Ppt on Adhesives

- 1. SUBMITTED BY AKANKSHA SHARMA ANEES KHAN FAHEEM AHMED Apeejay School Of Architecture And Planning, Greater Noida

- 2. A ADHESIVE IS A SUBSTANCE WHICH IS USE TO JOIN TWO OR MORE PARTS SO AS TO FORM A SINGLE UNIT .

- 4. ADHESIVES HAVE AN ADVANTAGE OVER RIVETS & BOLT FASTNERS BY DISTRIBUTING STRESS OVER LARGE AREAS OF JOINT

- 5. ITS USE REDUCES GALVANIC CORROSION BETWEEN DISSIMILAR METALS IT PROVIDE THE ABILITY TO CEMENT TOGETHER EXTREMLY THIN SHEETS

- 6. It must "wet" the surfaces - that is it must flow out over the surfaces that are being bonded, displacing all air and other contaminates that are present. It must adhere to the surfaces - That is a chemical bond must form between the surface of the adhesive and the substrate stay in position and become "tacky". It must develop strength - The material must now change its structure to become strong or non-tacky but still adherent. It must remain stable - The material must remain unaffected by age, environmental conditions and other factors as long as the bond is required.

- 7. COHESIVE STRENGTH ADHERENCE FLUIDITY WETTABILITY OF THE SUBSTRATE CREEP (tendency to flow under tension)

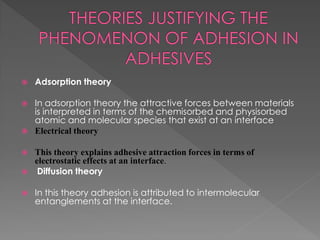

- 8. Adsorption theory In adsorption theory the attractive forces between materials is interpreted in terms of the chemisorbed and physisorbed atomic and molecular species that exist at an interface Electrical theory This theory explains adhesive attraction forces in terms of electrostatic effects at an interface. Diffusion theory In this theory adhesion is attributed to intermolecular entanglements at the interface.

- 9. ITS POOR RESISTENCE TO PEEL ITS PRE APPLICATION REQUIREMENT TO CLEAN THE SURFACE OF APPLICATION THOROUGHLY ITS CARE IN THE APPLICATION OF ADHESIVE THE TIME REQUIREMENT FOR THE FORMATION OF THE BOND

- 10. Surface preparation is the process whereby the adherent surface is cleaned and/or chemically treated to promote better adhesion. The surface of the substrate must be Clean Reasonably smooth Chemically receptive to the chosen adhesive

- 11. WOODEN SURFACE Contaminants Resin, Wax Various products of oxidation Its physical properties require special procedures in surface preparation to assure effective bonding. SURFACE PREPRATION Wood should be dried to the level of moisture content appropriate to its service use when bonded. Surface contamination should be sanded, planed, or machined away. Debris from such mechanical cleaning operations can be removed by Air pressure Vacuuming or Brushing Wiped away with a solvent-moistened cloth. METALLIC SURFACES Contaminants Grease Dust Dirt Oil Oxide caused by air corrosion Grease and oil not only interfere with bonding, but also make certain types of cleaning operations, such as chemical surface alteration, ineffective. SUFACE CLEANING Chemical surface alteration Solvent cleaning Abrasive blasting BOND STRENGTH It is determined by such factors as wettability of the metal its coefficient of thermal expansion (and that of the material it is being bonded to),

- 12. NON METTEALIC SURFACES Surface preparation Solvent Chemical Abrasive cleaning The order of cleaning The adherent surface receives an initial solvent cleaning Followed by chemical surface alteration or abrasion Then it is recleaned with solvent. NOTE - For effective adhesion, bonding should take place as soon as possible after surface preparation has been completed.

- 14. NATURAL SEMI SYNTHETIC SYNTHETIC INORGANIC STARCH & DEXTRIN CELLULOSIC VINYLS SOLUBLE SILICATES GELATIN (ANIMAL,FISH,VE GETABLE GLUES) ACRYLICS PHOSPHATES CEMENT ASPHALT AND BITUMIN REACTIVE ACRYLIC BASES HYDRAULIC CEMENTS NATURAL RUBBER SYNTHETIC RUBBER MISCELLANEOUS CEMENT RESIN,SHELLAC ALDEHYDE CONDENSATION RESIN EPOXIDES RESIN AMINE BASE RESIN POLYESTER RESIN POLYOLEFIN POLYMER

- 16. Natural Adhesives TYPES OF NATURAL ADHESIVES: STARCH AND DEXTRIN GELATINE ( animal, fish, vegetable glues ) Asphalt and bitumen Natural rubber Resins , shellac

- 19. The main use for these adhesives is the paper industry where they are used in multiwall bags, corrugated paper etc. Dextrin which is dry roasted starch is used in remoistenable adhesives.

- 21. PROCEDURE TO MAKE DEXTRIN GLUE

- 28. Cellulosic Cellulose is in the structural elements of plants and is a polymer made up of glucosidal rings joined by oxygen. The glucosidal ring contains three hydroxyl groups which are reacted to form the various derivatives. Ethers and esters can be formed to give either water soluble or solvent soluble polymers. Cellulose nitrate - mainly as a clear general purpose home handyman adhesive. Cellulose acetate butyrate - paper to paper and plastic adhesives. Methyl cellulose - leather paste to prevent shrinkage as drying and wallpaper pastes. Ethyl cellulose - low temperature adhesives.

- 30. VINYL ACRYLICS REACTIVE ACYRYLICS BASES SYNTHETIC RUBBER ALDEHYDE CONDENSATION RESIN EPOXIDES RESIN AMINE BASE RESIN POLYESTER RESIN POLYOLEFIN POLYMER

- 31. VINYL The vinyl ester family is one of the more polymers not only for the coating industry but also the adhesive industry. The number of vinyl derivatives is very large and all have some specific properties. Some members are produced either as an emulsion or as a solvent soluble type. Polyvinyl acetate paper converting, packaging, wood, leather, tile and home handyman adhesives. Polyvinyl alcohol paper applications, textiles. Polyvinyl butyral - laminated safety glass. Polyvinyl formal - adhesives wire enamel. Polyvinyl chloride - pipe adhesives. Polyvinyl ether - pressure sensitive tapes.

- 32. Structurally similar to the vinyls but have very different properties. They can be produced either as an emulsion or solvent soluble form. • They are used as • pressure sensitive adhesives • flooring • paper lamination, • Textiles • flocking adhesives etc.

- 33. VIDEO DESCRIBING APPLICATION OF PRESSURE SENSITIVE ADHESIVES

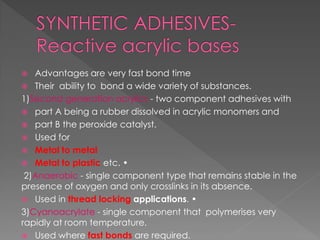

- 34. Advantages are very fast bond time Their ability to bond a wide variety of substances. 1)Second generation acrylics - two component adhesives with part A being a rubber dissolved in acrylic monomers and part B the peroxide catalyst. Used for Metal to metal Metal to plastic etc. • 2)Anaerobic - single component type that remains stable in the presence of oxygen and only crosslinks in its absence. Used in thread locking applications. • 3)Cyanoacrylate - single component that polymerises very rapidly at room temperature. Used where fast bonds are required.

- 35. Synthetic rubbers Natural rubber is polyisoprene and has good tack properties but normally not very high strength. • With all rubber adhesives it is usual to add various resins and other compounding ingredients to give specific properties Polychloroprene - most important type used for contact adhesives. Bonds a wide variety of substances such as wood, laminates, leather etc. Styrene - butadiene - pressure sensitive tapes, tile adhesives, floor adhesives etc. Syyrene-diene-styrene - pressure sensitive tapes, hot melt adhesives Polyisobutylene - electrical tapes, sealing tapes. Acrylonitrile-butdaiene - leather, rubber, vinyl adhesives. Polyurethane - often cross linked with an isocyanate, used in vinyl laminations. Polysulfide - mainly as sealants but also with epoxy resins for concrete adhesives. Silicone - used as an adhesive-sealant in glass to glass, glass to metal bonds.

- 37. STEPS OF USE STIR THE ADHESIVES RIGOUROUSLY INSIDE THE CONTAINER UNTIL THE COLOUR CHANGES TO PALE YELLOW USE NOTCHED LAMINATE SPREADER ONLY APPLY THE ADHESIVEIN ONE DIRECTION ONLY(DO NOT APPLY IN CRIS –CROSS MANNER) GIVE PROPER OPEN TIME (8-12 MINUTES) ENSURE TOUCH DRY CONDITION BEFORE PASTING THE LAMINATE. TO ENSURE PROPER ALIGNMENT KEEP WOODEN PLANKS ALONG THE PLYWOOD WIDTH BETWEEN PLYWOOD AND LAMINATE APPLY STRONG AND UNIFORM PRESSURE BY USING CLOTH WRAPPED WOODEN PLANK POINTS TO BE KEPT IN MIND WHILE VERTICAL APPLICATION IN VERTICAL APPLICATION ,KEEP 2 MM GAP BETWEEN TWO ADJACENT LAMINATES AND WIDTH OF EACH LAMINATE SHOULD BE MAX 2 FT ( FOR EXPANSION OF LAMINATES)

- 39. TO BOND PLYWOOD, MDF PARTICLE BOARD TO LAMINATE LAMINATE WITH LAMINATE USED IN FURNITURE,UPHOLSTERY & FOOTWARE INDUSTRY USED IN BUS BODY BUILDING TO PASTE ROOF TOPSRATE – rs /l

- 41. These are condensation polymers of aldehydes with amino compounds and phenolics forming methylol derivatives. Some of there resins are the earliest synthetics developed Phenolic – abrasive discs, brake linings, foundry industry, fibre bonding, plywood. Resorcinol plywood manufacture Urea particleboard, plywood Melamine particle board.

- 42. Epoxide Resins The reaction between epichlorohydri n and bisphenol A yields a large class of resins known as epoxy. These resins can be cross linked to hard strong adhesives. Epoxy - This is the main group and is characterised by having the epoxide group ideally at each end of the molecule. The group can be cross linked with amines and amides. The resultant adhesive is used in bonding metal, concrete, ceramics etc. Phenoxy - These are high molecular polyethers also derived from epichlorohydrin and bisphenol A (in an equimolar ratio). They differ from epoxy resins in that they are deficient in epoxide groups but have a high hydroxyl which allows cross linking with iso- cyanates, amines etc. They are used in ceramic and metal bonding.

- 43. ROUGHEN, DEGREASE SURFACES TO BE BONDED POUR OUT EQUAL AMOUNTS BY VOLUMES (RESIN & HARDNER) MIX THOROUGHLY APPLY THIN LAYERS ON BOTH THE SURFACES CLAMP JOINT OVERNIGHT AS ARALDITE SETS

- 44. 1)EXCELLENT ADHESION TO MANY DIFFERENT MATERIALS 2)GREAT STRENGH TOUGHNESS AND RESILENCE 3)EXCELLENT RESISTANT TO CHEMICAL ATTACK & TO MOISTURE OUTSTANDING 4)ELECTRICAL INSULATING PROPERTIES 890 RS/KG ADHESION WITH STONE TO METAL, STONE, WOOD,CON CREATE & METAL WITH METAL

- 47. 290 RS/KG

- 49. Amine Base Resins There are many amine derived polymers that show good adhesive properties. Most are condensation reactions and show good adhesion to metals particularly at high temperatures. Polyamide - most polyamide resins are used with epoxy adhesives; however those resins similar to nylon, (i.e. based on dimer acids) used as the thermoplastic adhesives in shoe electronic industries. Polyimide - the product of an aromatic dianhydride and an aromatic diprimary amine. Used as aluminium to aluminium adhesive at elevated temperatures. Polybenzimidazole - aromatic bis(odiamine) with a di-pthalate eg. 3,3'diaminobenzidine and di- phenylisophthalate. Used for stainless steel bonding. Polyquinoxaline - an aromatic bis-(o- diamine) with an aromatic bisglyoxal. used for stainless steel bonding at high temperatures. Polyethylenimine - a highly branched polyamine. Particular interest is that it is water soluble and used for priming cellophane aluminium foil

- 50. Reaction product of dipolyalcohol and a polybasic acid. Unsaturated - uses a cobalt salt together with a peroxide. Used for bonding glass fibres and metal to metal. Saturated - thermoplastic type mainly used in shoe lasting operations.

- 51. 1) ENSURE BOTH THE SURFACEARE CLEAN & DRY 2) STIR THE ADHESIVE WELL BEFORE USING IT 3)APPLY THE ADHESIVES EVENLY ON BOTH SURFACES TO BE BONDED 4)PRESS THE SURFACE TOFETHER & NAIL 5)ON BONDING REMOVE THE NAILS 6)THE WOOD SURFACE ARE READY TO USE FOR FURTHUR PROCESSING

- 52. 185 RS/KG

- 54. 1)POLYOLEFIN POLYMER 2)SOLUBLE SILICATES 3)PHOSPHATE CEMENT

- 55. Polyolefin Polymers Polyethylene and other olefins can also be used in adhesives particularly as the base for thermoplastic types. Normally some modification with other resins is carried out. Polyethylene used as the base for hot melt adhesives in packaging. Polypropylene used in packaging hot melts. Ethylene-vinyl acetate here the polyethylene chain has vinyl acetate groups attached. Commonly between 25 and 30% vinyl acetate is used. Main use is in hot melt adhesives for packaging, labelling, bookbinding. Ethylene-ethyl acrylate - an ethyl acrylate group is substituted for the vinyl acetate. Have better adhesion to polyolefin. Ionomers - These polymers contain carboxyl groups on the polyethylene chain partially neutralised with zinc or sodium. Used for bonding polyolefins.

- 56. Soluble silicates Manufactured by melting silica sand with sodium carbonate and then dissolving in water. Used in Bonding paper Corrugated board Metal to plywood bonds. Some versions can be used in refractory cements.

- 57. Phosphate cements Either silicate- phosphoric acid or zinc phosphate etc. Used as dental cements

- 58. HydrauliccementsHydrauliccements (EPOXYSHIELD) These products set by hydration and include calcium silicate (Portland cement), lime cements, gypsum cements etc. Used for bonding stone chips as concrete, grains to form mortar for bricks etc. PROPERTIES IT PERMANENTLY STOPS THE ACTIVE FLOW OF WATER THROUGH CONCRETE OR MASONARY SHIELD IT ADHERS TO THE WET SURFACE &EXPANDS AS IT DRIES TO FILL DEEP CRACKS & HOLES CRETING A WATER TIGHT SEAL IT CAN BE USED AS ANCHORING CEMENT USED FOR RETAINING WALLS MASONARY WALLS CINDER CONCRETE BLOCK INTERIOR & EXTERIOR DURABILITY SEALS IN 5 MINUTES

- 61. FOR USE IN FURNITURE INDUSTRY B)PAPER INDUSTRY ADVANTAGES a) HEAT & WATER RESISTANT b) LONG STORAGE LIFE c) ECONOMICAL IN LONG RUN d) UNSURPASSED BONDING STRENGTHRATE- 200 RS /KG

- 63. 980 RS/KG

- 65. 1319 RS/ 500 gm

- 68. MULTIPURPOSE WOOD ADHESIVES LONG LASTING ADHESION HYBRID POLYMER TECHNOLOGY 180 RS/ KG

- 69. USED IN TYPES OF ADHESIVES PAPER INDUSTRY Poly vinyl acetate, poly vinyl alcohol, TEXTILE INDUSTRY POLY VINYL ALCOHOL LEATHER INDUSTRY WOOD INDUSTRY TILE INDUSTRY LAMINATED SAFETY GLASS POLY VINYL BUTYRAL

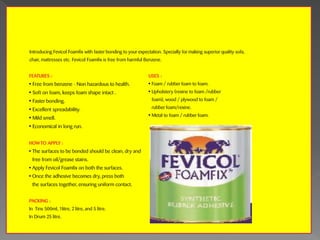

- 70. Glen A Rowland, Adhesives and Adhesion, CHEM NZ, 1998, No.71, 17-27. SHIELD.J.1970,LONDON,ADHESIVES HANDBOOK(THIRD EDITION),BUTTERWORTH &CO. Article by John Packer & Owen Brett (Ados Chemical Company) at a 1990 FEVICOL CATALOGUE