Plastics

- 1. PLASTICS Alejandra Alcácer Batres Celia Martínez de Alegrías Trapote Javier Medina Roldán

- 2. PROCESS OF OBTAINING PLASTICS First part: Sourcing of raw materials: Raw materials minerals, plants and animal. Extracted from nature, require chemical modification. Plant origin: latex. cotton and wood cellulose. oil. Animal origin : Mineral origin: casein. petroleum resin secretion industrial process from the lac bug. (shellac) coal

- 3. Second part :Synthesis of monomers: This stage very important in plastics derivied petroleum and fossil fuels. Extracting monomers raw materials. This proces carried out petrochemical industries. (Gasoline, diesel, kerosene, etc.). Semi-processed (ethylene and propylene).

- 4. Third part: Synthesis of basic polymers: Plastics mixing components, depending on the plastic we want. Components subjected to chemical process POLYMERIZATION, POLYCONDENSATION AND POLYADDITION, ETC.

- 5. Fourth part: Incorporation of additives: PYES OR PIGMENT Give it color. PLASTICIZERS Improve plasticity and shine. ANTISTATIC AGENT Reduce static electricity charge FIREPROOF Delay the formation in flames UV STABILIZERS Protect from atmospheric phenomena/prevent decomposition

- 6. FILLERS,REINFORCEMENTS, AND LUBRICANTS Improve mechanical properties. MOLD RELEASE AGENTS Make the piece come out of the mold easily. ANTIOXIDANTS Prevent reactions with oxygen.

- 7. SHAPING AND FISHING THERCOMPRESSION: Plastic pass through hot mold. Ex: Thermosetting plastics products. EXTRUSION MOLDING: Pass through a chute into a heat pipe. Ex: Pipes and bars. BLOW MOLDING: Used to pasted to the walls. Ex: Containers for liquids.

- 8. INJECTION MOLDING: This is used to make objects with complex shapes. Ex: casing for appliances, buckets, bowls. FOAM MOLDING: This is used to make thermal and acoustic insulation Ex: mattresses, pillows and sponges. VACCUM FORMING: A plastic sheet is placed on an open mold with channels through wich air flows. Ex: glasses, packaging and boxes. CALANDERING: The plastic passes throguh different sizes hot rollers that give the plastic different shapes. Ex: plastic wrap, plastic sheets.

- 9. PROPERTIES PHYSICAL PROPERTIES: -Electrical conductivy Ability let current flow. -Thermal conductivy Ability let heat pass through it. - Density Amount of mass per unit of volume. -Expansion Variation in dimension due to the temperature. - Melting point Temperature change between solid to gas. - Fusibility Property that refers amount of heat to melt.

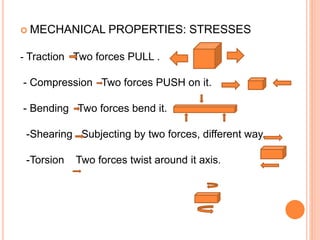

- 10. MECHANICAL PROPERTIES: STRESSES - Traction Two forces PULL . - Compression Two forces PUSH on it. - Bending Two forces bend it. -Shearing Subjecting by two forces, different way. -Torsion Two forces twist around it axis.

- 11. RESPONSE TO STRESS : - Elasticity Undergoes stress return original shape. Is removed. -Plasticity Remain deformed by a stress. Is removed. - Malleability Permanently deformed of COMPRESSION. - Ductility Permanently deformed of TRACTION. - Resistance Undergoo without breaking. - Hardness Resistance being scatched or punctured . -Weldeability Ability of join solid to another.

- 12. CHEMICAL PROPERTIES: Contact with other substances: - Permeability: Fluids and water pass throught it. - Solubility: Mix homogeneously another. As a solvent. - Combustility: Material to burn . Very polluting.

- 13. BIOLOGICAL PROPERTIES Effects to the enviroment. Recyclability Transform a material into another. Toxicity Produces negative effects on living organisms. Ex When plastic contact with food. Biodegrability Material when decompose due to interaction to enviroment. Ex When we throw a apple .

- 14. CLASSIFICATION OF PLASTICS Thermosetting: Not soften easy deform. Characteristics Uses Phenolic resins (PF) Hard, insoluble, inelastic. Electrical accesories, switches, buttons Ureic resins (UF) Can be dyed. Elastic. Impermable. Funiture, handles, doors , plates, cups. Melamine resins (MF) Can be dyed . Impermable. Elastic. Furniture. Polyester resins (UP) Solid and hard.Colorless . Impermeable. Thermal insulators and good electrical . Epoxy resins (EP) With catalyst , solidify and harden . Resistance to humidity. Adhesive , paints , varnishes , plastics , electronic systems.

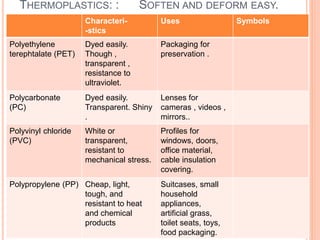

- 15. THERMOPLASTICS: : SOFTEN AND DEFORM EASY. Characteri- -stics Uses Symbols Polyethylene terephtalate (PET) Dyed easily. Though , transparent , resistance to ultraviolet. Packaging for preservation . Polycarbonate (PC) Dyed easily. Transparent. Shiny . Lenses for cameras , videos , mirrors.. Polyvinyl chloride (PVC) White or transparent, resistant to mechanical stress. Profiles for windows, doors, office material, cable insulation covering. Polypropylene (PP) Cheap, light, tough, and resistant to heat and chemical products Suitcases, small household appliances, artificial grass, toilet seats, toys, food packaging.

- 16. THERMOPLASTICS Characteri- -stics Uses Symbols Polyethylene (PE) White.Dyed easily. Toys, pipes, tanks, trash cans, containers for liquids, bags, greenhouses, sleeping bags Depending on the density Methacrylate or Polymethyl methacrylate (PMMA) Transparent. Mantain its colour when its dyed, Moldeable. Bathroom accessories, protective goggles, and windows and mirrors . Polystyrene (PS) Fragil material. Automobile interiors, cups, packages, film wrap. Polyamide (PA) Tough resistance to chemical and mechanical stresses Fabrics, household utensils, bearings, gears, screws.

- 17. ELASTOMERS Chracteristics. Uses. Rubber (CA) Impermeable. Good accoustic and electricty insulator. Natural rubber products. Ex Wheel Polychloroprene (PCP) Impermeable . Good resistance to stresses. Insulated wetsuits, joints, straps, cables, pipes. Silicone (SI) Impermeable. Resistance toatmospheric agents. Flexible molds, medical equipment, adhesives. Polyurethane Resistance to chemical agents. Good electrical accoustic, thermal insulator. Mattresses, foam rubber, adhesives, and paints. Synthetic rubber 1887 John Boyd Dunlop First air chamber . Resistance to organic liquids, oils and derivates. Good insulator .Electricity, heat… Tires, solid wheels, hoses, and transmission belts

Editor's Notes

- .