our factory presentation pictures

- 3. Plummy Fashions Limited sets forth its groundbreaking project- a Green Knit Apparel manufacturing unit with “LEED Platinum” standard as per the guidelines of the U.S. Green Building Council (USGBC).

- 4. PFL envisions sustainable and accountable business in Bangladesh thus leaves its path to be paved by others. This initiative resembles PFL’s commitment to people and planet, a driving force for better business.

- 5. This spectacular manufacturing unit is located in Narayanganj, 20 kilometers south from Dhaka city center, having an area of 6 acres land, ideally organized with a combination of several beautiful buildings and more than 50% open area with lush greeneries. Besides, PFL has ensured the most efficient natural water management system reusing the rainwater and surface water properly. A natural water body located inside the factory premises not only ensured the balanced eco system but also assured a complete tranquility in the area. About PFL

- 6. Environmental Features in PFL • Sustainable Site: The entrepreneurs have selected the site for PFL. very carefully. All facilities including market, school, mosque, bus stops are within a radius of 500 meter from the factory. Factory also provided bicycle parking facilities for the workers to discourage use of fossil fuel using vehicles.

- 7. Environmental Features in PFL Adequate Open Area: More than 50% of the total area kept as open space to restrict the footprint of the factory. Lush green environment enhance the natural beauty and provide mental comfort.

- 8. Environmental Features in PFL Rainwater Harvesting: Every drop of water that enter the factory site carefully managed. A rainwater management plant prevents rainwater from leaving the site. Rain water collected in a harvesting tank and used for toilet flushing and irrigation purpose.

- 9. Environmental Features in PFL Reduce Ozone Depletion: PFL has installed CFC free refrigerants for chillers and cooling system. CFC contains ozone depleting substances that contribute to global warming.

- 10. Environmental Features in PFL Reduce heat islands Effect: Reduce heat islands (thermal gradient differences between developed and undeveloped areas) to minimize impact on microclimate and human and wildlife habitats. PFL has installed roofing materials having Solar Reflecting Index 79 and Hardscape with light color paving blocks.

- 11. Environmental Features in PFL Water Efficient Landscaping: To reduce irrigation water demand upto 60% to 80% , landscaping has done by locally adapted plant species which does not require permanent irrigation system. If there any need of irrigation water that is met by non- potable water.

- 12. Use of Local Materials for Construction: More than 20% ( By Cost ) of local materials has been used for construction to support the local economy and to reduce the environmental impact resulting from transportation. Environmental Features in PFL

- 13. Use of Recyclable Contents in Construction Materials: More than 20% materials used for construction of this project have recyclable contents. It has done to reduce the environmental impact resulting from extraction of new virgin materials. Environmental Features in PFL

- 14. CO2 Monitoring System: PFL has installed carbon dioxide sensor to monitor the level of CO2 in the occupied areas. Depending on the CO2 level, feedback provides to the fans to regulate fresh air flow quantity. Environmental Features in PFL

- 15. Maximum Day Lighting: The factory has designed the windows and louvers in a way to use maximum daylight. Moreover, 44 signature series prismatic dome skylights by Sun optics, USA has been installed for ambient lighting during the day time. Environmental Features in PFL

- 16. Environmental Features in PFL Efficient Water Fixtures: PFL has installed most efficient water fixtures to reduce use of water up to 60%. Auto sensor for urinals, dual flush water closets and faucets with flow rate of 1.5 liter/ minute has been installed to comply with US-EPA ( US Energy Policy Act ).

- 17. Environmental Features in PFL Certified Woods and Paints: FSC certified wood and low VOC paints have been used to minimize impact on environment.

- 18. Environmental Features in PFL Onsite Renewable Energy: A 65 KW capacity solar power plant with highly efficient mono crystalline panels has been installed in this factory. It will produce at least 110 mw/ hour energy every year which will meet at least 13% of total power required.

- 19. Environmental Features in PFL ETP PLANT A 50 M3/Hr capacity ETP plant has been installed in this factory. It will produce at least 50 M3/ hour.

- 20. Compliance and Workers Safety • Modern Fire Fighting: • PFL has equipped the factory with high quality fire protection system. Beside adequate fire fighting equipment total factory is covered under addressable fire detection system . More than 250 smoke and heat detecting device has been installed to detect the fire. • Fire hydrant system with dedicated fire pump, water reservoir, separate diesel engine has been installed to fight against fire. In warehouse water sprinkler system has been installed. • Above all of these in the training center proper fire training and awareness program are arranged for the workers. A dedicated fire fighting unit has been deployed to face from the front in case of fire broken out.

- 21. Compliance and Workers Safety Child Care Centre PFL has Modern Child care Centre. Where Workers can keep there child and do there work tension free.

- 22. Compliance and Workers Safety Medical Facilities: A 6 bed mini hospital has been set up in the factory premises. Two full time doctors and nurses will take care of medical needs of the workers.

- 23. Compliance and Workers Safety Dining Hall PFL has Modern Dining Hall . Where at time 400 persons can take there lunch.

- 24. Compliance and Workers Safety Locker Facilities PFL has Modern Locker Facilities. Where Separate Locker Room for Men and Women's.

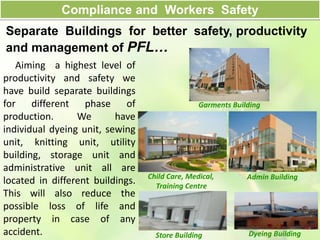

- 25. Compliance and Workers Safety Separate Buildings for better safety, productivity and management of PFL… Aiming a highest level of productivity and safety we have build separate buildings for different phase of production. We have individual dyeing unit, sewing unit, knitting unit, utility building, storage unit and administrative unit all are located in different buildings. This will also reduce the possible loss of life and property in case of any accident. Garments Building Child Care, Medical, Training Centre Admin Building Store Building Dyeing Building

- 26. Compliance and Workers Safety Training and development is our key motto for sustainability. - PFL… Training Center: PFL has started a full phased well equipped training centre to train the workers. Increasing workers’ efficiency for high quality production is the main objective of the centre. Training on health, sanitation, fire safety, labor laws are also in the agenda of the centre.

- 27. Latest wear housing facility in PFL Store Management System PFL has Modern Store Management Facilities. Where there are three stored modern store system.

- 28. Daily 15mts stand-up meeting with all dept heads Daily Management meeting. We do have daily standard morning meeting on sewing floor to discuss daily issues related to operation with all dept. heads..

- 29. Modern Machineries in PFL Modern Knitting PFL has Modern Knitting Machineries.

- 30. Modern Machineries in PFL Modern Dyeing & Finishing PFL has Modern Dyeing & Finishing Machineries.

- 31. Product Development Section in PFL Latest technology using in Sample section. for better quality on all samples we made such as auto pattern cutter, digitizer etc..

- 32. Modern Machineries in PFL PFL has Modern Cutting Room Machineries. All cutting Machineries are energy saving and more accuracy in productions.

- 33. Modern Machineries in PFL Energy Efficient Sewing Machineries: PFL machineries with very low energy consuming servo motors ( Brand new fully auto- matic juki sewing machines) to reduce energy requirement up to 50% than conventional factories.

- 34. Latest Quality Assurance System in PFL Modern Quality System PFL Follow Quality Assurance System such as as Traffic Light System, 7 zero system with mock up samples and technical spec etc. Also PFL is equipped with modern Lab machineries .

- 35. Label control - We have really strict method of controlling labels in either production lines and finishing. Also our finish goods 100% metal free and assured by our metal contaminated procedure. . Latest Quality Assurance System in PFL

- 36. Conclusion : PFL has been designed with two storied which gives a natural safety against fire or any kind of hazard. In the 2 storied building 5 exit in each floor has been made to make sure highest level of safety. We think, we can do some contribution for nature safety. We wish, in Bangladesh others make this type of factory. Then our Bangladesh will be simply green.