Submerged arc welding

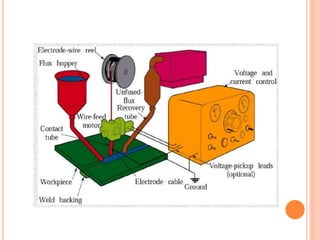

- 2. SUBMERGED ARC WELDING Arc: between consumable electrode and work piece Welding zone: covered by the large amount of granulated flux: delivered ahead of the electrode through welding flux feed tube Flux: silica +metal oxides fused together + crushed to proper size. Arc is completely submerged under the flux Part of flux melts, form slag and covers the weld zone No splatter of molten metal Prevent weld zone from contamination

- 5. ADVANTAGES Can be automated /much faster than regular arc welding Speed upto 3.8 m/min is possible 3mm thick steel Deep penetration with high quality weld is possible Capable of welding welding 75mm thick plate in a single pass