SPARE PARTS

- 1. SPARE PARTS IDENTIFICATION ................................................................. P002 SPARE PARTS CLAMP SCREW ................................................................ P003 SET BOLT ......................................................................... P009 SHIM .................................................................................. P010 SHIM PIN AND CLAMP LEVER........................................ P013 CLAMP LEVER AND LOCK PIN ...................................... P014 CLAMP BRIDGE ............................................................... P014 BREAKER PIECE ............................................................. P016 REPLACEMENT PARTS FOR OLD TYPE TOOLS TURNING HOLDERS ..................................................... P017 BORING BARS ............................................................... P023 BORING UNITS .............................................................. P026 FACE MILLS ................................................................... P027 INDEXABLE TYPE END MILLS ..................................... P032 INDEXABLE TYPE DRILLS ........................................... P036 ANTI SEIZE LUBRICANT ................................................. P039 P001

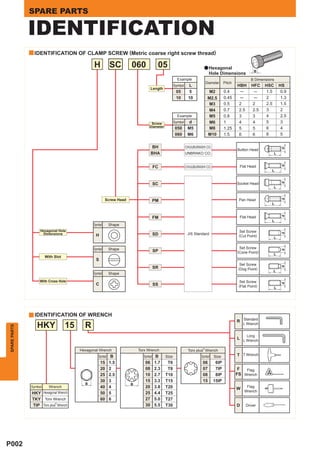

- 2. SPARE PARTS IDENTIFICATION y IDENTIFICATION OF CLAMP SCREW (Metric coarse right screw thread) H SC 060 05 a Hexagonal B Hole Dimensions Example B Dimensions Diameter Pitch Symbol L HBH HFC HSC HSp Length 05 5 M2 0.4 ─ ─ 1.5 0.9 10 10 M2.5 0.45 ─ ─ 2 1.3 M3 0.5 2 2 2.5 1.5 M4 0.7 2.5 2.5 3 2 Example M5 0.8 3 3 4 2.5 Screw Symbol d M6 1 4 4 5 3 Diameter 6 4 050 M5 M8 1.25 5 5 060 M6 M10 1.5 6 6 8 5 BH CHUUBURASHI CO. d Button Head BHA UNBRAKO CO. L FC Flat Head d CHUUBURASHI CO. L SC d Socket Head L Screw Head Pan Head d PM L d FM Flat Head L Symbol Shape Hexagonal Hole Set Screw Dimensions SD JIS Standard d H (Cut Point) L Symbol Shape Set Screw SP d (Cone Point) L With Slot S Set Screw SR d (Dog Point) L Symbol Shape With Cross Hole Set Screw C SS (Flat Point) d L y IDENTIFICATION OF WRENCH R Standard HKY 15 R L Wrench SPARE PARTS Long L L Wrench Hexagonal Wrench Torx Wrench Torx plus Wrench Symbol B Symbol B Size Symbol Size T T Wrench 15 1.5 06 1.7 T6 06 6IP 20 2 08 2.3 T8 07 7IP F Flag 25 2.5 10 2.7 T10 08 8IP FS Wrench 30 3 15 3.3 T15 15 15IP B B Symbol Wrench 40 4 20 3.8 T20 W Flag 25 4.4 Wrench HKY Hexagonal Wrench 50 5 T25 TKY Torx Wrench 60 6 27 5.0 T27 TIP Torx plus Wrench 30 5.5 T30 D Driver P002

- 3. SPARE PARTS CLAMP SCREW Dimensions (mm) Angle Drive Torque Geometry Order Number Tool Holder a b c d e '° Size (N•m) AJS3010T10 5 M3×0.5 10 1.5 2.8 120 T10 2.5 Profile Holder 4012T15 7 M4×0.7 12 2.2 3.4 120 T15 3.5 AJX Type Cutter 5014T25 8 M5×0.8 14 2.7 4.5 120 T25 7.5 BRS103 5 M3×0.5 9.9 2.9 3.4 120 T15 3.5 BRE Type Cutter 105 8 M5×0.8 13.8 3.8 4.5 120 T25 7.5 CS3(For Use with C3) 7 M4×0.7 14.6 2.6 2.5 ─ ─ 2.2 F Type Boring Bar CS4(For Use with C4) 9 M5×0.8 15.4 3.4 3 ─ ─ 3.3 CS5(For Use with C5) 10.5 M6×1 22 4 4 ─ ─ 7.0 This clamp screw is included with the clamp as a set. CAS51T 7.9 M5×0.8 19 5 4.5 10 T25 8.5 BF407 Type Cutter CS200T 3.2 M2×0.4 5 1.6 1.8 90 T6 0.6 AL Holder 250T 3.7 M2.5×0.45 6 1.8 2.4 90 T8 1.0 F Type Boring Bar * 250560T 300590T 3.9 4.1 M2.5×0.45 M3×0.5 5.2 5.5 2.5 2.1 2.4 2.4 60 T8 90 T8 1.0 1.0 MMTI Type Boring Bar SNT Type Boring Bar 300790TS 4.7 M3×0.5 7 2.3 2.8 90 T10 2.0 Milling Tools Series 300890T 4.1 M3×0.5 8 2.1 2.4 90 T8 1.0 SS Type Cartridge 350690T 4.8 M3.5×0.6 6.5 2.4 2.8 90 T10 2.5 Boring Unit * 350760T 350790T 5.5 4.8 M3.5×0.6 M3.5×0.6 7 7 4 2.4 3.4 2.8 60 T15 90 T10 3.5 2.5 MI Type Boring Bar * 350860T 350990T 5.5 4.8 M3.5×0.6 M3.5×0.6 8.4 9 4 2.4 3.4 2.8 60 T15 90 T10 3.5 2.5 400990T 6.0 M4×0.7 9 2.8 3.4 90 T15 3.5 401160T 5.7 M4×0.7 11 4.5 3.4 60 T15 3.5 401990T 6.0 M4×0.7 19 3.0 3.9 90 T20 3.5 451190T 6.3 M4.5×0.75 11 2.9 3.9 90 T20 5.0 * 501160T 501290T 7.0 7.0 M5×0.8 M5×0.8 11 11 3.6 3.5 3.9 4.5 60 T20 90 T25 5.0 7.5 502190T 8.5 M5×0.8 21 4.0 5.1 90 T27 7.5 6016060T 8.5 M6×1.0 16 4.5 4.5 60 T25 7.5 CSF401260T 7.2 M4×0.5 12 5.2 3.9 60 T20 5.0 PMR Type Cutter SPARE PARTS DC0520T 8.5 M5×0.8 22.5 2.5 3.4 ─ T15 3.5 DOUBLE CLAMP Holder 0621T 10.5 M6×1.0 25 4 3.9 ─ T20 5.0 DOUBLE CLAMP DIMPLE BAR HSK Tool Holder DGS51 11.5 M5×0.8 19 4 4 ─ ─ 7.0 DG Type Holder HSK Tool Holder DKS4 5.6 M4×0.7 18 3.5 3 ─ ─ 3.3 5 7.6 M5×0.8 19 4.5 4 ─ ─ 7.0 P003

- 4. SPARE PARTS SPARE PARTS CLAMP SCREW Dimensions (mm) Angle Drive Torque Geometry Order Number Tool Holder a b c d e '° Size (N•m) EGS06019 9 M6×1 22.5 3.5 3 ─ ─ 3.3 EG Type Holder 08024 11 M8×1.25 28.5 4.5 4 ─ ─ 7.0 FC400890T 5.6 M4×0.7 7.5 1.3 2.8 90 T10 2.5 AL Type Holder AL Type Boring Bar SMG Type Holder GY05016S 8.7 M5×0.8 16 3.5 3.9 90 T20 4.5 GY Series GY06013M 12 M6×1.0 18 5 5.6 ─ T30 6.0 GY Series HFF06015 10 M6×1 15 6 5 80 ─ 8.2 HS5S 6.8 M5×0.8 9 2.8 3 80 ─ 3.3 HSP05008C M5×0.8 8 ─ ─ 2.5 ─ ─ 2.5 MP Type Holder D Type Boring Head HY-A1 4.4 M3×0.5 7 2.1 2 82 ─ 1.5 Boring Unit -V1 5.5 M3×0.5 7 2.5 2 82 ─ 1.5 2 5.5 M3×0.5 10 2.5 2 82 ─ 1.5 3 7 M3.5×0.6 12 2.9 2 82 ─ 1.5 4 9.3 M5×0.8 16 3.6 3 82 ─ 3.3 JSS7 8 M7×0.75 4.4 1.5 1 ─ ─ ─ SPARE PARTS KS1 7 M4×0.7 14 5 ─ ─ ─ ─ V10000 Type Cutter 2 10 M6×1 18 7 ─ ─ ─ ─ LL Type Cartridge BC Type Cartridge 3 8 M4×0.7 14 6.5 ─ ─ ─ ─ SS Type Cartridge 1S 7 M4×0.7 14 5 ─ ─ ─ ─ SET/MG/DG Type Cartridge 2S 10 M6×1 18 7 ─ ─ ─ ─ MI Type Boring Bar KS11 8 M5×0.8 19 3 3 ─ ─ 3.3 12 10 M6×1 26 4 4 ─ ─ 7.0 13 10 M6×1 30 4 4 ─ ─ 7.0 14 13 M8×1.25 45 5 5 ─ ─ 9.0 LLR1 M5×0.8 ─ 3.5 ─ 2.5 ─ ─ ─ LL Type Cartridge 2 M6×1 ─ 5 ─ 3 ─ ─ ─ P004

- 5. Dimensions (mm) Angle Drive Torque Geometry Order Number Tool Holder a b c d e '° Size (N•m) d LLCS103 M3×0.5 4 11 4.6 2 ─ ─ 1.5 LL Type Holder * 105 106 M5×0.8 M5×0.8 M6×1 6 10 16.5 1.5 3.5 2 2.5 ─ ─ ─ ─ 1.5 2.2 P Type Boring Bar D Type Boring Head * 106S 108 M6×1 M8×1.25 8 6 13.4 21 0.7 6.5 2.5 3 ─ ─ ─ ─ 2.2 3.3 HSK Tool Holder KSMG Type Cutter * 108S 110 M8×1.25 8 M10×1.5 10 16.5 29 2 8 3 4 ─ ─ ─ ─ 3.3 7.0 LL Type Cartridge Boring Unit 112 M12×1 11.9 36.2 9 5 ─ ─ 8.0 125 M5×0.8 M5×0.8 12 2 2 ─ ─ 1.5 205 M5×0.8 M5×0.8 16 4 2 ─ ─ 1.5 206 M6×1 6 26 13 2.5 ─ ─ 2.2 208 M8×1.25 8 24 6.5 3 ─ ─ 3.3 306 M6×1 6 21 4 2.5 ─ ─ 2.2 308 M8×1.25 8 42 27.5 3 ─ ─ 3.3 310 M10×1 10 29 8 4 ─ ─ 7.0 The products with " " do not have a hexagonal hole at the end marked b. * 410 M10×1 10 30 6.6 4 ─ ─ 7.0 The products with "d" do not have a 508 M8×1 8 24 6.5 3 ─ ─ 3.3 hexagonal hole at the end marked a. * LS1 508S M8×1 M6×1 22 8 20.5 8 3 8 3 3 ─ ─ ─ ─ 3.3 5.0 DOUBLE CLAMP Holder (For Heavy Cutting) 2 M8×1 29 13 10 4 ─ ─ 8.2 MC Type Holder 3 M8×1 32 13 13 4 ─ ─ 8.2 UG Type Holder * 4 M6×1 15 8 4 3 ─ ─ 5.0 Right-Hand Screw Left-Hand Screw Milling Tools Series * 5 M6×1 18 8 5 3 ─ ─ 5.0 * 6 M8×1 24 13 5 4 ─ ─ 8.2 * 7 M8×1 27 13 8 4 ─ ─ 8.2 * 8 M6×0.75 18 7 7 3 ─ ─ 5.0 * 9 M6×0.75 22 8 8 3 ─ ─ 5.0 * 10 M7×0.75 16 6 6 4 ─ ─ 8.2 * 11 M8×1 16 6 6 4 ─ ─ 8.2 * 12 M8×1 24 7 7 4 ─ ─ 8.2 * 13 M8×1 34 12 12 4 ─ ─ 8.2 *Without Hexagonal Hole on Right-Hand Screw * 14 M7×0.75 24 10 10 4 ─ ─ 8.2 * 15 M7×0.75 18 6 8 4 ─ ─ 8.2 * 16 M7×0.75 23 11 8 4 ─ ─ 8.2 * 17 M8×1 42 17 11 4 ─ ─ 8.2 * 18 M7×0.75 14 6 4 4 ─ ─ 8.2 * 20 M10×1.5 26 9 9 5 ─ ─ 9.0 * 21 24 M10×1.5 32 M8×1.25 24 12 8.5 12 8.5 5 4 ─ ─ ─ ─ 9.0 8.2 25 M8×1.0 28.5 12.0 10.5 4 ─ ─ 8.2 LS10T M7×0.75 14 6 5 4.5 ─ T25 8.5 14T M7×0.75 24 10 10 4.5 ─ T25 8.5 SPARE PARTS 15T M7×0.75 18 7 7 4.5 ─ T25 8.5 Left-Hand Screw Right-Hand Screw 19T M6×0.75 11 4 4 3.4 ─ T15 5.0 10TS M7×0.75 13 6 4 4.5 ─ T25 8.5 0622T M6×0.75 22 8 8 3.4 ─ T15 6.0 LS24H M8×1.25 24 8.5 8.5 4 ─ ─ 8.2 APX3000 Type Cutter a a e c d Left-Hand Screw Right-Hand Screw b MGS6 10 M6×1 26 4 5 ─ ─ 9.0 b a e d c MHT1 11 M8×1 18.5 3.5 4 ─ ─ 8.7 b a e d c P005

- 6. SPARE PARTS SPARE PARTS CLAMP SCREW Dimensions (mm) Angle Drive Torque Geometry Order Number Tool Holder a b c d e '° Size (N•m) NS251 3.6 M2.5×0.45 7 ─ 2.2 60 ─ 0.7 SMALL TOOLS 401 5.8 M4×0.7 6 ─ 3.6 60 ─ 3.5 b a e c NS402W 5.85 M4×0.7 10 ─ 2.2 60 ─ 0.7 SMALL TOOLS 403W 5.85 M4×0.7 12 ─ 2.2 60 ─ 0.7 404W 5.8 M4×0.7 10 ─ 2.2 90 ─ 0.7 b a e c e NS501W 8 M5×0.8 16 ─ 2.5 120 ─ 2.2 SMALL TOOLS 502W 8 M5×0.8 20 ─ 2.5 120 ─ 2.2 b a e c e RN-S4S 5.8 M4×0.5 8.4 2.5 3.4 61 T15 3.5 -S4M 5.8 M4×0.5 10 2.2 3.4 61 T15 3.5 -S4 5.8 M4×0.5 12.5 2.2 3.4 61 T15 3.5 b a -S5 8.1 M5×0.5 15.4 3.6 3.9 61 T20 5.0 e d c -S6 9.5 M6×0.75 20.3 4.6 3.9 61 T20 5.0 -S7 11 M7×0.75 24.7 5.2 4.5 61 T25 7.5 RS3008T 4.3 M3×0.35 8.6 2 2.4 61 T8 1.5 SRF Type Cutter 3510T 5 M3.5×0.35 10 2.3 2.8 61 T10 2.5 4015T 6 M4×0.5 14 2.7 3.4 61 T15 3.3 b a 5020T 8.1 M5×0.5 16.4 3.6 3.9 61 T20 5.0 e d c 6025T 9.5 M6×0.75 21.5 4.2 4.5 61 T25 7.5 8030T 12 M8×0.75 25 5 5.6 61 T30 10.0 S1 3.5 M2×0.4 5.5 2.2 1.5 92 ─ 1.0 Boring Unit 3 4.5 M3×0.5 7.7 2.4 2 92 ─ 1.5 4 5.3 M4×0.7 8 1.8 2.5 62 ─ 2.2 b a d 5 6.8 M5×0.8 9 2.4 3 62 ─ 3.3 e c SD32 12 M8×1.25 28 7.2 6 50 ─ 9.5 D Type Head Arbor 40 12 M8×1.25 36 7.2 6 50 ─ 9.5 50 16 M10×1.5 46 8.2 8 50 ─ 1.0 b a d 63 16 M10×1.5 61 8.2 8 50 ─ 1.0 e c SETS51 6.8 M5×0.8 14.8 1.5 3.4 ─ T15 3.5 MMTE Type Holder 61 8 M6×1 20 1.8 3.9 ─ T20 5.0 MMTI Type Boring Bar b a SET Type Holder SNT Type Boring Bar e d HSK Tool Holder c SET Type Cartridge SPARE PARTS SLCS105 10 M5×0.8 25 6.3 4 90 ─ 7.0 WP Type Holder 106 12 M6×1 32 6.2 4 90 ─ 7.0 M Type Boring Bar b a e d c SPS1 8.5 M5×0.8 16 4 4.5 70 T25 5.0 b a e d c SRS5 6.7 M5×0.8 16 3.5 3.9 ─ T20 5.0 SRE Type Cutter a b e d c STS1 6.8 M3×0.5 7 2.2 2.8 90 T10 2.5 b a e d c P006

- 7. Dimensions (mm) Angle Drive Torque Geometry Order Number Tool Holder a b c d e '° Size (N•m) * TS16 2 2.5 2.7 M1.6×0.35 M2×0.4 3.2 4.6 1.6 1.4 1.8 1.8 60 60 T6 0.6 T6 0.6 SP Type Holder Profile Holder * 2A 2C 2.7 2.7 M2×0.4 M2×0.4 4.5 3.8 1.2 1.4 1.8 1.8 60 60 T6 0.6 T6 0.6 SMALL TOOLS DIMPLE BAR d 2D 3.8 M2×0.4 5.3 1.9 1.8 82 T6 0.6 MICRO-DEX 21 2.7 M2×0.4 3.4 1.4 1.8 60 T6 0.6 F Type Boring Bar * 22 3.0 M2.2×0.45 5 1.2 1.8 60 T6 0.6 S Type Boring Bar * d 25 25D 3.3 4.4 M2.5×0.45 M2.5×0.45 5.5 6.2 1.7 2.2 2.4 2.4 60 82 T8 1.0 T8 1.0 GY SERIES MMTI Type Boring Bar * 25H 202 3.6 2.7 M2.5×0.45 M2×0.4 5.5 5.5 2 1.8 2.4 1.8 60 60 T8 1.0 T6 0.6 SNT Type Boring Bar HSK Tool Holder 253 3.3 M2.5×0.45 4.5 1.7 2.4 60 T8 1.0 Milling Tools Series 254 3.3 M2.5×0.45 7 1.7 2.4 60 T8 1.0 SS Type Cartridge b a * 255 3 3.5 3.9 M2.5×0.45 M3×0.5 7.5 6 1.6 2 2.4 2.4 60 60 T8 1.0 T8 1.0 Boring Unit TAF Drill e d c 3D 5.0 M3×0.5 6 2.3 2.8 82 T10 2.5 * 3SB 31D 4.4 4.8 M3×0.5 M3×0.5 8 7.2 2 2.2 2.4 2.8 80 82 T8 1.5 T10 2.5 * 32 3.9 M3×0.5 7.5 2 2.4 60 T8 1.0 * 33 35 3.9 4.8 M3×0.5 M3.5×0.6 6.7 6.5 2 2.4 2.4 2.8 60 60 T8 1.0 T10 2.5 * * 35D 351 5.3 4.8 M3.5×0.6 M3.5×0.6 12 7.2 2.8 2.4 3.4 2.8 60 60 T15 3.5 T10 2.5 b a 4S 5.4 M4×0.7 7 2.4 3.4 80 T15 3.5 e d * 4SL 5.4 M4×0.7 8 2.4 3.4 80 T15 4.0 c * 4SB 5.8 M4×0.7 9 2.7 3.4 80 T15 3.5 * 4SBL 4 5.8 5.4 M4×0.7 M4×0.7 10.5 8 2.7 2.6 3.4 3.4 80 60 T15 3.5 T15 3.5 d 4D 5.6 M4×0.7 7.7 2.5 3.4 82 T15 3.5 42 5.4 M4×0.7 6 2.6 3.4 60 T15 3.5 a b 43 5.4 M4×0.7 10 2.6 3.4 60 T15 3.5 e d 44 5.4 M4×0.7 12 2.6 3.4 60 T15 3.5 c 407 5.4 M4×0.7 9 2.6 3.4 60 T15 3.5 450 5.9 M4.5×0.75 13 3.6 3.9 60 T20 5.0 5S 6.8 M5×0.8 9 2.9 4.5 80 T25 7.5 * 5SL 5 6.8 6.8 M5×0.8 M5×0.8 12 9 2.9 3.2 4.5 4.5 80 60 T25 7.5 T25 7.5 5L 6.8 M5×0.8 15 2.9 4.5 80 T25 7.5 52 6.8 M5×0.8 8 3.2 4.5 60 T25 7.5 54 6.8 M5×0.8 12 3.2 4.5 60 T25 7.5 55 6.8 M5×0.8 10.5 3.2 4.5 60 T25 7.5 * 6S 8.5 M6×1.0 13 4.4 5.6 60 T30 10.0 SPARE PARTS * TPS20 6 8.5 2.7 M6×1.0 M2×0.4 16 3.5 4.4 1.3 5.6 1.8 60 60 T30 10.0 6IP 0.6 ASX445 Type Cutter 22 3.0 M2.2×0.45 4.7 1.6 2.1 60 7IP 0.6 ASX400 Type Cutter 22S 3.0 M2.2×0.45 4.2 1.6 2.1 60 7IP 0.6 APX3000 Type Cutter 25 3.3 M2.5×0.45 5.5 1.7 2.1 60 7IP 1.0 APX4000 Type Cutter a b 25-1 3.3 M2.5×0.45 6.5 1.7 2.1 60 7IP 1.0 ARX Type Cutter e d c 35 5.3 M3.5×0.6 11.5 2.8 3.4 60 15IP 3.5 PMR Type Cutter 4 5.3 M4×0.7 8 2.6 3.4 60 15IP 3.5 43 5.3 M4×0.7 10 2.6 3.4 60 15IP 3.5 TSR05008S 3.5 M5×0.8 8 ─ 2.8 ─ T10 ─ CHAMFER RING 06011S 4 M6×1.0 11 ─ 3.9 ─ T20 ─ b a e d c P007

- 8. SPARE PARTS SPARE PARTS CLAMP SCREW Dimensions (mm) Angle Drive Torque Geometry Order Number Tool Holder a b c d e '° Size (N•m) TSS04005 ─ M4×0.7 5 ─ 2.4 ─ T8 ─ PMF Type Cutter 05006 ─ M5×0.8 6 ─ 2.8 ─ T10 ─ BC Type Cartridge b 06010 ─ M6×1 10 ─ 3.9 ─ T20 ─ SS Type Cartridge e c WCS503507H 6.3 M5×0.5 7 3.3 3.5 ─ ─ 6.5 ASX445 Type Cutter 604010H 7.8 M6×0.75 10 4.1 4.0 ─ ─ 7.0 ASX400 Type Cutter b a PMR Type Cutter d e c WS1 8.5 M5×0.8 19 5 4.5 ─ T25 7.5 b a e d c WS254012T 4 M2.5×0.45 11.5 2.2 2.4 80 T8 2.0 TAW Drill 254013T 4 M2.5×0.45 12.5 2.2 2.4 80 T8 2.0 254014T 4 M2.5×0.45 13.5 2.2 2.4 80 T8 2.0 254015T 4 M2.5×0.45 14.5 2.2 2.4 80 T8 2.0 254016T 4 M2.5×0.45 15.5 2.2 2.4 80 T8 2.0 304517T 4.5 M3×0.5 16.5 3.4 2.8 60 T10 3.5 a b 304518T 4.5 M3×0.5 17.5 3.4 2.8 60 T10 3.5 d 355520T 5.5 M3.5×0.6 19.5 3.9 3.4 60 T15 5.5 e c 355521T 5.5 M3.5×0.6 20.5 3.9 3.4 60 T15 5.5 406023T 6 M4×0.7 22.0 4.4 4.5 60 T25 8.5 406024T 6 M4×0.7 23.0 4.4 4.5 60 T25 8.5 508026T 8 M5×0.8 25.0 5.2 5.1 60 T27 12.0 508027T 8 M5×0.8 26.0 5.2 5.1 60 T27 12.0 SPARE PARTS P008

- 9. SET BOLT Dimensions (mm) Angle Drive Torque Geometry Order Number Tool Holder a b c d e '° Size (N•m) BOES101 15 M10×1.5 45 10 8 60 ─ 10.0 OCTACUT Type Cutter HSC08030H 13 M8×1.25 38 8 5 ─ ─ 24 APX3000 Type Cutter 10030H 16 M10×1.5 40 10 6 ─ ─ 40 APX4000 Type Cutter AXD4000 Type Cutter 12035H 18 M12×1.75 47 12 10 ─ ─ 80 AXD7000 Type Cutter 16040H 24 M16×2 56 16 14 ─ ─ 150 AJX Type Cutter BXD Type Cutter HFF08043H 11 M8×1.25 43 5 5 90 ─ 8.2 AXD4000 Type Cutter BXD Type Cutter MBA20040H 50 M20×2.5 54 14 17 ─ ─ 320 APX4000 Type Cutter 24045H 65 M24×3 59 14 17 ─ ─ 520 AXD4000 Type Cutter b a AXD7000 Type Cutter d AJX Type Cutter e c BXD Type Cutter Dimensions (mm) Torque Geometry Order Number (N•m) Tool Holder a a′ b c d e HDS08030 M8×0.75 M8×1.25 30 13.5 11.5 4 8.2 BRP Type Cutter Right-Hand Right-Hand 10031 M10×1.0 M10×1.5 31 14 12 5 9.0 OCTACUT Type Cutter Screw Screw PMF Type Cutter a e c d b SPARE PARTS P009

- 10. SPARE PARTS SPARE PARTS SHIM Dimensions (mm) Geometry Order Number Tool Holder a b c d e f CS32 9.52 3.18 0.8 0.8 1.2 1.2 MC Type Holder (Negative type) c d 42 12.70 3.18 0.8 0.8 1.2 1.6 * 43 12.70 4.76 0.8 0.8 1.2 1.6 62 19.05 3.18 1.2 1.2 1.6 1.6 a * PS31 8.28 2.38 0.2 0.2 0.6 0.6 MC Type Holder (Positive type) e a f b b * 42 11.46 3.18 0.2 0.2 0.6 1.0 BC Type Cartridge * 62 CT22 17.20 6.35 3.18 3.18 0.3 0.4 0.3 0.8 0.7 1.2 0.7 ─ MC Type Holder (Negative type) c 32 9.52 3.18 0.4 0.8 1.2 ─ * 33 9.52 4.76 0.4 0.8 1.2 ─ 42 12.70 3.18 0.4 0.8 1.2 ─ * PT21 5.11 2.38 0.2 0.2 0.6 ─ MC Type Holder (Positive type) d a e b b * 32 8.28 3.18 0.2 0.2 0.6 ─ F Type Boring Bar * 42 BPT322 10.85 7.8 3.18 3.18 0.3 ─ 0.3 ─ 0.7 ─ ─ ─ BC Type Cartridge 35° c DCSVN32 9.52 3.18 0.8 1.2 ─ ─ DOUBLE CLAMP Holder DOUBLE CLAMP DIMPLE BAR da b c d ESS42 12.70 3.18 0.8 0.8 1.2 1.6 ML Type Holder a e a f b c EST32 9.52 3.18 0.4 0.8 1.2 ─ ML Type Holder 43 12.70 4.76 0.4 0.8 1.2 ─ d a e b LLSCN3T3 9.52 3.97 0.4 0.4 0.8 0.8 DOUBLE CLAMP Holder d LL Type Holder c 33 9.52 4.76 0.4 0.4 0.8 0.8 * 42 12.70 3.18 0.8 0.8 1.2 1.2 DOUBLE CLAMP DIMPLE BAR P Type Boring Bar D Type Boring Head 53 15.87 4.76 1.2 1.2 1.6 1.6 HSK Tool Holder 63 19.05 4.76 1.2 1.2 1.6 1.6 LL Type Cartridge f e * LLSCP42 12.70 3.18 0.8 0.8 1.2 1.2 DOUBLE CLAMP DIMPLE BAR a b b * 63 19.05 4.76 1.2 1.2 1.6 1.6 P Type Boring Bar HSK Tool Holder c * LLSDN32 42 9.52 12.70 3.18 3.18 0.8 0.8 1.2 1.2 ─ ─ ─ ─ DOUBLE CLAMP Holder LL Type Holder DOUBLE CLAMP DIMPLE BAR 43 12.70 4.76 0.8 1.2 ─ ─ P Type Boring Bar D Type Boring Head 53 15.87 4.76 1.2 1.6 ─ ─ HSK Tool Holder SPARE PARTS ad b b * LLSDP42 LLSRN103 12.70 8.3 3.18 3.18 0.8 ─ 1.2 ─ ─ ─ ─ ─ DOUBLE CLAMP DIMPLE BAR LL Type Holder 123 9.8 3.18 ─ ─ ─ ─ HSK Tool Holder 164 13.6 4.76 ─ ─ ─ ─ 204 17.3 4.76 ─ ─ ─ ─ a b 256 22.0 6.35 ─ ─ ─ ─ 326 28.0 6.35 ─ ─ ─ ─ LLSSN32 9.52 3.18 0.8 0.8 1.2 1.2 LL Type Holder c d * 33 42 9.52 12.70 4.76 3.18 0.8 0.8 0.8 0.8 1.2 1.2 1.2 1.6 DOUBLE CLAMP DIMPLE BAR P Type Boring Bar a 53 15.87 4.76 1.2 1.2 1.6 1.6 LL Type Cartridge 63 19.05 4.76 1.2 1.2 1.6 2.0 e f a b b 84 25.40 6.35 1.6 1.6 2.4 2.4 * LLSSP42 12.70 3.18 0.8 0.8 1.2 1.6 P010

- 11. Dimensions (mm) Geometry Order Number Tool Holder a b c d e f c LLSTE32 7.6 3.18 0.4 0.4 0.4 ─ LL Type Holder * LLSTN32 9.52 3.18 0.4 0.8 1.2 ─ DOUBLE CLAMP Holder 33 9.52 4.76 0.4 0.8 1.2 ─ DOUBLE CLAMP DIMPLE BAR 42 12.70 3.18 0.4 0.8 1.2 ─ P Type Boring Bar 53 15.87 4.76 0.8 1.2 1.6 ─ D Type Boring Head d e a b b * LLSTP32 9.52 3.18 0.4 0.8 1.2 ─ LL Type Cartridge * 42 12.70 3.18 0.4 0.8 1.2 ─ Boring Unit c * LLSWN32 3T3 9.52 9.52 3.18 3.97 0.4 0.4 0.8 0.8 1.2 1.2 ─ ─ LL Type Holder DOUBLE CLAMP Holder 42 12.70 3.18 0.4 0.8 1.2 ─ DOUBLE CLAMP DIMPLE BAR d a e b b * LLSWP32 9.52 3.18 0.4 0.8 1.2 ─ d * 42 MHS532R/L 12.70 9.4 3.18 15.7 0.4 4.5 0.8 0.8 1.2 0.8 ─ ─ 533R/L 9.4 15.7 4.5 1.2 1.2 ─ a e 534R/L 9.4 15.7 4.5 1.6 1.6 ─ 55° c 542R/L 9.4 15.7 6.5 0.8 0.8 ─ b 543R/L 9.4 15.7 6.5 1.2 1.2 ─ 544R/L 9.4 15.7 6.5 1.6 1.6 ─ d c MLCP42 12.58 3.18 1.2 1.2 1.2 1.2 P Type Boring Bar f e a b c MLDP42 12.56 3.18 1.2 1.2 ─ ─ P Type Boring Bar ad b c d MLSP42 12.63 3.18 1.2 1.2 1.2 1.2 P Type Boring Bar e a f b c MLTP32 9.50 3.18 1.2 1.2 1.2 ─ P Type Boring Bar d e a b d c MSCN63 18.8 4.76 1.6 1.6 1.6 1.6 DOUBLE CLAMP Holder (For Heavy Cutting) SPARE PARTS f a e b c d MSSN63 18.8 4.76 1.6 1.6 1.6 1.6 DOUBLE CLAMP Holder (For Heavy Cutting) e a f b SET Type Holder CT32T1 9.525 15.03 3.18 ─ ─ ─ SNT Type Boring Bar SET Type Cartridge b PT32T1R 8.28 13.34 3.18 ─ ─ ─ 32T2R 8.28 13.19 3.18 ─ ─ ─ a c 42TR 10.85 17.20 3.18 ─ ─ ─ P011