Reactive Dye

- 1. A Presentation on . . . REACTIVE DYE

- 2. Prepared By : Mazadul Hasan Sheshir MSc in Textile Engg - Butex 4th Batch - Wet Processing Engineering BSc in Textile Engg - SEU 13th Batch - Wet Processing Technology Email: mazadulhasan@yahoo.com Blog : www. Textilelab.blogspot.com (visit) Southeast University Department Of Textile Engineering I/A 251,252 Tejgaon Dhaka Bangladesh Prepared By : ©right Bangladesh University of Textiles 92 Shaheed Tajuddin Ahmed Avenue, Tejgaon, Dhaka-1208, Bangladesh

- 3. Enhancing Our Presentation We have feature for every step of the way IntroIntro ductiducti on &on & DiscuDiscu ssionssion ChemiChemi stry &stry & MechMech anismanism ApplicApplic ationation && PractiPracti cesces

- 4. Introduction & Discussion Definition, naming, history, characteristics, classification, trade name etc

- 5. Definition • A dye, which is capable of reacting chemically with a substrate to form a covalent dye substrate linkage, is known as reactive dye. • Here the dye contains a reactive group and this reactive group makes covalent bond with the fiber polymer and act as an integral part of fiber.

- 6. Reaction D-SO2-CH2-CH2-O SO3Na + HO- cell → D-SO2-CH2-CH2-O-cell + NaHSO3 D-SO2-CH2-CH2-O SO3Na + NH2- wool → D-SO2-CH2-CH2-NH-Wool + NaHSO3 Here, D = dye part. Wool = wool polymer. Cell = cellulosic polymer.

- 7. Reasons for so named • Reactive dyes are so called because this is the only type of dye, which has reactive group, and that reactive group reacts chemically with fiber polymer molecules and form covalent bond.

- 8. Properties of reactive dye 1. Reactive dyes are cationic dyes, which are used for dyeing cellulose, protein and polyamide fibres. 2. Reactive dyes are found in powder, liquid and print paste form. 3. During dyeing the reactive group of this dye forms covalent bond with fibre polymer and becomes an integral parts of the fibre. 4. Reactive dyes are soluble in water. 5. They have very good light fastness with rating about 6. 6. Textile materials dyed with reactive dyes have very good wash fastness with rating about 4-5 due to strong covalent bonds formed between fibre polymer and reactive group of dye. 7. Reactive dye gives brighter shades and has moderate rubbing fastness. 8. Dyeing method of reactive dyes is easy. 9. It requires less time and low temperature for dyeing.

- 9. History two chemists of ICI company (UK) named Stephen and Rattee invent a new dye in 1956 They were awarded gold medal of the society of dyes and colorists for the year 1960 The first three reactive dyes were PROCION YELLOWR, PROCION BRILLIANT RED 2B PROCION BLUE 3G

- 10. Reason of Popularity • Ability to produce bright shades of wide range. • High leveling quality. • Good washing fastness. • Good light fastness. • Simple dyeing method therefore one stage dyeing. • Low temperature dyeing (below 1000 C) • Lower cost, i.e. cheaper.

- 11. Classification On the basis of reactive group: 1. Halogen derivatives Triazine group Pyridimine group Quinoxaline dyes 2. Activated vinyl compound On the basis of temperature: 1.Hot Brand 2.Cold Brand On the basis of reactivity: 1.Highly reactive 2.Moderate reactive 3.Lower reactive

- 12. Trade Name Trade name Manufacturer Country Procion I.C.I U.K Cibacron Ciba Switzerland Remazol Hoechst Germany Levafix Bayer Germany Reactone Geigy Switzerland Primazin BASF Germany Drimarine Sandoz Switzerland

- 13. Chemistry & Mechanism Chemistry of Reactive group, assistant, mechanism etc.

- 14. Characteristics of reactive group of reactive dye: • Reactive groups do not contribute to the color of dye. Chromogen group imparts it. • The reactivity of vinyl sulphone group is less than that of halogen group. • If no of reactive group increases, binding also increases. • Reactive dye absorb up to 90%. • Molecular weight of reactive group 69-211gm/ mole. • If the molecular weight of reactive group increases, reactivity increases. • Chlorine imparts medium reactivity, but it is cheap. • Reactivity of fluorine is the least and its rate hydrolysis is also less. • Reactivity of vinyl sulphone group increases with increasing temperature and pH. • Sulphone group has more solubility but it is not stable. • Generally low molecular weight dyes are of hot brand. • Less affinity dyes are used for pad method.

- 15. Assistants used for dyeing with reactive dyes • Salt: It neutralizes the electro negativity of fibre surface when immersed in solution. It puts extra energy to push the dye inside the fibre polymer i.e. increase absorption of dye. • Alkali: to maintain proper pH in dye bath and thus to create alkaline condition. Alkali is used as a dye-fixing agent. • Urea: It helps to get required shade of dye. • Soaping: Extra color is removed from fibre surface. Thus washing fastness is improved. Soaping increases the brightness and stability of the dye.

- 16. Dyeing mechanism of reactive dye • Exhaustion of dye in presence of electrolyte or dye absorption. • Fixation under the influence of alkali. • wash-off the unfixed dye from material surface.

- 17. Application & Practices Factors, Application methods, stripping, hydrolysis, faults & remedies

- 18. IMPORTANT FACTORS FOR DYEING CELLULOSIC FIBRE 1) pH of the dye bath 2) Amount of alkali 3) Dyeing temperature 4) Electrolyte concentration 5) Time of dyeing 6) Liquor ratio

- 19. Different methods of reactive dye application • Pad-batch method. • Pad batch processes are of two types- – Pad (alkali)-batch (cold) process. – Pad (alkali)-batch (warm or hot) process. • Pad dry method • Pad steam method.

- 20. Cold Pad Batch Steps: 1) The fabric is first padded in a padding mangle with reactive dye in presence of an alkali. 2) The padded fabric is rolled in a batch and the batches are wrapped by polyethylene sheets and stored in wet condition for 1-24 hours at 200- 300C in a room. 3) During the storage period, the rolls may be kept slowly rotating to prevent seepage of the dye liquor. 4) After storing time is finished fabric is washed in a rope washing machine to remove the unfixed dye from fabric surface.

- 21. Stripping Partial stripping: Acetic acid: 5-10 parts Water: 1000 parts Or Formic acid: 2.5 to 10 parts With water: 1000 parts Temperature: 70 - 100°C Time: until desired shade is obtained. Full stripping: Na-hypochlorite : 1% at room temperature Na-hydrosulpite: 1% at boil. Time : 30 min Stripping becomes necessary when uneven dyeing occurs. By stripping azo group (--N=N--) from the dye is removed.

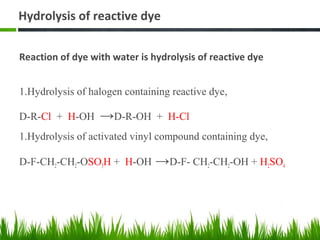

- 22. Hydrolysis of reactive dye Reaction of dye with water is hydrolysis of reactive dye 1.Hydrolysis of halogen containing reactive dye, D-R-Cl + H-OH →D-R-OH + H-Cl 1.Hydrolysis of activated vinyl compound containing dye, D-F-CH2-CH2-OSO3H + H-OH →D-F- CH2-CH2-OH + H2SO4

- 23. Prevention of Hydrolysis • As hydrolysis increases with increasing temperature during dissolving and application temperature should not be more than 40°C. • Dye and alkali solution are prepared separately and mixed just before using. • Dye and alkali should not be kept for long time after mixing.

- 24. Dyeing Faults • Uneven Dyeing • Batch to Batch Shade variation • Patchy dyeing effect • Roll to roll variation or Meter to Meter variation • Crease mark • Dye spot • Wrinkle mark • Softener Mark