Prefabrication

- 2. Definition :Definition : Prefabrication is the practice of assembling components of a structurep g p in a factory or other manufacturing site, and transporting complete assemblies or sub-assemblies to the construction site where the structure is to be locatedstructure is to be located. Meaning :Meaning : The assembly of buildings or their components at a location otherThe assembly of buildings or their components at a location other than the building site. The method controls construction costs by economizing on time, d i lwages, and materials. Prefabricated units may include doors, stairs, window, walls, wall panels, floor panels, roof trusses, room-sized components, andpanels, floor panels, roof trusses, room sized components, and even entire buildings. The term is used to distinguish this process from the more l f h bconventional construction practice of transporting the basic material to the construction site where all assembly is carried out.

- 3. PREFABRICATIONPREFABRICATION Prefabricated building is the completely assembled and erected building of which is the structural parts consist oferected building, of which is the structural parts consist of prefabricated individual units or assemblies using ordinary or controlled materials.

- 4. PREFABRICATION Prefabricated construction is a new technique and is desirable for large scale housing programmes, yet this has to take a firm hold in the countrythe country.

- 5. AIMS OF PREFABRICATION CONSTRUCTION Prefabrication is used to effect economy in costcost. Components manufactured under controlled conditions.conditions. The speed of construction is increased since no curing period is necessary. Prefabrication helps in the use of locally available materials with required h i i lik li h i hcharacteristics like light-weight; easy workability, thermal insulation, non- combustibility etccombustibility, etc.

- 6. ADVANTAGES OF PREFABRICATIONADVANTAGES OF PREFABRICATION • High quality product L b l t d i• Labor related savings • Savings in time • Overall efficiency is greatly increased• Overall efficiency is greatly increased • Mass production is easier and quick • Protected and controlled production environmentProtected and controlled production environment • Potential for lower production costs and other cost savings • Independence of climatic conditions • The disruption of traffic is avoided E hi h d f S f• Ensures high degree of Safety

- 7. CHARACTERISTICS ARETO BECHARACTERISTICS ARETO BE CONSIDEREDCONSIDEREDCONSIDEREDCONSIDERED Easy availability; Li h i h f h dli dLight weight for easy handling and transport, and to economies on sections and sizes of foundations;foundations; Thermal insulation property; E k bilitEasy workability; Durability in all weather conditions; N b ibiliNon-combustibility; Economy in cost, and Sound insulation.

- 8. Disadvantages :Disadvantages : Careful handling of prefabricated components such as concrete panels or steel and glass panels is required. Attention has to be paid to the strength and corrosion-resistance of theAttention has to be paid to the strength and corrosion-resistance of the joining of prefabricated sections to avoid failure of the joint. Similarly, leaks can form at joints in prefabricated components. Transportation costs may be higher for voluminous prefabricated sections than for the materials of which they are made, which can often be packed more compactlybe packed more compactly. Large prefabricated sections require heavy-duty cranes and precision measurement and handling to place in position.g p p

- 9. MATERIALSTO BE USED INMATERIALSTO BE USED IN PREFABRICATION SYSTEMPREFABRICATION SYSTEMPREFABRICATION SYSTEMPREFABRICATION SYSTEM Concrete, Steel, Treated wood, Aluminum, Cellular concrete, Light weight concrete elements, Ceramic products, etcp

- 10. COMPONENTS OF PREFABCOMPONENTS OF PREFAB CONSTRUCTIONCONSTRUCTIONCONSTRUCTIONCONSTRUCTION Flooring and Roofing Scheme Beams Columns Walls Staircase Lintels Sunshade/Chajja Projectionsjj j

- 11. PREFABRICATION SYSTEMSPREFABRICATION SYSTEMS The system of prefabricated construction depends on the extent of the use of prefab components, their materials sizes and the technique adopted f h i f d i b ildifor their manufacture and use in building.

- 12. VARIOUS PREFABRICATION SYSTEMSVARIOUS PREFABRICATION SYSTEMS OPEN PREFAB SYSTEM This system is based on the use of the basic structural elements to formy whole or part of a building.The standard prefab concrete components which can be used are:- Reinforced concrete channel units, Hollow core slabs, Hollow blocks and battens, Precast planks and battens, Precast joists and tilesPrecast joists and tiles, Cellular concrete slabs, Prestressed/reinforced concrete slabs, Reinforced/prestressed concrete beams, Reinforced/prestressed concrete columns, Precast lintels and chajjas, Reinforced concrete waffle slabs/shells, Room size reinforced/prestressed concrete panels,Room size reinforced/prestressed concrete panels, Reinforced/prestressed concrete walling elements, and Reinforced/prestressed concrete trusses

- 13. CATEGORIES OF OPEN PREFABCATEGORIES OF OPEN PREFAB SYSTEMSSYSTEMSSYSTEMSSYSTEMS There are two categories of open prefab systems d di h f f b i i d i hdepending on the extent of prefabrication used in the construction as given below: Partial prefab open systemPartial prefab open system Full prefab open system

- 14. PARTIAL PREFAB OPENPARTIAL PREFAB OPEN SYSTEMSYSTEMSYSTEMSYSTEM This system basically emphasizes the use of precast roofing and flooring components and other minor elements likeand flooring components and other minor elements like lintels, chajjas, kitchen sills in conventional building construction.The structural system could be in the form of f k l d b llin-situ framework or load bearing walls.

- 15. FULL PREFAB OPEN SYSTEMFULL PREFAB OPEN SYSTEMFULL PREFAB OPEN SYSTEMFULL PREFAB OPEN SYSTEM In this system almost all the structural components are P f b i d Th fill ll b f b i k hPrefabricated.The filler walls may be of bricks or any other local material.

- 16. LARGE PANEL PREFAB SYSTEM This system is based on the use of large prefab components. The components such as Precast concrete large panels for wallsThe components such as Precast concrete large panels for walls, floors, roofs, balconies, staircase, etc. The casting of the components could be at the site or off the site.

- 17. CLASSIFICATION OF STRUCTURALCLASSIFICATION OF STRUCTURAL SCHEMEWITH PRECAST LARGE PANELSCHEMEWITH PRECAST LARGE PANELSCHEMEWITH PRECAST LARGE PANELSCHEMEWITH PRECAST LARGE PANEL Wall Systems CrossWall System - In this scheme, the cross wall are load bearing walls whereas the facadeWalls are non load bearing this system is suitable for high risenon-load bearing this system is suitable for high rise buildings. Longitudinal Wall System - In this scheme the cross walls are non-load bearing whereas Longitudinal walls are load bearing walls.This system is suitable for low rise buildings.rise buildings. A combination of the above system with all load bearing walls can also be adopted.

- 18. PRECAST FLOORS precast flooring units could be homogeneous or non homogeneous.g Homogeneous floors :- could be solid slabs, cored slabs, ribbed or waffle slabs. N h fl ld b l l d hNon-homogeneous floors :- could be multi-layered ones with combinations of light weight Concrete or reinforced/prestressed concrete, with filler blocks

- 19. STAIRCASE SYSTEMS Staircase system could consist of single flights with in-built risers and treads in the element only.The flights are normally unidirectional transferring the loads to supporting landingg pp g g slabs or load bearing walls.

- 20. BOXTYPE CONSTRUCTION In this system, room size units are prefabricated and erected at site Toilets and kitchen blocks also be similarlyat site.Toilets and kitchen blocks also be similarly prefabricated and erected at site. This system derives its stability and stiffness from the box unit which are formed by the four adjacent walls.Walls are jointed to make rigid connections among themselves.The box unit rests on the plinth foundation which may be of conventionalrests on the plinth foundation which may be of conventional type or precast type.

- 21. JOINTSJOINTSJOINTSJOINTS The joints should be provided in the light of their assessment with respect to the following considerations: Feasibility -The feasibility of joint shall be determined by its loads- carrying capacity in the particular situation in which the joints is to function.function. Practicability -Practicability of joint shall be determined by the amount and type of Material, fabrication and erection and the time for fabrication and erectionfabrication and erection. Serviceability - Serviceability shall be determined by the joints/expected behavior to Repeated or possible overloading and li i h i l di iexposure to climatic or chemical conditions. Fire-Proofing - Appearance -Appearance

- 22. JOINTTECHNIQUES/MATERIALS NORMALLYJOINTTECHNIQUES/MATERIALS NORMALLY EMPLOYED ARE:EMPLOYED ARE: Welding if cleats or projecting steel. Overlapping reinforcement loops and linking steelOverlapping reinforcement, loops and linking steel grouted by concrete. Reinforced concrete ties all round a slabReinforced concrete ties all round a slab. Prestressing. Epoxy groutingEpoxy grouting. Bolts and nuts connection, and A combination of the aboveA combination of the above.

- 23. Components Fixing and Jointing :Components Fixing and Jointing : A h b i b ilt ithA house being built with prefabricated concrete panels The steel formwork for the core wall construction. Prefabricated wall panels being installed in public housing

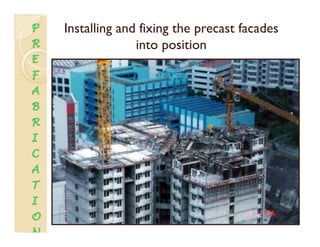

- 24. Installing and fixing the precast facades into positioninto position

- 25. PRECASTING METHODPRECASTING METHODPRECASTING METHODPRECASTING METHOD INDIVIDUAL MOULD METHOD U i ld hi h b il bl d f b dUsing mould which may be easily assembled out of bottom and sides, transportable , if necessary this may be either in timber or in steel using needle or mould vibrations and capable of taking prestressing forcesprestressing forces. Used in – Rib Slab, beams, Girders window panels, box type units and special elements.

- 26. BATTERY FORM METHODBATTERY FORM METHODBATTERY FORM METHODBATTERY FORM METHOD BATTERY FORM METHOD B f h d h i l b dj d i hBattery form method shuttering panels may be adjusted in the form of a battery at the required distances equal to the thickness if the concrete members. U d i I W ll ( P l Sh ll l f dUsed in – InteriorWalls ( Panels, Shell elements, reinforced concrete, battens, rafters , purlines, roof and floor slabs.

- 27. STACK METHODSTACK METHODSTACK METHODSTACK METHOD BATTERY FORM METHOD U d i Fl d R f l b lUsed in – Floor and Roof slabs panels.

- 28. TILTING METHODTILTING METHODTILTING METHODTILTING METHOD BATTERY FORM METHOD U d i M ld i W llUsed in – Mould exteriorWalls.

- 29. LONG LINE PRESTRESSING BEDLONG LINE PRESTRESSING BED METHODMETHOD METHODMETHODMETHODMETHOD METHODMETHOD BATTERY FORM METHOD U d i D bl ib l b li d bUsed in – Double tees, rib slabs, purlines and beams.

- 30. EXTRUSION METHODEXTRUSION METHOD BATTERY FORM METHOD - Long concrete mould with constant cross section and vibration will be done automatically justconstant cross section and vibration will be done automatically just as in concrete roads. Used in – roof slabs, concrete walls, panels and beams.

- 31. LimitationsLimitations of Prefabricationof Prefabrication 1. Small number of units required may prove to be uneconomical. 2. Special connections, such as special bearings to t it th ti l d h i t l l d ddtransmit the vertical and horizontal loads, can add cost to the system. 3 Waterproofing at joints3. Waterproofing at joints. 4. Transportation difficulties. 5. Need for cranes.5. Need for cranes.