Pilot Plant.pptx

- 1. Introduction to Industrial Pharmacy Pilot plant scale up techniques Ms. Ashwini U. Bhoir Assistant Professor in Pharmaceutics 10-08-2022 1

- 2. Pilot plant: It is defined as a part of the pharmaceutical industry where a lab scale process is transformed into a viable product by the Development of liable practical procedure for manufacture of dosage forms. This techniques for solid dosage form will provide guideline for the manufacture of large scale process and this will play a pivotal role in large scale manufacturing. An art of designing of prototype using the data obtained from the pilot plant model. 10-08-2022 2

- 3. Why conduct Pilot Plant Studies? 10-08-2022 3

- 4. A pilot plant can be used for 10-08-2022 4 Evaluating the results of laboratory studies and making product and process corrections and improvements. Producing small quantities of product for sensory, chemical, microbiological evaluations, limited market testing or furnishing samples to potential customers, shelf- live and storage stability studies. Determining possible salable by-products or waste stream requiring treatment before discharge. Providing data that can be used in making a decision on whether or not to proceed to a full-scale production process; and in the case of a positive decision, designing and constructing a full-size plant or modifying an existing plant.

- 5. Considerations in pilot plant development : 10-08-2022 5

- 6. Objective of Scale up techniques: Examination of the formula to determine it’s ability to with stand Batch-scale and process modification. Evaluation and Validation for process and equipment To identify the critical features of the process Guidelines for production and process controls. To provide master manufacturing formula with instructions for manufacturing procedure. To avoid the scale-up problems 10-08-2022 6

- 7. Importance of Pilot plant: Standardization of formulae. Review of range of relevant processing equipments The specification of raw materials Optimization and control of production rate. Information on infrastructure of equipments during the scale up batches physical space required. Identification of critical features to maintain quality of a product. Appropriate records and reports to support GMP. 10-08-2022 7

- 8. Scale up techniques: 10-08-2022 8 •Scale-up is defined as the process of increasing the batch size. •Also be viewed as a procedure for applying the same process to different output volumes. •Batch size enlargement does not always translate into a size increase of the processing volume. •In mixing applications, it is indeed concerned with increasing the linear dimensions from the laboratory to the plant size. •In processes exist (e.g., tableting), it simply means enlarging the output by increasing the speed. In moving from R &D to production scale, it is sometimes essential to have an intermediate batch scale. This scale also makes possible the production of enough product for clinical testing and samples for marketing. However, inserting an intermediate step between R&D and production scales doesn’t in itself guarantee a smooth transition.

- 9. Pilot plant scale up techniques for tablets 10-08-2022 9

- 10. Pilot plant scale up techniques for tablets 10-08-2022 10 Newly formulated tablets developed by product development personnel will prove to be efficiently, economically, and consistently reproducible on a production scale. The design and construction of the pharmaceutical pilot plant Location Each stage considered carefully from experimental lab batch size to intermediate and large scale production. May involve a major process change Points to be consider during scaling up the solid dosage forms; Batch size from intermediate to large scale production. Each stage of operation. Different types of equipment. Use of sophisticated instruments with larger volume load. Various sizes of equipment.

- 11. Figure 1 Pilot plant layout Pilot plant layout: 10-08-2022 11

- 12. • Handling of material is very necessary to prevent the contamination. • The flow system should be such that it must deliver the accurate amount of ingredient. • More sophisticated methods of handling materials are vacuum loading systems, metering pumps, screw feed system. Material flow Fig no. 2: Vacuum loading machine 10-08-2022 12

- 13. Process and equipments: Dry blending • It ensure good drug distribution. • Done by screening or milling of ingredients. • Equipments: V- blender Double cone blender Ribbon blender Bin blender • Scale up considerations: 1. Time of blending. 2. Blender loading. 3. Size of blender Fig no. 3: Various blending machine Granulation • It impart good flow to the material • Also increase the apparent density of the powders. • It changes the particle size distribution. Granulation Techniques Drying techniques Wet granulation Tray or fluid-bed dryer Vacuum/gas stripping/microwave Spray dryer Extrusion/ Spheronization / Pelletization Dry granulation Process Direct compression Slugging Mill Roller compactor Compacts milled Table no. 2: Various Drying techniques 10-08-2022 13

- 14. Wet granulation Can be done by using machines like Fig no. 4: Planetary mixer & Sigma blade mixer, Drying • Circulating hot air oven, which is heated by either steam or electricity. • Fluidized bed dryers (FBD) are an attractive alternative to the circulating hot air ovens. • Scale up considerations: optimum loads Rate of airflow Inlet air temperature and humidity. Fig no. 5: Fluidized bed dryer 10-08-2022 14

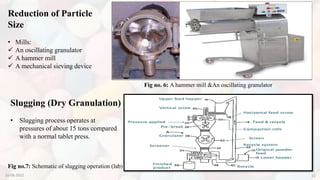

- 15. Reduction of Particle Size • Mills: An oscillating granulator A hammer mill A mechanical sieving device Slugging (Dry Granulation) • Slugging process operates at pressures of about 15 tons compared with a normal tablet press. Fig no. 6: A hammer mill &An oscillating granulator Fig no.7: Schematic of slugging operation (lab) 10-08-2022 15

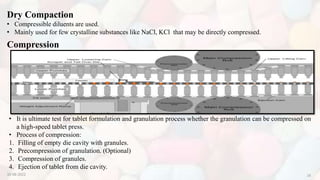

- 16. Compression Dry Compaction • Compressible diluents are used. • Mainly used for few crystalline substances like NaCl, KCl that may be directly compressed. • It is ultimate test for tablet formulation and granulation process whether the granulation can be compressed on a high-speed tablet press. • Process of compression: 1. Filling of empty die cavity with granules. 2. Precompression of granulation. (Optional) 3. Compression of granules. 4. Ejection of tablet from die cavity. 10-08-2022 16

- 17. Machines for compression of tablets 10-08-2022 17

- 18. 10-08-2022 18 Tablet Coating • Equipment: conventional coating pan, perforated pans or fluidized bed coating column. • Types: sugar coating, film coating. • Tablets must be sufficiently hard to withstand the tumbling. • Conditions: optimum tablet load, operation tablet, bed temperature, drying air flow rate, temperature, solution application rate. Fig no.8: Standard coating pan Fig no.9: Fluidized bed coating Fig no.10: Accela- cota system

- 19. Pilot plant scale up techniques for liquid 10-08-2022 19

- 20. Pilot plant scale up techniques for liquids 10-08-2022 20 The physical form of a drug product that can be incorporated demonstrates Newtonian or Pseudoplastic flow behaviour. It conforms to its container at room temperature. Liquid dosage forms may be dispersed systems or solutions. In dispersed systems there are two or more phases, where one phase is distributed in another. A solution refers to two or more substances mixed homogeneously.

- 21. Steps of liquid manufacturing process 10-08-2022 21 Planning of material requirements. Liquid preparation. Filling and Packing. Quality assurance.

- 22. Critical aspects of liquid manufacturing 10-08-2022 22 •Physical plant •Heating, ventilation and air controlling system. •The effect of long processing times at suboptimal temperatures should be considered in terms of consequences on the physical or chemical stability of ingredients as well as product.

- 23. 10-08-2022 23 • Impeller diameter. • Tank size (diameter). • Number of impellers. • Impeller type. • Mixing capability of impeller. • Rotational speed of the impeller. • Height of the filled volume in the tank. • Number of baffles. • Transfer system. • Clearance between Impeller Blades and wall of the mixing tank. • Filtration equipment • Passivation of Stainless Steel Points to be consider during scaling up the solution

- 24. 10-08-2022 24 •Points to be consider during scaling up the suspension Versator (To avoid air entrapment) Wetting of suspending agent. Addition and dispersion of suspending agents. Selection of the equipment according to batch size. Time and temperature required for hydration of the suspending agent. Mixing speeds Mesh size Suspension

- 26. Pilot plant scale up techniques for semi solids 10-08-2022 26

- 27. Parameters to be consider while scaling up of semisolids 10-08-2022 27 Mixing speed. Mixing equipment Motors Heating and cooling process. Component homogenization. Product transfer. Addition of active ingredients. Working temperature range. Shear during handling and transfer from manufacturing to holding tank to filling lines. Transfer pumps

- 28. Pilot plant scale up techniques for semisolids 10-08-2022 28

- 29. 10-08-2022 29 •Adequate records and reporting arrangement •An integral part Relevant Documentation Forms of Documents Earlier: Hard copy, Today: Soft copy formats, organized way of sharing knowledge, Configuration Management: Documentation management and control Types of Documents Permanent: Inclueds user manuals, help information, training materials; Ex. Design specificatios, source code, process diagrams etc. Temporary: Internal communication; No value once the project completed ex. Ideas, issues, control, working paper etc.

- 30. 10-08-2022 30 Structure and Circulation of Document Constructed in most appropriate and structured form with adequate indexing and controls so that it can be used as knowledge repository. An additional advantage of categorization of the information and documentation is that, items can be released for review, finalization, approval or action without waiting for other non- dependant elements to be completed. Helps the team members only to deal with the content that is relevant to them. They receive it in manageable size as parts. The complexity can be minimized

- 31. 10-08-2022 31 Documents at Start of Scale-Up The documentation should be constructed in most appropriate and structured A short and simple scale-up project- as simple as a spreadsheet Bigger scale-up projects- use of document management toolset. The key elements of the documents used in registration of specific information per document includes for example, description, purpose or objective, form and format, requirements for update, required protocols for review and quality assurance etc. Permanent documents: to be updated if something changes after it finalized; temporary documentation retainas a historic record even though something has subsequently been changed.

- 32. 10-08-2022 32 Documents Tracking Progress and Status Planned date of completion, current status and effective date, persons currently updating or reviewing the document, current projected date of completion. The project team members when using the document management system must incorporate further documents as required throughout the project; The team member must have ability to consult previous historic versions wherever relevant, and identify changes and determine the reasons for those changes

- 33. 10-08-2022 33 Document during the project Tracking of document status by project manager and/ or project office Document at the completion of the project Archival of temporary items, retention of permanent documents; Maintenance of project repository; reuse of valuable materials for another projects

- 34. 10-08-2022 34 Reference: 1. P. Ramasubramaniyan, C. Shibin raj, P. Nagarajan, D.Sherly, L. Subramanian, P. Solairaj, review: Pilot scale up techniques for solid dosage form- an overview for tablets. World Journal of Pharmaceutical Research 2014; Volume 3, Issue 8, 925-931. 2. Leon Lachman, Herbert A Lieberman, Joseph L Kanig: The Theory and Practice of Industrial Pharmacy: Section IV: Chapter 23: Pilot Plant Scale-Up Techniques: 3rd edition, published by Varghese Publishing house, 2009; 681-710. 3. James Swarbrick, James C Boylan: Encyclopedia of Pharmaceutical Technology: Pilot Plant Design, Volume 12 New York, 2001; 171-186. 4. Leon Lachman, Herbert A. Lieberman, Joseph B. Schwartz: Pharmaceutical dosage forms: Tablets. Volume 3. second edition. 303-365. 5. Kamya Chaudhary, A. C. Rana, Rajni Bala, Nimrata Seth, review: scale up process of tablet production: a prospective discussion, Int. J. of Pharm. and Bio. Sci. 2012; 2(3): 223-239