Sand

- 1. BUILDING MATERIALS SAND Presented by- Rishabh Dev,Dhir Dhwaj, Anant Nautiyal, Gaurav Soni, Riya Taneja, Priyvarth Arya State Institute of Urban Planning and Architecture

- 2. SAND Sand is a naturally occurring granular material composed of finely divided rock and mineral particles. the most common constituent of sand is silica (silicon dioxide, or SiO2), usually in the form of quartz.

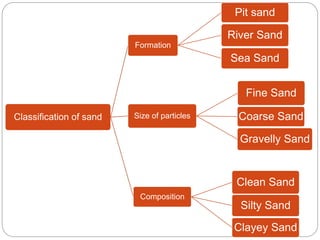

- 3. Classification of sand Formation Pit sand River Sand Sea Sand Size of particles Fine Sand Coarse Sand Gravelly Sand Composition Clean Sand Silty Sand Clayey Sand

- 4. Classification on the basis of formation

- 5. PIT SAND This sand is obtained by forming pits in soils. It is excavated from a depth of about 1-2 m from the ground level. This sand is found as deposits in soil and it consists of sharp angular grains, which are free from salts.

- 6. Pit Sand It serves as an excellent material for mortar or concrete work. Pit sand must be made free from clay and other organic materials before it can be used in mortar. A coating of oxide of iron over the sand grains should be removed.

- 7. RIVER SAND This sand is widely used for all purposes. It is obtained from the banks or beds of rivers and it consists of fine rounded grains. The presence of fine rounded grains is due to mutual attrition under the action of water current.

- 8. River sand The river sand is available in clean conditions. The river sand is almost white in color. It is mainly used for plastering. In north India , Yamuna banks are a great source of River sand .

- 9. River sand

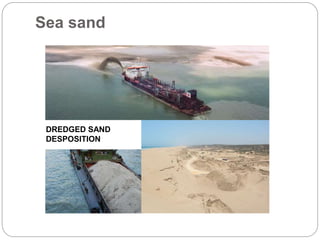

- 10. SEA SAND This is obtained from sea shores. It is brown in color and it also has the fine rounded grain.

- 12. As it is obtained from sea it contains salt, which is used in attracting moisture from atmosphere. Such absorption causes dampness and disintegration of work. It is generally not used for engineering purpose due to its retards setting action of cement. It is normally used for non structural purposes. Sea sand

- 13. Crushed Stone Sand / Artificial Sand It is a substitute for River Sand, fine aggregates which manufactured by crushing either granite or basalt rock using 3 stage crushing process.

- 15. Classification on the basis of size of particles

- 16. Fine sand The sand passing through a sieve with clear openings of 1.5mm is known as fine sand. Fine sand is mainly used for plastering.

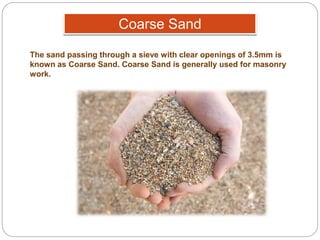

- 17. Coarse Sand The sand passing through a sieve with clear openings of 3.5mm is known as Coarse Sand. Coarse Sand is generally used for masonry work.

- 18. Gravelly Sand The sand passing through the sieve of 7.62mm is known as Gravelly Sand. It is generally used for concrete work.

- 19. Grading of sand: On the basis of particle size, fine aggregate is graded into four zones. IS Sieve Percentage passing for Grading Zone I Grading Zone II Grading Zone III Grading Zone IV 10mm 100 100 100 100 4.75mm 90 – 100 90 – 100 90 – 100 90 – 100 2.36mm 60 – 95 75 – 100 85 – 100 95 – 100 1.18 mm 30 – 70 55 – 90 75 – 100 90 – 100 600 micron 15 – 34 35 – 59 60 – 79 80 – 100 300 microns 5 – 20 8 – 30 12 – 40 15 – 50 150 microns 0 – 10 0 – 10 0 – 10 0 – 15

- 20. Classification of Sand on the basis of composition

- 21. Clean Sand •These are well graded sand containing mostly quartz (SiO2) •It is free from any organic or inorganic impurities •It is perfect for construction purposes

- 22. Silty Sand •These are poorly graded sand with considerable amount of Silt •The size of silt particles are very small and form lump •Not good for construction purpose

- 23. Clayey Sand This sand have prominent clay fraction and plastic fines. Traditionally used for the construction of walls Also used as mortar for bricks because of its high adhesive property

- 24. Use of sand in construction 1) Bricks work – Finest modulus of fine sand. The size of grains must be between 1.2 – 1.5 mm. it is formed by mixing clay and sand with small quantities of lime magnesia and iron oxide. Sand gives more shapely and uniform texture to the bricks. An excess of sand, however render the bricks too brittle and destroys cohesion. 25% of sand is said to be a good proportion. 2) Plastering work – Finest modulus of fine sand which have grain size not less than 1.5mm. It is usually mixed with cement in the ratio of 1:3 or 1:4. - It is the basic material for every construction. Most of the raw material for construction consists of some ratio of sand.

- 25. Sand for Construction Works Different construction works require different standards of sand for construction. • Brick Works: finest modulus of fine sand should be 1.2 to 1.5 and silt contents should not be more than 4%. Finest modulus of fine sand. The size of grains must be between 1.2 – 1.5 mm. it is formed by mixing clay and sand with small quantities of lime magnesia and iron oxide. Sand gives more shapely and uniform texture to the bricks. An excess of sand, however render the bricks too brittle and destroys cohesion. 25% of sand is said to be a good proportion.

- 26. • Plastering Works: finest modulus of fine sand should not be more than 1.5 and silt contents should not be more than 4%. • Concreting Works: coarse sand should be used with finest modulus 2.5 to 3.5 and silt contents should not be more than 4%. 3) Mortars and concrete work – Sand is used in mortar and concretes for the following purposes :- a) Strength – It helps in the adjustment of strength of mortar or concrete by variation of its proportion with cement or lime. It also increases the resistance of mortar against crushing.

- 27. SOIL BEARING CAPACITY Bearing capacity is the power of foundation soil to hold the forces from the superstructure without undergoing shear failure or excessive settlement. Foundation soil is that portion of ground which is subjected to additional stresses when foundation and superstructure are constructed on the ground. The following are a few important terminologies related to bearing capacity of soil Ultimate Bearing Capacity (qf) : It is the maximum pressure that a foundation soil can withstand without undergoing shear failure Net ultimate Bearing Capacity (qn) : It is the maximum extra pressure (in addition to initial overburden pressure) that a foundation soil can withstand without

- 30. a) Bulk – It act as an adulterant. Hence, the bulk volume of mortar is increased which results in reduction of cost. c) Setting – In the case of fat lime, CO2 is absorbed through the voids of sand and setting of lime occurs effectively. d) Shrinkage – It prevents excessive shrinkage of mortar in the course of drying. Hence, the cracking of mortar during setting is avoided. e) Surface area - It subdivides the paste of the binding material into a thin film and thus, more surface area is offered for its spreading and adhering.

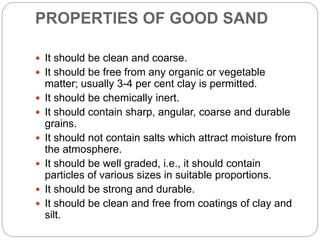

- 31. PROPERTIES OF GOOD SAND It should be clean and coarse. It should be free from any organic or vegetable matter; usually 3-4 per cent clay is permitted. It should be chemically inert. It should contain sharp, angular, coarse and durable grains. It should not contain salts which attract moisture from the atmosphere. It should be well graded, i.e., it should contain particles of various sizes in suitable proportions. It should be strong and durable. It should be clean and free from coatings of clay and silt.

- 32. Tests 1) Sieve test – Sand is filtered through sieve of suitable pore size. If the residue left is more than the filtered sand then the sand is of poor quality. 2) Take some quantity of sand in water. Then, shake it vigorously and allow it to settle down. If the clay and silt is present in sand , its distinct layer is formed at the top of water. The sand is acceptable if the amount of clay and silt present is not more than 5% than the total mixture. 3) To detect the presence of organic material in the sand, add NaOH or Caustic Soda to it. If the colour changes to brown, then the sand has organic impurities.

- 33. BULKING OF SAND The increase in the volume of sand due to the presence of moisture is known as bulking of sand. This is due to the fact that moisture forms a film of water around the sand particles and this results in an increase in the volume of sand. The extent of bulking depends on the grading of sand. The finer the material the more will be the increase in volume for the given moisture content. For a moisture content of 5–8 per cent, the increase in volume may be about 20–40 per cent depending upon the gradation of sand. When the moisture content is further increased, the sand particles pack near each other and the amount of bulking is decreased. Hence, dry sand and the sand completely

- 34. Deleterious materials in sand Sand shall not contain any harmful impurities such as iron, pyrites, alaklies, salts, coal or other organic impurities, mica, shale or similar laminated materials, soft fragments, sea shale in such form or in such quantities as to affect adversely the hardening, strength or durability of the mortar. The maximum quantities of clay, fine silt, fine dust and organic impurities in the sand / marble dust shall not exceed the following limits: (a) Clay, fine silt and fine dust when determined in accordance within not more than 5% by mass in IS 2386 (Part-II), natural sand or crushed gravel sand and crushed stone sand. (b) Organic impurities when determined in color of the liquid shall be lighter in lighter in accordance with IS 2386 (Part –II) than that specified in the code.

- 35. Transportation of sand It is usually transported in trucks or trolleys from the digging sites to the construction sites as it is required in bulk amount. It is measured in cubic feet. length height

- 36. Substitutes of Sand Sand has now become a scarce material and extraction of river sand is now said to affect the ecological balance. The use of substitutes for sand has gained greater importance. Surkhi, or finely grained burnt clay, is one of the materials used for this purpose. It can be used in all mortars except that for plastering. Processed quarry dust or stone screening is also being used as substitutes. It is abundantly available and if it is properly screened, it imparts more strength to the mortar. This is now being industrially manufactured.

- 38. THANK YOU