project ppt

- 1. SHIVAJIRAO S. JONDHALE COLLEGE OF ENGINEERING DOMBIVLI(E) DESIGN AND ANALYSIS OF LEADSCREW Presented by : 1. Madhushri Bardhan 2. Siddhesh Sawant 3. Sanket Chakke 4. Harshad Narvekar Guided by : Prof. A.D. Dhale

- 2. CONTENTS Objective Literature Review Introduction to Leadscrew Terminology of Leadscrew Application of Leadscrew Screw Jack Design of Leadscrew Introduction to PRO/E Modelling of Leadscrew using PRO/E Introduction to ANSYS Static Analysis Static Structural Analysis of Leadscrew Conclusion

- 3. OBJECTIVE • The primary objective of our Project is the design of Leadscrew based on the forces and the stresses developed in the component. • Analysis of the component for various forces. • Check for failures that may occur due to application of a particular force. • The design of the component to be achieved using PRO/E. • Analyse the component using ANSYS linked with PRO/E.

- 4. LITERATURE REVIEW • The design of automotive or industrial power screw jack involves many interrelated parameters. • It is necessary to understand this interrelationship and the constraints involved to obtain the optimum design of power screw jack. • Thus, Optimization play a key role in field of engineering application. • In our work powerscrew is machine component is to be optimized using the Graphical & Analysis software.

- 5. • It is essential to determine stresses in local areas and other areas using three dimensional, symmetric and axisymmetric models, the preliminary conclusion is that finite element analysis is an extremely powerful tool for design and optimization of power screw. • Depending on the desired solutions, there are different methods that offer faster run times and less error. • The recommended methods included symmetric models using shell elements and axisymmetric models using solid elements.

- 6. • Design optimization of power screw concerns with the idea to get optimized design dimensions of power screw to minimize weight under given set of constraint by taking pitch & mean diameter of as design variables and screw should be self locking assume coeffient of friction between screw and nut is 0.16, screw is safe in buckling, Permissible stress should be less than or equal to yield strength/FOS, screw should be safe in shear failure as design constraints. Further the verification of optimized graphical solution for minimum weight is compared with Analysis software.

- 7. INTRODUCTION TO LEADSCREW • A Leadscrew also known as a power screw or translation screw is a screw designed to translate turning motion into linear motion. • Power screws are classified by the geometry of their threads. • Various types of Leadscrew threads are: i. Square thread ii. Acme thread iii. Buttress thread

- 8. • Advantages of using a Leadscrew are: i. Large load carrying capability. ii. Compact, simple to design and easy to manufacture. iii. Minimal number of parts. iv. Smooth, quiet and low maintenance. • Disadvantages of using a Leadscrew are: i. They are not very efficient. ii. They have high degree of friction on threads resulting in quicker wear out of threads.

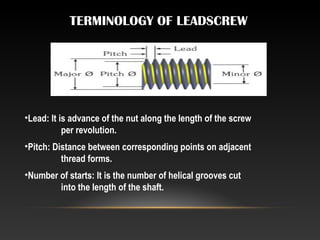

- 9. TERMINOLOGY OF LEADSCREW •Lead: It is advance of the nut along the length of the screw per revolution. •Pitch: Distance between corresponding points on adjacent thread forms. •Number of starts: It is the number of helical grooves cut into the length of the shaft.

- 10. • Pitch diameter: It is the diameter at which each pitch is equally divided between the mating male and female threads. • Major diameter: It is the largest diameter over the threaded section. • Minor diameter: It is the smallest diameter over the threaded section.

- 11. APPLICATION OF LEADSCREW • Engraving equipment • Medical equipment • Semiconductor manufacturing equipment • Laboratory equipment • Lathe machine • Screw jack

- 12. SCREW JACK

- 13. • A screw jack is a portable device consisting of a screw mechanism used to raise or lower the load. • There are two types of jacks viz. Hydraulic and Mechanical. • The rotation of the nut inside the frame is prevented by pressing a setscrew against it. • The screw is rotated in the nut by means of a handle which passes through a hole in the head of the screw. • The screw is subjected to torsional moment, compressive force and bending moment.

- 14. DESIGN OF LEADSCREW Theoretical design Calculations •Type of Application: Screw Jack for Automobile •Type of Screw Jack: Mechanical(Hand operated) •Load: 3 tonnes(3000kg) •Material: Plain Carbon Steel (C-10)

- 15. Dimensions: •Type of thread: Square thread •Number of Starts: Single start •Pitch: 7mm •Pitch diameter: 36mm •Major Diameter: 40mm •Minor diameter: 32mm •Length of Screw: 300mm •Helix angle: 3.5o

- 16. INTRODUCTION TO PRO-ENGINEER The power to quickly deliver the highest quality, most accurate digital models – that’s what Pro/ENGINEER is all about. As the primary design offering within PTC’s Product Development System, Pro/ENGINEER details the form, fit and function of products. With its seamless Web connectivity, product teams have access to the resources, information, and capabilities they need – from conceptual design to tooling development and machining. And, with Pro/ENGINEER, high-fidelity digital models have full associativity, so that product changes made anywhere can update deliverables everywhere. That’s what it takes to achieve the digital product confidence needed before investing significant capital in sourcing, manufacturing capacity, and volume production.

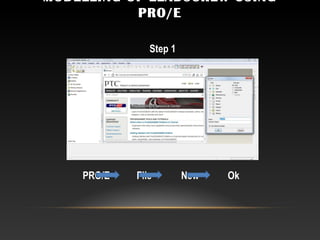

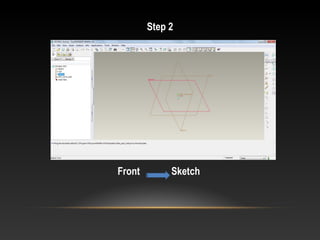

- 17. MODELLING OF LEADSCREW USING PRO/E Step 1 PRO/E File New Ok

- 19. Step 3 Circle Extrude Done

- 20. Step 4: Insert Helical sweep Cut Done Ok Default

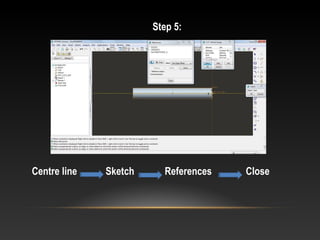

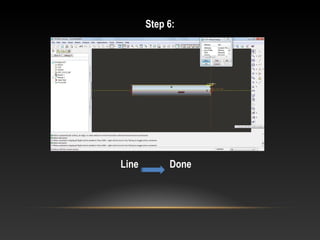

- 21. Step 5: Centre line Sketch References Close

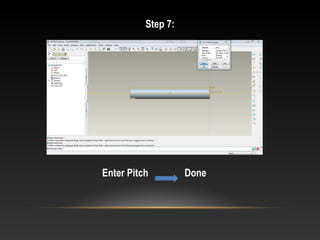

- 23. Step 7: Enter Pitch Done

- 24. Step 8: Rectangle Done Ok Preview Ok

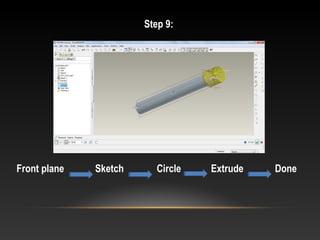

- 25. Step 9: Front plane Sketch Circle Extrude Done

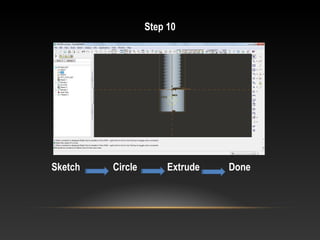

- 26. Step 10 Sketch Circle Extrude Done

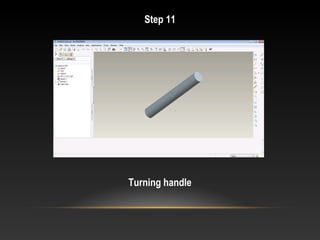

- 28. FINAL MODEL

- 29. INTRODUCTION TO ANSYS At ANSYS, we bring clarity and insight to customers' most complex design challenges through fast, accurate and reliable simulation. Our technology enables organizations to predict with confidence that their products will thrive in the real world. They trust our software to help ensure product integrity and drive business success through innovation.Every product is a promise to live up to and surpass expectations. By simulating early and often with ANSYS software, our customers become faster, more cost-effective and more innovative, realizing their own product promises

- 30. STATIC ANALYSIS • A static analysis calculates the effects of steady loading conditions on a structure, while ignoring inertia and damping effects, such as those caused by time-varying loads. A static analysis can, however, include steady inertia loads (such as gravity and rotational velocity), and time-varying loads that can be approximated as static equivalent loads (such as the static equivalent wind and seismic loads commonly defined in many building codes ). • Static analysis determines the displacements, stresses, strains, and forces in structures or components caused by loads that do not induce significant inertia and damping effects. Steady loading and response conditions are assumed; that is, the loads and the structure’s response are assumed to vary slowly with respect to time.

- 31. The types of loading that can be applied in a static analysis include: • Externally applied forces and pressures • Steady-state inertial forces (such as gravity or rotational velocity) • Imposed (nonzero) displacements • Temperatures (for thermal strain) • Fluences (for nuclear swelling)

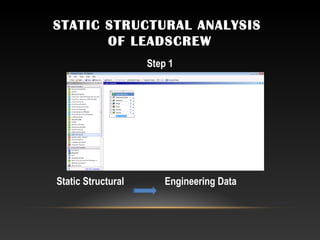

- 32. STATIC STRUCTURAL ANALYSIS OF LEADSCREW Step 1 Static Structural Engineering Data

- 34. Step 3 File Import an External File Generate

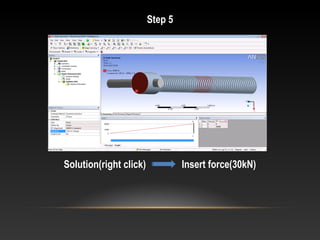

- 36. Step 5 Solution(right click) Insert force(30kN)

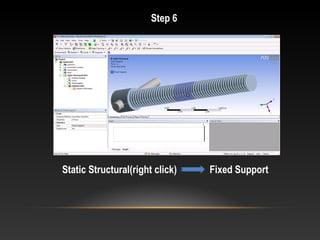

- 37. Step 6 Static Structural(right click) Fixed Support

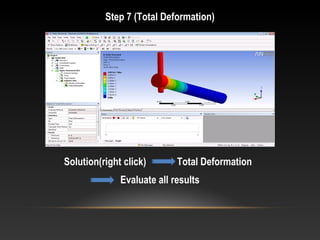

- 38. Step 7 (Total Deformation) Solution(right click) Total Deformation Evaluate all results

- 40. Results of Total Deformation Force: 30kN Maximum: 5.75e-7 metre Minimum: 0 Force: 25kN Maximum: 4.796e-7 metre Minimum: 0 Force: 20kN Maximum: 3.83e-7 metre Minimum: 0

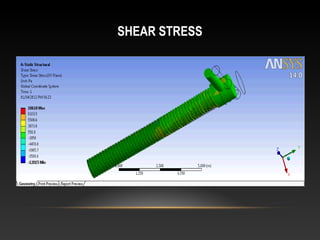

- 41. Step 8 (Shear Stress) Solution(right click) Shear Stress Evaluate all results

- 42. SHEAR STRESS

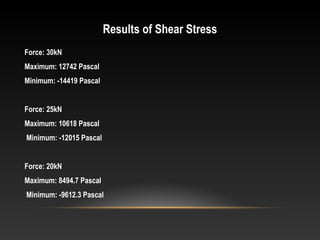

- 43. Results of Shear Stress Force: 30kN Maximum: 12742 Pascal Minimum: -14419 Pascal Force: 25kN Maximum: 10618 Pascal Minimum: -12015 Pascal Force: 20kN Maximum: 8494.7 Pascal Minimum: -9612.3 Pascal

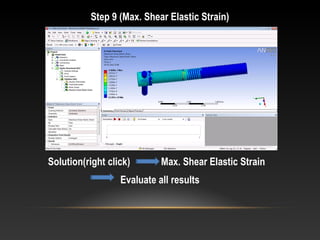

- 44. Step 9 (Max. Shear Elastic Strain) Solution(right click) Max. Shear Elastic Strain Evaluate all results

- 45. MAXIMUM SHEAR ELASTIC STRAIN

- 46. Results of Maximum Shear Elastic Strain Force: 30kN Maximum: 2.59e-7 Minimum: 6.53e-17 Force: 25kN Maximum: 2.15e-7 Minimum: 5.44e-17 Force: 20kN Maximum: 1.72e-7 Minimum: 4.35e-17

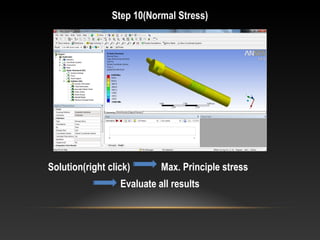

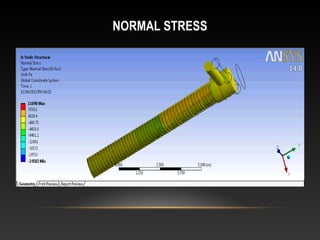

- 47. Step 10(Normal Stress) Solution(right click) Max. Principle stress Evaluate all results

- 48. NORMAL STRESS

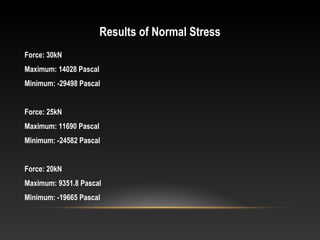

- 49. Results of Normal Stress Force: 30kN Maximum: 14028 Pascal Minimum: -29498 Pascal Force: 25kN Maximum: 11690 Pascal Minimum: -24582 Pascal Force: 20kN Maximum: 9351.8 Pascal Minimum: -19665 Pascal

- 50. Step 11 (Max. Principle stress) Solution(right click) Max. Principle stress Evaluate all results

- 52. Results of Maximum Principal Stress Force: 30kN Maximum: 18307 Pascal Minimum: -19718 Pascal Force: 25kN Maximum: 15256 Pascal Minimum: -16432 Pascal Force: 20kN Maximum: 12205 Pascal Minimum: -13145 Pascal

- 53. CONCLUSION • Thus we have successfully prepared the model of the component ‘Leadscrew’ in PRO/E. • The component has been imported in ANSYS and analysed for various stresses. • The component does not fail for the applied force. • The component shows satisfactorily results for reduced values of Forces.

- 54. Thank You