Partition wall

- 2. Partition walls Load bearing or non load bearing. Load bearing wall is called an internal wall Requirements : Strong-to carry its own load Resist impact Stable and strong to support wall fixtures. Thin and light Sound barrier Fire resistant

- 3. Types of partition walls Timber partitions Metal partitions Brick partitions Clay block partitions Concrete partitions Glass partitions Asbestos sheet or GI sheet partitions Metal lath

- 4. Timber partitions wooden framework either supported on the floor below or by side walls. The framework consists of a rigid arrangement of timber members which may be plastered or covered with boarding etc from both the sides. not fire-resistant

- 5. Brick partitions Plain brick partitions Reinforced brick partitions Brick nogging partitions

- 6. Plain brick partitions: Half brick thick stretcher bond Wall plastered on both side Strong and fire resistant.

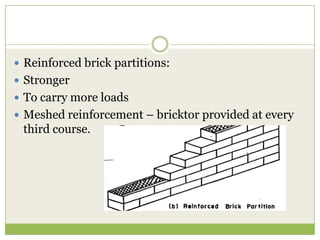

- 7. Reinforced brick partitions: Stronger To carry more loads Meshed reinforcement – bricktor provided at every third course.

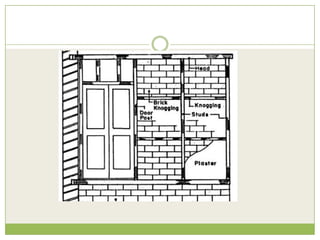

- 8. Brick Nogging partitions: brickwork built within a framework of wooden members. vertical posts called studs spaced at 60 cm to 150 cm apart . The nogging pieces are housed into the studs at 60 cm to 90cm apart vertically. 10cm thick partition wall, the studs and nogging should be 15 cm wide so that after the brickwork is plastered from both the faces

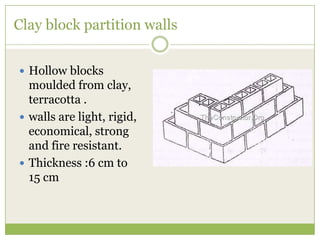

- 10. Clay block partition walls Hollow blocks moulded from clay, terracotta . walls are light, rigid, economical, strong and fire resistant. Thickness :6 cm to 15 cm

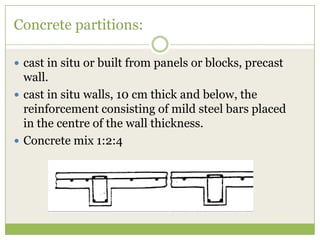

- 11. Concrete partitions: cast in situ or built from panels or blocks, precast wall. cast in situ walls, 10 cm thick and below, the reinforcement consisting of mild steel bars placed in the centre of the wall thickness. Concrete mix 1:2:4

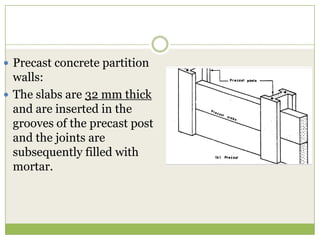

- 12. Precast concrete partition walls: The slabs are 32 mm thick and are inserted in the grooves of the precast post and the joints are subsequently filled with mortar.

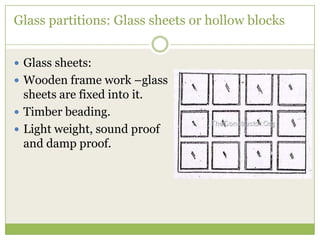

- 13. Glass partitions: Glass sheets or hollow blocks Glass sheets: Wooden frame work –glass sheets are fixed into it. Timber beading. Light weight, sound proof and damp proof.

- 14. Glass partitions: hollow block Translucent units of glass. Sqaure:14cmx14cm or 19cm x19cm Thickness 10cm. reduce thermal and sound transmission. glass block are not used as load- bearing walls. Laid in cement lime mortar (1:1:4).

- 15. Anchors and vinyl stack material for wall assembly. lock walls are tied into surrounding wall(s) using panel anchors or vinyl stack anchors every 3rd course

- 16. Asbestos sheet or GI sheet Partitions These walls are economical, light and fairly rigid if constructed properly. Fixed to frame of wood or steel. Each slab consists of core or corrugated asbestos cement sheet(5mm) with the plain asbestos cement sheet (10mm) attached to it on either side.

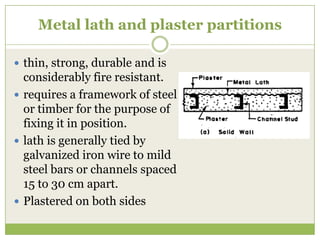

- 17. Metal lath and plaster partitions thin, strong, durable and is considerably fire resistant. requires a framework of steel or timber for the purpose of fixing it in position. lath is generally tied by galvanized iron wire to mild steel bars or channels spaced 15 to 30 cm apart. Plastered on both sides

- 18. Metal lath and plaster partitions improved insulation against heat and sound. metal lath and plaster partition walls-cavity. metal lath on both sides of specially shaped steel channels spaced at 30 to 45 cm apart. channels are generally 3 to 10cm deep.

- 19. Steel Partitions Studs (6.25 cm to 9cm) “C” shaped channels installed vertically, usually 40cm. Steel track :“U” (6.25 to 9cm) shaped channels installed to ceilings and floor to hold studs.

- 20. securing to ceiling joists with 1 1/4” drywall screws. Install track at floor

- 21. framing door & window openings

- 22. Install drywall wall panels Typically start at a corner or intersection. Avoid joints on both sides of the same stud. Secure panels to studs with drywall screws