New power energy new patent ap 7 26-19 --

- 1. 1 Copyright © 2019 by ASME Presented Not Published June 29, 2017 Power & Energy Conference Charlotte, North Carolina Updated expanded July 26, 2019 Power Energy “2017-3191” Analysis of Steam Zoning With Exhaust – Smoke Stack and Water Swirled Into Gas Turbine Technology – Draft – Work in Progress Leonard M. Andersen Water Swirled Into Gas Turbine Tech Caller Box 1529 New York, New York 10116, USA 914-237-7689 ABSTRACT Two and a half years ago I prepared a paper “Power Energy “2017-3191” -Analysis of Steam Zoning With Exhaust – Smoke Stack and Water Swirled Into Gas Turbine Technology and presented. It was not published as part of the proceedings. The New technology covered in PUB. APP. NO. 20170306843 “METHOD AND APPARATUS FOR INCREASING USEFUL ENERGY/THRUST OF A GAS TURBINE ENGINE BY ONE OR MORE ROTATING FLUID MOVING (AGITATOR) PIECES DUE TO FORMATION OF A DEFINED STEAM REGION” Filed: February 27, 2017 published October 26, 2017 first action March 4, 2019 not part of the presentation due to a request by the US Government. The new technology has been developed with water into a flow of hot gas in a swirling pattern most recently with a focus on internal combustion engines , fired boiler stacks and, water swirled into gas turbines combined cycles for more fuel efficiency. Beyond more fuel efficiency there is pollution control of PM 2.5 and PM 10 particulate in coal firing etc.. In electrical generation the latest advance is to have a fluid mover of a paddle nature moving a mass – volume of optimally positioned spaced sized water droplets in hot gas outward from a centerline into a tire / donut shaped volume space where said goes to steam / pressurization. Such pressurization happens making an extractive turbine turn which is connected to an electrical generator. In fired boilers and internal combustion engines the shaft of the fluid mover would be vertical and the extractive turbine would normally be horizontal. The horizontal extractive turbine would have water drops and combustion gas leaving at about 120 C with less particulates exiting. The work in new combined cycle gas turbines prior to this is my two patents is to at the end of the power turbine through blades and/or a mechanism to put water droplets into the hot thrust gas of 350 – 500 C going to steam in concentrated volume. Said volume goes in a steaming chamber. The energy is converted from heat to steam pressurized increase in volume. Increase in volume in the steaming chamber acts on an extractive turbine connected to an electrical generator. This could benefit from aforementioned. The tire / donut shape would be vertical. The maintenance and operation of this is a fast moving subject with in exhaust – stack gas plus 5 % per unit fuel and in the case of water swirled into gas turbines 15 – 25%. The motivation for the presentation is to get discussion going. A speaker on coal fired with experience of use and, second on internal combustion engines automotive / ship propulsion and third on new combined cycle gas turbine and a fourth on aircraft propulsion with the new tech was sought. At this time there is one speaker. This is a start ! NOMENCLATURE

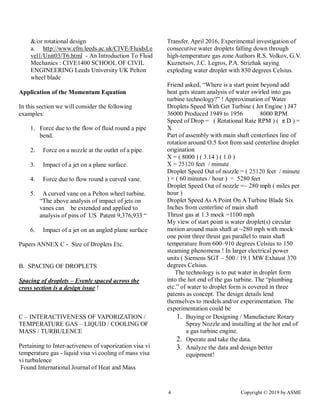

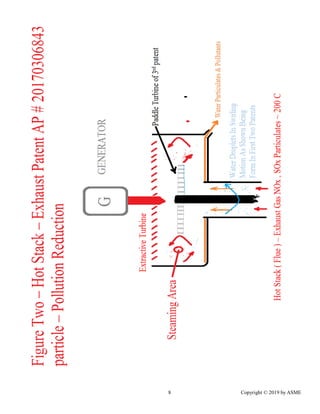

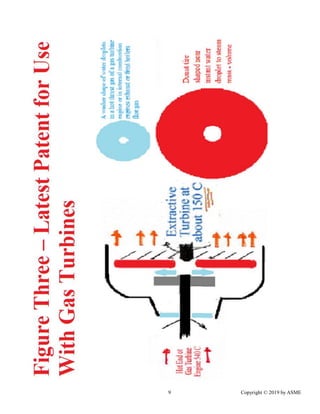

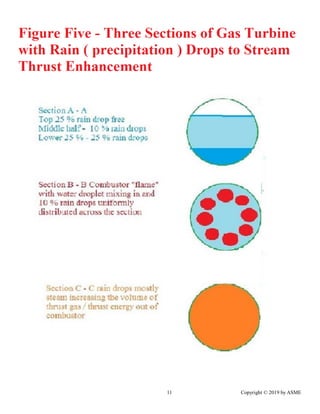

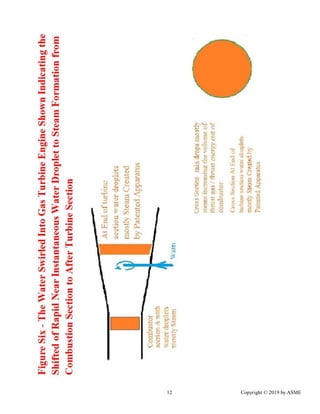

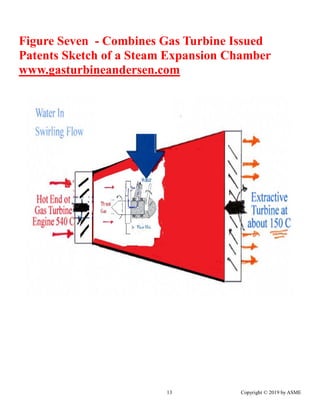

- 2. 2 Copyright © 2019 by ASME BTU - British thermal unit GTE - Gas Turbine Unit Meg - Million Watt Mock - Mock At sea level, mock 1 is 761 mph Mph - Miles per hour MW - Megawatt (MW) = 1,000 kilowatts Rpm - Revolutions per minute π - 3.14159 KEYWORDS – Natural Gas, Electrical Power Generation , Electrical Generation , Fuel Efficiency, Pollution , Boilers , Internal Combustion Engines, Gas Turbine , Aircraft , Jet Acknowledgments Edward J. Ellis | Leason Ellis – Patent Attorney 914.821.9071 ellis@leasonellis.com One Barker Avenue, Fifth Floor White Plains, New York 10601-1526 Ones Sharing Knowledge With me at ASME ( www.asme.org ) and WPC “World Petroleum Congress” ( www.world-petroleum.org ) events and at www.asme.org online inter-activeness etc. . REFERENCES United States Patents 8,671,696 , 9,376,933 and one pending PUB. APP. NO. 20170306843 “METHOD AND APPARATUS FOR INCREASING USEFUL ENERGY/THRUST OF A GAS TURBINE ENGINE BY ONE OR MORE ROTATING FLUID MOVING (AGITATOR) PIECES DUE TO FORMATION OF A DEFINED STEAM REGION” Len Andersen Gas Turbine Engineering Handbook Author(s): Meherwan P. Boyce 2011 INTRODUCTION The presenter started career with a coal fired air pollution project. At that time a third of a power plant cost was scrubber and resulting sludge cost. My technology is to a hot gas stream ( exhaust / stack / thrust ) as indicated in my first patents ( water droplets are added in optimal spacing positions with swirling around main shaft ) . Said mass in the latest patent is moved radially from center line to form a tire /donut where the water form steam ( pressure energy ) . Said moves extractive turbines or makes airplanes go. In the case of steam move to sides the hot gas at a higher than current off boiler tubes ( ~ 200 C ) and have an optimally water droplets in hot gas mass moved from center into a steam zone – space of donut / tire shape. Go to steam and move an extractive turbine connected to an electrical generator. A parallel is envisioned would be for internal combustion engines. The area of gas turbines is more addressed with many issues resolved. The concern we have is having such happen more cost effectively. My presentation is an answer that has been there since the beginning; add water without wear on the internals of the machine. In total it is the get the benefit in boilers , internal combustion engines , and thrust per unit fuel as with water being ingested into blower of furnace, air intake of an internal combustion engine, water into compressor and/or water injected into combustor of a gas turbine engine with less wear . WATER ADDED TO HOT STACK GAS - EXHAUST - - TURBINE ENGINE THRUST GAS EFFECTS ON PERFORMANCE gives a water droplet to steam volume increase which has a boost of performance per unit fuel. Note following Figure One - New Tech Hot Gas To Electricity , Figure Two – Hot Stack- Exhaust Patent PUB. APP. NO. 20170306843 particle – Pollution Reduction , Figure Three – Latest Patent for Use With Gas Turbines , Figures Four - Gas Turbine with Rain Ingestion Sectioned , Figure Five - Three Sections of Gas Turbine with Rain ( precipitation ) Drops to Stream Thrust Enhancement , Figure Six - The Water Swirled Into Gas Turbine Engine Shown Indicating the Shifted of Rapid Near Instantaneous Water Droplet to Steam Formation from Combustion Section to After Turbine Section and Figure Seven - Combines Gas Turbine Issued Patents Sketch of

- 3. 3 Copyright © 2019 by ASME a Steam Expansion Chamber www.gasturbineandersen.com . All Figures are at end of the Paper. In the case of gas turbines a swirling mass of water droplets. The way in which this is achieved is one or more of the following 1. Put water and/or volatile through the main shaft of a gas turbine and flow water of from turbine blades / end of main shaft. 2. And/or said liquid flowing out of a “stator” hitting “pins” rotating on the main shaft creating small droplets. 3. Beyond main shaft a rotating unit that is powered by thrust gas flow or other way with said liquid flowing through it and out of through flow points. Such systems can be applied to fired systems ( boilers etc. ) and internal combustion engines. What has been told me is very positive. First thermodynamic analysis is ANNEX A. My analysis follows ! ANALYSIS The analysis of the patent pending is the next paper / presentation. My background is an engineer who has had an electrical generation focus interviewing for jobs in field , hearing presentation about and having operational etc. with diesel generators. This is a New Tech Combined Cycle Gas Turbines (CCGT) technology. My focus will be analyze / explain the technology and in the electrical power grid context explore fits, factors and extrapolations. Made presentation of my technology to a large gas turbine manufacturer and got where is the analysis of gas turbine first two patents on claims of heard by me of 1. Twelve % gas , fourteen % liquid up in fuel to electricity or mechanical energy output compared to combined cycle now in use ! 2. Low capital cost combined cycle units, smaller and in greater numbers. 3. The efficiency of gas turbine electrical generator units 1 to 400 MW is nearly the same which would greatly reduce electrical distribution losses. Much lower startup shut down cost ! Before latest Patent Pending ! The analysis of the aforementioned is not easily done and has commercial interest. Note end of paper resume ANNEX B. As an engineer member of IGTI with plus twenty years experience having since June 2009 focused on gas turbine combined cycle I left quietly with, “I will get back to you!”. What is Water Swirled Into Gas Turbine Technology ? It is New Combine Cycle US Patents 8,671,696 & 9,376,933 & PUB. APP. NO. 20170306843 “METHOD AND APPARATUS FOR INCREASING USEFUL ENERGY/THRUST OF A GAS TURBINE ENGINE BY ONE OR MORE ROTATING FLUID MOVING (AGITATOR) PIECES DUE TO FORMATION OFA DEFINED STEAM REGION” published October 26, 2017 ! The Technology is to have water droplets into the hot end part of the gas turbine with the droplets of water traveling in a curved pattern after the combustion section. THERMODYNAMIC ANALYSIS First thermodynamic analysis is to determine if said water introduced into a gas turbine after the combustor in the turbine and/or end of turbine and/or in the nozzle or connector to extractive turbine “section” yields more thrust energy – electrical energy per unit fuel. Said preliminary analysis is positive and ANNEX A. It says water to steam would increase thrust. There is noted in a Gas Turbine Handbook the adding of water offshore as spray to the connector between the turbine and the extractive turbine is beneficial. A - SIZE OF DROPS The second analysis is mechanical – fluid dynamics of water flow as described in patent. A. Size of drops - 1. Size of Water Droplets Created by Nozzle Parameters &/or Impingement Design Detail

- 4. 4 Copyright © 2019 by ASME &/or rotational design a. http://www.efm.leeds.ac.uk/CIVE/FluidsLe vel1/Unit03/T6.html - An Introduction To Fluid Mechanics : CIVE1400 SCHOOL OF CIVIL ENGINEERING Leeds University UK Pelton wheel blade Application of the Momentum Equation In this section we will consider the following examples: 1. Force due to the flow of fluid round a pipe bend. 2. Force on a nozzle at the outlet of a pipe. 3. Impact of a jet on a plane surface. 4. Force due to flow round a curved vane. 5. A curved vane on a Pelton wheel turbine. “The above analysis of impact of jets on vanes can be extended and applied to analysis of pins of US Patent 9,376,933 “ 6. Impact of a jet on an angled plane surface Papers ANNEX C - Size of Droplets Etc. B. SPACING OF DROPLETS Spacing of droplets – Evenly spaced across the cross section is a design issue ! C – INTERACTIVENESS OF VAPORIZATION / TEMPERATURE GAS – LIQUID / COOLING OF MASS / TURBULENCE Pertaining to Inter-activeness of vaporization visa vi temperature gas - liquid visa vi cooling of mass visa vi turbulence Found International Journal of Heat and Mass Transfer. April 2016, Experimental investigation of consecutive water droplets falling down through high-temperature gas zone Authors R.S. Volkov, G.V. Kuznetsov, J.C. Legros, P.A. Strizhak saying exploding water droplet with 830 degrees Celsius. Friend asked, “Where is a start point beyond add heat gets steam analysis of water swirled into gas turbine technology?” ! Approximation of Water Droplets Speed With Get Turbine ( Jet Engine ) J47 36000 Produced 1949 to 1956 8000 RPM Speed of Drop = ( Rotational Rate RPM ) ( π D ) = X Part of assembly with main shaft centerlines line of rotation around O.5 foot from said centerline droplet origination X = ( 8000 ) ( 3.14 ) ( 1.0 ) X = 25120 feet / minute Droplet Speed Out of nozzle = ( 25120 feet / minute ) × ( 60 minutes / hour ) ÷ 5280 feet Droplet Speed Out of nozzle =~ 280 mph ( miles per hour ) Droplet Speed As A Point On A Turbine Blade Six Inches from centerline of main shaft Thrust gas at 1.3 mock =1100 mph My view of start point is water droplet(s) circular motion around main shaft at ~280 mph with mock one point three thrust gas parallel to main shaft temperature from 600–910 degrees Celsius to 150 steaming phenomena ! In larger electrical power units ( Siemens SGT – 500 / 19.1 MW Exhaust 370 degrees Celsius. The technology is to put water in droplet form into the hot end of the gas turbine. The “plumbing etc.” of water to droplet form is covered in three patents as concept. The design details lend themselves to models and/or experimentation. The experimentation could be 1. Buying or Designing / Manufacture Rotary Spray Nozzle and installing at the hot end of a gas turbine engine. 2. Operate and take the data. 3. Analyze the data and design better equipment!

- 5. 5 Copyright © 2019 by ASME Alternatively or as parallel effort hand calculation or model. From there finite element analysis with factors of Size of Water Droplets Created by Nozzle Parameters &/or Impingement Design Detail &/or rotational design, Spacing of droplets, Inter- activeness of vaporization visa vi temperature gas - liquid visa vi cooling of mass visa vi turbulence, etc. Work in progress ! There are start points. The two that appear to be most productive are rain ( precipitation ) into the combustor in a uniform across the cross section way which is covered for gas turbine aircraft propulsion and for electric power combustor sections of gas turbines. The other is extensive study / modeling of the combustors. Rain ( precipitation ) comes in a range of droplet sizes , intensity and by the action of compressor part of the gas turbine engine made uniform and smaller diameter. Rain ( precipitation ) ingestion into gas turbine engines go back 120 years. It rains and better power output. It is covered with papers , models , thesis , reports - “Parametric Analysis of the Exergoeconomic Operation Costs, Environmental and Human Toxicity Indexes of the MF501F3 Gas Turbine” Entropy. Aug 2016, Vol. 18 Issue 8, p1-26. 26p. Development and Integration of rain Ingestion Effects in Engine Performance Simulations, Authors: Roumeliotis, I. , Journal of Engineering for Gas Turbines & Power, Apr 2015, Vol. 137 Issue 4 The thesis is WATER INGESTION EFFECTS ON GAS TURBINE ENGINE PERFORMANCE Supervisor: P. Pilidis October 2008 https://core.ac.uk/download/pdf/138838.pdf A report is NORTH ATLANTIC TREATY ORGANISATION , RESEARCH AND TECHNOLOGYORGANISATION RTO TECHNICAL REPORT TR-AVT-036 2007 Performance Prediction and Simulation of Gas Turbine Engine Operation for Aircraft , Marine , Vehicular , and Power Generation. START POINT TWO COMBUSTOR MODEL PATENTS AND PAPERS Gas turbine engine and corresponding operating method EP 2476880 A1 A gas turbine engine has in flow series: a compressor section, a combustor, and a turbine section. The engine further has a steam generator, and a water and steam delivery system. During an engine start-up period, the delivery system delivers liquid water to the combustor and mixes the delivered water in its liquid state with working gas in the combustor. After the start-up period, the delivery system accepts steam from the steam generator, delivers the steam to the combustor and mixes the delivered steam in its gaseous state with the working gas in the combustor. Papers ANNEX D – Papers on Combustion Models OTHER FACTORS IN THE ANANLYSIS 1. Rotational speed and flow of thrust gas Siemens SGT-500 Turbine speed 3,450 RPM Mitsubishi M501F Turbine speed 3,600 RPM US Military J47 36000 Produced 8000 rpm 747 Gas Turbine JT9D exhaust speed 811 mph TRADE OFF’S – OPTIMIZATIONS Water Pressure Into System High 1. Mist –Diesel Injector Analysis 2. Cost Higher Beyond practicality

- 6. 6 Copyright © 2019 by ASME 3. Possibly used on aircraft after burner applications 4. Seal Concerns 5. Impinging patent possible fit Low 1. Exploding water drops 1200 degrees Celsius at less than 5 mph mist maker ? 2. “Only” way with seals with rotation through shaft ( main shaft ) / pressure happening through main shaft approximately 30 psi cooling air for turbine blades and lubricating oil. Efficiency – Weight – Uses - Combo 1. Impinging on pins – lighter aircraft / less expensive 2. Through main shaft aircraft / power generation 3. After main shaft heavier aircraft / larger power generation 4. Combo’s of the Above ? Power Generation Grid context explore fits , factors and extrapolations Grid modification – Currently 500 Meg units to “convenient” 5 Meg units ? Change plans with more local generation use. The steam engine use prior to grid analogy Trade offs Electrical Transmission loss against gas line installation – delivery cost Cheaper electricity Extrapolation one Meg power and up future. Heard it is happening ! COMMENTS AND REPLIES -– ANNEX E CONCLUSIONS A) Models using finite element analysis available for start point water droplet evenly distributed with different size etc. B) Using engineering and adequate and adopting model(s) the elements of the patents ( mechanical pieces ) an optimum space round center line of the main shaft with a thickness having an even water droplet density could be achieved. C) The potential of the invention ( three patents ) water swirled into gas turbine technology could be enhanced with analysis. SUMMARY - A start of the analysis of water swirled into gas turbine technology is presented . PRESENTER Leonard M. Andersen Engineer len@lenandersen.com ( HP SecureMail voltage connected ) POB 1529 New York, New York 10116 ( +$1299 per year Caller Box ) 914-536-7101 Cell Phone / 914-237-7689 Home / 800-428-4801 www.gasturbineandersen.com www.lenandersen.com

- 7. 7 Copyright © 2019 by ASME Figure One - New Tech Hot Gas To Electricity

- 8. 8 Copyright © 2019 by ASME

- 9. 9 Copyright © 2019 by ASME

- 10. 10 Copyright © 2019 by ASME

- 11. 11 Copyright © 2019 by ASME

- 12. 12 Copyright © 2019 by ASME

- 13. 13 Copyright © 2019 by ASME Figure Seven - Combines Gas Turbine Issued Patents Sketch of a Steam Expansion Chamber www.gasturbineandersen.com

- 14. 14 Copyright © 2019 by ASME ANNEX A The basis of the analysis is one unit of fuel per one unit of water on weight. * 19,000 BTU’s per pound of fuel ( Jet A ) * It takes 0.24 BTU’s to heat one pound air one degree Fahrenheit * 970 BTU’s per pound of water to create steam * Steam from one pound of water creates 27 cubic feet of one atmosphere steam * Air Fuel Ratio ( AFR ) is 150 to 1 * Thrust gas enters system at 1200 degrees Fahrenheit * Thrust gas volume per unit volume is directly proportional to gas volume which equals cooling effect of vaporization shrinkage and made larger by steam increase volume It follows water thrust gas ratio 150 to one therefore 970 BTU – Pound / 150 Pound = 6.4 BTU / Pound And 0.24 BTU per degree temperature change therefore 27 degree F temperature drop , volume decrease of 1-2 percent. Steam volume as partial of thrust per pound fuel equals 19000 / 970 = 18.5 pounds steam 18.5 pound x 28.8 cubic foot / pound = 500 cubic feet Total thrust gas volume = 150 pounds / 0.075 pound-cubic foot 2000. Net Thrust Gas Volume Increase about = 25-2 = 23 % Answer yes as preliminary analysis ANNEX B Resume of Presenter for Leonard M. Andersen – Gas Turbine Engineer len@lenandersen.com ( HP SecureMail voltage connected ) water-gas- turbine@lenandersen.com 914-536-7101 Cell Phone / 914-237-7689 Home / 800-428-4801 POB 1529 New York , New York 10116 ( +$1299 per year Caller Box / Most Secure Service At Large Post Office USA ) / 46 Alexander Av , Yonkers NY www.gasturbineandersen.com

- 15. 15 Copyright © 2019 by ASME www.lenandersen.com Professional Experience Ten years focus on Water Swirled into In Gas Turbine Technology work including attending IGTI ASME events , making technical presentations inTexas / Kingdom of Saudi Arabia / Qatar / Russia. The work has resulted in two patents issued and one patent pending . I attended at the Turbo Expo Pheonix 2019 / OSLO 2018 and attended many ASME Gas Turbine Technical Chapter Meetings www.asmegttc.org . I attended day long work shops “Design, Operation and Maintenance Considerations for Cogeneration and Combined Cycle Systems” at the Turbo Expo / Power Energy event 2017 , at the Turbo Expo Montreal in June 2015 took a short course “Gas Turbine Aerothermodynamics and Performance Calculations” and at Gas Turbine Users Symposium (GTUS) with Texas A&M’s Turbo machinery Symposium, 2010 Houston attended short course “Combined Cycle and Cogeneration Power Plants”! Welding Inspection Engineering New York , Connecticut , Ohio August 2014 to Present Journalist World Petroleum Congress Istanbul ( www.22wpc.com ) July 2017 Welding Inspector CWI / Construction Project Manager / Engineer Employed October 2000 to May 2014 New York City Department of Transportation - Division of Bridges. Spoke Chinese every day at work. Worked in Spanish language in Mexico, Spain etc., and Arabic in the Kingdom of Saudi Arabia for near a year, Norwegian in Norway etc. for about six months and worked in the Russian language. In journalism I covered the World Petroleum Congress www.world- petroleum.org events 2002 Rio de Janeiro Brazil , 2005 Johannesburg South Africa , 2008 Madrid Spain , 2011 Doha Qatar and Moscow Russia 2014 as an accredited journalist. Fellow journalist mentioned at the last one, "You know everyone". Inventing one patent issued in Lubricating / Motor Oil , two and pending in Power Generation / Gas Turbine Technology which I wrote. Pursuant to such I attended STLE ( www.stle.org ) events and International Gas Turbine Institute (IGTI) ASME events. Education –

- 16. 16 Copyright © 2019 by ASME Registered Representative www.sec.gov ( Stock Broker ) Securities Training Corporation New York , New York BSChE Chemical Engineering Degree, University of Arizona, Tucson, Arizona Published Works – Welding Journal - one and Society of Petroleum Engineers 30994 & Patents “METHOD AND APPARATUS FOR INCREASING USEFUL ENERGY/THRUST OF A GAS TURBINE ENGINE BY ONE OR MORE ROTATING FLUID MOVING (AGITATOR) PIECES DUE TO FORMATION OF A DEFINED STEAM REGION” , published October 26, 2017 Gas Turbine Thrust Fuel Efficiency Enhancement System Water (Volatile) Introduction Arrangement Method and Means 9,376,933 METHOD AND APPARATUS FOR INCREASING THRUST OR OTHER USEFUL ENERGY OUTPUT OF A DEVICE WITH A ROTATING ELEMENT 8,671,696 Lubricating/sealing oil-based composition and method of manufacture thereof - 6,358,891 Additionally Five patents in welding , two in petroleum extraction Active Memberships in Engineering and Technical Societies International Gas Turbine Institute ( IGTI ) events – Presentation at Power Energy 2017 and attending week long events 2010 / 2015 / 2017 / 2018 ! The Metropolitan Section of the American Society of Mechanical Engineers (ASME) in New York City attends meetings as a member metsection@asme.org / www.asmemetsection.org Society of Tribologists and Lubrication Engineers www.stle.org & SPE & AIChE & ASCE & AWS ANNEX C Size of Droplets Etc. Droplet impact cavity film thickness measurements versus time after drop impact and cavity radius for thin static residual liquid layer thicknesses.

- 17. 17 Copyright © 2019 by ASME By: Kuhlman, John M.; Hillen, Nicholas L. Experimental Thermal & Fluid Science. Oct 2016, Subjects: Liquid films; Thickness measurement; Reynolds number; Heat flux; Drops Optimization study on pin tip diameter of an impact-pin nozzle at high pressure ratio. By: Kumar, C.; Lee, Kwon; Park, Tae; Cha, Bong; Kim, Heuy. Journal of Mechanical Science & Technology. Sep 2016, Subjects: Gas turbines; MATHEMATICAL models; High pressure (Technology); Compressors; Jet impingement; Pump and compressor manufacturing; Industrial Machinery and Equipment Merchant Wholesalers; Air and Gas Compressor Manufacturing; Turbine and Turbine Generator Set Units Manufacturing; All Other Plastics Product Manufacturing; All other plastic product manufacturing; Nozzles Numerical and experimental investigation on droplet dynamics and dispersion of a jet engine injector. By: Keller, J.; Gebretsadik, M.; Habisreuther, P.; Turrini, F.; Zarzalis, N.; Trimis, D. International Journal of Multiphase Flow. Oct 2015, Subjects: Numerical analysis; Hypodermic jet injectors; Combustion chambers; Hydraulic turbines; Liquid fuels; Solid Waste Combustors and Incinerators; Waste treatment and disposal; Conventional oil and gas extraction; Turbine and Turbine Generator Set Units Manufacturing Three-Dimensional Mass Fraction Distribution of a Spray Measured by X-Ray Computed Tomography. By: Coletti, Filippo; Benson, Michael J.; Sagues, Alexander L.; Miller, Benjamin H.; Fahrig, Rebecca; Eaton, John K. Journal of Engineering for Gas Turbines & Power. May2014 Subjects: RESEARCH; X-ray computed microtomography; Other Basic Inorganic Chemical Manufacturing; All other basic inorganic chemical manufacturing; Atomization; Spray combustion; Pressure; Iodine "Numerical Analysis on Spray Cooling of Gas Turbine Exhaust Gas" By: HAN, D. International Journal of Transport Phenomena. 2014, Subjects: Spray cooling; Gas turbines -- Exhaust gas; Mass transfer; Turbulence -- Mathematical models; Numerical analysis; Particle size distribution ANNEX D Papers on Combustion Models Influence of Main Swirler Vane Angle on the Ignition Performance of TeLESS-II Combustor Bo Wang, Chi Zhang, Yuzhen Lin, Xin Hui and Jibao Li Bo Wang Eng. Gas Turbines Power 139(1), 011501 (Aug 16, 2016)

- 18. 18 Copyright © 2019 by ASME Unsteady Computational Fluid Dynamics Investigation of Effusion Cooling Process in a Lean Burn Aero-Engine Combustor L. Mazzei, A. Picchi, A. Andreini, B. Facchini and I. Vitale Eng. Gas Turbines Power 139(1), 011502 (Aug 16, 2016) Detached-Eddy Simulations (DES) of a complex swirl stabilized gas turbine model combustor. By: Ali, Ahlem Ben Sik; Kriaa, Wassim; Mhiri, Hatem; Bournot, Philippe. International Journal of Energy & Environment. 2016, Subjects: GAS turbines; COMBUSTION chambers; SWIRLING flow; SHEARING force; TURBULENCE; Conventional oil and gas extraction; Waste treatment and disposal; Solid Waste Combustors and Incinerators; Turbine and Turbine Generator Set Units Manufacturing Numerical Analysis of Turbulent Combustion in a Model Swirl Gas Turbine Combustor. By: Benim, Ali Cemal; Iqbal, Sohail; Joos, Franz; Wiedermann, Alexander “Journal of Combustion” 9/15/2016, Subjects: COMBUSTION gases -- Analysis; GAS turbines -- Combustion chambers; NUMERICAL analysis; NATURAL gas -- Measurement; REYNOLDS stress; FLUE gases -- Measurement; SYNTHESIS gas; Natural Gas Distribution ANNEX E Comments and Replies – What are you talking about ? 1. Excitement on a new on a new combine cycle system with fewer parts and less heat loss surface more efficiency. The system is water swirled into gas turbine section or behind it to get more electricity from fuel. 2. Start a discussion is the immediate goal. 3. Outcome so far is a lot of “looks good etc.” words heard ! Where does an engineer go with this ? 1. Act on the quick numbers indicate a low end of 10 % less fuel per unit electricity A. And “Today” precipitation happens more electricity come out of gas turbine units. Big rain drops; hail erodes the internals of gas turbine. Water into gas turbines goes to work done by the Air Force in 1944 to develop war emergency “afterburner” like system.

- 19. 19 Copyright © 2019 by ASME B. And the use of water into gas turbines for electrical generation before the turbine section is being done and is not included in the presentation. Such could be used with the technology presented. Impact and future ? 1. Cut electricity cost in some grids by half is a guess. 2. Follow-up development for twenty years is my view. Great benefit ? Heard it is so with few details a hundred times.