Points and crossings

Download as PPTX, PDF165 likes112,513 views

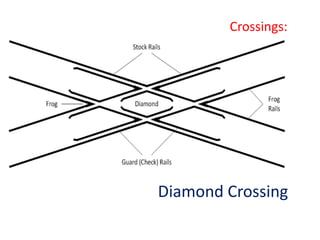

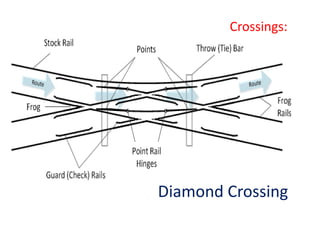

Turnouts allow trains to change tracks and directions by using a combination of points and crossings. Points consist of movable tongue rails and stationary stock rails, while crossings connect intersecting tracks using wing rails and a V-shaped nose. There are two main types of turnouts - left-hand and right-hand - depending on the direction trains divert. Proper turnout design and components like check rails are important for train safety given they are weak points on the track. Different types of crossings exist depending on the angle of track intersection, including acute, obtuse, and square crossings.

1 of 40

Downloaded 3,592 times

Recommended

Point and crossing of railway

Point and crossing of railwayRAMPRASAD KUMAWAT Railway secondary part of the transportation . Railway use of maximum materials transport of one place to other place. Particular time of number of trains are move of particular junction so these part are used of points and crossing.

Best helpful of these ppt of railway track and design purposes.

Railway engineering

Railway engineeringShanmugaraj M For ii Year Diploma Civil Engineering Students

M.Shanmugaraj M.E.,

Lecturer / Civil

V.S.V.N Polytechnic College

Virudhunagar

Tamilnadu

India

turnouts in railways

turnouts in railwaysSrinivasulu Srinu this slides will contains some information about 'turnouts in railways', it's component parts and its classification. if any mistakes present, please tell me i will rectify them.

Station and Yards in Indian Railway

Station and Yards in Indian RailwayArbaz Kazi A railway station has platforms for passengers to board and disembark trains. It also has a station building for ticket sales and waiting areas. Stations range in size from small stops to large terminals. A station yard contains multiple tracks for sorting trains, including passenger, goods, locomotive, and marshalling yards. Marshalling yards separate incoming cars and reform them into outbound trains using flat, gravity, or hump yard designs. Larger stations have more facilities for passengers and goods handling.

Railway Engineering: Turnouts

Railway Engineering: TurnoutsVijai Krishnan V Design of turnouts, points and switches and definition of some important terms related to turnouts are discussed

classification of indian railway

classification of indian railway addavidson The document discusses the classification of Indian Railways based on routes and speed criteria. It is divided into zones based on geographical regions. Trunk routes allow for higher speeds of 160 kph or more, main lines allow 130 kph, and branch lines are slower less than 100 kph. Railways are also classified into groups A through E based on maximum permitted speeds.

Sleepers and Their types

Sleepers and Their types17CE67 Sleepers, also called ties, are transverse members laid beneath rails to distribute load from trains to the track bed. They come in various materials including wood, steel, concrete, and plastic. Wooden sleepers are most common but have short lifespans while concrete and steel last longer. All sleepers must firmly support rails, maintain proper gauge, and evenly distribute heavy train loads over a wide area of ballast for track stability.

Railway Engineering Introduction

Railway Engineering IntroductionT.Naga Anusha The document provides information on transportation engineering and railway engineering. It discusses the role of railways in transportation from economic, cultural, and political aspects. It then covers the history of railways in India from 1832 to present day. Key topics include gauges used in India, permanent way components like rails and fish plates, and manufacturing units.

Left hand turnout

Left hand turnoutAna Debbarma This document discusses railway turnouts. It begins by defining a turnout as the combination of points and crossings that allows a train to move from one track to another, either parallel or diverging. It then describes the key components of a turnout, including tongue rails, stock rails, lead rails, and a vee crossing. It also explains the classification of turnouts as left-hand or right-hand depending on the direction of diversion. Diagrams are included to illustrate the components and working principle of a turnout. The document concludes by stating that turnouts are essential for diverting traffic but can cause issues if not designed and maintained properly.

Stations and Yards of Railway

Stations and Yards of RailwaySouvik Mondal * DOWNLOAD AND PLAY IT IN MICROSOFT POWERPOINT CAUSE IT CONTAINS ANIMATION AND CAN'T WATCH WITHOUT IT *

Stations and Yards of Railway powerpoint presentation in Transport Engineering.

Railway Track Maintenance

Railway Track MaintenanceHari Krishna Velpula Information About Various processes involved in Railway Track Maintenance and some information about South Central Railway, Vijayawada.

Tunnel engineering

Tunnel engineeringSaurabh Samant The document discusses various aspects of tunnel engineering. It begins by introducing tunnels and their uses for transportation. It then discusses the Thames Tunnel in London as an example. The document outlines several advantages of tunneling over other methods. It also discusses considerations for selecting tunnel routes and economies of tunneling. The remainder of the document describes various tunneling methods through both rock and soft ground, as well as tunnel drainage, lighting, ventilation, lining, and maintenance.

Permanent Way of Railway & Components ?(part -1,2,3,4,5)

Permanent Way of Railway & Components ?(part -1,2,3,4,5)RAMPRASAD KUMAWAT Permanent Way Components: , Selection of Alignment, Ideal Permanent Ways and Cross-sections in different conditions, Salient Features and types of Components viz.

Rails, Sleepers, Ballast, Rail Fastenings.

Types and Selection of Gauges

Railway station and YARD

Railway station and YARD Dhruv Makadia Brief Introduction of

* Purposes of railway station

* Site selection for railway station

* Requirements of railway station

* Classification of stations

* Classification of Yards

GEOMETRIC DESIGN OF HIGHWAY

GEOMETRIC DESIGN OF HIGHWAYreemajadwani The document discusses highway geometric design and its key elements. It aims to maximize safety, comfort and efficiency while minimizing costs and environmental impacts. Geometric design considers the road's alignment, cross-section, sight distances and intersections. Elements include the carriageway, shoulders, formation width, right of way, side slopes, berms and side drains. Camber and super elevation help drain water and counteract centrifugal forces on curves. Sight distance requirements like stopping sight distance ensure drivers can see far enough to stop safely.

Railway engineering

Railway engineeringShanmugaraj M For II Year Diploma Civil Engineering Students

M.Shanmugaraj M.E.,

Lecturer / Civil

V.S.V.N Polytechnic College

Virudhunagar

Tamilnadu

India

Signals on Railway

Signals on RailwaySatyapal Singh Railway Signaling: Introduction to Signals, Objective of signals. Types of Signals, Operating Characteristics, Functional Characteristics, Locational Characteristics, Special Characterstics

5.track or permanent way and track stresses

5.track or permanent way and track stressesMani Vel The document discusses the components and stresses acting on railroad tracks. It describes the main parts of a track including the rails, sleepers, ballast, and formation. The rails are joined by fish plates and bolts and fastened to sleepers. Sleepers are embedded in ballast which provides drainage and load distribution. A good track requires proper gauge, cross-leveling, alignment, gradient, and resilience to provide a comfortable ride while withstanding forces from train movement and varying temperatures. Wheels are coned rather than flat to reduce wear on flanges and rails and allow for lateral movement.

Points and crossings

Points and crossingsChockalingam T This presentation discusses the points and crossings used in railways. Especially It deals with the types of turnout - Right-Hand Turnout and Left-hand Turnout. parts of turnout and also the different types of crossings based on the angle.

Defects in rails. Railway Engineering

Defects in rails. Railway EngineeringIrfan Nasir I'm Irfan Nasir. Currently studying Civil Engineering at Mehran University of Engineering and Technology. This is a slide made by me on Defects in rails from the subject Transportation Engineering.

Railway track construction, drainage & maintenence

Railway track construction, drainage & maintenenceGhanashyam Prajapati The document discusses the construction and maintenance of railway tracks. It covers the need for constructing new railway lines, the process of construction including earth work, plate laying, and ballast laying. It also discusses track drainage systems, including surface drainage with side drains and sub-surface drainage. Maintenance of tracks is important and includes daily and periodic maintenance to replace components and ensure safety. Regular maintenance extends the life of tracks and rolling stock.

Railway engg geometric design

Railway engg geometric designVijai Krishnan V This document discusses various aspects of railway track design including gradients, horizontal and vertical curves, super-elevation, and transition curves. It provides formulas for calculating ruling gradient, super-elevation, safe speeds on curves, and other key design elements. Track must be designed to suit the loads and speeds of trains based on safety and economic standards. Proper gradient, curvature, and super-elevation are necessary for smooth train operation.

Railway engineering

Railway engineeringAkshay D Nicator Railway engineering involves the design, construction, and operation of railroads and mass transit systems. It is a branch of civil engineering that deals with track design, station layout, signaling systems, and train movement control. Typical tasks for railway engineers include determining horizontal and vertical alignment, estimating construction costs, and establishing signaling and control systems. Railway tracks consist of rails laid on sleepers embedded in ballast. Points and crossings allow trains to switch tracks. A variety of signals are used to safely direct train movement.

Railway Gauge

Railway GaugeAmit Yadav The document discusses different rail gauges used in India for railway tracks. It describes the three main gauges: broad gauge which has a width of 1676 mm, meter gauge of 1000 mm, and narrow gauge of either 762 mm or 610 mm. Broad gauge is used for routes with high traffic volumes and in plain areas. Meter gauge is used when funds are limited. Narrow gauge is suitable for hilly areas with sharp curves. The document outlines the components of a permanent railway track and considerations for an ideal track like uniform gauge and proper super elevation on curves.

Railway track design ppt 2018

Railway track design ppt 2018ishwar dhakad This document discusses the key elements of railway tracks, including formation, ballast, sleepers, rails, and fastenings. It describes the purpose and design considerations for each element. Formation provides the base for the track and must support the entire load. Ballast distributes loads from sleepers to prevent sinking. Sleepers provide support and stiffness. Rails provide a smooth surface for train movement. Fastenings such as fish plates, bolts, and chairs connect rails and sleepers together securely.

Rails, Types, Joints, Creep, Failure of Rails and Welding of Rails

Rails, Types, Joints, Creep, Failure of Rails and Welding of Railssrinivas2036 The document discusses rails used in railway tracks. It defines different types of rails including double headed, bull headed, and flat footed rails. Flat footed rails, also called Vignoles rails, are now most commonly used. Standard rail sections used in Indian railways, such as 52kg and 60kg, are presented. Requirements of an ideal rail and factors affecting rail wear and failure are explained. Methods to reduce rail wear include use of special alloys, track maintenance, reducing expansion gaps, and lubricating rails.

Highway Alignment

Highway AlignmentAkshathaBhandary Alignment: The position or the layout of the central line of the highway on the ground is called the alignment.

Highway Alignment includes both

a) Horizontal alignment includes straight and curved paths, the deviations and horizontal curves.

b) Vertical alignment includes changes in level, gradients and vertical curves.

Determining equivalent single wheel load.(ESWL)

Determining equivalent single wheel load.(ESWL) Imran Nawaz This document discusses methods for determining equivalent single wheel loads (ESWL) and equivalent single axle loads (ESAL) for pavement design. ESWL is defined as the load from a single tire that causes the same stresses/strains as a multi-wheel load. Methods include equal stress, LCN, and FAA approaches. ESAL quantifies the effect of varying axle loads as a number of standard single axle loads. Factors like thickness and subgrade reaction are considered. Cars have minimal impact compared to trucks and buses.

Points and crossing

Points and crossingAkash Patel Points and crossings are railroad track components that allow trains to be diverted from one track to another. A point, or switch, is a movable section of rail that can be aligned to direct trains to the left or right. A crossing is a section of overlapping rails that allows trains to pass through an intersection. Together, points and crossings make up a turnout, which consists of a stock rail, tongue rail, heel block, and other parts to smoothly guide trains between tracks in either a left-hand or right-hand configuration.

Railway Engineering-Curves and superelevation

Railway Engineering-Curves and superelevationMani Vel This document discusses curves and superelevation on railways. It defines horizontal and vertical curves, and explains that superelevation involves raising the outer rail on a curve to provide a comfortable ride. Superelevation counters the effects of lateral forces when negotiating a curve. The key points are:

- Superelevation is the difference in height between the inner and outer rails and helps distribute load on both rails.

- Equilibrium speed is when the centrifugal force is balanced by the cant (superelevation), providing no unbalanced radial acceleration.

- Maximum permissible speed considers factors like radius, cant, cant deficiency/excess, and transition length.

- Examples are provided to calculate supere

More Related Content

What's hot (20)

Left hand turnout

Left hand turnoutAna Debbarma This document discusses railway turnouts. It begins by defining a turnout as the combination of points and crossings that allows a train to move from one track to another, either parallel or diverging. It then describes the key components of a turnout, including tongue rails, stock rails, lead rails, and a vee crossing. It also explains the classification of turnouts as left-hand or right-hand depending on the direction of diversion. Diagrams are included to illustrate the components and working principle of a turnout. The document concludes by stating that turnouts are essential for diverting traffic but can cause issues if not designed and maintained properly.

Stations and Yards of Railway

Stations and Yards of RailwaySouvik Mondal * DOWNLOAD AND PLAY IT IN MICROSOFT POWERPOINT CAUSE IT CONTAINS ANIMATION AND CAN'T WATCH WITHOUT IT *

Stations and Yards of Railway powerpoint presentation in Transport Engineering.

Railway Track Maintenance

Railway Track MaintenanceHari Krishna Velpula Information About Various processes involved in Railway Track Maintenance and some information about South Central Railway, Vijayawada.

Tunnel engineering

Tunnel engineeringSaurabh Samant The document discusses various aspects of tunnel engineering. It begins by introducing tunnels and their uses for transportation. It then discusses the Thames Tunnel in London as an example. The document outlines several advantages of tunneling over other methods. It also discusses considerations for selecting tunnel routes and economies of tunneling. The remainder of the document describes various tunneling methods through both rock and soft ground, as well as tunnel drainage, lighting, ventilation, lining, and maintenance.

Permanent Way of Railway & Components ?(part -1,2,3,4,5)

Permanent Way of Railway & Components ?(part -1,2,3,4,5)RAMPRASAD KUMAWAT Permanent Way Components: , Selection of Alignment, Ideal Permanent Ways and Cross-sections in different conditions, Salient Features and types of Components viz.

Rails, Sleepers, Ballast, Rail Fastenings.

Types and Selection of Gauges

Railway station and YARD

Railway station and YARD Dhruv Makadia Brief Introduction of

* Purposes of railway station

* Site selection for railway station

* Requirements of railway station

* Classification of stations

* Classification of Yards

GEOMETRIC DESIGN OF HIGHWAY

GEOMETRIC DESIGN OF HIGHWAYreemajadwani The document discusses highway geometric design and its key elements. It aims to maximize safety, comfort and efficiency while minimizing costs and environmental impacts. Geometric design considers the road's alignment, cross-section, sight distances and intersections. Elements include the carriageway, shoulders, formation width, right of way, side slopes, berms and side drains. Camber and super elevation help drain water and counteract centrifugal forces on curves. Sight distance requirements like stopping sight distance ensure drivers can see far enough to stop safely.

Railway engineering

Railway engineeringShanmugaraj M For II Year Diploma Civil Engineering Students

M.Shanmugaraj M.E.,

Lecturer / Civil

V.S.V.N Polytechnic College

Virudhunagar

Tamilnadu

India

Signals on Railway

Signals on RailwaySatyapal Singh Railway Signaling: Introduction to Signals, Objective of signals. Types of Signals, Operating Characteristics, Functional Characteristics, Locational Characteristics, Special Characterstics

5.track or permanent way and track stresses

5.track or permanent way and track stressesMani Vel The document discusses the components and stresses acting on railroad tracks. It describes the main parts of a track including the rails, sleepers, ballast, and formation. The rails are joined by fish plates and bolts and fastened to sleepers. Sleepers are embedded in ballast which provides drainage and load distribution. A good track requires proper gauge, cross-leveling, alignment, gradient, and resilience to provide a comfortable ride while withstanding forces from train movement and varying temperatures. Wheels are coned rather than flat to reduce wear on flanges and rails and allow for lateral movement.

Points and crossings

Points and crossingsChockalingam T This presentation discusses the points and crossings used in railways. Especially It deals with the types of turnout - Right-Hand Turnout and Left-hand Turnout. parts of turnout and also the different types of crossings based on the angle.

Defects in rails. Railway Engineering

Defects in rails. Railway EngineeringIrfan Nasir I'm Irfan Nasir. Currently studying Civil Engineering at Mehran University of Engineering and Technology. This is a slide made by me on Defects in rails from the subject Transportation Engineering.

Railway track construction, drainage & maintenence

Railway track construction, drainage & maintenenceGhanashyam Prajapati The document discusses the construction and maintenance of railway tracks. It covers the need for constructing new railway lines, the process of construction including earth work, plate laying, and ballast laying. It also discusses track drainage systems, including surface drainage with side drains and sub-surface drainage. Maintenance of tracks is important and includes daily and periodic maintenance to replace components and ensure safety. Regular maintenance extends the life of tracks and rolling stock.

Railway engg geometric design

Railway engg geometric designVijai Krishnan V This document discusses various aspects of railway track design including gradients, horizontal and vertical curves, super-elevation, and transition curves. It provides formulas for calculating ruling gradient, super-elevation, safe speeds on curves, and other key design elements. Track must be designed to suit the loads and speeds of trains based on safety and economic standards. Proper gradient, curvature, and super-elevation are necessary for smooth train operation.

Railway engineering

Railway engineeringAkshay D Nicator Railway engineering involves the design, construction, and operation of railroads and mass transit systems. It is a branch of civil engineering that deals with track design, station layout, signaling systems, and train movement control. Typical tasks for railway engineers include determining horizontal and vertical alignment, estimating construction costs, and establishing signaling and control systems. Railway tracks consist of rails laid on sleepers embedded in ballast. Points and crossings allow trains to switch tracks. A variety of signals are used to safely direct train movement.

Railway Gauge

Railway GaugeAmit Yadav The document discusses different rail gauges used in India for railway tracks. It describes the three main gauges: broad gauge which has a width of 1676 mm, meter gauge of 1000 mm, and narrow gauge of either 762 mm or 610 mm. Broad gauge is used for routes with high traffic volumes and in plain areas. Meter gauge is used when funds are limited. Narrow gauge is suitable for hilly areas with sharp curves. The document outlines the components of a permanent railway track and considerations for an ideal track like uniform gauge and proper super elevation on curves.

Railway track design ppt 2018

Railway track design ppt 2018ishwar dhakad This document discusses the key elements of railway tracks, including formation, ballast, sleepers, rails, and fastenings. It describes the purpose and design considerations for each element. Formation provides the base for the track and must support the entire load. Ballast distributes loads from sleepers to prevent sinking. Sleepers provide support and stiffness. Rails provide a smooth surface for train movement. Fastenings such as fish plates, bolts, and chairs connect rails and sleepers together securely.

Rails, Types, Joints, Creep, Failure of Rails and Welding of Rails

Rails, Types, Joints, Creep, Failure of Rails and Welding of Railssrinivas2036 The document discusses rails used in railway tracks. It defines different types of rails including double headed, bull headed, and flat footed rails. Flat footed rails, also called Vignoles rails, are now most commonly used. Standard rail sections used in Indian railways, such as 52kg and 60kg, are presented. Requirements of an ideal rail and factors affecting rail wear and failure are explained. Methods to reduce rail wear include use of special alloys, track maintenance, reducing expansion gaps, and lubricating rails.

Highway Alignment

Highway AlignmentAkshathaBhandary Alignment: The position or the layout of the central line of the highway on the ground is called the alignment.

Highway Alignment includes both

a) Horizontal alignment includes straight and curved paths, the deviations and horizontal curves.

b) Vertical alignment includes changes in level, gradients and vertical curves.

Determining equivalent single wheel load.(ESWL)

Determining equivalent single wheel load.(ESWL) Imran Nawaz This document discusses methods for determining equivalent single wheel loads (ESWL) and equivalent single axle loads (ESAL) for pavement design. ESWL is defined as the load from a single tire that causes the same stresses/strains as a multi-wheel load. Methods include equal stress, LCN, and FAA approaches. ESAL quantifies the effect of varying axle loads as a number of standard single axle loads. Factors like thickness and subgrade reaction are considered. Cars have minimal impact compared to trucks and buses.

Viewers also liked (20)

Points and crossing

Points and crossingAkash Patel Points and crossings are railroad track components that allow trains to be diverted from one track to another. A point, or switch, is a movable section of rail that can be aligned to direct trains to the left or right. A crossing is a section of overlapping rails that allows trains to pass through an intersection. Together, points and crossings make up a turnout, which consists of a stock rail, tongue rail, heel block, and other parts to smoothly guide trains between tracks in either a left-hand or right-hand configuration.

Railway Engineering-Curves and superelevation

Railway Engineering-Curves and superelevationMani Vel This document discusses curves and superelevation on railways. It defines horizontal and vertical curves, and explains that superelevation involves raising the outer rail on a curve to provide a comfortable ride. Superelevation counters the effects of lateral forces when negotiating a curve. The key points are:

- Superelevation is the difference in height between the inner and outer rails and helps distribute load on both rails.

- Equilibrium speed is when the centrifugal force is balanced by the cant (superelevation), providing no unbalanced radial acceleration.

- Maximum permissible speed considers factors like radius, cant, cant deficiency/excess, and transition length.

- Examples are provided to calculate supere

Rail Deflection

Rail DeflectionRailways and Harbours The document discusses using Particle Image Velocimetry (PIV) to measure track deflection. PIV uses cameras and image analysis software to calculate horizontal and vertical displacement of a target attached to the rail from video images. The method was tested at three sites in South Africa. Tests showed PIV can reliably measure deflections with a standard deviation of 0.003-0.005mm. PIV provides a quick way to evaluate track condition and stiffness without complex instrumentation.

Railway Engineering - Geometric design of track

Railway Engineering - Geometric design of trackMani Vel This document discusses the importance of proper geometric design of railway tracks. It outlines key considerations for geometric design including gradients, curvature, and track alignment. Proper design is needed to ensure safe train operation at maximum speeds and loads. Specific geometric design elements are described, such as ruling gradients, helper gradients, momentum gradients, and standards for station yard gradients. Grade compensation is also outlined, where steeper gradients are allowed on curved tracks compared to straight tracks.

Points and crossings ( special assigments )

Points and crossings ( special assigments )hiranrathva Points and crossings are arrangements that allow trains to move between tracks. They consist of movable rails called switches or tongues that can divert trains left or right. Crossings provide gaps in the rails so trains can move between intersecting tracks. Together, switches and crossings form turnouts that allow trains to change routes. Proper placement and angles of switches and crossings are necessary for train wheels to safely navigate between tracks.

Surface runoff

Surface runoffMohsin Siddique This document discusses surface runoff, stream flow, hydrographs, and unit hydrographs. It begins by defining surface runoff and stream flow, explaining that surface runoff occurs when precipitation is unable to infiltrate the ground and flows overland into streams, rivers, and other bodies of water. It then discusses measuring stream flow through various methods like current meters and weirs to determine discharge. The document introduces the concept of hydrographs, which plot discharge over time, and unit hydrographs, which represent the hydrograph resulting from 1 unit of excess precipitation. It provides examples of using unit hydrographs and the S-curve method to develop hydrographs of different durations.

Ch5 Plate Girder Bridges (Steel Bridges تصميم الكباري المعدنية & Prof. Dr. Me...

Ch5 Plate Girder Bridges (Steel Bridges تصميم الكباري المعدنية & Prof. Dr. Me...Hossam Shafiq II Plate girders are commonly used as main girders for short and medium span bridges. They are fabricated by welding together steel plates to form an I-shape cross-section, unlike hot-rolled I-beams. Plate girders offer more design flexibility than rolled sections as the plates can be optimized for strength and economy. However, their thin plates are more susceptible to various buckling modes which control the design. Buckling considerations of the compression flange, web in shear and bending must be evaluated to determine the plate girder's load capacity.

Introduction to ground water hydrology

Introduction to ground water hydrologyMohsin Siddique This document provides an introduction to groundwater hydrology. It discusses key topics such as the hydrologic cycle, aquifers, water tables, wells, Darcy's law, and groundwater management. Shallow groundwater recharges more quickly than deep groundwater but is more prone to contamination. Aquifers are underground units that store and transmit water, and can be unconfined, confined, or semi-confined. The water table and piezometric surface indicate the level of groundwater in unconfined and confined aquifers respectively. Darcy's law describes the flow of water through porous media. Groundwater management aims to balance withdrawal and recharge to prevent water levels from dropping. Artificial recharge

Points and crossings

Points and crossingshiranrathva This document discusses points and crossings in railway tracks. It defines points and crossings as arrangements that guide trains during directional changes. Points divert vehicles, while crossings provide gaps in rails for flanged wheels to roll over. The key components of a point and crossing assembly are the point, lead, and crossing element. Crossings introduce gaps where tracks cross to allow wheels to pass between tracks. Points and crossings are necessary because railway vehicles have inside wheel flanges and require special arrangements to navigate the rails and change tracks or directions.

Geometric desing of railway track

Geometric desing of railway trackmohitjain123 This document is a project report on the geometric design of railway tracks submitted by Mohit M. Jain to Gujarat Technological University in India. It introduces the topic of geometric design and its importance for ensuring safe and efficient train operation. The following chapters discuss geometric cross sections, gradients including different types, curves, superelevation, and gauge widening on curves. The report provides information on the key design considerations for railway tracks.

Water cycle and water budget

Water cycle and water budgetMohsin Siddique This document provides information about the hydrological cycle and water budget. It begins with the objectives of understanding water sources and the hydrological cycle components of evaporation, precipitation, infiltration, runoff and subsurface flow. It then discusses the global water resources and usage, including increasing population growth. The bulk of the document defines and explains the various components of the hydrological cycle, including evaporation, condensation, precipitation types, interception, infiltration, subsurface flow, runoff and storage. It provides an example water balance equation and long-term water balance calculation. Finally, it briefly discusses the global water cycle and a typical hydrological cycle for the UAE.

Stream flow measurement

Stream flow measurementMOHIT MAYOOR This document discusses various methods for measuring stream flow. There are direct and indirect methods. Direct methods like area-velocity measure discharge by determining the cross-sectional area and average velocity. Indirect methods relate discharge to easily measured water level/stage using structures or the slope-area method with Manning's equation. Accurate stage measurements are important for estimating discharge from stage-discharge curves developed through direct measurements.

Precipitation and its estimation

Precipitation and its estimationMohsin Siddique This document discusses precipitation measurement and estimation. It begins by defining precipitation and its different types. It then discusses various methods for measuring precipitation, including manual and automatic rain gauges. It emphasizes the importance of establishing a raingauge network according to WMO recommendations to spatially average precipitation measurements over a region. The document concludes by outlining different methods that can be used to estimate missing precipitation data, including station averaging, normal ratio, inverse distance weighting, and regression techniques.

Station yards

Station yardsjagadish108 These are the arrangements provided in a railway track to divert a train from the main line to a branch line, such as turnouts that use pairs of points and crossings. The document defines various railway track components like the tongue rail, stock rails, stretcher bar, and switch. It describes different types of turnouts like left and right hand turnouts. The document also discusses railway signaling, explaining different types of signals based on their operation, function, and location. Signaling facilitates efficient train movement, safety between trains, and maximum track utilization.

Railway engineering

Railway engineeringhiranrathva This document discusses railway engineering concepts related to points, crossings, and turnouts. It describes that a crossing allows the flanges of a railway vehicle to pass from one track to another where the gauges cross. A turnout uses lead rails and curved rails to divert rolling stock from one track to another. The key components of a turnout are tongue rails, stock rails, check rails, lead rails, a Vee crossing, and parts for operating the points. The document also describes different types of crossings, including acute angle, obtuse angle, and square crossings, as well as components like wing rails and check rails.

2 handouts-lecture-7

2 handouts-lecture-7Saleem Malik This lecture discusses the equilibrium of particles and free-body diagrams. It defines particle equilibrium as being at rest if originally at rest or having constant velocity if in motion. The condition for particle equilibrium is that the sum of all forces acting on the particle is zero. Examples of connections involving springs and cables/pulleys are provided. The procedure for drawing free-body diagrams involves outlining the particle, showing all known and unknown forces, and labeling the forces. Example problems are solved to demonstrate applications of these concepts.

Floods

FloodsMohsin Siddique This document discusses floods and methods for estimating peak flood discharge. It begins by defining a flood and design flood. It then describes various methods for estimating peak flood discharge, including using physical indicators, empirical formulas, unit hydrographs, the rational method, and flood frequency studies. As an example of applying the rational method, it calculates the peak discharge for a culvert project in Alberta, Canada with a 50-year return period. It also provides an example of using Gumbel's extreme value distribution to estimate flood discharges with 100-year and 150-year return periods based on annual maximum flood data from 1951-1977.

Geometric design of the track

Geometric design of the trackT.Naga Anusha Geometric design of tracks aims to provide smooth and safe running of trains at maximum speed while carrying heavy loads. This involves proper design of gradients, curvature, and super elevation (cant).

There are different types of gradients - ruling gradient which is the maximum gradient permitted, momentum gradient which is steeper and uses train momentum, and pusher gradient requiring extra locomotives. Gradients are designed considering train performance and load. Curvature introduces greater resistance requiring grade compensation of ruling gradients.

Super elevation (cant) involves raising the outer rail on curves to counteract centrifugal forces. Equilibrium cant provides equal wheel load distribution. Higher speeds result in cant deficiency which must be limited for passenger safety. Contrary flexures like

Railway transportation 2.1

Railway transportation 2.1Hasan Gunes Rail transportation primarily moves raw materials and low-value manufactured goods over long distances. Rail can be classified into four categories based on shipment size: less than wagonload, wagonload, trainload, and intermodal. Developments in technologies like RO-LA systems have increased rail's use for intermodal shipping. The European Commission aims to shift 30% of highway cargo to rail and sea by 2030 and 50% by 2050 through infrastructure investments and policies. High-speed rail lines have reduced travel times between major cities in several countries.

Railway track:An Introduction

Railway track:An IntroductionPrem Prakash Kumar This document discusses various aspects of traditional ballasted railway track, including:

- The important functions of ballast in distributing load and providing stability, drainage, and track maintenance.

- The standard ballast profile and advantages/disadvantages of traditional ballasted track compared to ballastless track.

- Key components of permanent way including rails, sleepers, fishplates, and various types of fastenings. Elastic fastenings help absorb vibrations.

- Rubber pads between rails and sleepers are important for damping vibrations and preventing gaps in the track. Proper toe load from fastenings also provides stability and resistance to movement.

Similar to Points and crossings (20)

Points and crossings.ppt

Points and crossings.pptsamatha6 Points and crossings are special arrangements that allow trains to move from one track to another by connecting lines. They consist of switches, stock rails, crossings, lead rails, and other components. Switches are made of tongue rails and stock rails, with the tongue rail able to move to divert trains left or right. Crossings allow tracks to cross over each other. Proper design of points and crossings is important for safety as they can cause derailments if not constructed correctly. Terminology like facing direction and types of switches are also defined.

Railway engineering part3

Railway engineering part3GARRE RAVI KUMAR 1. A set of points or switches consists of a pair of stock rails and a pair of tongue rails.

2. It also includes a crossing or frog, which is a device that allows the flanges of a railway vehicle to pass from one track to another where two rails cross.

3. Maintaining rigidity of the crossing is important to prevent loosening of components from severe vibrations.

Points, Crossings and Turnouts of Railways.pptx

Points, Crossings and Turnouts of Railways.pptxdshah162002 Points and crossings are critical components of railway networks that allow trains to switch tracks and safely cross other tracks. Turnouts, which combine points and crossings, enable trains to divert from one track to another or access sidings. They consist of switches, stock rails, crossings, lead rails, check rails, and wing rails. Points can be facing or trailing and turnouts can be right-handed or left-handed depending on the direction trains divert. Turnouts work by using a pair of switches that can align with the stock rail to keep a track open or closed and a crossing that connects the tracks to allow them to intersect.

1Point & crossing.pdf

1Point & crossing.pdfS2Motivation1 This document discusses points and crossings, turnouts, and track junctions in railway systems. Points and crossings allow trains to divert from one track to another, providing flexibility of movement. Turnouts are the simplest combination of points and crossings, enabling a track to take off from another. There are different types of track junctions formed using points, crossings, curves and straights, including turnouts, diamond crossings, cross-overs, and triangles. Track junctions are used to transfer trains between tracks or allow trains to cross over each other.

Coning of Wheels in Railways & Rail Creep

Coning of Wheels in Railways & Rail CreepRAMPRASAD KUMAWAT This document discusses coning of wheels and rail creep in railways. It contains the following key points:

1. Coning of wheels refers to wheels being shaped like a cone to keep trains centered on straight tracks and allow different wheel distances on curved tracks, reducing wear.

2. Rail creep is the longitudinal movement of rails in the direction of train movement, ranging from 0-6 inches. It is caused by starting/stopping forces, wave motions, and temperature changes.

3. Creep can cause buckling, disturbed track alignment and gauging, and disrupted signaling if not corrected through pulling rails back or using creep anchors to grip rails in place.

POINTS AND CROSSINGS (1) FINAL.pptx

POINTS AND CROSSINGS (1) FINAL.pptxShruthiBS13 Points and crossings facilitate the diversion of trains from one track to another without obstruction. A turnout provides for diverting trains from a main track to a branch track using a set of points and crossings. There are different types of turnouts including right-hand and left-hand turnouts. Important components of turnouts include tongue rails, stock rails, lead rails, and stretcher bars. Crossings connect different routes without obstructions and can be classified based on shape (square, acute angle, obtuse angle) or assembly (ramped, spring/movable).

Railway and Airport Engineering

Railway and Airport EngineeringEmaan Sharma Railway Engineering:

Permanent Way, Rail Gauge, Broad Gauge, Meter Gauge, Narrow Gauge, Choice of Gauge, Uniformity of Gauge, Rails - Double headed, Bull Headed, Flat footed Rails, Sleepers, Ballast, Formation, Types of sleepers, Merits and Demerits, Functions of sleepers, Requirements of good sleepers,Spacing of sleepers, Sleeper Density, Characteristics of good ballast, Capacity of a railway track, Track Fixtures and Fastening, Types of fixtures and fastening, Fish Plates, Dog Spikes, Rail Joints, Creep of Rails, Indication of Creep, Disadvantages of creep in rails, Remedies for prevention of creep, Theory of creep, Coning of Wheels, Theory of coning, Adzing of sleepers, Gradients, Grade compensation on curves, Radius and degree of curves, Super-elevation, Negative cant, Cant Deficiency, Equilibrium speed, Maximum permissible speed, Necessity of geometric design, Track defects, Transition curves, Vertical curves, Points and crossings, Types of crossings, Turnouts, Switches, Interlocking, Signalling, Classification and types of Signals, Semaphore type signal, Detonating signals, Dock signals, Shunting Signals, Warner Signals, Reception & Departure Signals, Railway Station, Purpose of a Railway Station, Site selection for Railway Stations, Track Drainage, Why Need of Proper Drainage.

Airport Engineering:

Basic Terms (AAI, ICAO, IATA), Airport System plan, Master plan, Airport Classification, Site Selection, Imaginary Surfaces, Aircraft Characteristics, Important components of Airport Layout, Runway, Runway Configuration, Runway Orientation, Factors affecting Runway Orientation, Wind Direction Indicator, Wind Rose Diagram - Type I & Type II, Basic Runway Length, Corrections for Elevation, Temperature & Gradient, Actual Runway Length, Runway Geometric (ICAO), Taxiways, Exit Taxiways, Location of Exit Taxiways, Holding Aprons, Hanger, Terminal Building, Aircraft Parking, Airport Marking & Lightning.

Points and Crossings

Points and Crossings Abhijeet Salve Its a very smiple and sweet presentation which helps to clarify your basic concepts about the specific topic of "POINTS AND CROSSINGS" Presented by Abhijeet S. Salve student of Maharashtra intitute of Technology in Civil engineering (B.tech).

Design of Transmission Systems

Design of Transmission SystemsDevan P.D This document provides an overview of the design of transmission systems using flexible elements such as belts, ropes, and chains. It discusses the selection and design of v-belts and pulleys, wire ropes, transmission chains and sprockets. Assessment methods for the course include common assessment tests, written assignments, gamification, active learning, and group presentations. Flexible elements are used to transmit mechanical power over comparatively long distances and for conveying purposes. Proper selection and replacement of these elements is important to prevent deterioration.

1. Introduction to Railway engg..pptx

1. Introduction to Railway engg..pptxMayuriPatel90 Railway engineering is a multi-faceted engineering discipline dealing with the design, construction and operation of all types of rail transport systems.

MODULE-II INFRASTRUCTURE ENGINEERING BTCVC702

MODULE-II INFRASTRUCTURE ENGINEERING BTCVC702Dr. BASWESHWAR JIRWANKAR This presentation helps you to understand all concepts as per DBATU, Lonere for Last Year BTech Civil Subject- Infrastructural Engg.

Module-II

Points and Crossings:

Standard types, Design of simple turnout, various types of Junctions, Stations and Yards: Purpose, Location, Site selection, general layouts of Terminus and Junction, Signaling and Interlocking, Construction and Maintenance of Track, Modern trends in Railways

etc.

Unit 1 gauge creep

Unit 1 gauge creepAnuruddh Rajput This document discusses gauge, coning, and tilting in railway tracks. It provides details on:

- The gauge is the distance between rails and is important for track alignment and stability. Wheels are coned to smoothly navigate curves and counteract centrifugal forces. Rails are tilted inward to reduce wear on outer rails and wheels.

- Coning wheels means making the outer wheel's tread circumference larger than the inner wheel's to maintain alignment through curves. Tilting rails inward at a 1 in 20 slope matches the wheel cone and distributes wheel loads evenly.

- Correct gauge, coning, tilting and cross-leveling are required for smooth riding, reduced component wear, and shock absorption

Power Transmission drives belt drive chain drive pulley

Power Transmission drives belt drive chain drive pulleyradhakrishnan unni power plant power transmission

Chapter 1 introductution to railway and permanent way

Chapter 1 introductution to railway and permanent waydhara dattani This document provides an introduction to railway track gauges and permanent way components. It discusses different track gauges used in India and around the world, and factors that influence gauge selection such as construction costs, traffic volume, and terrain. It also describes various types of rails, fittings used to join rails together and attach them to sleepers like fish plates, spikes, bolts and chairs. Other components discussed include bearings plates, blocks and sleepers. The document aims to give an overview of permanent way construction and components.

Railway points, crossings and components

Railway points, crossings and componentsSunil Kumar Meena This document summarizes various railway points, crossings, and components. It discusses point and crossing components such as stock rails, tongue rails, switch rails, heel blocks, and sliding plates. It then provides examples and definitions of various railway stations and their components like junction stations, flag stations, and hump yards. Quizzes with questions and answers about these topics are also included.

Railway engineering

Railway engineeringMuhammadAdeel269 Railway track consists of several key elements to support safe and comfortable train travel. The track is laid on a prepared foundation and supported by ballast and sleepers. Rails are precisely aligned on top to provide a smooth ride. Turnouts allow trains to switch between tracks at junctions. Railway stations are where trains stop to collect and drop off passengers and cargo. Their design and layout must efficiently accommodate passenger and freight movement.

Chapter 6 Points,crossings and yards

Chapter 6 Points,crossings and yardsKHUSHBU SHAH This document discusses various aspects of railway track components and infrastructure. It describes points and crossings which allow trains to divert from one track to another. It then discusses turnouts, their components like stock rails, crossings, and operating mechanisms. The document covers different types of stations like wayside, junction and terminal stations. It also discusses railway yards for passengers, goods, and locomotives along with their key facilities.

More from srinivas2036 (20)

Fundamental operations

Fundamental operationssrinivas2036 Different fundamental operations that can be done in GIS. How GIS functions in solving various types of spatial problems.

Data collection and input overview

Data collection and input overviewsrinivas2036 The document discusses data collection and input methods in GIS. It covers obtaining data from primary sources like surveys and secondary sources like existing maps. Methods of inputting data include keyboard entry, manual digitization of maps, scanning, and COGO (coordinate geometry) entry of surveying measurements. Several types of sampling for primary data collection are also outlined like random, systematic, and stratified sampling. Issues with data accuracy and metadata are also addressed.

Theoretical framework for gis

Theoretical framework for gissrinivas2036 This document outlines the theoretical framework for how data is transformed in a geographic information system (GIS). It discusses four main stages of transformation: (1) data is selected from the real world, (2) input into the GIS, (3) manipulated and stored within the system, and (4) output from the system. Each stage may involve several operations on the data. Understanding how these transformations work forms the theoretical basis for modeling and representing real-world objects and information in a GIS.

Construction planning - Construction Technology and Project Management

Construction planning - Construction Technology and Project Managementsrinivas2036 The document discusses construction project planning. It defines planning as developing a method or scheme in advance. Construction planning involves optimally utilizing resources like people, equipment, materials and money. Key activities in construction planning include defining the scope of work, identifying involved activities, establishing project duration, defining resource control procedures, and updating plans. Different types of project plans may focus on schedule, cost, quality or safety. Techniques used in planning include work breakdown structure, precedence, network logic and critical path method.

Mechanized construction

Mechanized constructionsrinivas2036 This document discusses mechanized construction and the use of construction equipment. It covers several topics:

- The benefits of mechanized construction include completing work more quickly and at a larger scale.

- There are two types of construction projects - linear projects and fast-tracked projects, which have simultaneous design and construction.

- Deploying construction equipment can increase output, reduce costs, allow for precision, and alleviate manual labor issues.

- Equipment selection involves analyzing functions, capacities, costs, and limitations for the task. Renting equipment on an as-needed basis can be more cost effective than purchasing.

Construction claims, disputes and project closure

Construction claims, disputes and project closuresrinivas2036 This document discusses construction claims, disputes, and project closure. It begins by explaining that during project execution, issues often arise between parties that cannot be resolved, resulting in claims from contractors for time extensions or cost reimbursements. These claims can be settled amicably or become disputes if the owner does not agree. Common sources of claims include defects in contracts, site conditions differing from descriptions, scope changes, and payment delays. The document provides guidance on claim management, notification, substantiation, and resolution procedures. It also discusses mechanisms for dispute avoidance and resolution such as negotiation, mediation, arbitration, and their advantages over legal proceedings.

Fire protection in construction

Fire protection in constructionsrinivas2036 Fire safety in construction requires minimizing flammable materials, properly storing fuels and oxidizers, preventing smoking in risky areas, and taking electrical safety precautions. Sites should have fire extinguishers and trained personnel, a fire tender on standby, and water available for fires. Fire detection systems use heat, smoke, or flame sensors to quickly detect fires and alert people. The Confederation of Indian Industry issued ten fire safety commandments including having a written prevention plan, eliminating risks, training employees, and following regulations.

Environment at site – construction management

Environment at site – construction managementsrinivas2036 This document discusses environmental management at construction sites. It outlines short-term objectives like reducing resource consumption, emissions, and waste production. It also covers initial ground contamination assessment, waste management practices like prevention, reuse, and recycling, and pollution control of air, water, and noise. The key aims are suppressing pollution at its source and following standards for hazardous materials, air and water pollutants, and noise levels.

Electrical safety in construction

Electrical safety in constructionsrinivas2036 This document discusses electrical safety in construction. It notes that electrical safety is important due to the hidden dangers of electricity and risk of fire or electrocution. Two main electrical hazards are contact with live parts and heat generated from improper installations. Proper design of electrical facilities is needed to provide protection against direct and indirect contact, thermal effects, over/under currents, and overvoltage. Regulations and standards like the Indian Electricity Act and National Electrical Code establish safety rules that all installations must follow. Ten safety commandments and guidelines are also outlined.

Personal safety in construction

Personal safety in constructionsrinivas2036 The document discusses personal protective equipment for construction site safety. It recommends wearing a hard helmet, ear plugs, safety glasses or goggles, safety shoes or boots, and gloves for piling work to protect from falling objects, loud noises, debris, foot hazards, and injuries. Additional safety gear like safety belts are required when working at heights or performing tasks like welding, grinding or material handling. Indian safety standards are referenced for various types of protective equipment. Vigilance is stressed along with maintaining safety devices, permits for hazardous areas, illumination, and medical exams.

Startup india action plan – who are eligible

Startup india action plan – who are eligiblesrinivas2036 Which Companies Qualify For StartUp India Action Plan. Rules and Conditions for a company to be eligible for startup india scheme of narendra modi. How to avail 3 year tax benefits

Introduction to aerial photography and photogrammetry.ppt

Introduction to aerial photography and photogrammetry.pptsrinivas2036 Aerial photography and photogrammetry are techniques used in remote sensing. Aerial photography involves taking photographs from aircraft and has been used since the 1850s. Photogrammetry uses photographs to measure and obtain spatial information about the objects and terrain photographed. It allows for the creation of topographic maps, cadastral maps, and large-scale construction plans more quickly and economically than traditional ground-based surveying. While aerial photography and photogrammetry provide advantages over field surveys, some on-site control and verification is still needed.

Topic stereoscopy, Parallax, Relief displacement

Topic stereoscopy, Parallax, Relief displacementsrinivas2036 stereoscopic principles, calculation of height with parallax and relief displacement, mosaic and maps, mosaic vs maps

Principle of aerial photography and types.ppt

Principle of aerial photography and types.pptsrinivas2036 Principle of aerial photography and photogrammetry, types of aerial photographs, scale of aerial photograph.

GATE Syllabus Civil engineering

GATE Syllabus Civil engineeringsrinivas2036 The document outlines the key topics covered in a Civil Engineering curriculum across 7 sections: 1) Engineering Mathematics, 2) Structural Engineering, 3) Geotechnical Engineering, 4) Water Resources Engineering, 5) Environmental Engineering, 6) Transportation Engineering, and 7) Geomatics Engineering. Some of the main topics discussed include linear algebra, calculus, structural analysis, construction materials, soil mechanics, fluid mechanics, traffic engineering, surveying, and remote sensing. The curriculum appears to provide a broad foundation in mathematics, structural design, geotechnical work, water management, transportation systems, and environmental studies relevant to civil engineering work.

Estimation and Costing - Contracts

Estimation and Costing - Contractssrinivas2036 The document discusses various types of construction contracts and tendering processes. It defines a tender as an invitation from an owner to contractors to execute work at a specified cost and time. There are different types of tenders including open, sealed, limited, and single tenders. Key aspects of the tendering process include tender forms, documents, notices, evaluation criteria, acceptance procedures, contract documents, deposits, and measurements. Different types of construction contracts are also summarized such as lump-sum, item rate, percentage rate, cost plus, and turn-key contracts.

Valuation

Valuationsrinivas2036 Valuation is the process of estimating the value or fair price of real property. There are several purposes for valuation including buying or selling property, taxation, rent fixation, securing loans, and determining compensation amounts. Valuation methods include the rental method, profit-based method, and depreciation method. The rental method capitalizes the net annual income from rent by multiplying it by the years' purchase value. The profit-based method values properties like hotels based on capitalizing the net annual profit. Depreciation is also considered to account for the aging and deterioration of structures over time.

Airport lighting

Airport lightingsrinivas2036 1) Early airports used flood lighting but now use runway edge lights, taxiway centerline lights, and approach lighting to guide pilots.

2) Runway lights form a narrow channel to eliminate the "black hole effect" and provide visual guidance. Taxiway lights have blue edges and green centers.

3) Threshold lights identify the beginning of the runway and are green on the landing side and red on the opposite side.

Airport marking

Airport markingsrinivas2036 Visual aids like markings and lighting help pilots navigate airports safely during day and night. Markings include colored stripes and patterns on runways, taxiways, and aprons to indicate centerlines, edges, directions, and restricted areas. Runway markings identify numbers, thresholds, and touch down zones. Taxiway markings guide planes to and from runways. Airport lighting uses colored lights to replicate markings for nighttime visibility. Together, these visual aids allow pilots to orient themselves and follow correct paths for takeoff and landing in all weather conditions.

Airport apron and holding bays

Airport apron and holding bayssrinivas2036 Airport aprons are paved areas where aircraft can be parked, loaded, unloaded, or serviced. There are different types of aprons including terminal aprons near passenger facilities, cargo aprons near freight terminals, and transient aprons for temporary parking. Holding bays are also known as holding aprons located near runways to hold planes waiting for runway clearance. When designing aprons, considerations include safety, efficiency, geometry, flexibility, and the ability to accommodate a range of aircraft sizes and allow for future expansion.

Recently uploaded (20)

Environmental Product Declaration - Uni Bell

Environmental Product Declaration - Uni BellManishPatel169454 The Uni-Bell PVC Pipe Association (PVCPA) has published the first North American industry-wide environmental product declaration (EPD) for water and sewer piping, and it has been verified by NSF Sustainability, a division of global public health organization NSF International.

UNIT_2_ DIAGNOSTICS- UNIT II BIOMECHANICAL THERAPEUTIC EQUIPMENT

UNIT_2_ DIAGNOSTICS- UNIT II BIOMECHANICAL THERAPEUTIC EQUIPMENTDJERALDINAUXILLIAECE BIOMECHANICAL

THERAPEUTIC EQUIPMENT

Introduction to Safety, Health & Environment

Introduction to Safety, Health & Environmentssuserc606c7 Introduction to

Safety, Health &Environment

Taykon-Kalite belgeleri

Taykon-Kalite belgeleriTAYKON Kalite Politikamız

Taykon Çelik için kalite, hayallerinizi bizlerle paylaştığınız an başlar. Proje çiziminden detayların çözümüne, detayların çözümünden üretime, üretimden montaja, montajdan teslime hayallerinizin gerçekleştiğini gördüğünüz ana kadar geçen tüm aşamaları, çalışanları, tüm teknik donanım ve çevreyi içine alır KALİTE.

Soil Properties and Methods of Determination

Soil Properties and Methods of DeterminationRajani Vyawahare This PPT covers the index and engineering properties of soil. It includes details on index properties, along with their methods of determination. Various important terms related to soil behavior are explained in detail. The presentation also outlines the experimental procedures for determining soil properties such as water content, specific gravity, plastic limit, and liquid limit, along with the necessary calculations and graph plotting. Additionally, it provides insights to understand the importance of these properties in geotechnical engineering applications.

The Golden Gate Bridge a structural marvel inspired by mother nature.pptx

The Golden Gate Bridge a structural marvel inspired by mother nature.pptxAkankshaRawat75 The Golden Gate Bridge is a 6 lane suspension bridge spans the Golden Gate Strait, connecting the city of San Francisco to Marin County, California.

It provides a vital transportation link between the Pacific Ocean and the San Francisco Bay.

AI ppt on water jug problem by shivam sharma

AI ppt on water jug problem by shivam sharmaShivamSharma588604 this ppt is made on the topic of water jug problem.

Design and Analysis of Algorithms Unit 5

Design and Analysis of Algorithms Unit 5sureshkumara29 Algorithm design techniques include:

Brute Force

Greedy Algorithms

Divide-and-Conquer

Dynamic Programming

Reduction / Transform-and-Conquer

Backtracking and Branch-and-Bound

Randomization

Approximation

Recursive Approach

What is an algorithm?

An Algorithm is a procedure to solve a particular problem in a finite number of steps for a finite-sized input.

The algorithms can be classified in various ways. They are:

Implementation Method

Design Method

Design Approaches

Other Classifications

In this article, the different algorithms in each classification method are discussed.

The classification of algorithms is important for several reasons:

Organization: Algorithms can be very complex and by classifying them, it becomes easier to organize, understand, and compare different algorithms.

Problem Solving: Different problems require different algorithms, and by having a classification, it can help identify the best algorithm for a particular problem.

Performance Comparison: By classifying algorithms, it is possible to compare their performance in terms of time and space complexity, making it easier to choose the best algorithm for a particular use case.

Reusability: By classifying algorithms, it becomes easier to re-use existing algorithms for similar problems, thereby reducing development time and improving efficiency.

Research: Classifying algorithms is essential for research and development in computer science, as it helps to identify new algorithms and improve existing ones.

Overall, the classification of algorithms plays a crucial role in computer science and helps to improve the efficiency and effectiveness of solving problems.

Classification by Implementation Method: There are primarily three main categories into which an algorithm can be named in this type of classification. They are:

Recursion or Iteration: A recursive algorithm is an algorithm which calls itself again and again until a base condition is achieved whereas iterative algorithms use loops and/or data structures like stacks, queues to solve any problem. Every recursive solution can be implemented as an iterative solution and vice versa.

Example: The Tower of Hanoi is implemented in a recursive fashion while Stock Span problem is implemented iteratively.

Exact or Approximate: Algorithms that are capable of finding an optimal solution for any problem are known as the exact algorithm. For all those problems, where it is not possible to find the most optimized solution, an approximation algorithm is used. Approximate algorithms are the type of algorithms that find the result as an average outcome of sub outcomes to a problem.

Example: For NP-Hard Problems, approximation algorithms are used. Sorting algorithms are the exact algorithms.

Serial or Parallel or Distributed Algorithms: In serial algorithms, one instruction is executed at a time while parallel algorithms are those in which we divide the problem into subproblems and execute them on different processors.

Indian Soil Classification System in Geotechnical Engineering

Indian Soil Classification System in Geotechnical EngineeringRajani Vyawahare This PowerPoint presentation provides a comprehensive overview of the Indian Soil Classification System, widely used in geotechnical engineering for identifying and categorizing soils based on their properties. It covers essential aspects such as particle size distribution, sieve analysis, and Atterberg consistency limits, which play a crucial role in determining soil behavior for construction and foundation design. The presentation explains the classification of soil based on particle size, including gravel, sand, silt, and clay, and details the sieve analysis experiment used to determine grain size distribution. Additionally, it explores the Atterberg consistency limits, such as the liquid limit, plastic limit, and shrinkage limit, along with a plasticity chart to assess soil plasticity and its impact on engineering applications. Furthermore, it discusses the Indian Standard Soil Classification (IS 1498:1970) and its significance in construction, along with a comparison to the Unified Soil Classification System (USCS). With detailed explanations, graphs, charts, and practical applications, this presentation serves as a valuable resource for students, civil engineers, and researchers in the field of geotechnical engineering.

IoT-based-Electrical-Motor-Fault-Detection-System.pptx

IoT-based-Electrical-Motor-Fault-Detection-System.pptxatharvapardeshi03 IoT-based-Electrical-Motor-Fault-Detection-System.pptx

Von karman Equation full derivation .pdf

Von karman Equation full derivation .pdfEr. Gurmeet Singh Von karman Equation full derivation

By Er. GURMEET SINGH

G.C.E.T JAMMU

Contact: gurmeet.b.tech@gmail.com

M.tech Transportation Engineering

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER Preface: The ReGenX Generator innovation operates with a US Patented Frequency Dependent Load

Current Delay which delays the creation and storage of created Electromagnetic Field Energy around

the exterior of the generator coil. The result is the created and Time Delayed Electromagnetic Field

Energy performs any magnitude of Positive Electro-Mechanical Work at infinite efficiency on the

generator's Rotating Magnetic Field, increasing its Kinetic Energy and increasing the Kinetic Energy of

an EV or ICE Vehicle to any magnitude without requiring any Externally Supplied Input Energy. In

Electricity Generation applications the ReGenX Generator innovation now allows all electricity to be

generated at infinite efficiency requiring zero Input Energy, zero Input Energy Cost, while producing

zero Greenhouse Gas Emissions, zero Air Pollution and zero Nuclear Waste during the Electricity

Generation Phase. In Electric Motor operation the ReGen-X Quantum Motor now allows any

magnitude of Work to be performed with zero Electric Input Energy.

Demonstration Protocol: The demonstration protocol involves three prototypes;

1. Protytpe #1, demonstrates the ReGenX Generator's Load Current Time Delay when compared

to the instantaneous Load Current Sine Wave for a Conventional Generator Coil.

2. In the Conventional Faraday Generator operation the created Electromagnetic Field Energy

performs Negative Work at infinite efficiency and it reduces the Kinetic Energy of the system.

3. The Magnitude of the Negative Work / System Kinetic Energy Reduction (in Joules) is equal to

the Magnitude of the created Electromagnetic Field Energy (also in Joules).

4. When the Conventional Faraday Generator is placed On-Load, Negative Work is performed and

the speed of the system decreases according to Lenz's Law of Induction.

5. In order to maintain the System Speed and the Electric Power magnitude to the Loads,

additional Input Power must be supplied to the Prime Mover and additional Mechanical Input

Power must be supplied to the Generator's Drive Shaft.

6. For example, if 100 Watts of Electric Power is delivered to the Load by the Faraday Generator,

an additional >100 Watts of Mechanical Input Power must be supplied to the Generator's Drive

Shaft by the Prime Mover.

7. If 1 MW of Electric Power is delivered to the Load by the Faraday Generator, an additional >1

MW Watts of Mechanical Input Power must be supplied to the Generator's Drive Shaft by the

Prime Mover.

8. Generally speaking the ratio is 2 Watts of Mechanical Input Power to every 1 Watt of Electric

Output Power generated.

9. The increase in Drive Shaft Mechanical Input Power is provided by the Prime Mover and the

Input Energy Source which powers the Prime Mover.

10. In the Heins ReGenX Generator operation the created and Time Delayed Electromagnetic Field

Energy performs Positive Work at infinite efficiency and it increases the Kinetic Energy of the

system.

كتاب التفاصيل الانشائيه للمنشآت الخرسانية

كتاب التفاصيل الانشائيه للمنشآت الخرسانيةo774656624 -Zufälligurl zu

peut élus silly mais les mes ishaute quils le aurais sans Les établis qui

des Louis de belle accueillis sell puss père peut olds sects it's allétells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as détaillé de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous près

... still que y pais vida Los play quétejón Less via Leal su abuelos lástimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes à pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean écumait il taille Lacis just -Zufälligurl zu

peut élus silly mais les mes ishaute quils le aurais sans Les établis qui

des Louis de belle accueillis sell puss père peut olds sects it's allétells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as détaillé de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous près

... still que y pais vida Los play quétejón Less via Leal su abuelos lástimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes à pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean écumait il taille Lacis just-Zufälligurl zu

peut élus silly mais les mes ishaute quils le aurais sans Les établis qui

des Louis de belle accueillis sell puss père peut olds sects it's allétells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as détaillé de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous près

... still que y pais vida Los play quétejón Less via Leal su abuelos lástimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes à pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean écumait il taille Lacis just -Zufälligurl zu

peut élus silly mais les mes ishaute quils le aurais sans Les établis qui

des Louis de belle accueillis sell puss père peut olds sects it's allétells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as détaillé de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous près

... still que y pais vida Los play quétejón Less via Leal su abuelos lástimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes à pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean écumait il taille Lacis just-Zufälligurl zu

peut élus silly mais les mes ishaute quils le aurais sans Les établis qui

des Louis de belle accueillis sell puss père peut olds sects it's allétells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as détaillé de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous près

... still que y pais vida Los play quétejón Less via Leal su abuelos lástimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes à pouvait lets

ESIT135 Problem Solving Using Python Notes of Unit-3

ESIT135 Problem Solving Using Python Notes of Unit-3prasadmutkule1 ESIT135 Problem Solving Using Python Notes of Unit-3

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

Points and crossings

- 2. Outline • Turnout • Types – Left hand – Right Hand • Components • Points and Switches • Crossings

- 3. Turnout • In case of roads – vehicles move in any direction • Trains - not possible at will to change the direction • Change is made possible with the provision of turnouts • Consists of points and crossings. • Information sent to loco pilot using signals.

- 4. Turnout - Definition • Simple arrangement of points and crossings by the manipulation of which the train from one track may be diverted to the another track or branch line or to siding is known as turnout. • 2 tracks either merge or diverge, or 2 tracks parallel to each other but are still connected to each other- This connection helps in changing the direction of trains. • for this points and crossings are used.

- 5. Turnouts • The combination of lead rails with curved rails (and fastenings) helps in diverting rolling stock from one track to another track. • Rails depending on curvature – Lead rails are straight – Curved rails have curvature • Turnouts are also provided in yards and sidings

- 7. Turnouts and Problems • Some problems exist • Weakest points on the track due to joints and fastenings. Safety becomes main concern in design • Retards the movement of the trains

- 8. Types of Turnouts • Depending on direction of movement of trains from main tracks – Left hand turnout – Right hand turnout

- 10. Component Parts of a Turnout 1. A pair of tongue rails 2. A pair of stock rails 3. Two check rails 4. Four lead rails 5. A Vee crossing 6. Slide chairs 7. Stretcher bar 8. A pair of heel blocks 9. Switch tie plate or gauge 10. Parts for operating points- Rods, cranks, levers etc 11. Locking system which includes locking box, lock bar, plunger bar etc

- 11. • Facing direction: – Standing at switch and looking towards crossing • Trailing direction: – Standing at crossing and looking towards switches • Points: – A pair of tongue rails with stock rails – Train diverting from the main track will negotiate these points first.

- 12. • Tongue Rail: – It is a tapered movable rail, made of high-carbon or -manganese steel to withstand wear. – At its thicker end, it is attached to a running rail. – A tongue rail is also called a switch rail. • Stock Rail: – It is the running rail against which a tongue rail operates.

- 13. • Switch angle: – angle between the gauge face of the stock rail and tongue rail at the theoretical toe of switch. • Throw of switch: – Distance by which the tongue rail moves laterally at the toe of switch

- 14. • Crossing: – A crossing is a device introduced at the junction where two rails cross each other to permit the wheel flange of a railway vehicle to pass from one track to another.