Soil mechanics.. pdf

- 1. 1 | P a g e SAQIB IMRAN 0341-7549889 1 Assala mu alykum My Name is saqib imran and I am the student of b.tech (civil) in sarhad univeristy of science and technology peshawer. I have written this notes by different websites and some by self and prepare it for the student and also for engineer who work on field to get some knowledge from it. I hope you all students may like it. Remember me in your pray, allah bless me and all of you friends. If u have any confusion in this notes contact me on my gmail id: Saqibimran43@gmail.com or text me on 0341-7549889. Saqib imran.

- 2. 2 | P a g e SAQIB IMRAN 0341-7549889 2 Soil Mechanics Soil Mechanics Introduction and Definition Soil mechanics is defined as the application of the laws and principles of mechanics and hydraulics to engineering problems dealing with soil as an engineering material. Soil has many different meanings, depending on the field of study. To a geotechnical engineer, soil has a much broader meaning and can include not only agronomic material, but also broken- up fragments of rock, volcanic ash, alluvium, Aeolian sand, glacial material, and any other residual or transported product of rock weathering. As the name Soil Mechanics implies the subject is concerned with the deformation and strength of bodies of soil. It deals with the mechanical properties of the soil materials and with the application of the knowledge of these properties to engineering problems. In particular it is concerned with the interaction of structures with their foundation material. This includes both conventional structures and also structures such as earth dams, embankments and roads which are their-selves made of soil. Unconfined Compression (UC) Test

- 3. 3 | P a g e SAQIB IMRAN 0341-7549889 3 Purpose: The primary purpose of this test is to determine the unconfined compressive strength, which is then used to calculate the unconsolidated undrained shear strength of the clay under unconfined conditions. According to the ASTM standard, the unconfined compressive strength (qu) is defined as the compressive stress at which an unconfined cylindrical specimen of soil will fail in a simple compression test. In addition, in this test method, the unconfined compressive strength is taken as the maximum load attained per unit area, or the load per unit area at 15% axial strain, whichever occurs first during the performance of a test. Standard Reference: ASTM D 2166 - Standard Test Method for Unconfined Compressive Strength of Cohesive Soil Significance: For soils, the undrained shear strength (su) is necessary for the determination of the bearing capacity of foundations, dams, etc. The undrained shear strength (su) of clays is commonly determined from an unconfined compression test. The undrained shear strength (su) of a cohesive soil is equal to one half the unconfined compressive strength (qu) when the soil is under the f = 0 condition (f = the angle of internal friction). The most critical condition for the soil usually occurs immediately after construction, which represents undrained conditions, when the undrained shear strength is basically equal to the cohesion (c). This is expressed as: Then, as time passes, the pore water in the soil slowly dissipates, and the intergranular stress increases, so that the drained shear strength (s), given by s = c + s‘tan f , must be used. Where s‘ = intergranular pressure acting perpendicular to the shear plane; and s‘ = (s - u), s = total pressure, and u = pore water pressure; c’ and φ’ are drained shear strength parameters. The determination of drained shear strength parameters is given in Experiment 14 Equipment: Compression device, Load and deformation dial gauges, Sample trimming equipment, Balance, Moisture can. Test Procedure:

- 4. 4 | P a g e SAQIB IMRAN 0341-7549889 4 1. Extrude the soil sample from Shelby tube sampler. Cut a soil specimen so that the ratio (L/d) is approximately between 2 and 2.5. Where L and d are the length and diameter of soil specimen, respectively. 2. Measure the exact diameter of the top of the specimen at three locations 120° apart, and then make the same measurements on the bottom of the specimen. Average the measurements and record the average as the diameter on the data sheet. 3. Measure the exact length of the specimen at three locations 120° apart, and then average the measurements and record the average as the length on the data sheet. 4. Weigh the sample and record the mass on the data sheet. 5. Calculate the deformation (∆L) corresponding to 15% strain (ε). Where L0 = Original specimen length (as measured in step 3). 6. Carefully place the specimen in the compression device and center it on the bottom plate. Adjust the device so that the upper plate just makes contact with the specimen and set the load and deformation dials to zero. 7. Apply the load so that the device produces an axial strain at a rate of 0.5% to 2.0% per minute, and then record the load and deformation dial readings on the data sheet at every 20 to 50 divisions on deformation the dial. 8. Keep applying the load until (1) the load (load dial) decreases on the specimen significantly, (2) the load holds constant for at least four deformation dial readings, or (3) the deformation is significantly past the 15% strain that was determined in step 5. 9. Draw a sketch to depict the sample failure. 10. Remove the sample from the compression device and obtain a sample for water content determination. Determine the water content as in Experiment 1. Analysis: 1. Convert the dial readings to the appropriate load and length units, and enter these values on the data sheet in the deformation and total load columns. (Confirm that the conversion is done correctly, particularly proving dial gauge readings conversion into load) 2. Compute the sample cross-sectional area 3. Compute the strain 4. Computed the corrected area, 5. Using A’, compute the specimen stress, 6. Compute the water content, w%. 7. Plot the stress versus strain. Show qu as the peak stress (or at 15% strain) of the test. Be sure that the strain is plotted on the abscissa. See example data. 8. Draw Mohr’s circle using qu from the last step and show the undrained shear strength, su = c (or cohesion) = qu/2. See the example data. General Considerations and Assumptions in the Soil Stability Analysis

- 5. 5 | P a g e SAQIB IMRAN 0341-7549889 5 There are three distinct parts to an analysis of the stability of a slope. They are: 1. Testing of samples to determine the cohesion and angle of internal friction If the analysis is for a natural slope, it is essential that the sample be undisturbed. In such important respects as rate of shear application and state of initial consolidation, the condition of testing must represent as closely as possible the most unfavorable conditions ever likely to occur in the actual slope. 2. The study of items which are known to enter but which cannot be accounted for in the computations The most important of such items is progressive cracking which will start at the top of the slope where the soil is in tension, and aided by water pressure, may progress to considerable depth. In addition, there are the effects of the non‐homogeneous nature of the typical soil and other variations from the ideal conditions which must be assumed. 3. Computation If a slope is to fail along a surface, all the shearing strength must be overcome along that surface which then becomes a surface of rupture. Any one such as ABC in Fig. 2 (b) represents one of an infinite number of possible traces on which failure might occur.

- 6. 6 | P a g e SAQIB IMRAN 0341-7549889 6 It is assumed that the problem is two dimensional, which theoretically requires a long length of slope normal to the section. The shear strength of soil is assumed to follow Mohr Coulomb's law Τ or s = c̕+ σ' tan φ̕ Where, c' ‐ effective unit cohesion σ'= effective normal stress on the surface of rupture = (σ ‐ u) σ ‐ total normal stress on the surface of rupture u ‐ pore water pressure on the surface of rupture φ̕= effective angle of internal friction. The item of great importance is the loss of shearing strength which many clays show when subjected to a large shearing strain. The stress‐strain curves for such clay show the stress rising with increasing strain to a maximum value, after which it decreases and approaches an ultimate value which may be much less than the maximum. Since a rupture surface tends to develop progressively rather than with all the points at the same state of strain, it is generally the ultimate value that should be used for the shearing strength rather than the maximum value. Active Earth Pressure on Retaining Wall Active earth pressure on retaining wall: The following cases of active earth pressure on cohesionless backfill will now be considered: 1. Dry or moist backfill 2. Submerged backfill 3. Partly submerged backfill 4. Backfill with uniform surcharge 5. Backfill with sloping surcharge Dry or moist backfill: Consider an element at a depth z below the ground surface, When the wall is at the point of moving away (Outwards) from the backfill, there are two kinds of pressure acting on it. 1. The lateral (horizontal) pressure, it is the minimum principal stress. 2. The vertical pressure, it is the maximum principal stress.

- 7. 7 | P a g e SAQIB IMRAN 0341-7549889 7 Submerged back fill: In this case the sand back-fill behind the retaining wall is saturated with water. The lateral pressure is made up of two components: 1. Lateral pressure due to submerged weight (gamma) of the soil 2. Lateral pressure due to water Partly submerged backfill If the back-fill is partly submerged i.e. the backfill is moist up to depth H1 below the ground level and the it is submerged. Back-fill with uniform surcharge If the backfill is horizontal and carries a surcharge load of uniform intensity q per unit area. The vertical pressure increment at any depth will increase by q. The increase in the lateral pressure due to this will be kaq. Coefficients of earth pressure On a small unit at depth Z in the back there are two kinds of pressure. 1. Vertical Earth pressure: The pressure applied in the vertical direction due to the backfill lying above it. 2. Horizontal Earth pressure: The pressure applied in the horizontal direction due to backfill is called the horizontal pressure or lateral earth pressure Coefficient of active earth pressure at rest: When the retaining wall is at rest then the ratio between the lateral earth pressure and the vertical pressure is called the co-efficient of the earth pressure at rest, Ko =lateral pressure / vertical pressure Coefficient of active earth pressure When the retaining wall is moving away from the backfill the the ratio between lateral earth pressure and vertical earth pressure is called coefficient of active earth pressure.

- 8. 8 | P a g e SAQIB IMRAN 0341-7549889 8 Ka =lateral pressure / vertical pressure Coefficient of passive earth pressure: When the retaining wall is moving towards the back-fill, then the ratio between the lateral earth pressure and the vertical earth pressure is called the Coefficient of passive earth pressure. Ka =lateral pressure / vertical pressure Effects of Density and Moisture on Soil Behaviour Effect of Moisture on Performance of Soil Particles of fine grained soil are more influenced by variation in moisture content then by any other course. Soils that have ample supporting power under one set of moisture condition may be entirely unsatisfactory if the percentage of moisture change. From study of soil it in observed that between the dry state and where moisture demand is satisfied the volume increases as: Sand 2% Silt 16% Clay 160% Colloids950% (i.e. more effect on fine grained soil) The general properties of soil composed largely of course material are primarily controlled by the characteristics of the particles. But soil composed of clay & colloids the properties are primarily controlled By moisture film (i.e. chemistry and surface charges of soil) Atterberg's limits can be used to describe the different states of soil with varying degree of moisture Effect of Density on the Behavior of soil

- 9. 9 | P a g e SAQIB IMRAN 0341-7549889 9 The density of a soil is its weight per unit volume. It is sometime expressed as “Wet weight” or total weight including water. It is more commonly expressed as “dry weight” which in the weight of soil alone excluding the weight of the contained water. As a particle of soil become denser, it will contain a greater number of particles and the (pore) volume remaining for air and water will be decreased. In the increased density and decreased moisture content physical of soil improve. Strength in increased, consolidation under load and the rate of water movement through the soil and the changes under variation of moisture content all are decreased. Composed of sub grades and bases for high density to obtain above advantages is an accepted practice. Characteristics of Soil Particles PURPOSE The characteristics of soil particles are important in predicting the sub grade performance of the given soil. As the purpose of the sub grade is to given adequate support to the

- 10. 10 | P a g e SAQIB IMRAN 0341-7549889 10 pavement thus the sub grade should posses’ sufficient stability under the adverse climate and loading conditions. CHARACTERISTICS OF SOIL PARTICLES What is Soil Consists largely of mineral matter formed by the disintegration or decomposition of rocks, caused by the action of water, ice, frost or temperature changes or by plant and animal life. Some soils near surface may contain humus organic acid resulting from the decay of vegetation. In a road there is wide variation in soil type along the road (compared to buildings). Broad classification rather then bearing at a specific point is taken for finding soil properties. GRAIN SIZE The grains which soil is composed have been classified by AASHTO as follows. S. No. Classes Particle size (Diameter) mm Sieve Size Passing Sieve Size Retained 1 Gravel 80mm to 2mm 3 No 10 2 Coarse sand 2mm to 0.4 No 10 No 40 3 Fine sand 0.4 to 0.08 No 40 No. 200 4 Silt 0.08 to 0.002 No. 200 - 5 Clay 0.002 to 0.001 - - 6 Colloidal Clay smaller than 0.001 - - Grain shape Shape has importance in terms of strength & toughness for large soil particles. 1. Rounded: particles found in stream bed have undergone considerable weal and are probably quite strong. 2. Flat & Flaky: particles probably have not been subjected to such treatment and may be weak and friable and not suitable for highway use. 3. are useful in granular soil mixtures. Which contain little clay and large soil particles having on important influence on their behavior (used in base course) have, an angular particle shape produced by crushing strong, tough rock increase the resistance of soil mass to formation under load since the individual grains tend to lock together.

- 11. 11 | P a g e SAQIB IMRAN 0341-7549889 11 Surface Texture The surface texture of large soil particles greatly influences their performance in granular soil mixtures and Rough surface results in high coefficient of friction among the particles. As a result, the particles cannot slide over each other and provide resistance to deformation under load. (Freshly crushed rock) Rough surface of freshly crushed rock is more important than the angular shape in developing strength. Desirable properties of Soil i. Stability (Resistance to permanent deformation) ii. Incompressibility iii. Permanency of strength iv. Minimum change in volume & stability under adverse condition of weather & ground water. v. Good drainage vi. Ease of compaction (denser) To Determine Liquid Limit of Soil & Plastic Limit of Soil

- 12. 12 | P a g e SAQIB IMRAN 0341-7549889 12 Apparatus 1. Liquid Limit Device - a mechanical device consisting of a brass cup suspended from a carriage designed to control its drop onto a hard rubber base. The device may be operated by either a hand crank or electric motor. 2. Cup - brass with mass (including cup hanger) of 185 to 215 g. 3. Cam - designed to raise the cup smoothly and continuously to its maximum height, over a distance of at least 180o of cam rotation, without developing an upward or downward velocity of the cup when the cam follower leaves the cam. 4. Flat Grooving Tool - a tool made of plastic or non-corroding metal having specified dimensions. 5. Gage - A metal gage block for adjusting the height of the drop of the cup to 10 mm. 6. Ground Glass Plate - used for rolling plastic limit threads. Significance and Use This testing method is used as an integral part of several engineering classifications systems to characterize the fine-grained fractions of soils and to specify the fine-grained fraction of construction materials. The liquid limit, plastic limit and plasticity index of soils are also used extensively, either individually or together, with other soil properties

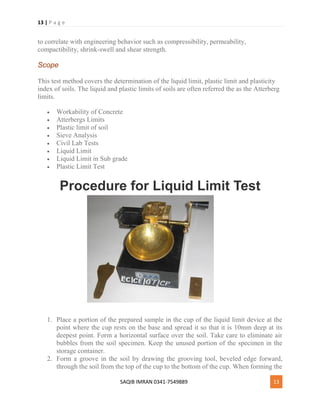

- 13. 13 | P a g e SAQIB IMRAN 0341-7549889 13 to correlate with engineering behavior such as compressibility, permeability, compactibility, shrink-swell and shear strength. Scope This test method covers the determination of the liquid limit, plastic limit and plasticity index of soils. The liquid and plastic limits of soils are often referred the as the Atterberg limits. Workability of Concrete Atterbergs Limits Plastic limit of soil Sieve Analysis Civil Lab Tests Liquid Limit Liquid Limit in Sub grade Plastic Limit Test Procedure for Liquid Limit Test 1. Place a portion of the prepared sample in the cup of the liquid limit device at the point where the cup rests on the base and spread it so that it is 10mm deep at its deepest point. Form a horizontal surface over the soil. Take care to eliminate air bubbles from the soil specimen. Keep the unused portion of the specimen in the storage container. 2. Form a groove in the soil by drawing the grooving tool, beveled edge forward, through the soil from the top of the cup to the bottom of the cup. When forming the

- 14. 14 | P a g e SAQIB IMRAN 0341-7549889 14 groove, hold the tip of the grooving tool against the surface of the cup and keep the tool perpendicular to the surface of the cup. 3. Lift and drop the cup at a rate of 2 drops per second. Continue cranking until the two halves of the soil specimen meet each other at the bottom of the groove. The two halves must meet along a distance of 13mm (1/2 in). 4. Record the number of drops required to close the groove. 5. Remove a slice of soil and determine its water content, w. 6. Repeat steps 1 through 5 with a sample of soil at a slightly higher or lower water content. Whether water should be added or removed depends on the number of blows required to close the grove in the previous sample. Note: The liquid limit is the water content at which it will takes 25 blows to close the groove over a distance of 13 mm. Run at least five tests increasing the water content each time. As the water content increases it will take less blows to close the groove. Observations & Calculations: Sample number 01 02 03 Container number 24 21 25 Number of Blows 17 25 34 Mass of empty container (M1), gm 44.9 46 44.6 Mass of container + wet soil (M2), gm 78.3 81.3 76.8 Mass of container + dry soil ( m3 ), gm 70 75.30 74.10 Water content= w = (M2 - m3 / m3 - M1) x 100, % 33.07 20.30 10.00 Standard Values for Liquid Limit Test Liquid Limit, LL Plot the relationship between the water content, w, and the corresponding number of drops, N, of the cup on a semi-logarithmic graph with water content as the ordinates and arithmetical scale, and the number of drops on the abscissas on a logarithmic scale. Draw the best fit straight line through the five or more plotted points. Take the water content corresponding to the intersection of the line with the 25 drop abscissa as the liquid limit, LL, of the soil.

- 15. 15 | P a g e SAQIB IMRAN 0341-7549889 15 Graph Following is the graph of relation between water content and number of blows Precautions After performing each test the cup and grooving tool must be cleaned. The number of blows should be just enough to close the groove. The number of blows should be between 10 and 40. Applications The value of liquid limit helps in classification of fine grain soil. The values of liquid limit are required to calculate flow index, toughness index etc. Limitations of Liquid Limit Test Procedure for Determination of the Plastic Limit 1. From the 20g sample select a 1.5 to 2 g specimen for testing. 2. Roll the test specimen between the palm or fingers on the ground glass plate to from a thread of uniform diameter. 3. Continue rolling the thread until it reaches a uniform diameter of 3.2mm or 1/8 in. 4. When the thread becomes a diameter of 1/8 in. reform it into a ball. 5. Knead the soil for a few minutes to reduce its water content slightly. 6. Repeat steps 2 to 5 until the thread crumbles when it reaches a uniform diameter of 1/8 in. 7. When the soil reaches the point where it will crumble, and when the thread is a uniform diameter of 1/8", it is at its plastic limit. Determine the water content of the soil. Note: Repeat this procedure three times to compute an average plastic limit for the sample.

- 16. 16 | P a g e SAQIB IMRAN 0341-7549889 16 Calculations Plastic Limit, PL Compute the average of the water contents obtained from the three plastic limit tests. The plastic limit, PL, is the average of the three water contents. Plasticity Index Calculate the plasticity index as follows: PI = LL - PL where: LL = liquid limit, and PL = plastic limit. Precautions The apparatus required for the experiment should be clean. All the readings should be noted carefully. Practical applications The value of liquid limit and plastic limit are used to classify fine grained soil. The values of liquid limit and plastic limits are used to calculate flow index, toughness index and plasticity index of the soil. Observations and calculations: Number of container 24 25 Weight of empty container(M1) gm 45.7 44.5 Weight of container + wet soil (M2) gm 50.6 49.5 Weight of container + dry soil ( m3 ) gm 48 46 Water content = (M2- m3 / m3 -M1)100 % 1.13 1.17 Average plastic limit = (1.13 + 1.7)/2 =1.15% To Determine The Shrinkage Limit of Soil

- 17. 17 | P a g e SAQIB IMRAN 0341-7549889 17 Apparatus Shrinkage dish, electric oven, mercury, electric balance, sieve#40, spatula and containers. Procedure Take a soil sample passing through sieve#40 and add some amount of water in it to form a thick uniform paste. Take the shrinkage dish, weigh it, and put some of the soil mixture in it by spatula, fill it and again weigh it. Place the shrinkage dish in the oven for 24hours at 110-115C. Find the volume of the shrinkage dish using mercury this will be equal to the volume of the saturated soil sample. Take mercury in container and weigh it, put dry soil in it the mercury is displaced. Collect carefully the displace mercury and weigh it with great accuracy. The volume of dry soil is then determined by dividing the weight by the unit weight of mercury. The shrinkage limit is then calculated using the formula. S.L = {{(w1-wd)-(v1-vd) γw}/ wd] x 100 Where, W1 = M2-M1

- 18. 18 | P a g e SAQIB IMRAN 0341-7549889 18 WD = m3 -M1 Precautions The displaced mercury should be carefully collected in order to get exact weight of mercury displaced. Rankine's Assumptions for Earth Pressure Theory for Active/Passive Pressure Rankine's Theory for Earth pressure As originally proposed, Rankine's theory is applied to uniform cohesion-less soil only. Later it was extended to include cohesive soil by Bell in 1915. Assumptions of Rankine's theory: Rankine approached the lateral earth pressure problem with the following assumptions: 1. The soil is homogeneous and isotropic, which means c, φ and γ have the same values everywhere, and they have the same values in all directions at every point (i.e., the

- 19. 19 | P a g e SAQIB IMRAN 0341-7549889 19 strength on a vertical plane is the same as that on a horizontal plane). This discussion will be expanded later to consider layered soils, where each layer has different values of c, φ and γ∙ 2. The most critical shear surface is a plane. In reality, it is slightly concave up, but this is a reasonable assumption (especially for the active case) and it simplifies the analysis. 3. The ground surface is a plane (although it does not necessarily need to be level). 4. The wall is infinitely long so that the problem may be analyzed in only two dimensions. Geotechnical engineers refer to this as a plane strain condition. 5. The wall moves sufficiently to develop the active or passive condition. 6. The resultant of the normal and shear forces that act on the back of the wall is inclined at an angle parallel to the ground surface (Coulomb's theory provides a more accurate model of shear forces acting on the wall). Active Condition With these assumptions, we can treat the wedge of soil behind the wall as a free body and evaluate the problem using the principles of statics, as shown in Figure 1a. This is similar to methods used to analyze the stability of earth slopes, and is known as a limit equilibrium analysis, which means that we consider the conditions that would exist if the soil along the base of the failure wedge was about to fail in shear. Weak seams or other non-uniformities in the soil may control the inclination of the critical shear surface. However, if the soil is homogeneous, Pa/b is greatest when this surface is inclined at an angle of 45 + φ/2 degrees from the horizontal, as shown in the Mohr's circle. Thus, this is the most critical angle. Solving this free body diagram for Pa/b and Va/b gives: The magnitude of Ka is usually between 0.2 and 0.9. Equation is valid only when β ≤ φ. If β= 0, it reduces to:

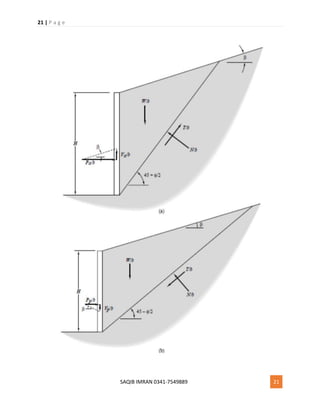

- 20. 20 | P a g e SAQIB IMRAN 0341-7549889 20 A solution of Pa/b as a function of H would show that the theoretical pressure distribution is triangular. Therefore, the theoretical pressure and shear stress acting against the wall, α and τ, respectively, are: Where; σ = soil pressure imparted on retaining wall from the soil τ = shear stress imparted on retaining wall from the soil Pa/b = normal force between soil and wall per unit length of wall Va/b = shear force between soil and wall per unit length of wall b = unit length of wall (usually 1 ft or 1 m) Ka = active coefficient of lateral earth pressureσz' = vertical effective stress β = inclination of ground surface above the wall H = wall height However, observations and measurements from real retaining structures indicate that the true pressure distribution, as shown in Figure 2, is not triangular. This difference is because of wall deflections, arching, and other factors. The magnitudes of Pa/b and Va/b are approximately correct, but the resultant acts at about 0.40H from the bottom, not 0.33H as predicted by theory (Duncan et al., 1990).

- 21. 21 | P a g e SAQIB IMRAN 0341-7549889 21

- 22. 22 | P a g e SAQIB IMRAN 0341-7549889 22 Figure 1: Free body diagram of soil behind a retaining wall using Rankine’s solution: (a) active case; and (b) passive case. Figure 2: Comparison between (a) theoretical and (b) observed distributions of earth pressures acting behind retaining structures Passive Condition Rankine analyzed the passive condition in a fashion similar to the active condition except that the shear force acting along the base of the wedge now acts in the opposite direction (it always opposes the movement of the wedge) and the free body diagram becomes as shown in Figure 1b. Notice that the failure wedge is much flatter than it was in the active case and the critical angle is now 45 – φ/2 degrees from the horizontal. The normal and shear forces, Pp/b and Vp/b, respectively, acting on the wall in the passive case are:

- 23. 23 | P a g e SAQIB IMRAN 0341-7549889 23 Equation is valid only when β≤ φ. If β = 0, it reduces to: Methods to Determine Stress in Soil Both immediate and consolidation settlement analysis requires estimate of increase in pressure (ΔHσ) in the soil layers from the applied loads. Several methods are available to estimate the increase in pressure at any depth z from the applied load. We will discuss: 1. 2:1 Slope method 2. Boussinesq Method.

- 24. 24 | P a g e SAQIB IMRAN 0341-7549889 24 2h: 1v Slope Method An early method is to use 2 (horizontal): 1 (vertical) slope as shown in figure. For rectangular footing (B x L), the vertical pressure increase ΔHσ(z) at a depth z beneath the loaded area due to base load P is: For square footing the above equation simplifies to The 2:1 method compares reasonably well with more theoretical methods from z1 = B to about z2 = 4B but should not be used in the depth zone from z = 0 to B. The average stress increase in a stratum from H = Z2 – Z1 is Boussinesq Method of Stress Determination: This method is based on theory of elasticity and is basically developed for a semi-infinite, isotropic, homogeneous half-space, however the method is used for all type of masses (layered etc), Newmark presented numerical solution to the Boussinesq equation, which is applicable beneath the corner of an area B x L. Δσ = q0 m Iα Where m is the number of corners contributing to is Δσ; m = 1 when Δσ under the corner of a footing is required and m=4 if Δσ under the center of a footing is required. To Determine the Specific Gravity of Soil

- 25. 25 | P a g e SAQIB IMRAN 0341-7549889 25 ASTM Designation: C128 Apparatus Sieve #4, balance, electric oven, pycnometer. Theory Specific gravity is defined as the ratio of the weight of given volume of material to the weight of an equal volume of water. G = density of soil/density of equal volume of water G = mass of dry soil/mass of and equal volume of water. Procedure

- 26. 26 | P a g e SAQIB IMRAN 0341-7549889 26 Take at least 25g of soil which has been passed through sieve#4 and place it in an oven at fixed temperature of 105-110 °C for 24 hours to dry it completely. Clean and dry the pycnometer thoroughly and find its mass (M1). Find the mass (M2) of pycnometer by placing dried soil in it. Add sufficient quantity of water to fill the pycnometer up to the given mark and then find mass of the pycnometer ( m3 ) and its content. Empty the pycnometer then fill it with water up to the same level. Now find the mass (M4) of the pycnometer having water in it. Determine the specific gravity of the given soil sample. Precautions The graduated cylinder used should be cleaned. Dry the coarse aggregate so that it does not absorb moisture otherwise it will not give the desired results. All the readings of mass should be noted carefully. Practical applications The value of specific gravity helps us to some extent in identification and classification of soil. It gives the idea about the suitability of a given soil as a construction material. It is utilized in calculating voids ratio, porosity, and degree of saturation if the density or unit weight and water content are known. Shear Strength of Pervious and Impervious Soils

- 27. 27 | P a g e SAQIB IMRAN 0341-7549889 27 Soils derive their strength from contact between particles capable of transmitting normal as well as shear forces. The contact between soil particles is mainly due to friction and the corresponding stress between the soil grains is called the effective (or inter-granular) stress s'. Thus, the shear strength of a soil is mainly governed by the effective stress. Besides the effective stress between soil grains, the pore water contained in the void spaces of the soil also exerts pressure which is known as pore pressure, u. The sum of the effective stress and pore pressure acting an any given surface within a compacted earth embankment is called the total stress s. As the pore water cannot resist shear, all shear stresses are resisted by the soil grains only. The effective stress is approximately equal to the average intergranular force per unit area and cannot be measured directly. The total stress is equal to the total force per unit area acting normal to the plane. The pore water affects the physical interaction of soil particles. Soils with inactive surfaces do not absorb water, but clay particles, formed of silicates which are frequently, charged electrically, absorb water readily and exhibit plastic, shrinkage, and swelling characteristics. Besides, a change in pore pressure can directly affect the effective stress. The pore water thus influences the shear strength parameters of a soil to a considerable extent. The shear strength of a soil is fully mobilized when a soil element can only just support the stresses exerted on it. For most soils, the shear strength of any surface, at failure, is approximated by the following Mohr-Coulomb's linear relationship s = c' + s' tan f'

- 28. 28 | P a g e SAQIB IMRAN 0341-7549889 28 where, s = shear strength of soil (or shear stress at failure) on the surface under consideration, c' = cohesion, f' = angle of internal friction (or angle of shearing resistance), and s' = effective normal stress acting on the failure surface = s - u. Here, c' and f' are determined using effective stresses. While analyzing the stability of an embankment, the designer uses one of the two methods. These are: 1. Total stress method, 2. Effective stress method Laboratory tests (for determining shear strength parameters of a soil) for the total stress method are performed such that the experimental conditions with regard to pore pressure simulate the pore pressure conditions in the embankment at failure and the shear strength of the soil sample is measured in terms of total stress without pore pressure measurements. For the effective stress method, pore pressures on the potential failure surface are estimated and the shear strength determined in terms of the effective stresses. The total stress method is relatively simpler. But, the effective stress method is more fundamental in nature and, hence, is recommended for the stability analysis of embankment dams. Shear Strength for Impervious Soils There are three types of laboratory tests which are commonly used for the determination of shear strength of compacted impervious soils. These methods differ in the method of consolidating the soil sample before the sample is failed in shear. These methods are as follows: 1. Undrained test, 2. Consolidated-undrained test, and 3. Drained test In the undrained test (also known as the 'quick', 'unconsolidated-undrained' or 'Q' test), drainage or dissipation of pore pressure is not allowed at any stage of the test. The relationship between the shear strength and normal pressure, obtained in terms of total stress, is used in the stability analysis of an embankment dam for 'during' and 'immediately after' construction condition. The soil samples are tested at a moisture

- 29. 29 | P a g e SAQIB IMRAN 0341-7549889 29 content and density which would prevail during or immediately after construction. If the moisture content corresponds to saturation level, it will be found that all soil samples (saturated) have the same shear strength if no consolidation (i.e., drainage) is allowed. In consolidated undrained test (also known as 'consolidated-quick' or 'R' test) the sample is first allowed to consolidate (with full pore pressure dissipation) under a specified consolidation pressure, and is then failed in shear without permitting drainage. To obtain strength parameters in terms of effective stress (i.e., c' and f'), the pore pressure should be measured. These values are used for effective stress method of stability analysis. If the test values are to be used for the total stress method of stability analysis, the sample should be tested (without pore pressure measurement) at a water content which is anticipated in the dam during the period being analyzed. It should often be difficult to determine the water content which would prevail in the dam. Hence, it is usual practice to conduct the tests on saturated samples for total stress method of analysis. The results of these tests would be useful for analyzing sudden draw-down condition of impervious zones of embankment and foundation. The test results would also be useful for analyzing the upstream slope during a partial pool condition and the downstream slope during steady seepage. Drained test (also known as the 'slow' test or 'S' test) permits drainage and complete dissipation of pore pressure at all stages of the test. The strength parameters are determined in terms of effective stress. The results of this test are to be used for freely-draining soils in which pore pressures do not develop. Shear Strength of Pervious Soils In embankment sections of clean sand and gravel, the pore pressures develop primarily due to seepage flow. The changes in pore pressure on account of changes in the embankment volume are short-lived and can be neglected. Consequently, the effective stress method of stability analysis is used for sections of pervious sand and gravel. The strength characteristics of sand and gravel are determined by drained tests. Because of the limitations of the size of test equipment, it may not be possible to test gravels of larger size. The strength characteristics of such soil can safely be assumed as those obtained for finer fractions of the same soil. Total Stress and Effective Stress Analysis in Soil

- 30. 30 | P a g e SAQIB IMRAN 0341-7549889 30 Plastic saturated soils (silts and clays) usually have lower shear strength than non-plastic cohesion less soil and are more susceptible to bearing capacity failure. For saturated plastic soils, the bearing capacity often has to be calculated for different condition. Total Stress Analysis (Short term condition) that uses the un-drained shear strength of the plastic soil. Effective stress analysis (Long term condition that uses the drained shear strength parameters (c' & F') of the plastic soil). Total Stress Analysis Total stress analysis uses the un-drained shear strength of the plastic soil. The un-drained shear strength (sigma a) could be determined from field tests, such as the vane shear test (VST), or in the laboratory from unconfined compression tests. If the un-drained shear strength is approximately constant with depth, then sigma a=c and F = 0 For F = 0, the bearing capacity factors are Nc = 5.5, N ? = 0 and Nq = 1 (Put these values in Terzaghi's bearing capacity equation) (For strip footing) Q ult = 5.5c + ? Df

- 31. 31 | P a g e SAQIB IMRAN 0341-7549889 31 Because of the use of total stress parameters the ground water table does not affect the above equation. The ultimate bearing capacity of the above example, the ultimate bearing capacity of plastic soil is often much less than the ultimate bearing capacity of cohesion less soil. This is the reason that building codes allow higher allowable bearing pressure for cohesion less soil (such as sand) than plastic soil (clay). Also, because the ultimate bearing capacity does not increase with footing width for saturated plastic soils, there is often no increase allowed for an increase in footing width. In some cases, it may be appropriated to use total stress parameters "c" and "F" in order to calculate the ultimate bearing capacity [For example, a structure such as an oil tank or grain elevator could be constructed and the sufficient time elapses so that the saturated plastic soil consolidates under this load. If an oil tank or grain elevator were then quickly filled, the saturated plastic soil would be subjected to an un-drained loading.] This condition can be modeled by performing consolidated un-drained tri-axial tests (ASTM 4767-02, 2004) in order to determine the total stress parameter (c & F). Based on F value, the bearing capacity factors would be obtained from figure; and then the ultimate bearing capacity would be calculated from equation 1. If site consists of two layers of cohesive soil having different shear strength parameters/properties; Calculate the ratio of the un-drained shear strength of layer 2 to the un-drained shear strength of layer 1 i.e. c2/c1 = su2/su1 Determine the ratio T/B, where T= vertical distance from the bottom of the foundation to the top of the layer 2 and B = width of the foundation. Enter the values (c2/c1) in graph, intersect appropriate T/B curve, and determine the value of Nc For strip footing; F = 0 (N ? = 0 Nq = 1). Effective stress Analysis The effective stress analysis uses the drained shear strength (c' & F') of the plastic soil. The drained shear strength could be obtained from tri-axial compression tests. This analysis is termed as long term analysis because the shear induced pore water pressure from the loading have dissipated and the hydrostatic pore water conditions now prevail in the field. Because an effective stress analysis is being performed the location of the ground water table must be considered in the analysis. The first step to perform the bearing capacity analysis would be to obtain the bearing capacity factors (Nc, N ?, Nq) from Fig; using the value of F'. An adjustment to the total unit weight may be required depending on the location of the ground water table. Then Terzaghi's bearing capacity equation would be utilized (with c' substituted for c) to obtain the ultimate bearing capacity, with a factor of safety of 3 applied in order to calculate the allowable bearing capacity or pressure.

- 32. 32 | P a g e SAQIB IMRAN 0341-7549889 32 Governing case: Total stress analysis will provide a lower allowable bearing capacity for soft or very soft saturated plastic soils. This is because load will consolidate the plastic soil leading to an increase in the shear strength as the time passes. For long term case, the shear strength of the plastic soil is higher with a resulting higher bearing capacity. Effective stress analysis will provide a lower allowable bearing capacity for very stiff or hard saturated plastic soils. Firm to stiff plastic soils are intermediate condition. The ORC and the tendency of the saturated plastic soil to consolidate (gain shear strength) will determine whether the short term condition or the long term condition provides the lower bearing capacity. Bearing capacity analysis for granular soils Granular soil does not liquefy, but rather there is a reduction in shear strength due to an increase in pore water pressure. Examples include sands and gravels that are below the ground water table and have a factor of safety against liquefaction is greater then 2 the earthquake induced excess pore water pressure will typically be small enough that its effect can be neglected. Using the Terzaghi's bearing capacity equation and an effective stress analysis and recognizing that sands and gravels are cohesion less (i.e. c' = 0) Terzaghi's bearing capacity equation Qult = cNc + q'Nq + 1/2 t BN For cohesion less soil Qult = 1/2 t BN? + t Df Nq For shallow foundations, it sis best to neglect the second term (?t Df Nq) in equation 2. This is because the term represents the resistance of soil located above the bottom of the footing, which may not be mobilized for punching shear failure. So, Qult = 1/2 ?t BN? Cohesion less soils include gravel, sands Cohesion less soil develops its shear strength as a result of frictional and interlocking resistance between the individual soil particles. This is due to confining pressure. In case of cohesion less soil c = 0 Qult = cNc + q'Nq + 1/2 ?t BN? First term c = 0 Qult = qNq + 1/2 ?t BN? For cohesion less soil the location of the ground water table can effect the ultimate bearing capacity. The depth of the bearing capacity failure is often assumed that the soil involved in the bearing capacity failure extends to a depth equal to width of footing. Thus for a ground water table located in this zone, change the third term in the above equation.

- 33. 33 | P a g e SAQIB IMRAN 0341-7549889 33 Engineering Properties of Silt and Clay Silt and Clay are considered to be smaller family members of soil group, Even small amounts of fines can have significant effects on the engineering properties of soils. If as little as 10 percent of the particles in sand and gravel are smaller than the No.200 sieve size, the soil can be virtually impervious, especially when the coarse grains are well graded. Silica is decided to be acidic and magnesia bricks are strongly basic. However, fire clay bricks are generally placed in the neutral group. Chemical reaction may take place when the refractory comes in contact with fuel ashes, slag, gases inside the furnace, and the products such as glass or steel. Moreover, serious frost heaving in well graded sands and gravels can be caused by fines making up less than 10 percent of the total soil weight. The utility of coarse-grained materials for roads can be improved by the addition of a small amount of clay to act as a binder for the sand and gravel particles. Soils containing large quantities of silt and clay are the most troublesome to the engineer. These materials exhibit marked changes in physical properties with changes in water content. A hard, dry clay, for example, may be suitable as a foundation for heavy loads so long as it remains dry, but it may become unstable when wet.

- 34. 34 | P a g e SAQIB IMRAN 0341-7549889 34 Many of the fine soils shrink on drying and expand on wetting, which may adversely affect structures founded upon them or constructed of them. Even when the water content does not change, the properties of fine soils may vary considerably between their natural condition in the ground and their state after being disturbed. Deposits of fine particles that have been subjected to loading in geologic time frequently have a structure that gives the material unique properties in the undisturbed state. When the soil is excavated for use as a construction material or when the natural deposit is disturbed, for example by driving piles, the soil structure is destroyed and the properties of the soil are

- 35. 35 | P a g e SAQIB IMRAN 0341-7549889 35 changed radically. Silts are different from clays in many important respects, but because of their similar appearance, they are often mistaken for each other, sometimes with unfortunate results. Dry, powdered silt and clay are indistinguishable, but they are easily identified by their behavior in the presence of water. Recognition of fines as either silt or clay is an essential part of the USCS. Silts are the nonplastic fines, they are inherently unstable in the presence of water and have a tendency to become "quick" when saturated that is, they assume the character of a viscous fluid and can flow. Silts are fairly impervious, difficult to compact, and highly susceptible to frost heaving. Silt masses undergo change of volume with change of shape (the property of dilatancy), in contrast with clays, which retain their volume with change of shape (the property of plasticity). The dilatancy of silt together with its quick reaction to vibration affords a means of identifying typical silt in the loose, wet state. When dry, silt can be pulverized easily under finger pressure (indicative of very slight dry strength), and has a smooth feel between the fingers unlike the grittiness of fine sand. Silts differ among themselves in size and shape of grains. This is reflected mainly in the property of compressibility. Generally, the higher the liquid limit of a silt, the more compressible it is. The liquid limit of a typical bulky- grained, inorganic silt is about 30 percent; whereas, highly micaceous or diatomaceous silts (elastic silts), consisting mainly of flaky grains, may have liquid limits as high as 100 percent. Clays are the plastic fines. They have low resistance to deformation when wet, but they dry to hard, cohesive masses. Clays are virtually impervious, difficult to compact when wet, and impossible to drain by ordinary means. Large expansion and contraction with changes in water content are characteristics of clays. The small size, flat shape, and mineral composition of clay particles combine to produce a material that is both compressible and plastic. Generally, the higher the liquid limit of a clay, the more compressible it will be. At the same liquid limit, the higher the plasticity index, the more cohesive the clay. Field differentiation among clays is accomplished by the toughness test, in which the moist soil is molded and rolled into threads until crumbling occurs, and by the dry strength test, which measures the resistance of the clay to breaking and pulverizing. The clays of low compressibility and low plasticity, lean clays, can be readily differentiated from the highly plastic, highly compressible fat clays.

- 36. 36 | P a g e SAQIB IMRAN 0341-7549889 36 To Determine Moisture Content of Soil By Oven Drying Method (AASHTO DESIGNATION: T-265 ASTM D-2216-90) The water-content determination is a routine laboratory procedure. ASTM has designeated it with a Standard, ASTM D-2216-90 which can be found in “ASTM Standards vol. 4.08”, and also AASHTO T-265, found under “AASHTO Materials: Part II: Tests”. This is a laboratory procedure to determine the amount of water Ww present in a quantity of soil in terms of its dry weight Ws. The water content w is usually expressed in percent. Although it ia a simple experiment to perform, there are several sources of error that can occur. The most significant is the oven temperature. Many soil-forming minerals are

- 37. 37 | P a g e SAQIB IMRAN 0341-7549889 37 hydrous, meaning they contain water within their crystal structures. Normally, the water content of a soil is measured by oven drying the soil at 110º C. This temperature is used because it is high enough to evaporate all the water present in the pore spaces of the soil but is not so large that it drives water out of the structure of most minerals. Other sources of error include: the time period used for drying the soil, the sample size, and weighing errors. Apparatus: 1. Three to five moisture cans (tin or aluminum) with their lids; 2. Temperature controlled oven (a forced-draft type). The oven should be kept at a temperature of 110 ± 5°C; 3. An electronic scale. PROCEDURE: 1. Weigh each of the empty moisture cans with their lids and record their weight W1 and its number; you may have to mark it with a felt tip pen 2. Take the sample of soil (under 100 g) collected from the field and place a sample of it into a can. If you are not testing a field sample, then moisten the sample given to you (20 to 40 g) with a small amount of water and thoroughly mix it with a spatula. Place the cap on the can and, weigh and record the can with the lid and the moist soil weight W2; 3. Always use the same scale, and always check to see that they read zero; 4. Remove the lid, place it underneath the can, and put the can into the drying oven 5. Repeat these steps for the two other cans. There should be three moisture cans in the oven. The temperature of the drying oven should be kept between 105º and 110º C, and the cans should remain in the oven for at least 24 hours; 6. After 12 to 18 hours (or overnight), weigh and record the new weight of the moisture can with the dried soil and its lid W3. This procedure is adequate for small amounts of soil (10 to 200 grams). Much larger soil samples may require occasional stirring so that a uniform drying takes place; 7. Remove from the oven with tongs or heat-treated loves and weigh immediately; some manuals claim that convection currents affect the result, but this writer has never found this to be true; 8. The total weight difference between W3 and W2 is the weight of the water that was evaporated from the soil. This weight loss will be then used to calculate the percentage of water content w in the soil. 9. Report the water content to the nearest 0.1 percent, but in computations w is used as a decimal quantity.

- 38. 38 | P a g e SAQIB IMRAN 0341-7549889 38 TEST SAMPLE: Sample shall be washed and oven-dried at a temperature of 105 °C-110 °C and should conform to one of the grading in observation. Ca n (#) Weig ht of Can (W1l b) (Lb) Weigh t of Can + Moist Soil (W2lb) (lb) Weig ht of Can (W1g ) (g) (1) Weigh t of Can + Moist Soil (W2g) (g) Weig ht of Can + Dry Soil (W3) (g) (2) Weig ht of Wate r (WW ) (g) (3) Weig ht of Dry Soil (WS) (g) (4) Water Conte nt (W) (%) (5) Erro r (%) 1 0.034 5 0.0690 15.65 31.30 28.9 2.398 13.25 1 18.10 4.97 2 0.034 5 0.0625 15.65 28.35 26.4 1.950 10.75 1 18.13 4.77 3 0.035 5 0.0695 16.10 31.52 28.9 2.625 12.79 7 20.51 7.71 4 0.035 0 0.0635 15.88 28.80 26.7 2.103 10.82 4 19.43 2.04 Average 19.04 4.8 7 Standard Deviation 1.16 Sample Calculations: Conversion of pounds to grams = Weight of water in Sample = Precautions: The soil sample should be loosely placed in the container. Over heating should be avoided. Mass should be found carefully.

- 39. 39 | P a g e SAQIB IMRAN 0341-7549889 39 USES AND SIGNIFICANCE: 1. Moisture content plays an important role in understanding the behavior of soil. 2. It shows the degree of compaction of soil in the field. Standard Test Methods are: AASHTO T 96 and ASTM C 131: Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine ASTM C 535: Resistance to Degradation of Large-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine Modes of Shear Failure of Soil | General, Local, Punching Shear Failure

- 40. 40 | P a g e SAQIB IMRAN 0341-7549889 40 Shear failure of Soil

- 41. 41 | P a g e SAQIB IMRAN 0341-7549889 41 There are three modes of shear failure, i.e. General, Local and Punching shear failures depending upon the compressibility of soil and depth of footing with respect to its breadth (i.e D/B Ratio). When the ultimate bearing capacity of the soil is reached, it may fail in one of the following three failure mode depending upon the type of soil and depth to width ratio of the footing (i.e. D/B) General Shear Failure Local Shear Failure Punching Shear Failure 1. General Shear Failure In this mode a slight downward movement of the footing develops fully plastic zones and a sudden failure takes place with a considerable bulging of the ground surface adjacent to the footing Characterized by well defined failure pattern, consisting of a wedge and slip surface and bulging (heaving) of soil surface adjacent to the footing Sudden collapse occurs, accompanied by tilting of the footing This type of failure occurs in case of dense sand or stiff cohesive soil supporting the footing Failure load is well defined The load-settlement diagram is similar to stress-strain for dense sand or over-consolidated clay as shown The ultimate load is well defined on this curve as shown typically in figure given below 2. Local shear failure Failure pattern consists of wedge and slip surface but is well defined only under the footing. Slight bulging of soil surface occurs. Tilting of footing is not expected. In this mode a large deformation takes place under the footing before the development of failure zones, i.e. large vertical settlement takes place before slight bulging of the ground surface Tilting of footing is not expected Ultimate load is not well defined It takes place in moderately compressible soils or loose sand i.e Occurs in soil of high compressibility Yielding takes place close to the lower edges of the footing Several yield developments may occur accompanied by settlement in a series of jerks The bearing pressure at which the first yield takes place is referred to as the first-failure pressure or first failure load

- 42. 42 | P a g e SAQIB IMRAN 0341-7549889 42 3. Punching shear failure Failure pattern is not well defined No bulging of ground surface and no tilting of footing occurs The yield surfaces are vertical planes immediately adjacent to the sides of the foundation The ground surface may be dragged down thus, no bulging of the surface takes place Failure take place immediately below footing and surrounding soil remains relatively unaffected Large settlements-ultimate load is not well defined Punching Shear Failure takes place in weak compressible soils with considerable vertical settlement i.e Occurs in soil of very high compressibility It also occurs in the soil of low compressibility, if the foundation is located at considerable depth. After the first yield the load-settlement curve will steepen slightly, but remain fairly flat Punching Shear Failure may also take place in soil of low compressibility, if the foundation is located at a considerable depth Modes of Shear Failure (Summary) General Local Punching Relative Settlement Less Large Large Bulging Significant Less No Tilting of Footing Expected Not expected Not expected Ultimate Load Well defined Not well defined Not well defined Failure Pattern Wedge + Slip Surface + Bulging Wedge + Slip Surface + Bulging(no or less) Not well defined Occurs in (Soil Type) Dense Less compressible Highly Compressible How to find Bearing Capacity of Soil

- 43. 43 | P a g e SAQIB IMRAN 0341-7549889 43 Methods of bearing capacity determination Analytic method i.e. through bearing capacity equations like using Terzaghi equation, Meyerhof equation, Hansen equation etc Correlation with field test data e.g. Standard penetration test (SPT), Cone penetration test (CPT) etc On site determination of bearing capacity e.g Plate load test, Pile load test Presumptive bearing capacity (recommended bearing capacity, in various codes) Following are the methods: 1. Analytical Method of Bearing capacity determination Analytical Method Lower Bound Failure Lower bound failure states that “If an equilibrium distribution of stress can be found which balances the applied load and nowhere violates the yield criterion, the soil mass will not fail or will just be at a point of failure i.e. it will be a lower bound estimate of capacity. Consider the equilibrium conditions in soil under the footing load. When the foundation pushes into the ground, stress block 1 has principal stresses, as shown. The push into the ground however, displaces the soil on the right side of the line OY laterally,

- 44. 44 | P a g e SAQIB IMRAN 0341-7549889 44 resulting in the major principal stress on block 2 being horizontal as shown. When the two blocks are adjacent to each other at the vertical line OY, then Some Formulae Upper Bound theorem Upper bound theorem states that “If a solution is kinematically admissible and simultaneously satisfies equilibrium failure must result” i.e. it will be an upper bound estimate of capacity. For a possible upper bound, consider failure surface as semicircle. Taking moment about O Terzaghi’s bearing capacity equation (1943) Terzaghi developed a general formula for ultimate bearing capacity of spread footing foundation under the following assumptions: The depth of the footing is less than or equal to its width (D, B) The foundation is rigid and has a rough bottom The soil beneath the foundation is homogeneous semi-infinite mass Strip foundation with a horizontal base and level ground surface under vertical loads. The general shear mode of failure governs and no consolidation if the soil occurs (settlement is due only to shearing and lateral movements of the soil) The shear strength of the soil is described by s = c + σ tan Presumptive Soil Bearing Values by Soil Description Presumptive Soil Bearing Values by Soil Description Presumptive Load Bearing Value (psf) Soil Description 1500 Clay, Sandy Clay, Silty Clay, Clayey Silt, Silt and Sandy Silt 2000 Sand, Silty Sand, Clayey Sand, Silty Gravel and Clayey Gravel 3000 Gravel and Sandy Gravel 4000 Sedimentary Rock 12000 Crystalline Bedrock Index Properties of Soil

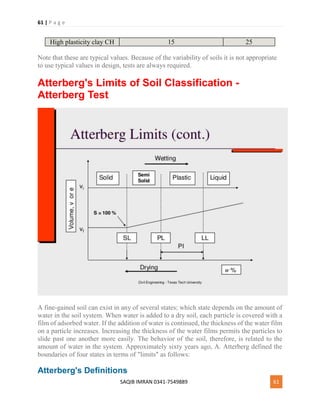

- 45. 45 | P a g e SAQIB IMRAN 0341-7549889 45 The soil properties on which their classification and identification are based are known as index properties. The index properties which are used are: Grain Size Distribution Consistency Limits Plasticity Index Grain Size Distribution (Sieve Analysis) The sieves are arranged, keeping the finest below and the coarser above it. A definite quantity of soil is dried in an electric oven (for 24 hrs at 105°C) and put in the top sieve. The cover is placed over the top sieve and a pan below the lowest sieve. Then the sieves are placed in the sieve shaker and are shaken for few minutes. The weight of soil thus retained on each sieve is determined and is converted into a percentage. Consistency of Soil Consistency of soil is the physical state of soil with respect to moisture content present at that time. By consistency means the relative ease with which soil can be deformed. Consistency is related to the fine grained soil. Consistency Limits or Atterberg Limits The moisture content at which the soil change from one state to another State is called consistency limits or Atterberg limits There are four different states of soil:

- 46. 46 | P a g e SAQIB IMRAN 0341-7549889 46 1. Solid State 2. Semi Solid State 3. Plastic State 4. Liquid State When water is added to the dry soil mass its change from solid state to liquid state passing through semi solid and plastic state. Atterberg identify some other limits which are most useful for engineering purpose. Why Study Soil Mechanics in Civil Engg? Definition of Soil: Soil is a natural agglomerate used as a construction as well as supporting material and is composed of particles of broken rocks which keep on changing in their texture, structure, consistency, color, chemical, biological and other characteristics from their parent material (rock) by chemical and mechanical processes like disintegration erosion, freezing and thawing. Definition of Mechanics:

- 47. 47 | P a g e SAQIB IMRAN 0341-7549889 47 Mechanics is the branch of science dealing with the behavior or response of bodies at rest or with negligible velocity subjected to forces, pressures or displacements. Soil Mechanics Soil Mechanics is the branch of civil engineering that is concerned with behavior of soil at rest under different conditions of direct (Structural Loads) and indirect (Thermal Stresses) loading. According to Terzaghi Soil Mechanics is the application of the laws of mechanics and hydraulics to engineering problems dealing with sediments and other unconsolidated accumulations of solid particles produced by chemical and mechanical disintegration of rocks regardless of whether or not they contain an admixture of organic constituents. Why do we Study Soil Mechanics? Every man made structure rests on earth and thus need a foundation to transfer the ultimate load without failure. To determine the behavior of soil and to resist these ultimate loads we need to study its mechanics. To make new researches in the relevant field To replace the old (unscientific) methods of construction with the new and advanced ones Uses of Soil in Civil Engineering In civil engineering the soil can be used in different ways. The uses of soil can be divided into three categories: 1) As a Supporting Material Soil is used as a supporting material to bear the load of structures e.g. Bridges, Roads Buildings 2) As a Raw Material (Unprocessed Material) In natural form soil can be used for the following purposes Flood Control Embankments Road Embankments Earth-Filled Dam

- 48. 48 | P a g e SAQIB IMRAN 0341-7549889 48 3) As a Processed Material Passed through some process to get Burnt Bricks Concrete Mixes Formation of Soil The formation of soil starts with the parent material and continues for a very long period of time taking 1000 years or more. As the parent material is weathered and / or transported, deposited and precipitated it is transformed into a soil. The parent material may be in the form of bedrock, glacial deposits, and loose deposits under water or material moving down sloping land. Factors Affecting Formation of Soil Soil formation process is influenced by the following factors Composition of Parent Material Climate Topography Organisms Time Bare rocks exposed to warm climate, frequent and heavy annual rainfalls causes faster development of soil. Standard Values for Liquid Limit of Soil and Limitations of L.L Test

- 49. 49 | P a g e SAQIB IMRAN 0341-7549889 49 The liquid limit of a soil is the moisture content, expressed as a percentage of the mass of the oven-dried soil, at the boundary between the liquid and plastic states The moisture content at this boundary is arbitrarily defined as the liquid limit and is the moisture content at a consistency as determined by means of the standard liquid limit apparatus. Introduction to Liquid Limit Test The liquid limit test is one of the most widely used tests in the soil engineering practice. Several properties, including mechanical properties (for example, compressive index), have correlations with the liquid limit. In this paper detailed investigations of the liquid limit of soil mixtures have been carried out using bentonite, kaolinite, sand (coarse grained, fine grained, rounded and angular

- 50. 50 | P a g e SAQIB IMRAN 0341-7549889 50 shaped), and silts. Based on the results obtained, it has been shown that the liquid limits of soil mixtures are not governed by the linear law of mixtures. While the shape of the sand was not found to influence the liquid limit, the size of the sand particles had a definite influence. First of all a grooved is made in the soil sample by using a standard grooving tool along the diameter through the center line of the cam follower so that a clean, sharp groove of proper dimension is formed, the cup shall be dropped by turning the crank at the rate of two revolutions per seconds and the number of blows counted until the two halves of the soil cake come into contact with the bottom of the groove along a distance of about 12 mm. A representative soul sample nearer the groove is taken for moisture content determination. The moisture content is reported along with number of blows required to close a groove. The operations specified above shall be repeated for at least three trails at different moisture content. The specimens shall be not less than 15 and more than 35/ the test should proceed from the drier (more drops) to wetter (less drops) condition of the soil. It has been found that the liquid limit of certain materials is influenced by the time of mixing. There is a tendency, particularly noticeable in the case of decomposed dolerites and certain pedogenic materials, for the liquid limit to increase as the time of mixing is increased, although this increase will, of course, not continue indefinitely. Hence it was considered necessary to stipulate a mixing time and a period of ten minutes was decided on. Some times soil tends to slide on the surface of the cup instead of flowing. If this occurs, the results should be discarded and the test repeated until flowing does occur. If sliding still occurs, the test is not applicable and it should be reported that the liquid limit could not be obtained. Standard Values for Liquid Limit Test Liquid limit is the water content at which a part of soil, cut by a groove of standard dimensions, will flow together for a distance of 1.25 cm under an impact of 25 blows in a standard liquid limit apparatus. The soil at the water content has some strength which is about 0.17 N/cm.sq. (17 gms/sq.cm.) .

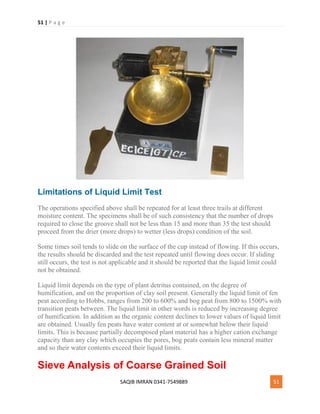

- 51. 51 | P a g e SAQIB IMRAN 0341-7549889 51 Limitations of Liquid Limit Test The operations specified above shall be repeated for at least three trails at different moisture content. The specimens shall be of such consistency that the number of drops required to close the groove shall not be less than 15 and more than 35 the test should proceed from the drier (more drops) to wetter (less drops) condition of the soil. Some times soil tends to slide on the surface of the cup instead of flowing. If this occurs, the results should be discarded and the test repeated until flowing does occur. If sliding still occurs, the test is not applicable and it should be reported that the liquid limit could not be obtained. Liquid limit depends on the type of plant detritus contained, on the degree of humification, and on the proportion of clay soil present. Generally the liquid limit of fen peat according to Hobbs, ranges from 200 to 600% and bog peat from 800 to 1500% with transition peats between. The liquid limit in other words is reduced by increasing degree of humification. In addition as the organic content declines to lower values of liquid limit are obtained. Usually fen peats have water content at or somewhat below their liquid limits. This is because partially decomposed plant material has a higher cation exchange capacity than any clay which occupies the pores, bog peats contain less mineral matter and so their water contents exceed their liquid limits. Sieve Analysis of Coarse Grained Soil

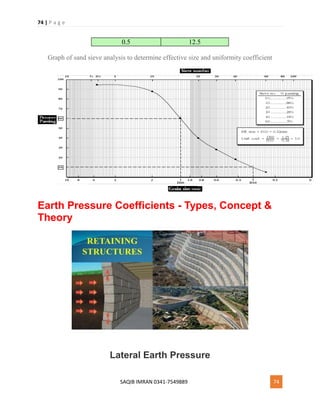

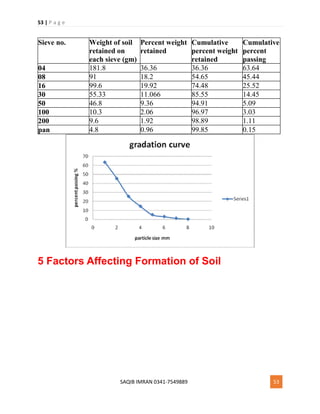

- 52. 52 | P a g e SAQIB IMRAN 0341-7549889 52 Apparatus A set of various sizes of sieves, balance. Procedure 1. Arrange different types of sieves in order of there decreasing size of opening. 2. Find the total weight of the given soil sample and pour it in the top sieve. 3. Place the set of sieves on mechanical shakers and shake it properly. 4. Find the weight of soil retained on each sieve. 5. Calculate percentage weight of soil passing through each sieve. 6. Draw a grain size distribution/gradation curve. Precautions: During shaking soil sample should not b allowed to spell out. All the readings should be noted carefully. Practical applications Grain size analysis gives an idea regarding the gradation of soil. It is used to proportion the selected soil in order to obtain the desired soil mix. It is also utilized in part of the specification of soil for air field’s roads, earth dams and other soil embankment construction. Observations & Calculations:

- 53. 53 | P a g e SAQIB IMRAN 0341-7549889 53 Sieve no. Weight of soil retained on each sieve (gm) Percent weight retained Cumulative percent weight retained Cumulative percent passing 04 181.8 36.36 36.36 63.64 08 91 18.2 54.65 45.44 16 99.6 19.92 74.48 25.52 30 55.33 11.066 85.55 14.45 50 46.8 9.36 94.91 5.09 100 10.3 2.06 96.97 3.03 200 9.6 1.92 98.89 1.11 pan 4.8 0.96 99.85 0.15 5 Factors Affecting Formation of Soil

- 54. 54 | P a g e SAQIB IMRAN 0341-7549889 54 The formation of soil starts with the parent material and continues for a very long period of time taking 1000 years or more. As the parent material is weathered and / or transported, deposited and precipitated it is transformed into a soil. The parent material may be in the form of bedrock, glacial deposits, and loose deposits under water or material moving down sloping land. Factors Affecting Formation of Soil Soil formation process is influenced by the following factors Composition of Parent Material Climate Topography Organisms Time Bare rocks exposed to warm climate, frequent and heavy annual rainfalls causes faster development of soil. Weathering It is a natural process of breaking down of rocks, and minerals as well as artificial materials due to its prolonged exposure to the environment. These particles when moved away by gravity, water, ice, wind etc is then known as erosion. In short, when a particle is

- 55. 55 | P a g e SAQIB IMRAN 0341-7549889 55 loosened by a chemical or physical process, but does not move, it is called Weathering. When the particle moves, it is called Erosion. Types of Weathering Depending upon the mechanism and causes, weathering can be divided into three broad categories 1. Physical Weathering 2. Chemical Weathering 3. Biological Weathering Physical Weathering Physical Weathering also known as Mechanical Weathering may occur due to the following reasons 1. High Speed Winds High Speed winds causes the erosion of surface material 2. Thermal Stress Thermal stresses are caused by repeated heating and cooling. In deserts the temperature at day time is more causing expansion of bodies while at night the temperature decreases causing contraction eventually leading to breaking of rocks 3. Freezing and Thawing The moisture or water penetrated into cracks when freezes, it expands causing stresses and breaking of rock 4. Pressure Releases When some of the material is removed from the surface, the load is reduced and the underlying body expands up causing cracking. 5. Hydraulic Actions Water from power full waves when strike against the rock causes erosion.

- 56. 56 | P a g e SAQIB IMRAN 0341-7549889 56 6. Salt-Crystals Growth When saline solutions seep into cracks and joints in the rocks and evaporate it leaves salt crystals behind. These salt crystals expand as they are heated up thus exerting pressure on the confining rock. In Physical Weathering the broken down particles have same properties as the parent material Chemical Weathering Chemical Weathering may occur due to the following processes and reactions 1) Dissolution and Carbonation 2) Hydration 3) Hydrolysis 4) Oxidation In Chemical Weathering the broken particles have different composition from the parent material and change into different substances 1) Dissolution and Carbonation In unpolluted environments, the rainfall pH is around 5.6. Acid rain occurs when gases such as sulfur dioxide and nitrogen oxides are present in the atmosphere. These oxides react with the rain water to produce stronger acids and lower the pH to 4.5 or even 3.0 causing solution weathering to the rocks on which it falls. When rain combines with carbon dioxide or an organic acid it forms a weak carbonic acid which reacts with calcium carbonate (Rock) and forms calcium bicarbonate. The process speeds up with a decrease in temperature because colder water holds more dissolved carbon dioxide gas 2) Hydration In this process rock minerals absorb water and expand, creating stress which causes the disintegration of rocks. Iron Oxide + Water ---> Iron Hydroxide (Increased Volume) Anhydrite + Water ---> Gypsum (Increased Volume) Anhydrite is Unhydrated Calcium Sulphate.

- 57. 57 | P a g e SAQIB IMRAN 0341-7549889 57 Gypsum is Hydrated Calcium Sulphate 3) Hydrolysis In this process a chemical reaction takes place between the minerals (Silicates and Carbonates) in the rock and Hydrogen (H+) in rain water. 4) Oxidation In this process oxygen combine with water and minerals in the rock such as iron, calcium and magnesium to form their oxides When iron reacts with oxygen, reddish-brown iron oxide is formed. The iron-oxide crust crumbles easily and weakens the rock. This process is commonly known as Rusting Iron + Oxygen ---> Iron Oxide (Crumbles) Common Types of Soil Gravel Course grained soils that possess little or no cohesion. Distinguished by their relative stability under wheel loads when confined, by their high permeability and by their low shrinkage and expansion in deter mental amount with change in moisture content. Size range from 2 mm to 60 mm

- 58. 58 | P a g e SAQIB IMRAN 0341-7549889 58 Sand: Fine grained soils of low to medium plasticity intermediate in size bw sand & clay. Generally possess little cohesion, undergo considerable shrinkage and expansion with. Change in moisture content and possess a variable amount of stability under wheel load. Organic soils contain appreciable amount of decomposed organic matter and is generally highly compressible & unstable. Size of sand ranges from 0.06 mm to 2 mm Silt The size of silt particles range from 0.002 mm to 0.06 mm Clay: Fine grain soil of size 0.002 mm or finer. Possess medium to high plasticity, have considerable strength when dry, undergo extreme changes in volume with change in moisture content and practically impervious to flow of water. Types: Lean clay: Silty clay. Flat clay: Finer colloidal clay with high plasticity Clay may possess considerable strength in their natural state; this strength is sharply reduced and sometimes completely destroyed when their natural structure is disturbed, that is when they are remolded. Loam: Agricultural term, fairly well graded from course to fine that is easily worked & that is the reason of plant life. Sandy loam Silty loam & Clay loam Depending on the size of predominant soil fraction Loess: Uniform grain size predominantly silts with low density. Muck: Soft silt or clay very high in organic content Found in swampy areas and rivers or lake bottoms. Peat: Composed of practically decomposed vegetable matter Due to high water content, woody natural and high compressibility it is extremely undesirable for use in roads.

- 59. 59 | P a g e SAQIB IMRAN 0341-7549889 59 Compaction of Soil and Factors Affecting Compaction Compaction is the application of mechanical energy to a soil to rearrange the particles and reduce the void ratio. Purpose of Compaction of Soil The principal reason for compacting soil is to reduce subsequent settlement under working loads. Compaction increases the shear strength of the soil. Compaction reduces the voids ratio making it more difficult for water to flow through soil. This is important if the soil is being used to retain water such as would be required for an earth dam. Compaction can prevent the build up of large water pressures that cause soil to liquefy during earthquakes.

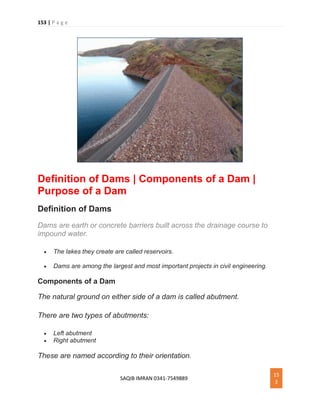

- 60. 60 | P a g e SAQIB IMRAN 0341-7549889 60 Factors affecting Soil Compaction Water content of the soil The type of soil being compacted The amount of compactive energy used Effects of different factors on compaction of soil Water content: As water is added to a soil ( at low moisture content) it becomes easier for the particles to move past one another during the application of the compacting forces. As the soil compacts the voids are reduced and this causes the dry unit weight ( or dry density) to increase. Initially then, as the moisture content increases so does the dry unit weight. However, the increase cannot occur indefinitely because the soil state approaches the zero air voids line which gives the maximum dry unit weight for a given moisture content. Thus as the state approaches the no air voidsline further moisture content increases must result in a reduction in dry unit weight. As the state approaches the no air voids line a maximum dry unit weight is reached and the moisture content at this maximum is called the optimum moisture content. Increased compactive effort Increased compactive effort enables greater dry unit weights to be achieved which because of the shape of the no air voids line must occur at lower optimum moisture contents. It should be noted that for moisture contents greater than the optimum the use of heavier compaction machinery will have only a small effect on increasing dry unit weights. For this reason it is important to have good control over moisture content during compaction of soil layers in the field. Effects of soil type The table below contains typical values for the different soil types obtained from the Standard Compaction Test. Typical Compaction Values Type of Soil (gdry )max (kN/ m3 ) mopt (%) Well graded sand SW 22 7 Sandy clay SC 19 12 Poorly graded sand SP 18 15 Low plasticity clay CL 18 15 Non plastic silt ML 17 17