Sanitization and hygiene.ppt

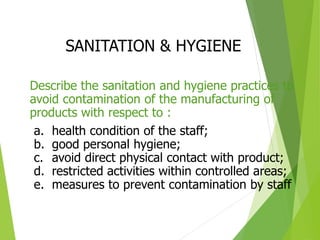

- 1. SANITATION & HYGIENE Describe the sanitation and hygiene practices to avoid contamination of the manufacturing of products with respect to : a. health condition of the staff; b. good personal hygiene; c. avoid direct physical contact with product; d. restricted activities within controlled areas; e. measures to prevent contamination by staff

- 2. Sanitization, Hygiene and storage Made by Kashish Wilson Assistant Professor MM College of Pharmacy MM(DU) Mullana,Ambala

- 3. PRODUCTION Describe the control of manufacturing process with respect to the following : a. Checking and verification of starting materials (r.m., p.m., and water) b. Traceability of starting materials to the product c. Handling of rejected materials d. Batch numbering system e. Weighing and measurement f. Production process g. Labeling and packaging h. Finished product: Quarantine and Delivery

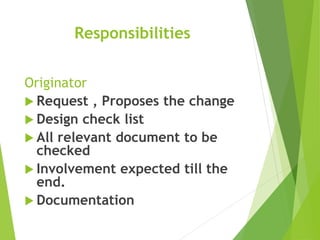

- 4. Responsibilities Originator Request , Proposes the change Design check list All relevant document to be checked Involvement expected till the end. Documentation

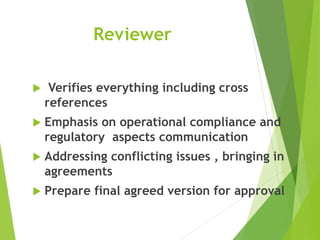

- 5. Reviewer Verifies everything including cross references Emphasis on operational compliance and regulatory aspects communication Addressing conflicting issues , bringing in agreements Prepare final agreed version for approval

- 6. Responsibilities Approval Traces all activities with time frame Resolution of comment Overview in totality Ensure approval for implementation

- 7. Objective Consistency in manufacture and assurance of quality Regulatory complaints Facilitating … continuous … improvement Building…. Successful….. Lot… Histories…. Systemizing… preventing and corrective action Guard business practice

- 8. STORAGE Specify the requirements concerning storage of materials/ products with respect to the following a. Space, design, security and cleanliness b. Storage of quarantine stocks c. Storage of hazardous substances d. Conditions of storage area (e.g. temperature & relative humidity) e. Receiving of incoming materials f. Stock control (e.g. FIFO principle, proper labeling on the container)