView®32 to FactoryTalk® View SE Migration Guide – Lit Library Doc ID: FTALK-QR004A-EN-P Covers details on what does and does not convert, importing RSView®32 app into FactoryTalk® View SE Knowledgebase articles 27708- RSView®32 to View SE Conversion Guidelines 46786 – How to convert an RSView® project to FactoryTalk® View SE Distributed 51770 – Sample app showing VBA migration 70818 – FactoryTalk® Alarms and Events with Win-911 57990 – FactoryTalk® ViewPoint tips and best practices 40891 – FactoryTalk® View SE Server Redundancy Guidelines

- 38. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 42Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Helpful Links RSView®32 to FactoryTalk® View SE migration site: http://campaign.rockwellautomation.com/hmi-home Collection of tools to help with the process of migrating Videos and other materials covering why you should consider migrating, technical tips and demo of migrating an app, and success stories Ask about the StepForward™ program for commercial incentives to migrate

- 39. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 43Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Additional Resources PanelView™ Plus 6 to PanelView™ Plus 7 Migration guide http://literature.rockwellautomation.com/idc/groups/literature/document s/ap/2711p-ap004_-en-p.pdf Legacy PanelView™ to PanelView™ Plus 7 Catalog Conversion Guide http://literature.rockwellautomation.com/idc/groups/literature/document s/ap/2711p-ap005_-en-p.pdf

- 40. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 44Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Call to Action Download Software NOW! Reach out to local distributor and check out additional resources Visit the HMI Migration Website

- 41. PUBLIC Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 45Rockwell Automation TechED 2017 @ROKTechED #ROKTechED Please take a moment to complete the brief session survey on our mobile app and let us know how we’re doing! Username: Last name Password: Email address used to register Locate the session in the “Schedule” icon Click on the “Survey” icon in the lower right corner of the session details Complete survey & submit Download the ROKTechED app and login: Thank you! Complete A Survey

- 42. www.rockwellautomation.com Copyright © 2017 Rockwell Automation, Inc. All Rights Reserved. 46Rockwell Automation TechED 2017 @ROKTechED #ROKTechED PUBLIC Thank you!