Presentation @germany

- 1. Clean Cookstove Sustainability for Indonesia Team 16 Biokraftstoffe

- 2. Menu of The Day Background Biokraftstoffe Project Key Partner Business Model CPO chain Project detail Customer Acquisition & Retention Organization Structure Financial Projection

- 3. Background

- 4. Biokraftstoffe Project BSH Home Appliances BioFuel Stove Reduce Used Oil User Fast Food Restaurant Green Company

- 5. Key Partners Used Oil CPO Company Suppliers Charity Program: 1 euro cent from the first 7.5 million BSH unit sold in Europe Astra Agro Lestari has the largest from non cash transaction planted CPO area in Indonesia. Approximately 125,000 ha Used oil will be provided by modern and traditional food chain and food processing companya (398 KFC and 120 MCD nation wide)

- 6. Business Model Cost Structure Revenue Stream 1. Stove manufacturing cost 1. Partnership program 2. Cookstove price subsidy 2. Cookstove , used oil and preheating 3. Operational cost material sales 4. CDM registration and audit fee 3. VER Credits

- 7. CPO Chain with total production 2.160.000 ton CPO/year, this company indirectly responsible for used oil as the waste of CPO Usage

- 8. B/S/H/ Europe Charity Program + 1 cent Euro = 2,579 Free Unit Protos/year Reduce 2,776 ton CO2/year for Indonesia or Plant 102,460 trees/year

- 9. Project Location Majalengka, West Java Large Area: 1.204.24 km2 divided into 23 districts. Education Background Total Populations: 1.153.442 Uneducated Considerations: 6% 1% 9% 1. Poorly educated (See diagram) Elementary 32% School 2. Low economic level Junior High (20 percent of 12 million poor people in West 52% School Java, located in this rural areas) Senior High 3. High unemployment (7.83% of total labor force) School D3/S1

- 10. CDM AMS-II.G Project Scenario Drop 8,000 Protos in 5 years Revenue and Cost from CDM AMS-II.G 150000 Baseline Emission 139,071 Number of Scenario Reduction 125000 Protos (tCO2/year) (tCO2/year) 100000 98,814 in € (Euro) Year 1 4,416 1,600 1,722 Revenue Year 2 4,968 3,400 3,660 75000 75,000 Year 3 5,520 5,400 5,813 62,216 50000 CDM Fee (Initial Year 4 6,072 7,600 8,181 and Annual) Year 5 6,624 10,000 10,764 25000 29,278 0 0 13,514 13,514 13,514 13,514 13,514 0 1 2 3 4 5 Year

- 11. Customer Acquisition Educate Partisipants in Monthly Arisan Offer Partisipants to Fill out Application Form Verification (Survey and Interview) Promote/ Offer Protos to Users Sentra Gorengan Merchants Households Ex Users of Gas Stove Ex Users of Kerosene Stove Existing Users of Wood-fire stove

- 12. Restaurant Fast Food CDM AMS-I.H Project Scenario Filtering process Coloring process Storage Distribution Used oil Hotels Food stall Revenue and Cost from CDM AMS-I.H 80,000 75,000 67,932 60,000 51,628 in € (Euro) Revenue Baseline Emission 40,000 36,683 Number of Scenario Reduction Fee (Initial and Protos annual) (tCO2/year) (tCO2/year) 20,000 23,097 Year 1 710 1,600 639 13,514 Year 2 1,510 3,400 1,359 13,514 13,514 13,514 13,514 Year 3 2,398 5,400 2,158 0 0 0 0 1 2 3 4 5 Year 4 3,374 7,600 3,037 Year Year 5 4,440 10,000 3,996

- 13. Used Oil Source Purchase Price for Suppliers Rp. 1,800/ Litre KFC Fast Food Chain Sentra Gorengan Majalengka 398 stores national wide 1000 L/day 239 stores Java only 180,000 L/year Oil Supply 24 targetted store 9,000 L/year/store 214,290 L/year oil supply

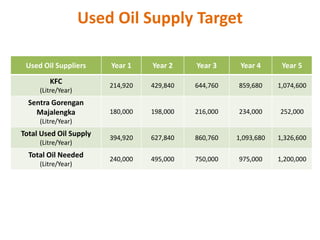

- 14. Used Oil Supply Target Used Oil Suppliers Year 1 Year 2 Year 3 Year 4 Year 5 KFC 214,920 429,840 644,760 859,680 1,074,600 (Litre/Year) Sentra Gorengan Majalengka 180,000 198,000 216,000 234,000 252,000 (Litre/Year) Total Used Oil Supply 394,920 627,840 860,760 1,093,680 1,326,600 (Litre/Year) Total Oil Needed 240,000 495,000 750,000 975,000 1,200,000 (Litre/Year)

- 15. CDM Project Timeline Project Year 0 Year 1 Year 2 Year 3 Year 4 Year 5 AMS ii-G Proposal & CER CER CER CER CER Approval Claim Claim Claim Claim Claim AMS I-H - Proposal & CER CER CER CER Approval Claim Claim Claim Claim

- 16. CDM Project Summary CDM Revenue and Cost 300,000 250,000 250,920 200,000 in € (Euro) 190,699 Total Revenue 150,000 135,497 from CDM 100,000 75,000 75,000 CDM Cost 85,313 50,000 29,278 0 0 27,027 27,027 27,027 27,027 0 1 2 3 4 5 Year Annual Revenue from CDM Covering Cost Gap for (based on 3rd year projection) = 2,579 Unit Protos/year note: Protos price is free

- 17. Modern and traditional Supply Chain food chain Used oil Protos, oil & preheating material Biokraftstoffe Household Team Small business Preheating material

- 18. Customer Retention Protos Food Bazaar Protos Cooking Competition Protos Membership Card Protos After Sales Service

- 19. Training and Event Materials Benefits of How to get How to Use Requirement Using Protos Used Oil and Protos to Get Protos Cookstove spiritus Protos Protos Protos Protos Ambassador Membership Cooking Cooking Awards Program Competition Bazaar

- 20. Pricing Strategy Item Sold 1st year 2nd year 3rd year 4th year 5th year Distribution of Protos 1,600 1,700 1,700 1,500 1,500 Cookstove per unit Price of Protos Rp. 49,000 Rp. 49,000 Rp. 49,000 Rp. 49,000 Rp. 49,000 Cookstove per Unit Price of Used Oil per Litre Rp. 4,000 Rp. 4,268 Rp. 4,554 Rp. 4,859 Rp. 5,185 Price of Spiritus per Litre Rp. 9,000 Rp. 9,603 Rp. 10,246 Rp. 10,933 Rp. 11,665

- 21. Financial Projection Revenue and EBIT 950,000 750,000 € (Euro) 550,000 350,000 150,000 (50,000) Year 1 Year 2 Year 3 Year 4 Year 5 Revenue 177,626 349,471 572,883 841,575 1,161,502 EBIT (24,467) 18,116 89,152 184,674 297,634 Break Event Point 16,000,000,000 14,000,000,000 12,000,000,000 5 years project: 10,000,000,000 NPV = € 248,365 Rp 8,000,000,000 Revenue Total Cost 6,000,000,000 IRR = 50 % 4,000,000,000 BEP = Q2 year 2 2,000,000,000 0 0 0.25 0.5 0.75 1 1.25 1.5 1.75 2 2.25 2.5 2.75 3 3.25 3.5 3.75 4 4.25 4.5 4.75 5 Years

- 22. Conclusion The project will be runned by Biokraftstoffe Team based on Partnership with BSH, Astra Agro Lestari and Oil Suppliers All activities are under consideration of CDM AMS-II.G and CDM AMS-I.H Implementation. 3 Main Projects : 1. Distribute 10.000 unit protos in 5 years in Majalengka, West Java; 2. Provide and Guarantee Supply of used oil as fuel; 3. Provide Supply of spiritus as preheating materials. By 5 years projection, We believe to see result: NPV: Positive; IRR for 50 %; BEP: Q2 Years 2

- 23. Reference Power Point, Pdf and Excel CDM_Methodology_Booklet 2010.pdf Indocement-Experience-in-the-Plantation-of-Jatropha-Curcas by Kuky Permana, HR Manager of Indocement.pdf Shell Sustainability Report 2010.pdf Bogor Agricultural University - Masa Depan Pengembangan Jarak Pagar di Indonesia.pdf EB51_repan18_AMS-II.G_ver02.pdf EB55_repan28_AMS-I.G_ver01.pdf EB55_repan29_AMS-I.H_ver01.pdf Photos Credits www.slideshare.net Business Plan Prase1.pdf www.flickr.com Protos BP Competition 8 Mar '11.pdf www.istockphoto.com Protos Case Study.pdf powerpointcookbook-090809173153-phpapp01 transport-carbon-footprint-calculator.xls Websites CO2-calculator-EFN.xls http://cdm.unfccc.int/ http://www.carbonindependent.org/sources_home_ energy.htm All images are used under “fair use” and obtained from the public domain. They are the property of the respective copyright holders