Pre-Insulated Pipe Supports - October

- 1. Pre-insulated Pipe Supports PIPING TECHNOLOGY & PRODUCTS, INC. Presents

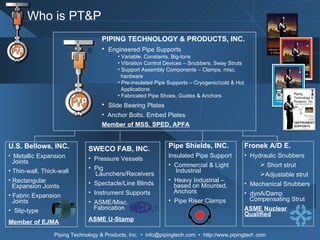

- 2. Pipe Shields, INC. Insulated Pipe Support Commercial & Light Industrial Heavy Industrial – based on Mounted, Anchors Pipe Riser Clamps Fronek A/D E. Hydraulic Snubbers Short strut Adjustable strut Mechanical Snubbers dynA/Damp Compensating Strut ASME Nuclear Qualified SWECO FAB, INC. Pressure Vessels Pig Launchers/Receivers Spectacle/Line Blinds Instrument Supports ASME/Misc. Fabrication ASME U-Stamp U.S. Bellows, INC. Metallic Expansion Joints Thin-wall, Thick-wall Rectangular Expansion Joints Fabric Expansion Joints Slip-type Member of EJMA Who is PT&P PIPING TECHNOLOGY & PRODUCTS, INC. Engineered Pipe Supports Variable, Constants, Big-tons Vibration Control Devices – Snubbers, Sway Struts Support Assembly Components – Clamps, misc. hardware Pre-insulated Pipe Supports – Cryogenic/cold & Hot Applications Fabricated Pipe Shoes, Guides & Anchors Slide Bearing Plates Anchor Bolts, Embed Plates Member of MSS, SPED, APFA

- 3. PT&P Certifications ASME U-Stamp EJMA ASME “R” Stamp Certified ASME NS Certified ISO 9001:2000 Certified Minority Business Enterprise (MBE) by the City of Houston

- 4. Overview Liquefied Natural Gas Liquefied Petroleum Gas Power Plants Polypropylene Plants Polyethylene Plants Steam Water Pipelines For more than 10 years, Piping Technology & Products, Inc. has been a major international supplier of pre-insulated pipe supports for a variety of applications: Chilled Water Pipelines Chemical Plants Nitrogen Production Plants Liquefied Natural Gas (LNG) Pipelines Cogeneration Plants

- 5. Manufacturing Facility - Foam Shop > 100,000 lb. raw materials in stock

- 6. Manufacturing Facility - Cold Shoe Assembly Line insulated supports assembly area

- 7. Manufacturing Facility - Shipping Area

- 8. Manufacturing Facility - Stock Inventory Stock inventory for standard items

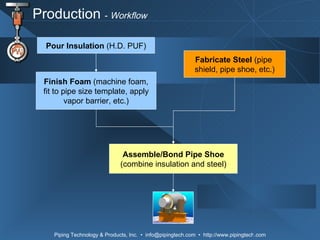

- 9. Production - Workflow Pour Insulation (H.D. PUF) Finish Foam (machine foam, fit to pipe size template, apply vapor barrier, etc.) Fabricate Steel (pipe shield, pipe shoe, etc.) Assemble/Bond Pipe Shoe (combine insulation and steel)

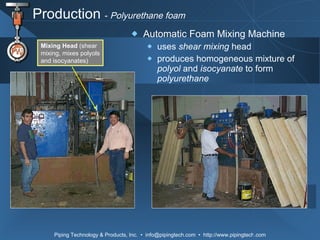

- 10. Production - Polyurethane foam Automatic Foam Mixing Machine uses shear mixing head produces homogeneous mixture of polyol and isocyanate to form polyurethane Mixing Head (shear mixing, mixes polyols and isocyanates)

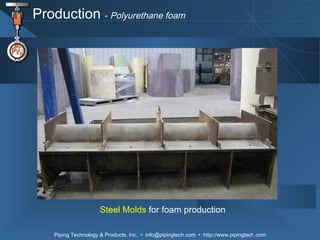

- 11. Production - Polyurethane foam Steel Molds for foam production

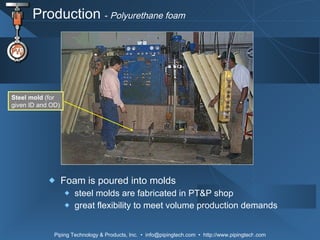

- 12. Production - Polyurethane foam Foam is poured into molds steel molds are fabricated in PT&P shop great flexibility to meet volume production demands Steel mold (for given ID and OD)

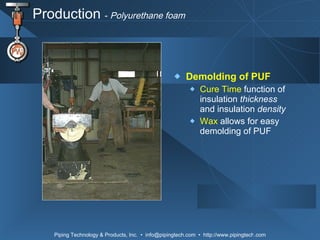

- 13. Production - Polyurethane foam Demolding of PUF Cure Time function of insulation thickness and insulation density Wax allows for easy demolding of PUF

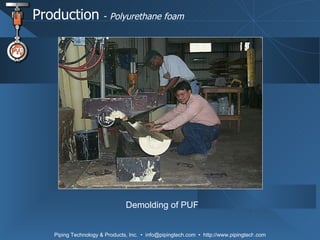

- 14. Production - Polyurethane foam Demolding of PUF

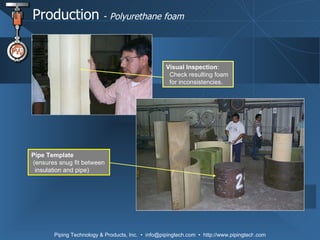

- 15. Production - Polyurethane foam Pipe Template (ensures snug fit between insulation and pipe) Visual Inspection : Check resulting foam for inconsistencies.

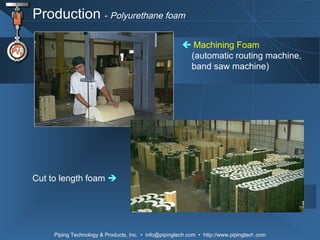

- 16. Production - Polyurethane foam Machining Foam (automatic routing machine, band saw machine) Cut to length foam

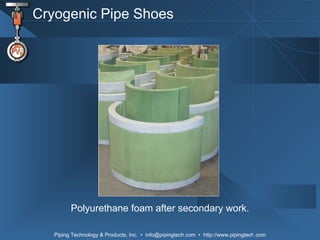

- 17. Cryogenic Pipe Shoes Polyurethane foam after secondary work.

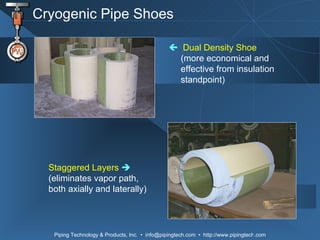

- 18. Cryogenic Pipe Shoes Dual Density Shoe (more economical and effective from insulation standpoint) Staggered Layers (eliminates vapor path, both axially and laterally)

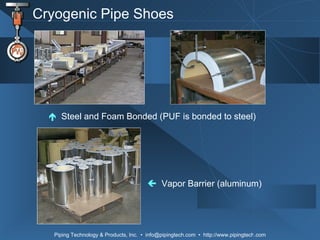

- 19. Cryogenic Pipe Shoes Steel and Foam Bonded (PUF is bonded to steel) Vapor Barrier (aluminum)

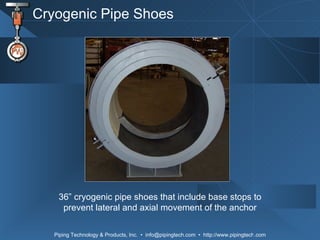

- 20. Cryogenic Pipe Shoes 36” cryogenic pipe shoes that include base stops to prevent lateral and axial movement of the anchor

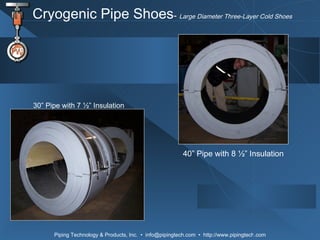

- 21. Cryogenic Pipe Shoes - Large Diameter Three-Layer Cold Shoes 30” Pipe with 7 ½” Insulation 40” Pipe with 8 ½” Insulation

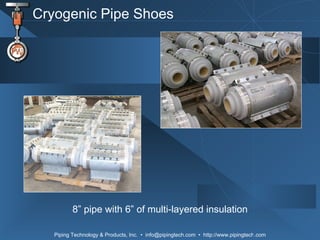

- 22. Cryogenic Pipe Shoes 8” pipe with 6” of multi-layered insulation

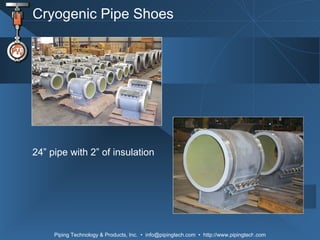

- 23. Cryogenic Pipe Shoes 24” pipe with 2” of insulation

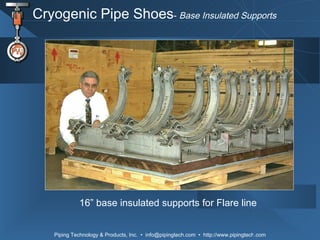

- 24. Cryogenic Pipe Shoes - Base Insulated Supports 16” base insulated supports for Flare line

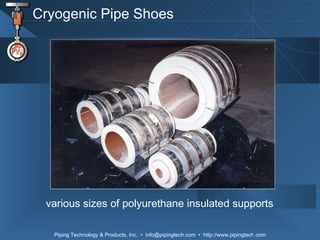

- 25. Cryogenic Pipe Shoes various sizes of polyurethane insulated supports

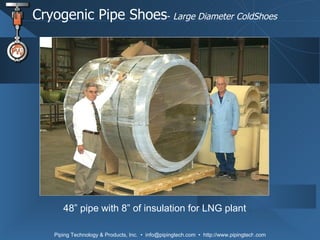

- 26. Cryogenic Pipe Shoes - Large Diameter ColdShoes 48” pipe with 8” of insulation for LNG plant

- 27. Hot Shoe Hot Shoe Designed for 84” Pipe

- 28. Hot Shoes Custom Designed Hot Shoes

- 29. Cryogenic Experience Elba Island Project Cove Point Maryland Project Chevron Sadaf Westlake Quantum Chemical ALNG - Port Lisas, Trinidad & Tobago Sonatrach - Algeria Oxymar - Texas Petroquimica Bahia Blanca - Argentina Exxon Baytown Refinery Navacar - Alabama Hassi Messaoud LPG Recovery Project PSC II - Singapore Maraven BASF Exxon Singapore Olefins Project (SOP) Texaco - Syngas Exxon Baton Rouge Polyproplyne (BRPO) HCJV - Pertamina - Train H - LNG Expansion Project Maraven Texaco Sonatrach Pequiven Amoco Chemical

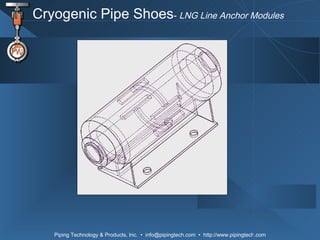

- 30. Cryogenic Pipe Shoes - LNG Line Anchor Modules

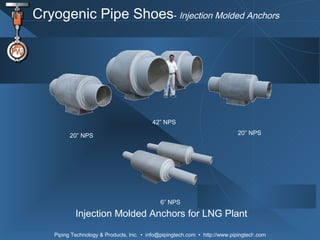

- 31. Cryogenic Pipe Shoes - Injection Molded Anchors Injection Molded Anchors for LNG Plant 20” NPS 42” NPS 20” NPS 6” NPS

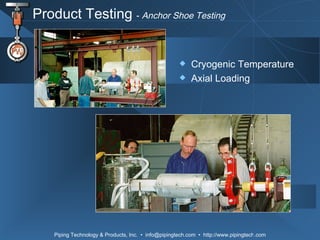

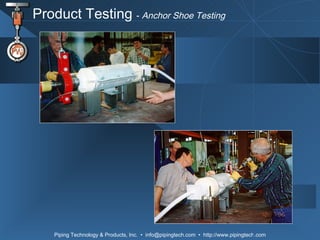

- 32. Product Testing - Anchor Shoe Testing Cryogenic Temperature Axial Loading

- 33. Product Testing - Anchor Shoe Testing

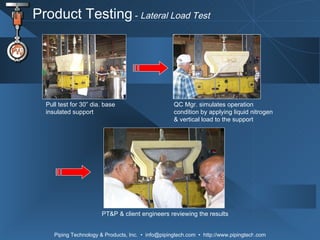

- 34. Product Testing - Lateral Load Test Pull test for 30” dia. base insulated support QC Mgr. simulates operation condition by applying liquid nitrogen & vertical load to the support PT&P & client engineers reviewing the results

- 35. Product Testing - Compressive Strength Testing Compressive Strength Test

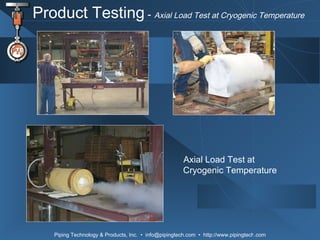

- 36. Product Testing - Axial Load Test at Cryogenic Temperature Axial Load Test at Cryogenic Temperature

- 37. Product Testing Axial Load to determine max. force using Bellville Washer

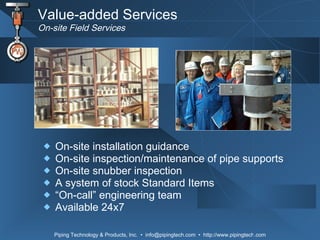

- 38. Value-added Services On-site Field Services On-site installation guidance On-site inspection/maintenance of pipe supports On-site snubber inspection A system of stock Standard Items “ On-call” engineering team Available 24x7

- 39. Value-added Services Web-based Emergency Services PT&P’s “On-call” engineering team guarantees a response time of 30 minutes

- 40. Conclusion Pre-Insulated Supports serve in a variety of applications including LNG pipelines, power plants, nitrogen production plants, and chilled water pipelines PT&P has over 100,000 lb. of raw material in stock Our field service team is available to inspect current pipe supports for repair/replacement or determine where they need to be installed in your piping system

- 41. Thank You for joining PT&P’s Pre-Insulated Pipe Supports Webinar Please forward any additional questions or inquiries to us at info@pipingtech.com or visit our website at www.pipingtech.com

Editor's Notes

- Kellogg Brown & Root