Reactive dye and disperse dye

- 1. Reactive Dye and Disperse Dye

- 2. Prepared By : Mazadul Hasan sheshir ID: 2010000400008 13th Batch (session 2009-2013) Department : Wet Processing Technology Email: mazadulhasan@yahoo.com Blog : www. Textilelab.blogspot.com (visit) Southeast University Department Of Textile Engineering I/A 251,252 Tejgaon Dhaka Bangladesh Prepared By :

- 7. 7 Chronology of Dye Companies ICI Zeneca BASF Mobay Miles Bayer Hoechst DyStar Sandoz Sodyeco Sandoz Clariant Ciba + Geigy Ciba-Geigy Ciba Crompton and Knowles Yorkshire Sumitomo DyStar

- 8. 8 Dyes Dyeing Condition (pH) Acid (Wool) 2-4, 4-6, 6-8 (depends on types of dyes) Acid (Nylon) 4.5-5.5, 6-7 (depends on types of dyes) Basic 3.5-4 Direct 7.0 Disperse (Polyester) 5-6 Disperse (Acetate) 6.5-7.0 Disperse (Triacetate) 4.5-6.5 Reactive 7.0 (Exhaustion) 11.0 (Fixing) -------------------------

- 9. 9 Textile Auxilaries 1. Salt - reduce negative charges on the fibers 2. Water - dyeing media 3. Soda Ash - excite the dye to link with the fibers with covalent bonding. Therefore, it enhances wet fastness 4. Fixing Agent - enhance wet fastness for heavy shade but usually reduce light fastness.

- 10. 10 Textile Auxiliaries 1. Leveling agent - for levelness dyeing 2. Retarding agent - for inhibiting the dye not attach to fibers too fast 3. Acid - adjust the dyeing condition and make the fibers to show negative charges 4. Water - dyeing media

- 11. 2004 Introduction to Coloration & Finishing 11

- 12. Reactive Dyes water-soluble compounds give excellent wet-fastness easy to hydrolized Enough simple dyeing proses Choice of more complete available colour Good colour resilience General Properties of Reactive dyes

- 13. Permanency of the colour Easy washing Chemical Binding Types of reactive dyes Vinylsulphone Dye (VS) Monochlorotriazine Dye (MCT) Bi-functional Dye Advantages of the Reactive Dyes

- 14. 1. Hot reactive dyes Reactive dyes which have low reactivity ( monochlorotriazin faction ) Example of : Procion HE type ( ICI ) , Begative HE type ( Colorindo ) 2. Cool reactive dyes Reactive dyes which have high reactivity ( dichlorotriazin faction ) Example : Procion MX type ( ICI ) Based on its reactivity , reactive dye divided 2 faction :

- 15. Illustrating reaction which happened by at dyeing process between reactive dye with cellulose fibre

- 19. Side Reaction •Hydrolysis of dichlorotriazine 1.Results in wasted dye 2.Economic and environmental concern •Typically fixation of around 60% is obtained

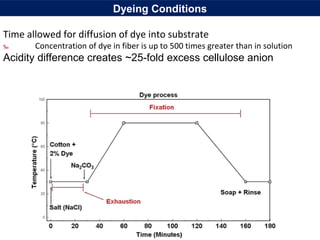

- 20. Dyeing Conditions Time allowed for diffusion of dye into substrate ‰ Concentration of dye in fiber is up to 500 times greater than in solution Acidity difference creates ~25-fold excess cellulose anion

- 21. Leaving Groups Variation of substituents = variations in fixation ‰ “Cold” dyes = fixation temperature of 30-40°C ‰ “Warm” dyes = fixation temperature of 50-80°C ‰ “Hot” dyes = fixation temperature of >80°C

- 22. 2004 22 REACTIVE DYES This is an entirely class of dye introduced to the market in 1956. They react chemically with the fibre being dyed & if correctly applied, cannot be removed by washing or boiling.

- 23. 2004 23 REACTIVE DYES The main feature of the dyestuff is its low affinity to cellulose; therefore large amounts of salt are required to force its deposition on he fabric.

- 24. 2004 24 REACTIVE DYES After this has been achieved, addition of alkali causes the deposited dyes to react with the fibre. Only a successfully concluded reaction guarantees a fast dyeing. Basically there are two types of reactive dyes: the cold dyeing & hot dyeing types.

- 25. 2004 25 REACTIVE DYES - USE: Reactive dyes are used where bright dyeing with high light & wash fastness is required. Cold dyeing is used extensively in batik work. Although some reactive dyestuffs have been specially modified to dye wool, their main usage is in dyeing cotton linen & viscose rayon.

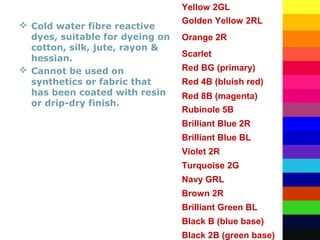

- 26. 2004 26 REACTIVE DYES Cold water fibre reactive dyes, suitable for dyeing on cotton, silk, jute, rayon & hessian. Cannot be used on synthetics or fabric that has been coated with resin or drip-dry finish. Yellow 2GL Golden Yellow 2RL Orange 2R Scarlet Red BG (primary) Red 4B (bluish red) Red 8B (magenta) Rubinole 5B Brilliant Blue 2R Brilliant Blue BL Violet 2R Turquoise 2G Navy GRL Brown 2R Brilliant Green BL Black B (blue base) Black 2B (green base)

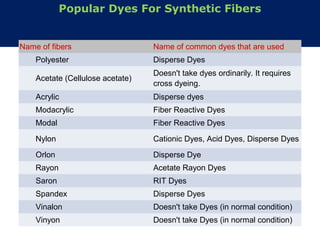

- 27. DYES for SYINTHETIC FIBERS Popular Dyes For Synthetic Fibers Name of fibers Name of common dyes that are used Polyester Disperse Dyes Acetate (Cellulose acetate) Doesn't take dyes ordinarily. It requires cross dyeing. Acrylic Disperse dyes Modacrylic Fiber Reactive Dyes Modal Fiber Reactive Dyes Nylon Cationic Dyes, Acid Dyes, Disperse Dyes Orlon Disperse Dye Rayon Acetate Rayon Dyes Saron RIT Dyes Spandex Disperse Dyes Vinalon Doesn't take Dyes (in normal condition) Vinyon Doesn't take Dyes (in normal condition)

- 28. Disperse Dyes DISPERSE DYES FOR DYEING IS DIVIDED BY 3 FACTION : 1. Disperse dyes of the size molecule small Example : Dispersol B ( ICI ) 2. Disperse dyes of the size molecule medium Example : Dispersol C ( ICI ) 3. Disperse dyes of the size molecule big Example : Dispersol D ( ICI )

- 29. 2004 29 Dye for Other Fibres: Disperse Dyes for Polyester, Acetate Cationic Dyes for Acrylic

- 30. 2004 Introduction to Coloration & Finishing 30 Classification of dyes Dye Class General description Main application Disperse Require skill in application (either by carrier or under high temperature); moderate price; complete colour range; limited solubility in water (normally dispersed in water for application); good fastness after reduction clearing treatment; sublimation property. Mostly used for polyester & acetate; can also be applied on nylon & Acrylic.

- 31. 2004 31 DISPERSE DYES The introduction of a new regenerated cellulose acetate fibre in 1920 led to the necessity to develop an entirely new range of dyes. It was found that acetate (or Celanese) fibre had hardly any affinity for water-soluble dyes. A new dyeing principle was introduced: dyeing with water dispersed coloured organic substances. These finely coloured particles are applied in aqueous dispersion to the acetate material & actually dissolved in the fibres.

- 32. 2004 32 DISPERSE DYES - USE: Basically developed for dyeing of acetate fibres, Disperse dyes are also used for dyeing of polyamide (Nylon) & acrylic (Orlon & Acrylan) fibres. With the addition of 'carriers' or swelling agents these dyes are also used in dyeing of Polyester (Terylene, Dacron, etc.)

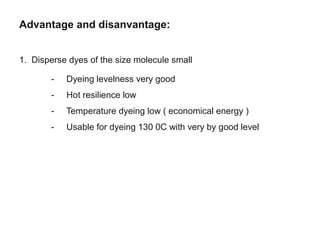

- 35. Advantage and disanvantage: 1. Disperse dyes of the size molecule small - Dyeing levelness very good - Hot resilience low - Temperature dyeing low ( economical energy ) - Usable for dyeing 130 0C with very by good level

- 36. 2. Disperse dyes of the size molecule medium - Dyeing levelness good - Good colour resilience - Absorbtion dye into maximum fibre - Not sensitive to temperature and time - Accessible dye at characteristic temperature 130 C in a short time

- 37. 3. Disperse dye of the size molecule big - Resilience colour to temperature very good - Sensitive to time and temperature - Need to process reduction clearing ( RC )

- 38. Disperse Dyes for Polyester Dyeing Method 1. High temperature high pressure dyeing dyeing at atmospheric pressure Fixation 45 to 60 minutes at 120°C t0 130°C

- 39. 2. Carrier dyeing carried out under atmosphere pressure by an addition of carrier Fixation 90-120 min at 100°C. 3. Thermosol dyeing continuous dyeing method fixation dry heating for 60-120 sec. at 180- 210°C (depending on the form of the material and type of disperse dyes)

- 40. Dyeing of polyester/cotton blend Three well known exhaust dyeing procedures : (1) a conventional two bath procedure (2) a reverse two bath procedure (3) a one bath, multi step procedure

- 41. (1) The conventional two bath procedure 1. first dyed with a disperse dye at pH 5-7 at 120°-140° C to dye the polyester. 2. removed from this first dye bath and transferred to a second dye bath containing a fiber reactive dye, electrolyte and alkali. (2)The reverse two bath procedure 1.first dyeing the cotton with the fiber reactive dye 2. dyed the polyester with the disperse dye in separate dye baths.

- 42. (3) In the one bath multi-step procedure 1. a single dye bath is prepared and the cotton portion of the blend is dyed alkaline conditions low temperature the presence of electrolyte. 2.The dye bath is then acidified to lower the pH and a disperse dye is added the polyester portion of the blend is dyed at 120° C. to 130° C.

- 44. 1. Yarn Manufacturing Technology Link : http://www.facebook.com/pages/Yarn-Manufacturing- Technology/485014954866808 2. Fabric Manufacturing Technology Link : http://www.facebook.com/pages/Fabric-Manufacturing- Technology/459520217425605 3. Garments Manufacturing Technology Link : http://www.facebook.com/pages/Garments-Manufacturing- Technology/472364799463126 3. Wet processing Technology Link : http://www.facebook.com/pages/Wet-Processing-Technology- Dyeing-/468645219825404 4. Fashion-Design-and-Technology Link : http://www.facebook.com/pages/Fashion-Design-and- Technology/587655294583875?ref=ts&fref=ts My Facebook Textile related Pages http://www.textilelab.blogspot.com (Visit My Blog for more Info )