Presentation on the_entire_laundry (1)

- 1. -BY LOVELY SINGH BATCH:- SY“C” ROLL NO.:- 71 PADMASHREE Dr D Y Patil University DHTS , Nerul Navi-Mumbai

- 2. The ‘Laundry’ can be defined as a place where the washing & finishing of clothes are carried out.

- 4. COMMERCIAL LAUNDRIES These are also known as off site laundry or contracted laundries. These cater to hotel on a contract basis. Usually the soiled linen are laundered & delivered back to the hotel within 24-48 hours.

- 5. ON-PREMISES LAUNDARIES (OPL) These are also known as on-site laundry or in-house laundry. It is the hotel’s own laundry situated on its premises. It may be run by the management or managed on a contract. Services are faster (maximum of 8 hours), hence the stocks are reduced. There is better control, better supervisor, and hence a long life for linen.

- 6. PLANNING AN OPL Location Size Ventilation Equipment selection Labour Other cost

- 7. LAYOUT OF AN OPL Chemical room WM 1 WM 2 D1 D2 Wor Calen sink Soiled - daring linen area king tabl machi e ne Dry cleaning machine Laundry manager Steam Flat bed room iron iron Shelves

- 8. LAUNDRY EQUIPMENTS Washing machine Washer-cum-extracting machine Dry cleaning tumbler/ drying machine Flat bed pressure Steam iron Calendaring machine linen trolleys Working table Hampers

- 10. LAUNDRY PROCESS

- 11. 1.PRE-WASHING È The soiled linen are collected from all the departments of the Hotel like F&B, Kitchen, Banquets, etc. & The soiled linen are then transported to the laundry in two ways, first is, the soiled linen are put in the trolley and are then taken to the laundry via elevators and the second way is that the soiled linen are dumped into the linen chute which is directly connected to the laundry. i The soiled linen are then sorted on three basis i.e. by the type of fabric, color of the fabric, and degree of soiling. c After sorting the soiled linen, the linen are weighed according to the washing machine capacity and are put into the washing machine for wash cycle.

- 12. 2.WASHING The washing depends on 4 things which varies as per the fabric:- Fabric temperature Water level Time Less soiled Low Less less More soiled high more More

- 13. This is done by using hot and cold water, which are usually recovered 7 recycled from earlier steps during the last rinse in order to save water.

- 14. Hydro means water & extraction to remove. Extraction removes at least 80% of the water from the linen used in the rinsing process. It also reduces the drying time.

- 15. 5.FINISHING

- 17. WASH CYCLE

- 18. In this process, the washing machine automatically sucks the high level of water in which the soiled linen are added at medium temperature to reduce the soil load for the upcoming suds flushes.

- 19. In this stage, the high alkaline product is added, which may be followed by additional flushes. The break cycle is usually carried out at a medium temperature and low water level.

- 20. This is the actual wash cycle in which acid part of the hoppers is sucked by the machine. It takes place in hot water at low water level.

- 21. This rinse cycle removes soils and alkaline to help the bleach work more effectively later. In this process 50-60% water is removed from the linen.

- 22. In this stage, the washing machine sucks the bleach automatically from the hoppers in the hot water at a low water level. Bleach kills bacteria, whitens fabrics and removes stains.

- 23. The washing machine sucks the high level of water and remove detergent and soils from the linen.

- 24. This high speed spin removes left over detergent and soil from the linen, usually after the first rinse step. It removes 70% of water from the linen. The washing machine spins at 200 RPM.

- 25. Softener and sours are added to condition fabric. This cycle is run at a medium temperature and at low water level. Starches are added to stiffen cotton fabrics. Sizing may also replace the sour/softener step.

- 26. A high speed spin removes most of the moisture from the linen. The length of the spin depends on the fabric type, extractor capacity, and extractor spend. Around 95% of water is removed in this stage.

- 27. WASH CYCLE TABLE Sr. Stage Water Temperature Time No. Level 1 flush High Medium 1½-3 min 2 Breaks Low Medium 4-5 min 3 Suds Low High 3-8 min 4 Intermediate-Rinse Less Less 1-2 min 5 Bleach Less High 5-7 min 6 Rinse High Medium 2-8 min 7 Intermediate-Extraction Less Medium 5 min 8 Softener/Sizing Less Medium 2-8 min 9 Final Extraction - - 8 min

- 29. DRY CLEANING This is the cleaning of fabrics in substantially non-aqueous liquid medium. Dry cleaning removes oils as well as many water soluble & some insoluble materials with the help of detergents & various other agents. It is done by using dry powder, liquid such as petrol, benzene, & so on. Unlike laundry, dry cleaning does not cause swelling of the fibers, & so does not lead to shrinkage , wrinkle, & bleeding of color of the fabric and thus it is a safe method for cleaning delicate textiles. It was earlier known as ‘French Cleaning’ or ‘Chemical Cleaning’.

- 30. ADVANTAGES OF DRY CLEANING Dry cleaning cleans clothes for which laundering is not suitable. It causes no shrinkage to the fabric. It does not flatten the pile of fabrics such as velvet. Finishes such as moireing are retained even after dry- cleaning. Colors do not bleed on dry-cleaning. Stains are more readily removed by dry-cleaning.

- 31. DISADVANTAGES OF DRY- CLEANING Dry-cleaning is expansive as compare to the laundering. Many dry-cleaning solvents are harmful to health if inhaled for long duration. After cleaning with solvents, a certain unpleasant smell tends to be retained by the articles.

- 33. When soiled linen garments are delivered for dry- cleaning, they are first sent to the marking areas. Here, a piece of white fabric with a number or some other code stamped on it with indelible marking ink is securely attached to the garments. Every article is marked individually to facilitate identification.

- 34. The garments then pass on to the sorting areas.it is done on the basis of soil level,colour and in this case the fabric/cloth pouches are checked for the valuables of the guests.

- 35. Absorbents are applied to remove grease spots from all kind of materials like french chalk,bran or flour etc/

- 36. Heavily soiled areas of the garments are treated with solvents. Volatile dry solvents such as amyl acetate to remove oil-borne stains, while non-volatile solvents are used on paint and varnish stains.

- 37. A load of approximately 45kg is transferred to the dry- cleaning cylinder. Very delicate cloths are placed in a net bags first. An appropriate solvent is circulated through the clothes.

- 38. Excess solvent is removed from the garments by centrafugal action in a revolving perforated cylinder contained in a tumbler.

- 39. After extraction, the garments are dried in a dryer that has a perforated drum enclosed in a tumbler.The temperature for the same should not exceed 70 degree as otherwise it may catch fire.

- 40. Solvents are expensive and therefore filtered out, distilled, and reused, they are not allowed to evaporate after use. But used in recycled manner

- 41. Dried garments are inspected to check that they are perfectly clean. If necessary, they are spot-cleaned a second time.

- 42. In this process, the garments are restored as nearly as possible to its original size, shape, feel, and appearance.

- 43. Buttons and buckles that had been removed are stitched back on. Finally the garments are packed in a paper or suspended from clothes hangers covered with polythene bags. They are now ready for delivery

- 44. DRY-CLEANING MATERIALS 1. Dry-cleaning detergents 2. Absorbents 3. Solvents 4. Petroleum solvents/Stoddard solvent 5. Halogenated hydrocarbons

- 46. A stain is a spot or localized discolouration left on fabric by reaction of a foreign substance or absorption or adsorption of any unwanted colour,liquid etc

- 47. Stain removal or spot cleaning is a skill that demands special attraction, special techniques, and long experience.

- 48. TYPES OF STAINS Animal stains Vegetable stains Grease Mineral stains Metalloid stains Acidic stains Basic/alkaline stains Natural dyes & pigments Synthetic dyes &pigments Sugar solution with colouring matter miscellaneous

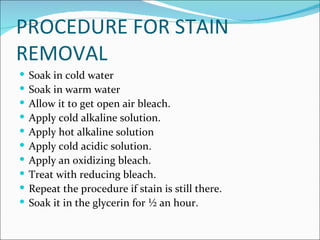

- 50. PROCEDURE FOR STAIN REMOVAL Soak in cold water Soak in warm water Allow it to get open air bleach. Apply cold alkaline solution. Apply hot alkaline solution Apply cold acidic solution. Apply an oxidizing bleach. Treat with reducing bleach. Repeat the procedure if stain is still there. Soak it in the glycerin for ½ an hour.

- 51. VALET SERVICE It is the service given by housekeeping to guests in which the guest clothes are taken and returned back from the room. It is chargeable service.

- 52. Guest Laundry list Valet/GRA Marking/tagging Examining & sorting Tailor Wet cleaning Dry-cleaning Pressing Sorting according to room numbers Pressing Valet/GRA Bill sent to front office Guest