PLASTIC IN ARCHITECTURE

- 1. RECYCLING OF PLASTICS… • Aaron Marsh • Divine Blesso • Rohith

- 2. • Plastics are organic substances formed by macrocells called polymers. • These polymers are large groups of monomers linked by a chemical process called polymerization. • Plastics provide the necessary balance of properties that can not be achieved with other materials such as: color, lightweight, soft touch and resistance to environmental and biological degradation.

- 3. The properties and characteristics of most plastics are these: * Easy to work and shape * Have a low production cost * Possess low density * Tend to be waterproof * Good electrical insulators Properties of plastics Plastics used as insulator

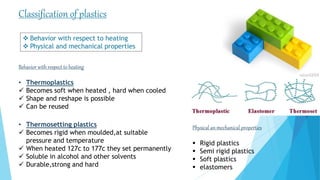

- 4. Physical an mechanical properties Rigid plastics Semi rigid plastics Soft plastics elastomers Classification of plastics Behavior with respect to heating • Thermoplastics Becomes soft when heated , hard when cooled Shape and reshape is possible Can be reused • Thermosetting plastics Becomes rigid when moulded,at suitable pressure and temperature When heated 127c to 177c they set permanently Soluble in alcohol and other solvents Durable,strong and hard Behavior with respect to heating Physical and mechanical properties

- 5. Did you know? • Simple things like combining thermal insulation with tripled glazed windows can reduce energy consumption by up to 80%. • Plastics are one of the few materials that can do both jobs. • Plastic insulation products save over 200 times more energy over their lifetime than is used for their production and are roughly 16% more energy efficient than alternative insulation materials. • If plastic window frames were installed all over Europe tomorrow we would eliminate the need for five large power station. • Plastics are a source of stored energy and, when not recycled, can be used to generate heat power at the end of their useful life. eco-house utilising recycled plastic insulation.

- 6. Advantages of Plastic • Plastic materials are light in weight, unbreakable, odourless and can be easily moulded. • They have excellent finishing; possess good shock absorption capacity, high strength as well as toughness. • The plastics materials are corrosion resistant • Plastics have water resistant property and possess good adhesiveness. • They are strong, durable, good and cheap to produce. • It is possible to recycle plastic; therefore no decomposition required which is much more expensive and hazardous than recycling. • Plastic can be used in building, construction, electronics, packing and transportation industries.

- 7. . What is Plastic Recycling? • Plastic recycling is the process of recovering different types of plastic material in order to reprocess them into varied other products, unlike their original form. • An item made out of plastic is recycled into a different product, which usually cannot be recycled again

- 8. Stages in Plastic Recycling 1.Sorting: It is necessary that every plastic item is separated according to its make and type so that it can be processed accordingly in the shredding machine. 2.Washing: Once the sorting has been done, the plastic waste needs to be washed properly to remove impurities such as labels and adhesives. This enhances the quality of the finished product. 3.Shredding: After washing, the plastic waste is loaded into different conveyer belts that run the waste through the different shredders. These shredders tear up the plastic into small pellets, preparing them for recycling into other products. 4.Identification and Classification of Plastic: After shredding, a proper testing of the plastic pellets is conducted in order to ascertain their quality and class. 5.Extruding: This involves melting the shredded plastic so that it can be extruded into pellets, which are then used for making different types of plastic products.

- 10. GRADES OF PLASTIC Grade 1 plastics are made up of polyethylene terephthalate (PET). It is commonly used in beverage bottles, water bottles, medicinal jars and bean bags. Grade 2 plastics are made up of high-density polyethylene, or HDPE. It is extremely safe as it does not leach chemicals into foods or drinks. It is used in shampoo bottles, milk containers, motor oils, and bleaches. Grade 3 plastics are made up of polyvinyl chloride, or PVC. This plastic is used in all kinds of pipes and tiles. Grade 4 is made up of low-density polyethylene, or LDPE. It is used to make cling wraps, sandwich bags, squeezable bottles and grocery bags. Grade 5 plastics are made up of polypropylene, or PP. It is used to make plastic diapers, lunch boxes (Hunger Box), small containers (Munchie Box), margarine containers, syrup bottle and yogurt boxes. Grade 6 plastics are made up of polystyrene, also known as PS. This is basically used to make disposable items like spoons, plates, coffee cups, etc. Grade 7 plastics are designated for other kinds of plastic which don't fall under the first six classifications. Plastics like polycarbonate, ABS, and polylactide fall under this category. Polycarbonate (PC) is used to make baby bottles, compact disc, and medicinal storages.

- 11. Packaging Recycled PET Grade 1 and HDPE Grade 2 is increasingly used in primary packaging by retailers and branded manufacturers for bottles and trays. Household names such as Coca Cola, M&S, Boots, The Body Shop, Innocent Drinks and Halfords all currently use recycled plastic in selected product lines. Use of recycled plastic helps demonstrate a commitment to sustainable resource use. Construction Recycled plastic is widely used in mainstream construction products such as damp proof membrane, drainage pipes, ducting and flooring. It is also used in innovative products such as scaffolding boards or kerbstones, where its durability and weight has significant Health & Safety benefits. Landscaping Walkways, jetties, pontoons, bridges, fences and signs are increasingly being made from recycled plastic. Durability, low maintenance, vandal resistance, and its resistance to rot are all key reasons for plastic being used. Uses of recycled plastics

- 12. Use of Plastics in Different Aspectsof the ConstructionIndustry Flooring Plastic materials like polyvinyl chloride (PVC) and polyethylene are used to make flooring less prone to wear and tear. It also decreases the sound pollution level and can be cleaned easily. Roofing To protect the outer surface of the roof from damage, two layers of different plastic materials are required. The upper part is made of colored thermoplastic olefin or vinyl while the lower part consists of polyurethane foam which consumes less energy and keeps the interior of a house cooler. Insulation Polyurethane spray is frequently used for insulation when constructing green or low energy buildings. Rigid polyurethane foam is known for its high thermal resistance which promotes temperature consistency. Polyurethane foam is also popular because it is lightweight, chemical resistant, and flame retardant. Due to its closed cell nature, polyurethane insulation performs as an air barrier, resulting in significant energy savings.

- 13. Wall A structural insulated panel (SIP) is a sandwich of expanded polystyrene amidst two slim layers of oriented strand board. This type of pre-fab, composite wall board can be transferred to the work place easily for a particular task and provide good support to columns and other associated essentials during renovation. Pipes Commonly made up of polyvinyl chloride (PVC), CPVC, acrylonitrile butadiene styrene (ABS) or polyethylene, plastic pipes are flexible and very light in weight, making them easy to install. All of these plastic materials are also highly chemical and water resistant, making them suitable for many extreme environments. Windows Polycarbonate is used to manufacture building windows. This plastic material is strong, clear and very light in weight. Polycarbonate windows are considered more burglar- proof than regular glass windows. Two plastics materials, vinyl and fiberglass, are used commonly in the production of window frames. Fiberglass is extremely strong while vinyl is quite durable and also inexpensive.

- 14. Some construction projects use doors made from a stiff polyurethane foam core with a fiber reinforced plastic (FRP) coating. The sandwich structure of these doors makes them incredibly strong. Doors

- 15. CASE STUDY