Plastics ( manufacture, types,application,examples)

- 1. PLASTICS

- 2. DEFINITION AND CONCEPT A plastic material is any of a wide range of synthetic or semi-synthetic organic solids that are moldable Macro molecular Consists large chain like molecules containing carbon

- 3. PROPERTIES OF PLASTICS Less brittle than glass ,hence can be made transparent and smooth. Corrosion resistance Low electrical and thermal conductivity, insulator Easily formed into complex shapes, can be formed, casted and joined. Wide choice of appearance, colors and transparencies Light weight but posses good strength and rigidity. Low moisture absorbtion. Heat resistance.

- 4. TYPES OF PLASTICS THERMOPLASTICS Thermoplastics are the plastics that do not undergo chemical change in their composition when heated and can be molded again and again THERMOSETTING PLASTICS Thermosets can melt and take shape once; after they have solidified, they stay solid. In the thermosetting process, a chemical reaction occurs that is irreversible

- 5. MANUFACTURE OF PLASTICS The production of plastics can be roughly divided into four categories: 1. Acquiring the raw material or monomer. 2. Synthesizing the basic polymer. 3. Compounding the polymer into a material that can be used for fabrication. 4. Molding or shaping the plastic into its final form.

- 6. 1.Raw Materials Historically, resins derived from vegetable matter were used to produce most plastics. This included such materials as cellulose (from cotton), furfural (from oat hulls), oils (from seeds) and various starch derivatives. Today, most plastics are produced from petrochemicals which are widely available and tend to be cheaper than other raw materials.

- 7. 2. Synthesis of the Polymer The first step in plastic manufacturing is polymerization. The two basic methods by which polymerization can occur are addition and condensation reactions. This is achieved by adding reinforcements such as glass or carbon fibers to the plastics, increasing their strength and stability.

- 8. Additives Chemical additives can be used in the production of plastics to achieve certain characteristics. These additives include: 1. antioxidants to protect the polymer from degradation by ozone or oxygen 2. ultraviolet stabilizers to protect against weathering 3. plasticizers to increase the polymer’s flexibility 4. lubricants to reduce friction problems 5. pigments to give the plastic colour

- 9. 3.Shaping and Finishing 1.COMPRESSION MOLDING Pre-measured amount of polymer introduced into the heated mold then the top half comes down and applies pressure. Usually uses thermosetting plastics and produces products like dishes, container caps, etc.

- 11. EXTRUSION A device, called an extruder, forces softened plastic through a shaped die from which it may emerge in almost any form, including a circular rod or tube, and a wide, flat sheet. The driving force is supplied by a screw which provides constant pressure.

- 12. INJECTION MOLDING Involves one or more extruders which force melted plastic into a cold mold where it is allowed to set to the required shape. An adaptation of this method is injection blow molding which is used to make plastic pop bottles. A thick-walled plastic tube is initially injection-molded around a blowing stick and is then transferred to a blowing mold. The tube is reheated and expanded to the shape of the mold by passing air down the blowing stick.

- 13. THERMOSETTING RESINS Once hardened and set, they do not soften with application of heat. Reason: consist of linear, relatively low molecular wt thermoplastic polymer chains with crosslinks which bond the chains together. when heated the entire structure becomes a single molecule. Objects made of this can be used at higher temperatures without damage. More stronger and harder than thermoplastic resins.

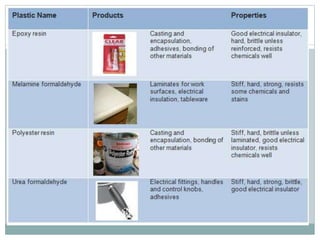

- 14. APPLICATIONS Telephonic receivers, electric plugs, radio and TV cabinets, camera bodies, automotive parts, electric baker, switch panels. EXAMPLES Phenol formaldehyde resins Urea formaldehyde resins Melanine formaldehyde resins Polyester resins. Epoxy resins Silicone resins

- 16. THERMOPLASTICS Can be repeatedly softened by heat and hardened by cooling. Reason: they are composed of linear and long chain molecules. application of heat weakens the intermolecular bonds by increasing thermal agitation of the molecules and hence the material softens. Cannot use at high temperatures as they will soften under heat. Usually supplied as granular materials. Comparatively software and less strong.

- 17. APPLICATIONS Toys, combs, toilet goods, photographic films, insulating tapes, hoses, electric insulation EXAMPLES Polystyrene Abs Methacrylate PVC Polycarbonate Polychoroacetal

- 19. DISADVANTAGES OF USING PLASTICS Low strength Low useful temperature range (up to 600 oF) Less dimensional stability over period of time (creep effect) Aging effect, hardens and become brittle over time Sensitive to environment, moisture and chemicals Poor machinability

- 20. LATEST DEVELOPMENTS Bullet Proof Polymer - Scientists at Rice University, Texas have created a new super polymer material that can stop a 9mm bullet and seal the hole behind it. The material is a complex multiblock copolymer polyurethanem, which is a synthetic compound build in the lab.

- 21. Plastics Blood - Developed by the University of Sheffield to mimic haemoglobin, for use in trauma situations where blood is needed quickly The "plastic" blood consists of an iron-containing porphyrin which is permanently bonded to a hyperbranched polymer (HBP or dendrimer) "shell"

- 22. Plastic Solar Cells - A polymer solar cell that can produce electricity from sunlight by the photovoltaic effect provides a lightweight, disposable and inexpensive alternative to traditional solar panels PET –polyethylene terephthalate ITO – indium tin oxide

- 23. Implantable Polymers - Medical grade and implantable biomaterials such as PEEK will be used in neurological applications to help control epilepsy, Parkinson’s d. Commercial - Space Flights Lightweight carbon composite materials will be crucial in the realisation of sub-orbital tourist spaceflightsisease and brain trauma

- 24. 3D Printed - Body Parts Using plastic materials such as PMMA car parts can be printed at home and doctors can produce replica livers or kidneys for transplant patients.

- 25. Flexible Plastic Screens - Organic light-emitting diodes are placed on plastic foil to create electronic devices with flexible displays.

- 26. THE FUTURE The future (2022) - The 2022 FIFA World Cup Qatar Showcase Stadium has been designed to use super reflective, triangulated PVC fabric to create a zero carbon, sustainable stadium providing comfortable playing conditions