Other clay products

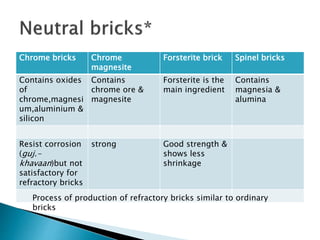

- 2. Chrome bricks Chrome magnesite Forsterite brick Spinel bricks Contains oxides of chrome,magnesi um,aluminium & silicon Contains chrome ore & magnesite Forsterite is the main ingredient Contains magnesia & alumina Resist corrosion (guj.- khavaan)but not satisfactory for refractory bricks strong Good strength & shows less shrinkage Process of production of refractory bricks similar to ordinary bricks

- 3. Page 30 in Gujarati / Page 35 in English

- 4. Clay Products Brick Clay Bricks Tiles Earthenware Terracotta Polished terracotta Porcelain China clay Stoneware Fire clay Fire Bricks Acidic Basic Neutral Bentonite(used as filler material for soap, rubber, leather industries,grouting

- 6. Tiles are bricks with reduced thickness Prepared from selected clay after moulding (gujarati-aakar aapvu) & drying in kilns(Bhatti) Needs careful handling & burning

- 7. Tiles Floor Tiles Roof Tiles Pot tiles Pan tiles Flat tiles Mangalore tiles Allahabad tiles Corrugated tiles Guna tiles Encaustic tiles

- 8. Hard & compact, flat tiles-can resist wear & tears Have square rectangular or hexagonal shape Colored floor tiles can be prepared Not suitable for pavement

- 9. Hard round country tiles with tapering diameter Prepared on potter’s wheel Dimensions vary with the region Leak proof & not easily displaced Break easily & hence frequent maintenance required

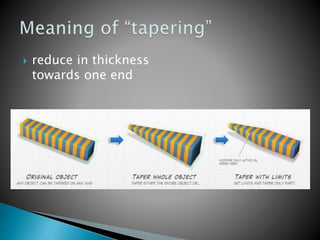

- 10. reduce in thickness towards one end

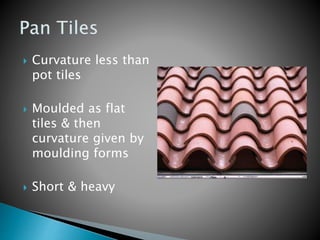

- 11. Curvature less than pot tiles Moulded as flat tiles & then curvature given by moulding forms Short & heavy

- 12. Rectangular in shape Uniform in shape & size Strong Can be used in combination with pot tiles

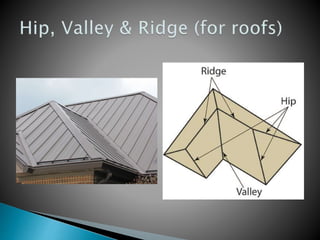

- 13. Good in appearance Good interlocking Easy fixing Less maintenance Economical Special tiles available for hip, valley, ridge About 20 years life These were the only tiles recommended for government buildings in India under the British Raj

- 16. Made from selected clay Moulded under pressure by machines Projections are provided for interlocking Strong Special tiles for hip, valley & ridge

- 17. Corrugation like G.I. sheets Side laps can be formed easily Efficient drainage for rain water Light in weight hence may be blown away in wind storm

- 18. Process of applying protective zinc coating to steel or iron to prevent rusting

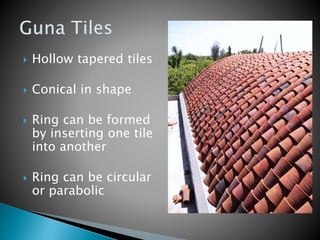

- 20. Hollow tapered tiles Conical in shape Ring can be formed by inserting one tile into another Ring can be circular or parabolic

- 21. Tiles with different colors & design Prepared from selected clay

- 23. the art or craft of manufacture of clay objects

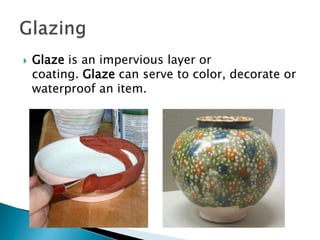

- 26. Glaze is an impervious layer or coating. Glaze can serve to color, decorate or waterproof an item.

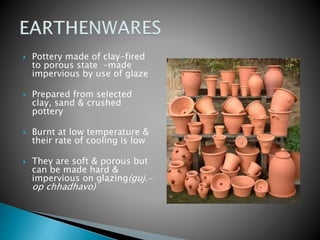

- 27. Pottery made of clay-fired to porous state –made impervious by use of glaze Prepared from selected clay, sand & crushed pottery Burnt at low temperature & their rate of cooling is low They are soft & porous but can be made hard & impervious on glazing(guj.- op chhadhavo)

- 29. Cork is an impervious material, of bark tissue that is harvested for commercial use primarily from a tree Saw dust

- 30. Saw dust or cork is added together with clay They are burnt in kiln leaving pores in particles Fire proof &a sound proof material Can be chiseled easily

- 31. Articles first burnt at lower temperature & converted into biscuit form After removal from kiln & cooling, they are coated with glazing compound & burnt again in kiln Available in varieties of color Superior quality of terra- cotta Not affected by weathering action

- 32. quartz feldspar

- 33. White, thin & semi transparent earthenware prepared from pure plastic clay feldspar & quartz Hard brittle & non porous Used as electric insulators, sanitary wares, storage vessels etc

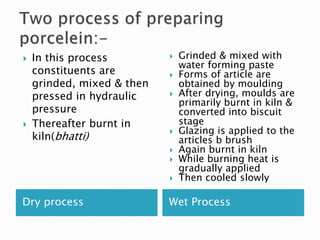

- 34. Dry process Wet Process In this process constituents are grinded, mixed & then pressed in hydraulic pressure Thereafter burnt in kiln(bhatti) Grinded & mixed with water forming paste Forms of article are obtained by moulding After drying, moulds are primarily burnt in kiln & converted into biscuit stage Glazing is applied to the articles b brush Again burnt in kiln While burning heat is gradually applied Then cooled slowly

- 36. Dry process Wet process Low voltage porcelain prepared by dry process Sanitary wares, crucibles High voltage porcelain prepared by wet process Storage vessels, toys, tiles

- 37. Sanitary wares Crucibles-ceramic container in which metals or other substances may be melted

- 38. Refractory clay mixed with powder of stone & crushed pottery, feldspar & powdered stone Articles are burnt in kiln at high temperature & then cooled down slowing Durable, impervious ,strong & resist corrosion Suitable for sanitary ware, sewer pipes, glaze tiles, w.c pan, washbasin, sink, bath tub etc

- 39. Glazing is a protective treatment given to articles. It can be transparent, colored or opaque GTU Jan 2010, Dec 2010, May 2011, May/June 2012

- 42. Process suitable for glazing earthen ware & stone ware Articles are heated in the kiln up to 1200OC. Sufficient amount of salt added. Salt gets vaporized & spreads over the surface of the articles & glass glaze is formed Not suitable for cheap clay products

- 43. In this method articles burnt in kiln & then dipped in a bath containing oxides of lead & tin Articles then reburnt at higher temperature. Better quality glazed surface Suitable for fire clay wares & terracotta

- 44. Selected quality of clay, feldspar, boric oxide flint & metalic oxides are mixed And water is added to prepare a paste called ‘slip’ Clay products are dried thoroughly & then dipped in sliip Then kept in kiln at high temperature Uniform glaze of desired color can be formed on the surface