Shaft and resistance of bored piles

- 2. Presented by Mehwish Riaz 2007-MS-GEO-06 Relative Proportions of shaft and base resistance of bored piles in Punjab submerged sands

- 3. Contents Introduction Soil Profile Construction Method Load Test Programme Evaluation of ultimate Load Resistance along Pile Shaft and Base Probable Reasoning Conclusion

- 4. Introduction Project is up gradation of NHA(Mianchannu-Sahiwal Section) 25 m deep boreholes at canal bank at bridge site. Pile foundations of 660 mm diameter and 13-18 m length were recommended with allowable load (from load test result) of 140-155 tonnes. Full Scale Load tests were performed up to 2-2.5 times the initial design load. Results showed premature failure at less then design load as well as absence of adequate base resistance.

- 5. Soil Profile Formation of relatively heterogeneous quaternary soil deposits comprising a combination of alluvium and loess is present.

- 6. Construction Method Pile testing was distributed in the form of packages 6 (a) and 6 (b) For package 6 (a) construction of test piles was done by wash boring method. For package 6 (b) construction was undertaken by reverse rotary method.

- 7. Load Test Programme 6 (a) Bridge 1 310 tonnes Bridge Kassowal 280 tonnes Bridge 1 310 tonnes Bridge Kassowal 280 tonnes 6 (b) Bridge 4 310 tonnes Bridge 6 310 tonnes Bridge 7 310 tonnes Bridge 8 310 tonnes

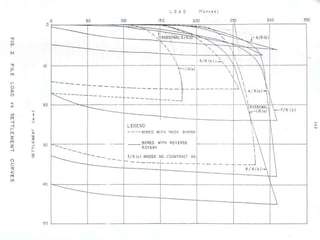

- 8. Evaluation of Ultimate /Failure Load

- 10. Resistance along Pile Shaft and Base Ideal way to measure ultimate skin Friction (USF) mobilized at onset of failure is the measurement of base resistance by placing load cell and then subtracting the value from total load. For this study, USF is determined by two methods (a) evaluation of load corresponding to 6 mm butt settlement (b) estimation of skin component by van weel’s graphical construction

- 11. Drawing a line parallel to the yield zone of the load-settlement curve, from the origin Skin friction values by both these methods agree closely with each other and their average is slightly short of AASHTO failure load This suggests that after mobilization of full skin resistance, the pile base does not take appreciable load in materials terms

- 15. These bored piles took only about 8 % of the load at the base, at failure up to 92 % of load was resisted by the shaft. Percentage proportion of shaft and base resistance components for the two kind of borings were as follows

- 16. Probable Reasoning The increase in shaft resistance proportions is understandable, owing to high degree of roughening of borehole walls by the tool movement. Piles of highly irregular skin would have resulted after casting, which yielded high skin friction. Insitu soils at the pile tip horizons were not weak, so the most probable reason for less base resistance is very method of construction. It creates looseness at the base of bore hole resulting into higher settlements before base resistance can be mobilized.

- 17. So the less base resistance may b due to………………. Looseness of soil at the base by the movement of the bit and improper cleaning of the boreholes before pouring concrete. During lowering of steel cage, assemblage of loose soils scratched from the borehole walls at the base. Inadequate control over boiling of sand during boring. Introduction of loose soils from borehole within pile concrete resulted into necking. Segregation or honey combing in the poured concrete.

- 18. Conclusion In normal works in Pakistan, the boring of piles with wash boring and reverse rotary excessively loosens the soils at the base of hole and thus reduce the base resistance components to negligible proportions. The conventional pile capacity forecast method fails to predict the skin friction and end bearing resistance components. The design method should be carefully adopted giving due consideration to the method of construction. There is need for more stringent construction supervision.

- 19. THANK YOU