Reflux ratio

- 1. REFLUX RATIO

- 3. CONTENT Introduction of feed Total reflux ratio Minimum reflux ratio Optimum reflux ratio

- 4. Introduction of Feed The plate on which feed is introduced is called the feed plate. The condition of the feed introduced on the feed plate alters the phase flow rates The feed to the column may be introduced as a 1. Cool liquid – its increases liquid flow rate in stripping section 2. Liquid at bubble point (saturated liquid)- its increases liquid flow rate in stripping section 3. Partially vaporised ( partialy vapour and partialy liquid) - its increases liquid flow rate in stripping section and vapour flow rate in rectifying section 4. Satureted vapour at its dew point - its increases vapour flow rate in rectifying section 5. Superheated vapour - its increases vapour flow rate in rectifying section

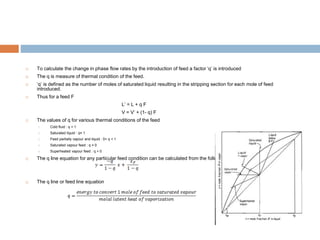

- 5. To calculate the change in phase flow rates by the introduction of feed a factor ‘q’ is introduced The q is measure of thermal condition of the feed. ‘q’ is defined as the number of moles of saturated liquid resulting in the stripping section for each mole of feed introduced. Thus for a feed F L’ = L + q F V = V’ + (1- q) F The values of q for various thermal conditions of the feed 1. Cold fluid : q > 1 2. Saturated liquid : q= 1 3. Feed partially vapour and liquid : 0< q < 1 4. Saturated vapour feed : q = 0 5. Superheated vapour feed : q < 0 The q line equation for any particular feed condition can be calculated from the following relation The q line or feed line equation

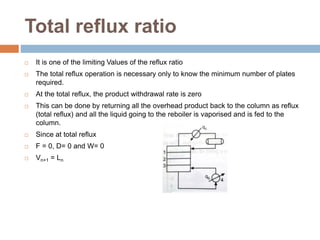

- 6. Total reflux ratio It is one of the limiting Values of the reflux ratio The total reflux operation is necessary only to know the minimum number of plates required. At the total reflux, the product withdrawal rate is zero This can be done by returning all the overhead product back to the column as reflux (total reflux) and all the liquid going to the reboiler is vaporised and is fed to the column. Since at total reflux F = 0, D= 0 and W= 0 Vn+1 = Ln

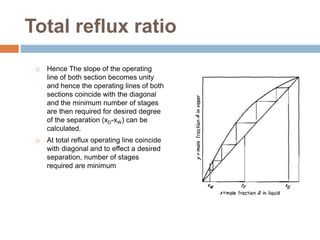

- 7. Total reflux ratio Hence The slope of the operating line of both section becomes unity and hence the operating lines of both sections coincide with the diagonal and the minimum number of stages are then required for desired degree of the separation (xD-xW) can be calculated. At total reflux operating line coincide with diagonal and to effect a desired separation, number of stages required are minimum

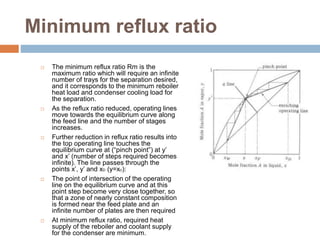

- 8. Minimum reflux ratio The minimum reflux ratio Rm is the maximum ratio which will require an infinite number of trays for the separation desired, and it corresponds to the minimum reboiler heat load and condenser cooling load for the separation. As the reflux ratio reduced, operating lines move towards the equilibrium curve along the feed line and the number of stages increases. Further reduction in reflux ratio results into the top operating line touches the equilibrium curve at (“pinch point”) at y’ and x’ (number of steps required becomes infinite). The line passes through the points x’, y’ and xD (y=xD): The point of intersection of the operating line on the equilibrium curve and at this point step become very close together, so that a zone of nearly constant composition is formed near the feed plate and an infinite number of plates are then required At minimum reflux ratio, required heat supply of the reboiler and coolant supply for the condenser are minimum.

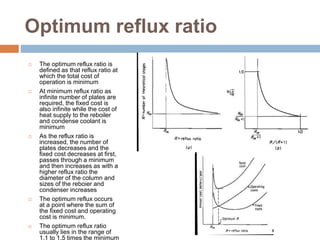

- 9. Optimum reflux ratio The optimum reflux ratio is defined as that reflux ratio at which the total cost of operation is minimum At minimum reflux ratio as infinite number of plates are required, the fixed cost is also infinite while the cost of heat supply to the reboiler and condense coolant is minimum As the reflux ratio is increased, the number of plates decreases and the fixed cost decreases at first, passes through a minimum and then increases as with a higher reflux ratio the diameter of the column and sizes of the reboier and condenser increases The optimum reflux occurs at a point where the sum of the fixed cost and operating cost is minimum. The optimum reflux ratio usually lies in the range of 1.1 to 1.5 times the minimum