Roof truss

- 1. Roof Truss

- 2. ContentContent Introduction Need of Roof truss Factor affecting roof truss Advantage and disadvantage of roof truss Components of roof truss Various term used in Roof truss Type of roof truss Roof covering material Economical spanning of roof truss

- 3. Introduction “A frame structure in which separate straight member are so arranged and connected at their end that the member form a triangle which lies in the same plane” Normally it is provided for more than 6 m . Industrial shed Ceiling for large room Auditorium ,Cinema hall, marriage hall ,godowns etc. The member carrying compressive forces in roof truss is know as struts. The member carrying tensile forces in roof truss is know as tie member .

- 5. Components of Roof trussComponents of Roof truss The member of roof truss classified into two category Main member: Carrying load and distributing the applied load , provide the stability Secondary member : provide the stability to the primary member Web member Bottom chord member Top chord member

- 6. Need of Roof truss Day light requirement Required more head room More clear span available No provision for internal supports To reduce the addict moisture To provide the proper ventilation Light load on structure There is less chances of excess bending

- 7. Factor affecting selection of roof trussFactor affecting selection of roof truss Span Annual rain/snow fall Pitch of truss Maximum natural light requirement Roof covering material Style of your home Availability of funds Types of building State building code Functionality Aesthetic view Energy efficiency

- 8. Advantage and disadvantage of Roof trussAdvantage and disadvantage of Roof truss Suitable for sloping roof Suitable for light load and large span It permitting variety of roof shape Providing greater vertical span Most economical for spanning 6 m Dead load of structure Disadvantage : Problems in transportation aesthetic appearance of the roof is very low wooden roofs are susceptible to fire Cost is high Corrosion

- 9. Various Term used in steel Roof trussVarious Term used in steel Roof truss Span Rise Pitch Slope Purlins Rafter Sheathing Panel Bay Ridge line Principal Rafter Camber Eaves

- 10. • When the span exceeds 10 m, timber trusses become heavy and uneconomical. Steel trusses are more economical for larger spans. • Steel trusses are fabricated from rolled steel structural members such as channels, angles, T-sections and plates. • Most of the roof trusses are fabricated from angle-sections because they can resist effectively both tension as well as compression, and their jointing is easy. Steel trusses may be grouped in the following categories : (а) Open trusses (b) North light trusses (c) Bow string trusses 31 Type of Steel Roof Trusses

- 11. 11

- 12. 12

- 13. 13

- 14. 3 5

- 15. 15 A king-post truss consists of the following components : (i) lower tie beam, (ii) two inclined principal rafters, (iii) two struts, and (iv) a king post. King-post Roof Truss

- 16. 16

- 17. 17 The spacing of the kingpost truss is limited to 3 m centre to centre. The truss is suitable for spans varying from 5 to 8 meters. The principal rafter is jointed to the tie beam by a single abutment and ‘tenon joint’ or by a ‘bridle joint’. The king-post is provided with splayed shoulders and feet, and is tenoned into the upper edge of the tie beam for a sufficient distance.

- 18. 2 5

- 19. 2 6

- 20. 20 • A queen-post truss differs from a king-post truss in having two vertical posts, rather than one. • The vertical posts are known as queen-posts, the tops of which are connected by a horizontal piece, known as straining beam. • In absence of the straining sill, the thrust from the strut would tend to force the foot of the queen-post inwards. • These trusses are suitable for spans between 8 to 12 meters. • The joint at the head of queen-post -is formed due to the junction of two compression members (principal rafter and straining beam) and a tension member(queen-post). Queen-post Roof Truss

- 21. 21

- 23. 23

- 24. Roofs Covering The structural elements consists of; -Trusses -Portals -Slabs -Domes -A. C sheets covering -G. I sheets coverings -Shingles -Slates, etc 24

- 25. . • The following are the roof-covering materials commonly used for pitched roofs: 1.Thatch covering 2.Wood shingles 3.Tiles 4.Asbestos cement sheets 5.Galvanized corrugated iron sheets 6.Eternit slates. 7. Light weight roofing 37 Roofs Covering

- 26. 26 • This is the cheapest roof-covering, commonly used in villages. • It s very light, but is highly combustible. • It is unstable against high winds. • It absorbs moisture and is liable to decay. • Thatch roof-covering consists of bundles of reeds or straw . • The frame work to support thatch consists of round bamboo rafters spaced 20 to 30 cm apart and tied with split bamboos laid at right angles to the rafters. • The thatch is tightly secured to the frame work with the help of ropes or twines. • In order to drain the roof effectively, a minimum slope of 45° is kept. • The thickness of thatch covering should at least be 15 cm . Thatch covering

- 27. 27

- 28. 28 • Shingles are thin slabs of wood used to cover roofs. • The use of shingles is restricted to hilly areas where local timber is easily available at low cost. • shingle roofing is light weight, it is not fire and termite resistant. • Wood shingles are obtained from well seasoned timber, by either sawing or splitting. • They are approximately 10 mm thick at the tail. • They are laid in a similar fashion as tiles and slates. Wood Shingle Roofing

- 29. 29

- 30. 30 • Use of tiles for roofing is one of the oldest, and is still preferred for residential buildings and country houses. • This is because country tiles are manufactured from locally available earth. • Tiles are named according to their shape and pattern, and they are manufactured by a process similar to the one used for the manufacture of bricks. • The various types of tiles generally used are : • 1. Plain or flat files. • 2. Curved or pan-tiles. • 3. Pot tiles or half-round country tiles. • 4. Italian or Allahabad tiles. • 5. Inter-locking tiles. Tile Roofing

- 31. 31

- 32. • Asbestos cement sheets are now increasingly becoming popular for industrial buildings, factories, sheds, cinema houses, auditorium and even residential buildings, since they are cheap, light weight, tough, durable, water tight, fire-resisting. • The biggest advantage is that they are available in bigger units unlike tiles, and hence supporting frame work (ground work) is also cheaper, easier and lighter. • These sheets do not require any protective paint, and no elaborate maintenance is required. Also, the construction with A.C. sheets is very fast. A.C. sheets are manufactured from asbestos, fiber (about 15%) and Portland cement. Asbestos is a silky fibrous mineral made up of metamorphosed volcanic rocks. • In India, asbestos cement roof coverings are available in following forms: • Everest big-six corrugated A.C. sheets. • Everest standard corrugated A.C. sheets. • Everest Trafford A.C. tiles (or sheets). • These' sheets have length of 1.25 to 3 meters in increments of 15 cm. 44 Asbestos Cement Sheets (A.C. Sheets)

- 33. Asbesto s 33

- 34. 34 • G.I. sheets are also widely used. • They are stronger than A.C. sheets. However, because of their higher cost, they are now gradually replaced by A.C. sheets. • They are not used for slopes flatter than 1 in 4. • G.I. sheets are made of iron sheets which are galvanized with zinc to protect them from rusting action of water and wet weather. • These sheets are fixed in a manner similar to the A.C. sheets. End lap should not be less than 15 cm and The holes are either drilled or punched in the sheet crowns. • The sheets are secured to purlins by means of G.I. hook bolts, screws and nails etc., with curved washers. • The sheets should be fixed to eaves by means of flat iron wind ties. Galvanized Iron Corrugated Sheets (G.I. Sheets)

- 35. 35

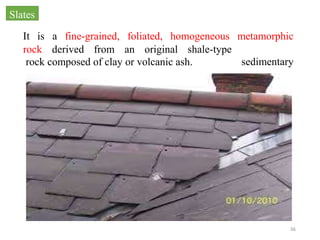

- 36. It is a fine-grained, foliated, homogeneous metamorphic sedimentary rock derived from an original shale-type rock composed of clay or volcanic ash. Slates 36

- 37. 57 Thank you

- 38. Column BaseColumn Base The column base used to transfer the load from column to the base and further distribute the effectively to foundation If the column base not provided it punched into concrete The column base classified into (i) Slab Base (ii) Gusset base (iii) Grillage base

- 39. Column bases are structural elements used in the design of steel structures to transfer the column load to the footings. Column base consist following components (i) Column (ii) Base plate (iii) Anchoring Assembly

- 40. TYPE OF COLUMN BASETYPE OF COLUMN BASE (1)Slab Base: Used for axially loaded columns where load is moderate Slab bases are used where the columns have independent concrete pedestals A thick steel base plate and two cleat angles connecting the flanges of the column to the base plate. web cleats are provided to connect the web of the column to the base plate.

- 42. Gusset base Gusseted bases are provided for columns carrying heavier loads requiring large base plates The load coming to the column transmitted to the base plate attached to the flange of the column by means of column . Thickness of the base plate is gusseted base will be less than slab The bearing area of gusset base is more than the slab base https://qph.ec.quoracdn.net/main-qimg- 9416e57ce82b31027faa5aef1f0c4078.webp

- 43. Grillage foundationGrillage foundation Used when the load is extremely high example: tall buildings. Used when the soil bearing capacity is poor. The base plate is supported by the tiers of beams

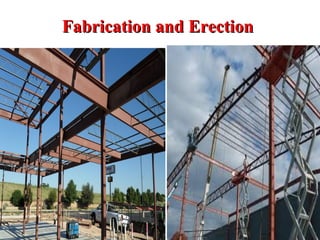

- 44. Fabrication and ErectionFabrication and Erection

- 45. Fabrication and Erection(IS:7205-1974)Fabrication and Erection(IS:7205-1974) The availability of advance design program , technology , and equipment in erection and fabrication have tiled toward more use of steel structure . in most of construction works , mild steel being used in various shape and form (i) I section (ii)Channel section (iii)Angle section (iv)Steel bar (v)Steel Flat (vi)Steel sheet and Strip (vii)Steel tube (viii)Steel plate

- 47. FabricationFabrication The process of preparing components ready for assembly at site is know as fabrication. Following steps should be followed (i) Design drawing (shop drawing ) (ii)Quantities calculation (iii)Best fit to minimum wastage (iv) Equipment ,tool and machinery like hydra, cutting, drilling (v)Proper storage ,numbering or color scheme (vi)Cut material fit proper shape and size (vii) Non- destructive test (viii) Material are stored or transported depending upon requirements

- 49. ERECTIONERECTION Erection is the process of assembling the fabricated components on site . It is necessary to order sufficient amount of in advance The following precaution should be followed (i) Proper layout and sequence of erection (ii)After every fixing checks should be applied (iii)Erection sequence must be match the stability of structure (iv)Quality assessment and maintains (v)Follow erection steps as per IS code

- 51. Factor affecting Erection and fabrication ofFactor affecting Erection and fabrication of steel structuresteel structure Planning Fabrication (cleaning , sawing,shearing,grinding) Dispatch Foundation Erection Jointing Lateral bracing Setting out guidance Inspections and quality control

- 52. Erection of column at siteErection of column at site Following point should be kept in mind (i) Each column has to be correctly positioned in plane and line (ii) Rolled steel I section used as column (iii) Must be check the verticality (iv) Always use centre line method (v) Column should be fastened with base with the help of nut, bolts