Rolling

- 1. MANUFACTURING TECHNOLOGY – I CRAFTED BY: RAMESH KUMAR A Assistant Professor Sona College of Technology Salem 07-02-2019 05:42 1

- 2. ROLLING OF METALS 07-02-2019 05:42 2

- 3. TYPES OF ROLLING MILLS Two high rolling mill Three high rolling mill Two high reverse rolling mill Four high rolling mill Multi rolling mill Universal rolling mill Planetary rolling mill 07-02-2019 05:42 3

- 4. TWO HIGH ROLLING MILL Two rolls Rolls rotate in a constant direction Both cold and hot working 07-02-2019 05:42 4

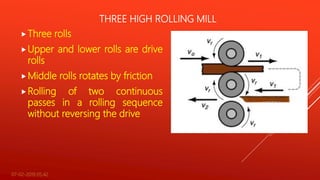

- 5. THREE HIGH ROLLING MILL Three rolls Upper and lower rolls are drive rolls Middle rolls rotates by friction Rolling of two continuous passes in a rolling sequence without reversing the drive 07-02-2019 05:42 5

- 6. TWO HIGH REVERSIBLE ROLLING MILL Rolls can rotate in both direction Reducing the handling of hot metal in between the rolling passes 07-02-2019 05:42 6

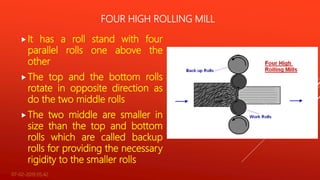

- 7. FOUR HIGH ROLLING MILL It has a roll stand with four parallel rolls one above the other The top and the bottom rolls rotate in opposite direction as do the two middle rolls The two middle are smaller in size than the top and bottom rolls which are called backup rolls for providing the necessary rigidity to the smaller rolls 07-02-2019 05:42 7

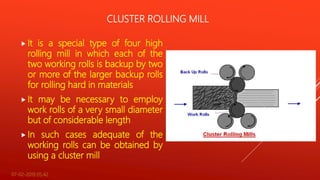

- 8. CLUSTER ROLLING MILL It is a special type of four high rolling mill in which each of the two working rolls is backup by two or more of the larger backup rolls for rolling hard in materials It may be necessary to employ work rolls of a very small diameter but of considerable length In such cases adequate of the working rolls can be obtained by using a cluster mill 07-02-2019 05:42 8

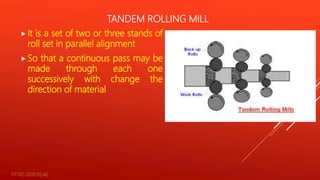

- 9. TANDEM ROLLING MILL It is a set of two or three stands of roll set in parallel alignment So that a continuous pass may be made through each one successively with change the direction of material 07-02-2019 05:42 9

- 10. UNIVERSAL ROLLING MILL Metal is reduced to desired shape by both horizontal and vertical rolls Sheets, plates, slabs and beams 07-02-2019 05:42 10

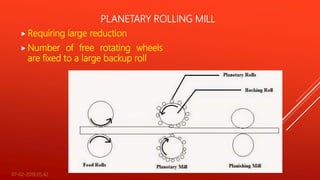

- 11. PLANETARY ROLLING MILL Requiring large reduction Number of free rotating wheels are fixed to a large backup roll 07-02-2019 05:42 11

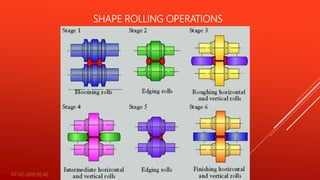

- 13. SHAPE ROLLING OPERATIONS 07-02-2019 05:42 13

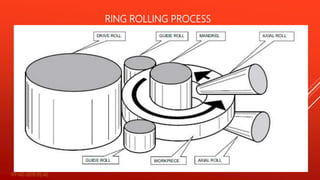

- 14. RING ROLLING PROCESS 07-02-2019 05:42 14

- 15. RING ROLLING PROCESS 07-02-2019 05:42 15

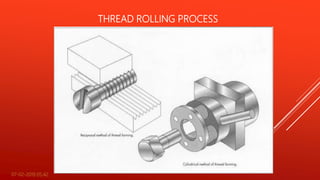

- 16. THREAD ROLLING PROCESS 07-02-2019 05:42 16

- 17. THREAD ROLLING PROCESS 07-02-2019 05:42 17

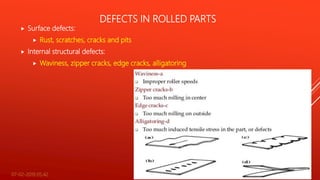

- 18. DEFECTS IN ROLLED PARTS Surface defects: Rust, scratches, cracks and pits Internal structural defects: Waviness, zipper cracks, edge cracks, alligatoring 07-02-2019 05:42 18