sunoco 2006 Form 10-K

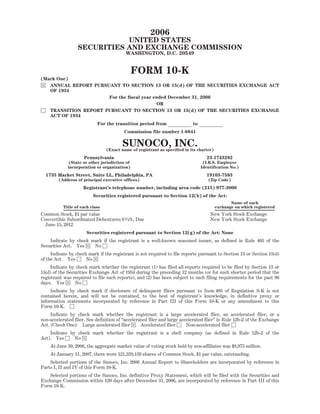

- 1. 2006 UNITED STATES SECURITIES AND EXCHANGE COMMISSION WASHINGTON, D.C. 20549 FORM 10-K (Mark One) È ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 For the fiscal year ended December 31, 2006 OR ‘ TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 For the transition period from to Commission file number 1-6841 SUNOCO, INC. (Exact name of registrant as specified in its charter) Pennsylvania 23-1743282 (State or other jurisdiction of (I.R.S. Employer incorporation or organization) Identification No.) 1735 Market Street, Suite LL, Philadelphia, PA 19103-7583 (Address of principal executive offices) (Zip Code) Registrant’s telephone number, including area code (215) 977-3000 Securities registered pursuant to Section 12(b) of the Act: Name of each Title of each class exchange on which registered Common Stock, $1 par value New York Stock Exchange Convertible Subordinated Debentures 6 3⁄4%, Due New York Stock Exchange June 15, 2012 Securities registered pursuant to Section 12(g) of the Act: None Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes È No ‘ Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ‘ No È Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes È No ‘ Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ‘ Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, or a non-accelerated filer. See definition of “accelerated filer and large accelerated filer” in Rule 12b-2 of the Exchange Act. (Check One): Large accelerated filer È Accelerated filer ‘ Non-accelerated filer ‘ Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ‘ No È At June 30, 2006, the aggregate market value of voting stock held by non-affiliates was $8,975 million. At January 31, 2007, there were 121,339,139 shares of Common Stock, $1 par value, outstanding. Selected portions of the Sunoco, Inc. 2006 Annual Report to Shareholders are incorporated by reference in Parts I, II and IV of this Form 10-K. Selected portions of the Sunoco, Inc. definitive Proxy Statement, which will be filed with the Securities and Exchange Commission within 120 days after December 31, 2006, are incorporated by reference in Part III of this Form 10-K.

- 2. PART I ITEMS 1 AND 2. BUSINESS AND PROPERTIES Those statements in the Business and Properties discussion that are not historical in nature should be deemed forward-looking statements that are inherently uncertain. See “Forward-Looking Statements” in Management’s Discussion and Analysis of Financial Condition and Results of Operations in the Company’s 2006 Annual Report to Shareholders* for a discussion of the factors that could cause actual results to differ materially from those projected. General Sunoco, Inc.** was incorporated in Pennsylvania in 1971. It or its predecessors have been active in the petroleum industry since 1886. Its principal executive offices are located at 1735 Market Street, Suite LL, Philadelphia, PA 19103-7583. Its telephone number is (215) 977-3000 and its Internet website address is www.SunocoInc.com. The Company makes available free of charge on its website all materials that it files electronically with the Securities and Exchange Commission (the “SEC”), including its Annual Report on Form 10-K, Quarterly Reports on Form 10-Q, Current Reports on Form 8-K and amendments to these reports as soon as reasonably practicable after such materials are electronically filed with, or furnished to, the SEC. The Company, through its subsidiaries, is principally a petroleum refiner and marketer and chemicals manufacturer with interests in logistics and cokemaking. Sunoco’s petroleum refining and marketing operations include the manufacturing and marketing of a full range of petroleum products, including fuels, lubricants and some petrochemicals. Sunoco’s chemical operations comprise the manufacturing, distribution and marketing of commodity and intermediate petrochemicals. The petroleum refining and marketing, chemicals and logistics operations are conducted principally in the eastern half of the United States. Sunoco’s cokemaking operations currently are conducted in Virginia, Indiana and Ohio. The Company’s operations are organized into five business segments (Refining and Supply, Retail Marketing, Chemicals, Logistics and Coke) plus a holding company and a professional services group. Sunoco, Inc., the holding company, is a non-operating parent company which includes certain corporate officers. The professional services group consists of a number of staff functions, including: finance; legal and risk management; materials management; human resources; information systems; health, environment and safety; engineering services; facilities management; transaction processing; and government and public affairs. Costs incurred by the professional services group to provide these services are allocated to the five business segments and the holding company. This discussion of the Company’s business and properties reflects this organizational structure. For additional information regarding these business units, see Management’s Discussion and Analysis of Financial Condition and Results of Operations and the business segment information presented in Note 19 to the Consolidated Financial Statements, both in the Company’s 2006 Annual Report to Shareholders. Sunoco owns and operates five refineries which are located in Marcus Hook, PA, Philadelphia, PA, Westville, NJ, Toledo, OH and Tulsa, OK. The refineries in Marcus Hook, Philadelphia, Westville and * References in this Annual Report on Form 10-K to material in the Company’s 2006 Annual Report to Shareholders and in the Company’s definitive Proxy Statement, which will be filed with the Securities and Exchange Commission within 120 days after December 31, 2006, mean that such material is incorporated herein by reference; other material in those documents is not deemed to be filed as part of this Annual Report on Form 10-K. ** In this report, the terms “Company” and “Sunoco” are used interchangeably to mean Sunoco, Inc. or collectively, Sunoco, Inc. and its subsidiaries. The use of these terms is for convenience of discussion and is not intended to be a precise description of corporate relationships. 1

- 3. Toledo produce principally fuels and commodity petrochemicals while the refinery in Tulsa emphasizes lubricants production with related fuels production being sold in the wholesale market. The refinery in Westville (also known as the Eagle Point refinery) was acquired in January 2004 (see “Refining and Supply” below). Sunoco markets gasoline and middle distillates, and offers a broad range of convenience store merchandise through a network of 4,691 retail outlets in 25 states primarily on the East Coast and in the Midwest United States. During April 2004, Sunoco completed the purchase from ConocoPhillips of 340 Mobil® retail gasoline sites located primarily in Delaware, Maryland, Virginia and Washington, D.C. In 2006, the Company continued its Retail Portfolio Management program which selectively reduced its invested capital in Company-owned or leased sites, while retaining most of the gasoline sales volumes attributable to the divested sites (see “Retail Marketing” below). Sunoco owns and operates facilities in Philadelphia, PA and Haverhill, OH, which produce phenol and acetone, and in LaPorte, TX, Neal, WV and Bayport, TX, which produce polypropylene. In addition, Sunoco is a joint-venture partner in a facility in Marcus Hook, PA, which upgrades propylene and produces polypropylene. In September 2004, Sunoco sold its interest in the Mont Belvieu, TX, Belvieu Environmental Fuels (“BEF”) MTBE production facility to Enterprise Products Operating L.P. In addition, a facility in Pasadena, TX, which produces plasticizers, was sold to BASF in January 2004 (see “Chemicals” below). Sunoco owns, principally through Sunoco Logistics Partners L.P. (the “Partnership”) (a master limited partnership), a geographically diverse and complementary group of pipelines and terminal facilities which transport, terminal and store refined products and crude oil. Sunoco has a 43 percent interest in the Partnership, which includes a 2 percent general partnership interest (see “Logistics” below). Sunoco, through Sun Coke Company and its affiliates (individually and collectively, “Sun Coke”), makes high-quality, blast-furnace coke at its facilities in East Chicago, IN (Indiana Harbor), Vansant, VA (Jewell) and Franklin Furnace, OH (Haverhill), and produces metallurgical coal from mines in Virginia primarily for use at the Jewell cokemaking facility. An additional cokemaking facility in Vitória, Brazil is expected to commence limited operations in the first quarter of 2007, with full production expected in mid-2007. Sun Coke will be the operator and has a joint-venture interest in this facility (see “Coke” below). The following are separate discussions of Sunoco’s business segments. Refining and Supply The Refining and Supply business manufactures petroleum products, including gasoline, middle distillates (mainly jet fuel, heating oil and diesel fuel) and residual fuel oil as well as commodity petrochemicals, including olefins and their derivatives (ethylene, ethylene oxide polymers and refinery-grade propylene) and aromatics and their derivatives (benzene, cyclohexane, toluene and xylene) at the Marcus Hook, Philadelphia, Eagle Point and Toledo refineries, and sells these products to other Sunoco business units and to wholesale and industrial customers. This business also manufactures petroleum and lubricant products at the Tulsa refinery. In January 2004, Sunoco completed the purchase of the 150 thousand barrels-per-day Eagle Point refinery and related assets from El Paso Corporation for $250 million, including inventory. In connection with this transaction, Sunoco also assumed certain environmental and other liabilities. The acquisition of the Eagle Point refinery complements and enhances the Company’s refining operations in the Northeast and enables the capture of significant synergies in Northeast Refining. The related 2

- 4. assets acquired include a $40 million cumene facility attributable to Sunoco’s Chemicals business and certain pipeline and other logistics assets associated with the refinery which Sunoco subsequently sold to Sunoco Logistics Partners L.P. for $20 million in March 2004. The Company’s refinery operations are comprised of Northeast Refining (the Marcus Hook, Philadelphia and Eagle Point refineries) and MidContinent Refining (the Toledo and Tulsa refineries). The following tables set forth information concerning the Company’s refinery operations over the last three years (in thousands of barrels daily and percentages): Mid- Northeast Continent 2006 Refining Refining Total Crude Unit Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 655.0 245.0 900.0 Crude Inputs as Percent of Crude Unit Rated Capacity . . . . . . . . 94% 92% 93% Conversion Capacity* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270.0 122.0 392.0 Conversion Unit Capacity Utilized . . . . . . . . . . . . . . . . . . . . . . . . . . 94% 96% 95% Throughputs: Crude Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 616.1 224.5 840.6 Other Feedstocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64.2 8.6 72.8 Total Throughputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 680.3 233.1 913.4 Products Manufactured: Gasoline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323.5 112.7 436.2 Middle Distillates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230.2 75.3 305.5 Residual Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69.8 4.2 74.0 Petrochemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.3 7.3 35.6 Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . — 13.2 13.2 Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51.2 31.0 82.2 Total Production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 703.0 243.7 946.7 Less Production Used as Fuel in Refinery Operations . . . . . . . 32.8 11.1 43.9 Total Production Available for Sale . . . . . . . . . . . . . . . . . . . . . 670.2 232.6 902.8 * Represents capacity to upgrade lower-value, heavier petroleum products into higher-value, lighter products. Reflects an increase from 102 to 122 thousand barrels per day in June 2006 attributable to an expansion project at the Toledo refinery. 3

- 5. Mid- Northeast Continent 2005 Refining* Refining** Total Crude Unit Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 655.0 245.0 900.0 Crude Inputs as Percent of Crude Unit Rated Capacity . . . . . . . 99% 94% 98% Conversion Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270.0 102.0 372.0 Conversion Unit Capacity Utilized . . . . . . . . . . . . . . . . . . . . . . . . . 100% 107% 101% Throughputs: Crude Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 650.6 230.4 881.0 Other Feedstocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52.8 6.6 59.4 Total Throughputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 703.4 237.0 940.4 Products Manufactured: Gasoline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330.5 112.9 443.4 Middle Distillates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242.1 77.4 319.5 Residual Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71.7 4.5 76.2 Petrochemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.6 8.2 36.8 Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . — 13.2 13.2 Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.8 30.8 86.6 Total Production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 728.7 247.0 975.7 Less Production Used as Fuel in Refinery Operations . . . . . . . 36.7 11.9 48.6 Total Production Available for Sale . . . . . . . . . . . . . . . . . . . . . 692.0 235.1 927.1 * In January 2005, conversion capacity was increased from 265 to 270 thousand barrels per day due to an adjustment in Northeast Refining. ** In January 2005, crude unit capacity was increased from 235 to 245 thousand barrels per day and conversion capacity was increased from 96.7 to 102 thousand barrels per day as a result of adjustments in MidContinent Refining. 4

- 6. Mid- Northeast Continent 2004 Refining* Refining** Total Crude Unit Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 655.0 235.0 890.0 Crude Inputs as Percent of Crude Unit Rated Capacity . . . . . . . 97% 95% 97% Conversion Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265.0 96.7 361.7 Conversion Unit Capacity Utilized . . . . . . . . . . . . . . . . . . . . . . . . . . 97% 101% 98% Throughputs: Crude Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 633.3 222.4 855.7 Other Feedstocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52.9 5.9 58.8 Total Throughputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 686.2 228.3 914.5 Products Manufactured: Gasoline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327.8 114.2 442.0 Middle Distillates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231.5 68.8 300.3 Residual Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69.2 3.8 73.0 Petrochemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.0 7.1 38.1 Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . — 13.6 13.6 Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51.7 30.3 82.0 Total Production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 711.2 237.8 949.0 Less Production Used as Fuel in Refinery Operations . . . . . . . 35.6 10.6 46.2 Total Production Available for Sale . . . . . . . . . . . . . . . . . . . . . 675.6 227.2 902.8 * In January 2004, crude unit capacity was increased from 505 to 655 thousand barrels per day and conversion capacity was increased from 210 to 265 thousand barrels per day as a result of the acquisition of the Eagle Point refinery. Throughput and products manufactured data pertaining to the Eagle Point refinery are based on the amounts attributable to the 354-day ownership period (January 13, 2004 – December 31, 2004) divided by 366, the number of days in the year. ** In January 2004, crude unit capacity was increased from 225 to 235 thousand barrels per day as a result of a 10 thousand-barrels-per-day adjustment in MidContinent Refining. Sunoco meets all of its crude oil requirements through purchases from third parties. There has been an ample supply of crude oil available to meet worldwide refining needs, and Sunoco has been able to supply its refineries with the proper mix and quality of crude oils without material disruption. Most of the crude oil processed at Sunoco’s refineries is light-sweet crude oil. The Company believes that ample supplies of light-sweet crude oil will continue to be available. In the second half of 2004, the Company also began processing limited amounts of discounted high-acid sweet crude oils in its Northeast refineries. During 2006, approximately 63 thousand barrels per day of such crude oils were processed. The Philadelphia, Marcus Hook and Eagle Point refineries process crude oils supplied from foreign sources. The Toledo refinery processes domestic and Canadian crude oils as well as crude oils supplied from other foreign sources. The Tulsa refinery processes domestic and foreign-sourced crude oils. The foreign crude oil processed at the Company’s Northeast refineries is delivered utilizing ocean- going tankers and coastal distribution tankers and barges that are owned and operated by third parties. Approximately 40 percent of the Company’s ocean-going tanker marine transportation requirements pertaining to its Northeast Refining crude supply are met through time charters. Time charter leases for the various marine transportation vessels typically require a fixed-price payment or a fixed-price minimum and a variable component based on spot-market rates and generally contain 5

- 7. terms of between three to seven years with renewal and sub-lease options. The cost of the remaining marine transportation requirements reflects spot-market rates. Approximately 45 percent of Sunoco’s crude oil supply during 2006 came from Nigeria. Some of the crude oil producing areas of this West African country have experienced political and ethnic violence as well as labor disruptions in recent years, which has resulted in the shutdown of a small portion of total Nigerian crude oil production during that time. The lost crude oil production in Nigeria did not have a material impact on Sunoco’s operations, and the Company believes other sources of light-sweet crude oil are available in the event it is unable to obtain crude oil from Nigeria in the future. The following table sets forth information concerning the source of the Company’s crude oil purchases (in thousands of barrels daily): 2006 2005 2004 Crude Oil Source: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . West Africa . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 562.1 611.6 605.9 Domestic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128.9 145.2 138.2 Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76.7 61.5 75.0 Central Asia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.1 — — North Sea . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.5 9.3 41.9 South and Central America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27.7 42.3 1.8 “Lubes-Extracted” Gasoil/Naphtha Intermediate Feedstock . . . . . 10.0 10.7 6.5 838.0 880.6 869.3 Refining and Supply sells fuels through wholesale and industrial channels principally in the Northeast and upper Midwest and sells petrochemicals and lubricants on a worldwide basis. The following table sets forth Refining and Supply’s refined product sales (in thousands of barrels daily): 2006 2005 2004 To Unaffiliated Customers: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gasoline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193.2 216.7 211.1 Middle Distillates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290.3 294.0 275.2 Residual Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77.4 89.0 80.5 Petrochemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14.8 15.4 16.3 Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.8 13.3 13.5 Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.6 33.6 47.5 622.1 662.0 644.1 To Affiliates* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366.7 365.3 360.6 988.8 1,027.3 1,004.7 * Includes gasoline and middle distillate sales to Retail Marketing and benzene and refinery-grade propylene sales to Chemicals. Feedstocks can be moved between refineries in Northeast Refining by barge, truck and rail. In addition, an interrefinery pipeline leased from Sunoco Logistics Partners L.P. enables the transfer of unfinished stocks, including butanes, naphtha, distillate blendstocks and gasoline blendstocks between the Philadelphia and Marcus Hook refineries. Finished products are delivered to customers via the pipeline and terminal network owned and operated by Sunoco Logistics Partners L.P. (see “Logistics” below) as well as by third-party pipelines and barges and by truck and rail. 6

- 8. The Clean Air Act phased in limitations on the sulfur content of gasoline beginning in 2004 and the sulfur content of on-road diesel fuel beginning in mid-2006 (“Tier II”). The rules include banking and trading credit systems, providing refiners flexibility through 2006 for the low-sulfur gasoline and through May 2010 for the on-road low-sulfur diesel. Tier II capital spending, which was completed in 2006, totaled $755 million. It included outlays to construct new gasoline hydrotreaters at the Marcus Hook, Philadelphia, Eagle Point and Toledo refineries to meet the new gasoline requirements. In addition, the new on-road diesel specifications were met with differing facility-specific solutions involving the modification of existing refinery assets. Higher operating costs are also being incurred as the low-sulfur fuels are produced. Another rule was adopted in May 2004 which will phase in limitations on the allowable sulfur content in off-road diesel beginning in mid-2007. The rule also provides for banking and trading credit systems. The ultimate impact of this rule may depend upon the effectiveness of the related banking and trading credit systems, Sunoco’s flexibility to modify its production slate and the impact on any capital expenditures of technology selection, permitting requirements and construction schedules, as well as any effect on prices created by the changes in the level of off-road diesel fuel production. In connection with the phase in of these new off-road diesel fuel specifications, Sunoco is evaluating its alternatives for its Tulsa refinery, including consideration of significant capital expenditures which could result in increased crude flexibility and an upgraded product slate. The majority of any such capital expenditures would likely not occur until the 2009-2010 timeframe. During the 2006-2008 period, Refining and Supply expects capital expenditures to be approximately $700-$800 million annually, including a total of $800 million for income improvement projects over the three-year period. Refining and Supply has placed a greater emphasis on income improvement projects, which are designed to increase, by 2008, total crude unit capacity from 900 to 930 thousand barrels per day and total conversion capacity from 372 to 430 thousand barrels per day. These projects are designed to result in an improvement in product yields and crude oil and other feedstock processing flexibility. In addition, Refining and Supply’s anticipated capital expenditures during the 2006-2008 period include approximately $500 million to be spent largely to complete projects at its Philadelphia and Toledo refineries under a 2005 Consent Decree, which settled certain alleged violations under the Clean Air Act. Subsequently, additional capital outlays related to projects at the Marcus Hook and Tulsa refineries are expected to be made under the 2005 Consent Decree through 2013. The current status of these capital projects ranges from the preliminary design and engineering phase to the construction phase. During 2006, market conditions for engineering, procurement and construction of refinery projects have tightened, resulting in increasing costs and project delays. In addition, as more detailed engineering work is completed, increases in the original scope of work have been identified. The Refining and Supply capital plan for the 2006-2008 period includes a $500 million project to expand the capacity of one of the fluid catalytic cracking units at the Philadelphia refinery by 15 thousand barrels per day, which is designed to result in an upgrade of approximately 25 thousand barrels per day of residual fuel production into higher-value gasoline and distillate production (the “Philadelphia Project”). Capital outlays pertaining to the Philadelphia Project amounted to $279 and $43 million in 2006 and 2005, respectively, and are expected to total $178 million in 2007. Refining and Supply’s capital program also includes a $50 million project which is designed to expand the Toledo refinery’s crude unit capacity by 20 thousand barrels per day. Both projects are expected to be completed in the first half of 2007 and include significant capital for related base infrastructure and refinery turnarounds, as well as capital required under the 2005 Consent Decree. The Refining and Supply capital plan for the 2006-2008 period also includes a project at the Philadelphia refinery to reconfigure a previously idled hydrocracking unit to enable desulfurization of diesel fuel. This project, which is scheduled for completion in early 2009 at an estimated cost of $225- 7

- 9. $275 million, is designed to increase the facility’s ultra-low-sulfur diesel fuel production capability by 40-50 thousand barrels per day. In addition, a hydrocracker conversion project at the Toledo refinery, targeted for completion by the end of 2008 at an estimated cost of $10-$20 million, is designed to expand hydrocracking capacity at this facility by 5-10 thousand barrels per day. Other previously announced projects to further expand the Toledo refinery’s crude unit and conversion capacity by 2008 have been deferred. In 2006, Refining and Supply initiated an alkylation process improvement project at its Philadelphia refinery’s HF alkylation unit. The project will involve the incorporation of ReVAP™ technology which will require substantial improvements and modifications to the alkylation unit and supporting utility systems. The project is scheduled for completion during 2009 at an estimated cost of $80 million. While a significant change in the overall level of total capital spending in Refining and Supply during the 2007-2008 period is not expected, the Company currently believes that the cost of many of these capital projects could be significantly higher than anticipated. The pressures on project scope, costs and timing as well as labor productivity issues are also likely to result in the extension of project completion dates and the deferral of some lower-return projects. The Company may also elect to cancel or reduce the scope of projects which no longer meet required investment-return criteria. During 2005, Refining and Supply completed the construction of a sulfur plant at the Eagle Point refinery at a cost of $36 million. The new unit provides the Company with additional sulfur processing capacity and redundant processing capability to meet new permit compliance requirements. In September 2004, Refining and Supply entered into a 15-year product supply agreement with BOC Americas (PGS), Inc. (“BOC”), an affiliate of The BOC Group plc. Under this agreement, Refining and Supply is providing BOC with feedstock and utilities for use by BOC at its new hydrogen plant located on land leased from Refining and Supply at the Toledo refinery which commenced operations in March 2006. BOC utilizes the feedstock and utilities to generate hydrogen and steam at the new facility for sale to Refining and Supply for use at its Toledo refinery and for sale to another third party. During 1999, Refining and Supply entered into an agreement with a subsidiary of FPL Energy (“FPL”) to purchase steam from a 750-megawatt, natural gas fired cogeneration power plant or four auxiliary boilers to be constructed, owned and operated by FPL at Sunoco’s Marcus Hook refinery. Construction of the cogeneration plant and auxiliary boilers was completed in 2004. In December 2004, Sunoco and FPL agreed to a restructuring of the agreement. Under the restructured terms, FPL surrendered its easement interest in land adjacent to the power plant on which the auxiliary boilers were constructed, thereby transferring ownership of the auxiliary boilers to Sunoco. FPL operates the auxiliary boilers on Sunoco’s behalf. When the cogeneration plant is in operation, Sunoco has the option to purchase steam from that facility at a rate equivalent to that set forth in the original agreement. As part of the restructuring, Sunoco has agreed to a long-term lease to FPL of the land on which the cogeneration facility was constructed and to modify certain terms in the existing agreement for an aggregate cash payment of $48 million, most of which is attributable to prepaid rent. Sunoco received this $48 million payment in January 2005. No gain or loss was recognized in connection with the restructuring. Retail Marketing The Retail Marketing business consists of the retail sale of gasoline and middle distillates and the operation of convenience stores in 25 states, primarily on the East Coast and in the Midwest region of the United States. The highest concentrations of outlets are located in Connecticut, Florida, Maryland, Massachusetts, Michigan, New Jersey, New York, Ohio, Pennsylvania and Virginia. 8

- 10. The following table sets forth Sunoco’s retail gasoline outlets at December 31, 2006, 2005 and 2004: 2006 2005 2004 Direct Outlets: Company Owned or Leased: Company Operated: Traditional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93 118 134 APlus® Convenience Stores . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 472 482 515 565 600 649 Dealer Operated: Traditional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243 293 340 APlus® Convenience Stores . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234 231 223 Ultra Service Centers® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154 164 184 631 688 747 Total Company Owned or Leased* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,196 1,288 1,396 Dealer Owned** . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 564 544 546 Total Direct Outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,760 1,832 1,942 Distributor Outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,931 2,931 2,862 4,691 4,763 4,804 * Gasoline and diesel throughput per Company-owned or leased outlet averaged 143.5, 136.3 and 132.6 thousand gallons per month during 2006, 2005 and 2004, respectively. ** Primarily traditional outlets. Retail Marketing has a portfolio of outlets that differ in various ways including: product distribution to the outlets; site ownership and operation; and types of products and services provided. Direct outlets may be operated by Sunoco or by an independent dealer, and are sites at which fuel products are delivered directly to the site by Sunoco’s 132 trucks or by its contract carriers. The Company or an independent dealer owns or leases the property. These sites may be traditional locations that sell almost exclusively fuel products under the Sunoco® and Coastal® brands or may include APlus® convenience stores or Ultra Service Centers® that provide automotive diagnostics and repair. Included among Retail Marketing’s outlets at December 31, 2006 were 56 outlets on turnpikes and expressways in Pennsylvania, New Jersey, New York and Maryland. Of these outlets, 39 were Company-operated sites providing gasoline, diesel fuel and convenience store merchandise. Distributor outlets are sites in which the distributor takes delivery of fuel products at a terminal where branded products are available. Sunoco does not own, lease or operate these locations. In the second quarter of 2004, Sunoco completed the purchase of 340 retail outlets operated under the Mobil® brand from ConocoPhillips for $181 million, including inventory. Of the total sites acquired, 50 were owned outright and 62 were subject to long-term leases. The remaining network consisted of contracts to supply 34 dealer-owned and operated locations and 194 branded distributor-owned sites. These outlets, which included 31 sites that are Company-operated and have convenience stores, are located primarily in Delaware, Maryland, Virginia and Washington, D.C. These sites have been re-branded to Sunoco® gasoline and APlus® convenience stores. This acquisition fits the Company’s long-term strategy of building a retail and convenience store network designed to provide attractive long-term returns. During the 2004-2006 period, Sunoco generated $189 million of divestment proceeds related to the sale of 338 sites under a retail portfolio management (“RPM”) program to selectively reduce the 9

- 11. Company’s invested capital in Company-owned or leased sites. Most of the sites were converted to contract dealers or distributors thereby retaining most of the gasoline sales attributable to the divested sites within the Sunoco branded business. During 2006, 2005 and 2004, net after-tax gains totaling $10, $5 and $7 million, respectively, were recognized in connection with the RPM program. Sunoco expects to continue to identify sites for divestment in the future. During 2004, Sunoco sold its private label consumer and commercial credit card business and related accounts receivable to Citibank. In connection with this divestment, Sunoco received $100 million in cash proceeds (primarily due to the sale of existing accounts receivable), recognized a $2 million after-tax gain on the divestment and established a $2 million after-tax accrual that has been paid out for employee terminations and other exit costs. In addition, the two companies signed a seven- year agreement for Citibank to operate and service the Sunoco private label credit card program. Branded fuels sales (including middle distillates) averaged 346.1 thousand barrels per day in 2006 compared to 343.6 thousand barrels per day in 2005 and 339.0 thousand barrels per day in 2004. Retail Marketing is one of the largest providers of heating products in the eastern United States. In 2006, the Company sold 156 million gallons of these products to approximately 110 thousand customers. Sunoco is also the largest manufacturer and marketer of high performance (racing) gasoline in the United States with approximately 10 million gallons sold during 2006. The Sunoco® brand is positioned as a premium brand. Brand improvements in recent years have focused on physical image, customer service and product offerings. In addition, Sunoco believes its brands and high performance gasoline business have benefited from its sponsorship agreement with NASCAR that continues until 2016. Under this agreement, Sunoco® is the Official Fuel of NASCAR and the exclusive fuel supplier to NASCAR events, and APlus® is the Official Convenience Store of NASCAR. Sunoco’s APlus® convenience stores are located principally in Florida, Massachusetts, Michigan, New York, Ohio, Pennsylvania and South Carolina. These stores supplement sales of fuel products with a broad mix of merchandise such as groceries, fast foods, beverages and tobacco products. The following table sets forth information concerning Sunoco’s APlus® convenience stores: 2006 2005 2004 Number of Stores (at December 31) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 739 746 757 Merchandise Sales (Thousands of Dollars/Store/Month) . . . . . . . . . . . . $80 $78 $73 Merchandise Margin (Company Operated) (% of Sales) . . . . . . . . . . . . . 27.4% 28.2% 25.6% The Company intends to grow its convenience store business principally through acquisitions and redesign of traditional gasoline outlets. Chemicals The Chemicals business manufactures, distributes and markets commodity and intermediate petrochemicals. The chemicals consist of aromatic derivatives (cumene, phenol, acetone, bisphenol-A, and other phenol derivatives) and polypropylene. Cumene is produced at the Philadelphia, PA and Eagle Point refineries; phenol and acetone are produced at facilities in Philadelphia, PA and Haverhill, OH; and polypropylene is produced at facilities in LaPorte, TX, Neal, WV and Bayport, TX, as well as at the Epsilon Products Company, LLC (“Epsilon”) consolidated joint venture in Marcus Hook, PA which also upgrades polymer-grade propylene. In January 2004, a facility in Pasadena, TX, which produces plasticizers, was sold to BASF. (See “Refining and Supply” for a discussion of the commodity petrochemicals produced by Refining and Supply at the Marcus Hook, Philadelphia, Eagle Point and Toledo refineries.) 10

- 12. During 2003, Sunoco formed a limited partnership with Equistar Chemicals, L.P. (“Equistar”) involving Equistar’s ethylene facility in LaPorte, TX. Equistar is a wholly owned subsidiary of Lyondell Chemical Company. Under the terms of the partnership agreement, the partnership has agreed to provide Sunoco with 700 million pounds-per-year of propylene pursuant to a 15-year supply contract. Of this amount, 500 million pounds per year is priced on a cost-based formula that includes a fixed discount that declines over the life of the contract, while the remaining 200 million pounds per year is based on market prices. Sunoco also purchased Equistar’s polypropylene facility in Bayport, TX. Through the partnership, the Company believes it has secured a favorable long-term supply of propylene for its Gulf Coast polypropylene business. Realization of these benefits is largely dependent upon performance by Equistar, which has a credit rating below investment grade. Equistar has not given any indication that it will not perform under its contracts. In the event of nonperformance, Sunoco has collateral and certain other contractual rights under the partnership agreement. In 2004, Sunoco Chemicals sold its one-third partnership interest in the Mont Belvieu, TX Belvieu Environmental Fuels (“BEF”) MTBE production facility to Enterprise Products Operating L.P. (“Enterprise”) for $15 million in cash, resulting in an $8 million after-tax loss on divestment. In connection with the sale, Sunoco has retained one-third of any liabilities and damages arising from any claims resulting from the ownership of the assets and liabilities of BEF for the period prior to the divestment date, except for any on-site environmental claims which are retained by Enterprise. During 2003, Sunoco announced its decision to sell its plasticizer business and recorded a $17 million after-tax charge to write down the assets held for sale to their estimated fair values less costs to sell and to establish accruals that have been paid out for employee terminations and other required exit costs. Sunoco sold this business and related inventory in January 2004 to BASF for approximately $90 million in cash. The Company’s Neville Island, PA site was not part of the transaction and Sunoco is now providing terminalling services at this facility to BASF for a 15–year period. Sunoco Chemicals has an interest in the Epsilon joint venture, which is comprised of its 750 million pounds-per-year polymer-grade propylene operations at the Marcus Hook refinery and the adjacent 750 million pounds-per-year polypropylene plant. The Chemicals business is currently entitled to 65 percent of any cash distributions from the joint venture. This distribution percentage will decline to 55 percent on June 15, 2008 and remain at that level until 2015 at which time it will decline to 50 percent. The Chemicals business markets the joint venture’s production under the Sunoco® name along with the production from its LaPorte, TX, Neal, WV and Bayport, TX polypropylene plants. Epsilon was unable to repay its $120 million term loan that was due in September 2006 and $31 million of borrowings under its $40 million revolving credit facility that matured in September 2006. Upon such default, the lenders made a demand on Sunoco, Inc., as guarantor, and Sunoco, Inc. satisfied its guarantee obligations in the third quarter of 2006. Sunoco, Inc. is now subrogated to the rights and privileges of the former debtholders. In January 2007, Sunoco, Inc., as subrogee, made a demand for payment of the outstanding amounts, but Epsilon was unable to make payment. Sunoco, Inc., Epsilon and the Epsilon joint-venture partners are currently in litigation to resolve this matter. Sunoco’s Philadelphia phenol facility has the capacity to produce annually more than one billion pounds of phenol and 700 million pounds of acetone. Under a long-term contract, the Chemicals business supplies Honeywell International Inc. (“Honeywell”) with approximately 745 million pounds of phenol annually at a price based on the market value of cumene feedstock plus an amount approximating other phenol production costs. During the third quarter of 2005, an arbitrator ruled that Sunoco was liable in an arbitration proceeding for breaching the pricing provisions of this contract relating to phenol produced at the Philadelphia plant from June 2003 through April 2005. In January 2006, the arbitrator ruled that Sunoco should bill Honeywell based on the pricing formula established in the arbitration until a second arbitration finalized pricing for 2005 and beyond under provisions of a 11

- 13. supply agreement which provide for a price reopener on and after January 1, 2005. Damages of approximately $95 million ($56 million after tax), including prejudgment interest, were assessed, of which $27, $48 and $20 million pertained to 2005, 2004 and 2003, respectively. Such damages, which were paid to Honeywell in April 2006, were reported as a charge against 2005 earnings and are shown separately as Phenol Supply Contract Dispute under Corporate and Other in the Earnings Profile of Sunoco Businesses in Management’s Discussion and Analysis of Financial Condition and Results of Operations in the Company’s 2006 Annual Report to Shareholders. In March 2006, a U.S. District Court judge upheld the first arbitrator’s ruling. In July 2006, the second arbitrator ruled that the pricing through July 2009 should be based essentially on the pricing formula established in the first arbitration. The prices charged to Honeywell during 2006 have been based on this formula. The following table sets forth information concerning petrochemicals production by the Chemicals business (in millions of pounds): Production Capacity at December 31, 2006 2006 2005 2004 Phenol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,125* 1,536 1,526 1,539 Acetone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,300* 951 944 953 Bisphenol-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240 202 209 187 Other Phenol Derivatives . . . . . . . . . . . . . . . . . . . . . . . . 120 79 76 79 Cumene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,925 1,556 1,577 1,533 Polypropylene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,550 2,260 2,224 2,204 Plasticizers and Related Feedstocks** . . . . . . . . . . . . — — — 33 Propylene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 750 632 655 618 Total Production . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9,010 7,216 7,211 7,146 Less: Production Used as Feedstocks*** . . . . . . . . . . 2,417 2,468 2,367 Total Production Available for Sale . . . . . . . . . . . 4,799 4,743 4,779 * Includes 350 million pounds per year of phenol capacity and 217 million pounds per year of associated acetone capacity related to a production line in Haverhill, OH, which has been temporarily idled. ** Consists of amounts attributable to the plasticizer business, which was divested in January 2004. *** Includes cumene (used in the manufacture of phenol and acetone), phenol and acetone (used in the manufacture of bisphenol-A) and polymer-grade propylene (used in the manufacture of polypropylene). Petrochemical products produced by the Chemicals business are distributed and sold on a worldwide basis with most of the sales made to customers in the United States. The following table sets forth the sale of petrochemicals to third parties by Chemicals (in millions of pounds): 2006 2005 2004 Phenol and Related Products (including Bisphenol-A) . . . . . . . . . . . . . . . . 2,535 2,579 2,615 Polypropylene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,243 2,218 2,239 Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88 91 215 4,866 4,888 5,069 The tables above reflect only volumes manufactured and sold directly by the Chemicals business and the consolidated Epsilon joint venture. Chemicals also manages the third-party chemicals sales for Refining and Supply and a joint venture with Suncor Energy Inc., bringing the total petrochemicals sold under the Sunoco® name to approximately 7.1 billion pounds in 2006. 12

- 14. Sales made by the Chemicals business during 2006 were distributed through the following channels: • Phenol and Related Products—Long-term phenol contract sales to Honeywell are used in nylon production. Other phenol contract sales are to large manufacturers of resins and adhesives primarily for use in building products. Large contract sales of acetone are to major customers who manufacture polymers. Other sales of acetone are made to individually smaller customers for use in inks, paints, varnishes and adhesives. Bisphenol-A, manufactured from phenol and acetone, is sold to manufacturers of epoxy resins and polycarbonates; and • Polypropylene—Sales are made to a diverse group of customers for use in fibers, carpeting, packaging, automotive, furniture and other end-products. Logistics The Logistics business operates refined product and crude oil pipelines and terminals and conducts crude oil acquisition and marketing activities primarily in the Northeast, Midwest and South Central regions of the United States. The Logistics business also has an ownership interest in several refined product and crude oil pipeline joint ventures. During the 2004-2006 period, Sunoco Logistics Partners L.P. issued 10.5 million limited partnership units in a series of public offerings, generating $399 million of net proceeds. Coincident with these offerings, the Partnership redeemed 5.0 million limited partnership units owned by Sunoco for $182 million. As a result of these transactions, Sunoco’s ownership interest in this master limited partnership, including its 2 percent general partnership interest, was reduced from 75 percent to 43 percent. For additional information regarding these transactions, see “Financial Condition—Capital Resources and Liquidity—Other Cash Flow Information” in Management’s Discussion and Analysis of Financial Condition and Results of Operations in the Company’s 2006 Annual Report to Shareholders. Sunoco is a party in various agreements with the Partnership which require Sunoco to pay for minimum storage and throughput usage of certain Partnership assets. Sunoco also has agreements with the Partnership which establish fees for administrative services provided by Sunoco to the Partnership and provide indemnifications by Sunoco to the Partnership for certain environmental, toxic tort and other liabilities. Pipeline operations are primarily conducted through the Partnership’s pipelines and also through other pipelines in which the Partnership or Sunoco has an ownership interest. The pipelines are principally common carriers and, as such, are regulated by the Federal Energy Regulatory Commission for interstate movements and by state regulatory agencies for intrastate movements. The tariff rates charged, while regulated by the governing agencies, are generally based upon competition from other pipelines or alternate modes of transportation. Refined product pipeline operations, located primarily in the Northeast and Midwest, transport gasoline, jet fuel, diesel fuel, home heating oil and other products for Sunoco’s other businesses and for third-party integrated petroleum companies, independent refiners, independent marketers and distributors. Crude oil pipeline operations, located primarily in the South Central United States, transport foreign crude oil received at the Partnership’s Nederland, TX and Marysville, MI terminals and crude oil produced primarily in Oklahoma and Texas to refiners (including Sunoco’s Tulsa and Toledo refineries) or to local trade points. In March 2006, the Partnership purchased two separate crude oil pipeline systems and related storage facilities located in Texas, one from affiliates of Black Hills Energy, Inc. (“Black Hills”) for $41 million and the other from affiliates of Alon USA Energy, Inc. (“Alon”) for $68 million. The Black Hills 13

- 15. acquisition also includes a lease acquisition marketing business and related inventory. In August 2006, the Partnership purchased from Sunoco for $65 million a company that has a 55 percent interest in Mid-Valley Pipeline Company, a joint venture which owns a crude oil pipeline system in the Midwest. Sunoco did not recognize any gain or loss on this transaction. In August 2005, the Partnership completed the acquisition of a crude oil pipeline system and related storage facilities located in Texas from ExxonMobil for $100 million and, in the fourth quarter of 2005, completed the construction of a $16 million, 20-mile crude oil pipeline connecting these assets to the West Texas Gulf Pipeline, which is 43.8 percent owned by the Partnership. In December 2005, the Partnership completed the acquisition of an ownership interest in the Mesa Pipeline from Chevron for $5 million, which, coupled with the 7.2 percent interest it acquired from Sunoco, gave it a 37.0 percent ownership interest. In 2004, the Partnership completed the following acquisitions: in March, certain pipeline and other logistics assets that had previously been acquired by Sunoco with the Eagle Point refinery for $20 million; in April, ConocoPhillips’ Baltimore, MD and Manassas, VA refined product terminals for $12 million; in June, an additional one-third interest in the Harbor Pipeline from El Paso Corporation for $7 million; and in November, a refined product terminal located in Columbus, OH from a subsidiary of Certified Oil Company for $8 million. At December 31, 2006, the Partnership owned and operated approximately 3,800 miles of crude oil pipelines and approximately 1,650 miles of refined product pipelines. In 2006, crude oil and refined product shipments on these pipelines totaled 21.1 and 17.7 billion barrel miles, respectively, as compared to 16.3 and 17.1 billion barrel miles in 2005 and 13.9 and 17.2 billion barrel miles in 2004. These amounts represent 100 percent of the pipeline shipments of these pipelines. Product terminalling operations include 38 terminals in the Northeast and Midwest that receive refined products from pipelines and distribute them primarily to Sunoco and also to third parties, who in turn make deliveries to end-users such as retail outlets. During 2006, 2005 and 2004, throughput at these product terminals totaled 392, 390 and 341 thousand barrels daily, respectively. Terminalling operations also include an LPG terminal near Detroit, MI, a crude oil terminal complex adjacent to Sunoco’s Philadelphia refinery, ship and barge docks adjacent to Sunoco’s Eagle Point refinery and a refined product terminal adjacent to Sunoco’s Marcus Hook refinery. During 2006, 2005 and 2004, throughput at these other terminals totaled 688, 702 and 685 thousand barrels daily, respectively. The Partnership’s Nederland, TX terminal provides approximately 12.9 million barrels of storage and provides terminalling throughput capacity exceeding one million barrels per day. Its Gulf Coast location provides local, south central and midwestern refiners access to foreign and offshore domestic crude oil. The facility is also a key link in the distribution system for U.S. government purchases for and sales from the Strategic Petroleum Reserve storage facilities. During 2006, 2005 and 2004, throughput at the Nederland terminal totaled 462, 458 and 488 thousand barrels daily, respectively. During 2006, the Partnership continued its construction of seven new crude oil storage tanks with 4.2 million barrels of capacity, which are designed to allow the Nederland terminal to efficiently service the increased volumes related to the 2006 acquisitions discussed above. In addition, the Partnership announced a project to construct three new storage tanks with a combined capacity of 2.0 million barrels and a 12-mile crude oil pipeline from the Nederland terminal to Motiva Enterprise LLC’s Port Arthur, TX refinery. This project is expected to be completed by January 2010 at a cost in excess of $70 million. The Partnership’s crude oil pipeline operations in the South Central United States are complemented by crude oil acquisition and marketing operations. During 2006, 2005 and 2004, approximately 192, 186 and 187 thousand barrels daily, respectively, of crude oil were purchased (including exchanges) from third-party leases and approximately 295, 237 and 282 thousand barrels daily, respectively, were purchased in bulk or other exchange transactions. Purchased crude oil is delivered to various trunk pipelines either directly from the wellhead through gathering pipelines or utilizing the Partnership’s fleet of approximately 115 trucks or third-party trucking operations. 14

- 16. Coke Sun Coke Company, through its affiliates (individually and collectively, “Sun Coke”), operates metallurgical coke plants located in East Chicago, IN (Indiana Harbor), Vansant, VA (Jewell), and Franklin Furnace, OH (Haverhill), and metallurgical coal mines located in Virginia. Aggregate coke production from the plants approximates 2.55 million tons per year. The Indiana Harbor plant produces approximately 1.3 million tons per year, the Jewell plant produces approximately 700 thousand tons per year and the Haverhill plant produces approximately 550 thousand tons per year. In addition, the Indiana Harbor plant produces heat as a by-product of Sun Coke’s proprietary process that is used by a third party to produce electricity and the Haverhill plant produces steam that is sold to Sunoco’s Chemicals business. These facilities use a proprietary low-cost cokemaking technology, which is environmentally superior to the chemical by-product recovery technology currently used by most other coke producers. Sunoco received a total of $309 million in exchange for interests in its Jewell cokemaking operations in two separate transactions in 1995 and 2000. Sunoco also received a total of $415 million in exchange for interests in its Indiana Harbor cokemaking operations in two separate transactions in 1998 and 2002. Sunoco did not recognize any gain as of the dates of these transactions because the third-party investors were entitled to a preferential return on their respective investments. In December 2006, Sunoco acquired the limited partnership interest of the third-party investor in the Jewell cokemaking operation for $155 million and recognized a $3 million after-tax loss in connection with this transaction. This loss is included in Net Financing Expenses and Other under Corporate and Other in the Earnings Profile of Sunoco Businesses in Management’s Discussion and Analysis of Financial Condition and Results of Operations in the Company’s 2006 Annual Report to Shareholders. As a result, such third-party investor is no longer entitled to any preferential or residual return. The preferential returns of the investors in the Indiana Harbor cokemaking operations are currently equal to 98 percent of the cash flows and tax benefits from such cokemaking operations during the preferential return period, which continues until the investor entitled to the preferential return recovers its investment and achieves a cumulative annual after-tax return of approximately 10 percent. The preferential return period for the Indiana Harbor operations is projected to end during 2007. The accuracy of this estimate is somewhat uncertain as the length of the preferential return period is dependent upon estimated future cash flows as well as projected tax benefits which could be impacted by their potential phase-out (see below). Higher-than-expected cash flows and tax benefits will shorten the investor’s preferential return period, while lower-than-expected cash flows and tax benefits will lengthen the period. After payment of the preferential return, the investors in the Indiana Harbor operations will be entitled to a minority interest in the related cash flows and tax benefits initially amounting to 34 percent and thereafter declining to 10 percent by 2038. Under existing tax law, most of the coke production at Jewell and all of the coke production at Indiana Harbor are not eligible to generate nonconventional fuel tax credits after 2007. In addition, prior to the expiration dates for such credits, they would be phased out, on a ratable basis, if the average annual price of domestic crude oil at the wellhead is within a certain inflation-adjusted price range. (This range was $53.20 to $66.79 per barrel for 2005, the latest year for which the range is available.) The domestic wellhead price averaged $60.03 per barrel for the eleven months ended November 30, 2006. The corresponding price for West Texas Intermediate (“WTI”) crude oil, a widely published reference price for domestic crude oil, was $66.59 per barrel for the eleven months ended November 30, 2006. Based on the Company’s estimate of the domestic wellhead price for the full-year 2006, Sun Coke recorded only 65 percent of the benefit of the tax credits that otherwise would have been available without regard to these phase-out provisions. The estimated impact of this phase-out 15

- 17. reduced earnings for 2006 by $8 million after tax. The ultimate amount of the credits to be earned for 2006 will be based upon the average annual price of domestic crude oil at the wellhead. If the annual crude oil price averages at or above the top of the inflation-adjusted range during 2007, then it is estimated that the corresponding reduction in Sun Coke’s after-tax income would approximate $30 million for that year. The above estimates incorporate increased coke prices resulting from the expiration or any phase-out of the tax credits with respect to coke sold under the long-term contract from the Indiana Harbor plant. The energy policy legislation enacted in August 2005 includes additional tax credits pertaining to a portion of the coke production at Jewell, all of the production at Haverhill and all future domestic coke plants placed into service by January 1, 2010. The credits cover a four-year period, effective January 1, 2006 or the date any new facility is placed into service, if later. The credits attributable to Sun Coke’s existing Jewell and Haverhill facilities are expected to benefit Sun Coke’s future annual income by approximately $8 million after tax. These tax credits are not subject to any phase-out based upon crude oil prices. The following table sets forth information concerning cokemaking and coal mining operations: 2006 2005 2004 Production (Thousands of Tons): Coke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,510 2,405 1,965 Metallurgical Coal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,179 1,252 1,166 Proven and Probable Metallurgical Coal Reserves at December 31 (Millions of Tons) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102 103 105 In 2006, 82 percent of Sun Coke’s metallurgical coal production was converted into coke at the Jewell plant, 10 percent was converted into coke at the Indiana Harbor and Haverhill plants and 8 percent was sold in spot market transactions. Those sales are consistent with Sun Coke’s strategy of using its metallurgical coal production principally to supply its Jewell cokemaking operation. Most of the metallurgical coal used to produce coke at the Indiana Harbor and Haverhill cokemaking operations is purchased from third parties. Sun Coke believes there is an ample supply of metallurgical coal available, and it has been able to supply these facilities without any significant disruption in coke production. Substantially all coke sales from the Indiana Harbor, Jewell and Haverhill plants are made pursuant to long-term contracts with Mittal Steel USA, Inc. (“Mittal USA”). Mittal USA has not provided any indication that it will not perform under those contracts. However, in the event of nonperformance, Sun Coke’s results of operations and cash flows may be adversely affected. Production from the Indiana Harbor plant is sold and delivered principally to Mittal USA’s Indiana Harbor Works steel plant, which is adjacent to the Indiana Harbor coke plant. The coke purchase agreement requires Sun Coke to provide Mittal USA with 1.2 million tons of coke annually on a take-or-pay basis through 2013. Additional production of approximately 100 thousand tons per year is sold either to Mittal USA or to other steel producers. Indiana Harbor also supplies the hot exhaust gas produced at the plant to a contiguous cogeneration plant operated by an independent power producer for use in the generation of electricity. In exchange, the independent power producer reduces the sulfur and particulate content of that hot exhaust gas to acceptable emission levels. Sun Coke is supplying 550 thousand tons per year of coke from the Haverhill operation to Mittal USA through September 2020. Under the applicable coke supply agreement, coke is being supplied to 16

- 18. Mittal USA on a take-or-pay basis through September 2012, and thereafter based upon requirements in excess of Mittal USA’s existing coke production and its other off-take obligations with respect to Sun Coke’s Indiana Harbor plant. Initial coke production from the Haverhill plant began during March 2005. The flue gas produced during the cokemaking process is used to generate low-cost steam that is sold to the adjacent chemical manufacturing complex owned and operated by Sunoco’s Chemicals business. Sun Coke is also supplying Mittal USA with 700 thousand tons per year of coke from the Jewell operation. Under the applicable coke supply agreement, the term of that agreement is concurrent with the term of the Haverhill agreement. Coke is being supplied on a take-or-pay basis through September 2012, and thereafter will be supplied based upon Mittal USA’s requirements in excess of its existing coke production (subject to the Indiana Harbor coke supply agreement). Under the above agreements, coke production at Jewell through 2007 is sold at fixed prices which escalate semiannually. Beginning in 2008, selling prices for coke at Jewell will consist of a coal charge equal to the cost of the coal delivered to the plant multiplied by an adjustment factor (which is expected to exceed such delivered coal costs) as well as the pass through of transportation costs, operating costs indexed for inflation and a fixed-price component. Coke selling prices for Indiana Harbor and Haverhill production reflect the pass through of coal costs and transportation costs. Such prices also include an operating cost and fixed-price component. In August 2004, Sun Coke entered into a series of agreements with Companhia Siderúrgica de Tubarão and Cia. Siderúrgica Belgo-Mineira (the “Off-takers”) with respect to the development of a 1.7 million tons-per-year cokemaking facility and associated cogeneration power plant in Vitória, Brazil. Those agreements generally include: technology license agreements whereby Sun Coke has licensed its proprietary technology to a project company (the “Project Company”); an engineering and technical services agreement whereby Sun Coke is providing engineering and construction-related technical services to the Project Company; an operating agreement whereby a local subsidiary of Sun Coke will operate the cokemaking and water treatment plant facilities for a term of not less than 15 years; and an investment agreement by and among Sun Coke and the Off-takers whereby Sun Coke has acquired a one percent equity interest in the Project Company and expects to make an additional $35 million investment in 2007. The Off-takers will purchase from the Project Company all coke production under long-term agreements, and one of the Off-takers will purchase all of the electricity produced at the cogeneration power plant. Limited operations are expected to commence at the facilities in the first quarter of 2007, with full production expected in mid-2007. In February 2007, Sun Coke entered into an agreement with two customers under which Sun Coke will build, own and operate a second 550,000 tons-per-year cokemaking facility at its Haverhill site. Construction of this facility, which is estimated to cost approximately $230 million, is expected to commence in the first quarter of 2007, and the facility is expected to be operational in the second half of 2008. In connection with this agreement, the customers agreed to purchase, over a 15-year period, a combined 550,000 tons per year of coke from this facility. In addition, the heat recovery steam generation associated with the cokemaking process at this facility will produce and supply steam to a 67 megawatt turbine, which will provide, on average, 46 megawatts of power into the regional power market. Sun Coke is currently discussing other opportunities for developing new heat recovery cokemaking facilities with several domestic and international steel companies. Such cokemaking facilities could be either wholly owned or owned through a joint venture with one or more parties. The steel company customers would be expected to purchase the coke production under a long-term take-or-pay contract or equivalent basis. 17

- 19. Competition In all of its operations, Sunoco is subject to competition, both from companies in the industries in which it operates and from products of companies in other industries. The refining and marketing business is very competitive. Sunoco competes with a number of other domestic refiners and marketers in the eastern half of the United States, with integrated oil companies, with foreign refiners that import products into the United States and with producers and marketers in other industries supplying alternative forms of energy and fuels to satisfy the requirements of the Company’s industrial, commercial and individual consumers. Profitability in the refining and marketing industry depends largely on refined product margins, which can fluctuate significantly, as well as operating efficiency, product mix, and costs of product distribution and transportation. Certain of Sunoco’s competitors that have larger and more complex refineries may be able to realize lower per-barrel costs or higher margins per barrel of throughput. Several of Sunoco’s principal competitors are integrated national or international oil companies that are larger and have substantially greater resources than Sunoco. Because of their integrated operations and larger capitalization, these companies may be more flexible in responding to volatile industry or market conditions, such as shortages of feedstocks or intense price fluctuations. Refining margins are frequently impacted by sharp changes in crude oil costs, which may not be immediately reflected in product prices. The refining industry is highly competitive with respect to feedstock supply. Unlike certain of its competitors that have access to proprietary sources of controlled crude oil production available for use at their own refineries, Sunoco obtains substantially all of its crude oil and other feedstocks from unaffiliated sources. Most of the crude oils processed in Sunoco’s refining system are light-sweet crude oils. However, management believes that any potential competitive impact of Sunoco’s inability to process significant quantities of less expensive heavy-sour crude oils will likely be mitigated by: the higher-value product slate obtained from light-sweet crude oils, the lower cost to process light-sweet crude oils, the processing of a limited amount of discounted high-acid sweet crude oils and the continued availability of ample quantities of light-sweet crude oils. Sunoco also faces strong competition in the market for the sale of retail gasoline and merchandise. Sunoco’s competitors include service stations of large integrated oil companies, independent gasoline service stations, convenience stores, fast food stores, and other similar retail outlets, some of which are well-recognized national or regional retail systems. The number of competitors varies depending on the geographical area. It also varies with gasoline and convenience store offerings. This competition is expected to continue. The principal competitive factors affecting Sunoco’s retail marketing operations include site location, product price, selection and quality, appearance and cleanliness, hours of operation, store safety, customer loyalty and brand recognition. Sunoco competes by pricing gasoline competitively, combining its retail gasoline business with convenience stores that provide a wide variety of products, and using advertising and promotional campaigns. Sunoco believes that it is in a position to compete effectively as a marketer of refined products because of the location of its Northeast and Midwest refineries and retail network which are well integrated with the distribution system owned by Sunoco Logistics Partners L.P., the master limited partnership that is 43 percent owned by Sunoco. Sunoco’s chemical business is largely a commodities business and competes with local, regional, national and international companies, some of which have greater financial, research and development, production and other resources than Sunoco. Although competitive factors may vary among product lines, in general, Sunoco’s competitive position is primarily based on raw material costs, selling prices, product quality, manufacturing technology, access to new markets, proximity to the market and 18

- 20. customer service and support. Sunoco’s competitors can be expected in the future to improve technologies, expand capacity, and, in certain product lines, develop and introduce new products. While there can be no assurances of its ability to do so, Sunoco believes that it will have sufficient resources to maintain its current position. Sunoco faces similarly strong competition in the sale of base oil lubricant products. Logistics operations are very competitive. Generally, pipelines are the lowest cost method for long-haul, overland movement of crude oil and refined products. Therefore, the most significant competitors for large volume shipments in the areas served by the Partnership’s pipelines are other pipelines. However, high capital requirements, environmental considerations and the difficulty in acquiring rights-of-way and related permits make it difficult for other companies to build competing pipelines in areas served by the Partnership’s pipelines. As a result, competing pipelines are likely to be built only in those cases in which strong market demand and attractive tariff rates support additional capacity in an area. In addition, pipeline operations face competition from trucks that deliver product in a number of areas that the Partnership’s pipeline operations serve. While their costs may not be competitive for longer hauls or large volume shipments, trucks compete effectively for incremental and marginal volumes in many areas served by the Partnership’s pipelines. The Partnership’s refined product terminals compete with other independent terminals with respect to price, versatility and services provided. The competition primarily comes from integrated petroleum companies, refining and marketing companies, independent terminal companies and distribution companies with marketing and trading operations. Cokemaking operations are also highly competitive. Current production from Sunoco’s cokemaking business is largely committed under long-term contracts; therefore, competition mainly impacts its ability to obtain new contracts supporting development of additional production capacity, both in the United States and internationally. The principal competitive factors affecting Sunoco’s cokemaking business include coke quality and price, technology, reliability of supply, proximity to market, access to metallurgical coal, and environmental performance. Competitors include conventional chemical by-product coke oven engineering and construction companies, other merchant coke producers and engineering companies that are attempting to develop heat-recovery cokemaking technology. Most of the world’s coke production capacity is owned by integrated steel companies utilizing conventional chemical by-product coke oven technology. The international merchant coke market is largely supplied by Chinese producers. Sunoco believes it is well-positioned to compete with other coke producers since its proven proprietary technology allows Sunoco to construct coke plants that, when compared to other proven technologies, are more environmentally benign, produce consistently higher quality coke, are substantially less costly to build, and require significantly fewer workers to operate. Research and Development Sunoco’s research and development activities are currently focused on applied research, process and product development, and engineering and technical services related to chemicals. Sunoco spent $12, $12 and $13 million on research and development activities in 2006, 2005 and 2004, respectively. As of December 31, 2006, approximately 100 scientists, engineers, technicians and support personnel participated in these activities. Sunoco owns or has made application for numerous patents. Employees As of December 31, 2006, Sunoco had approximately 14,000 employees compared to approximately 13,800 employees as of December 31, 2005. Approximately 5,800 of Sunoco’s employees as of December 31, 2006 were employed in Company-operated convenience stores and service stations and in the Company’s heating products business. Approximately 20 percent of Sunoco’s employees were 19