Supply Chain Management_ Making Supply Meet Demand

- 1. Abhishek Pratap Singh Rojer Choudhary Saurabh Barwani Dushyant Singh Ajay Singh Sanjay Choudhar y

- 2. Evolution of the Integrated Logistics Concept What is the Right Supply Chain for Your Product? Making Supply Meet Demand in an Uncertain World Mass Customization at HP: The power of postponement The Power of Virtual Integration: An interview with Dell Computer’s Michael Dell

- 3.

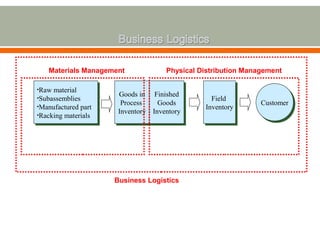

- 4. Materials Management Physical Distribution Management •Raw material •Subassemblies •Manufactured part •Racking materials •Raw material •Subassemblies •Manufactured part •Racking materials Goods in Process Inventory Finished Goods Inventory Field Inventory CCuussttoommeerr Field Inventory Business Logistics

- 5. Physical distribution Post-World War 2 business management “The movement and handling of goods from the point of production to the point on production to the point of consumption or user” Business logistics Emerged during 1980s~1990s as strategy From raw material through finished goods inventory Materials Management All materials employed in the production of the finished product Inventory control, purchasing, traffic, materials handling, receiving

- 6. Pressure on cost reduction o During the late 1950s~1960s o Increasing marketing costs, well advanced production technology o Relatively untouched areas distribution(10%~30%) Data processing technology o Computer technology became increasingly powerful, less costly o Automated inventory control Customer focus o Right time in the right quantity o Particular importance for those companies selling relatively homogeneous products Profit Leverage o 5% cost reduction more than 5% revenue increase

- 7. Vendor Procurement Customer (30%) Operations (30%) Physical Distribution (40%) Stage 1 Stage 2(Internal Linkage) Stage 3(External Linkages)

- 8. Physical Distribution o 1950s~1960s o Focus: to meet customer expectation at lowest possible cost o Why the integration process started with finished goods • The Largest single segment on inventory(40%) • Directly impacts customer service • Without venturing into production processes • Low risk, high gain o Limitation Internal Linkages o Around 1985 o 60%~100% of the firm's total inventory could be better managed o Elimination of buffer inventories between loops External Linkages o Efficiencies in relationships with vendors, customers, third parties o EDI, JIT, DRP

- 9. Cycles-time-to-market o Removal of time o Reducing the design-build-ship cycle o Process setup elimination Supply Chain Management o Last half of the 1990s~2000s o Both internal and external units are forged together o Low-cost and high-value performance to the consumer o More responsive inventory systems

- 10. • Bar code scanners • Electronic inventory • Bar code scanners • Electronic inventory Retailer Automatically track the flow of goods Electronically transmit replenishment orders Fewer stockouts Automatically track the flow of goods Electronically transmit replenishment orders Fewer stockouts Supplier Synchronize production schedules to real-time Synchronize production schedules to real-time demand data demand data Fewer inventory Fewer inventory

- 11. Data error o 35 leading retailer - 2/3 of SKU(Stock Keeping Unit) o Reduced the company’s overall profits by 10% o Phantom stockouts • Employees routinely put products in the wrong places • 16% stockouts but the items available Why? o Human nature o Retailers’ distribution centers • Wrong quantities for 29% of the SKUs, deviation from actual supplies of 25% • Items shipped in error that cost less than a certain amount • Most stores perform audits solely for financial reasons, to measure the “shrink” of goods that have been lost or pilfered. • Measure inventory by dollar value, not by item

- 12. Global competition Faster product development Variety of products Global competition Faster product development Variety of products New Technology •Point-of-sale scanners •Electronic data interchange •Flexible manufacturing •Automated warehousing •Rapid logistic •Point-of-sale scanners •Electronic data interchange •Flexible manufacturing •Automated warehousing •Rapid logistic New Concept •Quick response •Efficient consumer response •Accurate response •Mass customization •Lean manufacturing •Agile manufacturing •Quick response •Efficient consumer response •Accurate response •Mass customization •Lean manufacturing •Agile manufacturing But •Excess and shortage of products •Markdowns and stockouts •ex) U.S. food industry, poor coordination is wasting $30billion •Excess and shortage of products •Markdowns and stockouts •ex) U.S. food industry, poor coordination is wasting $30billion Why? Lack of framework for deciding

- 13. Physical function o Function • Converting raw materials into parts, component, finished goods • Transporting all of them from one point in the supply chain to next o Cost • Production, transportation, inventory storage Market mediation function o Function • matched what consumers want to buy o Cost • markdown, stock outs & dissatisfied customer

- 14. Supply Chain focus Type Physically Efficient Process Market-Responsive Process Primary purpose at lowest possible cost minimize stockouts & markdowns Manufacturing focus maintain high average utilization deploy excess buffer capacity Inventory strategy high turns, minimum inventory deploy significant buffer stocks Lead-time shorten lead time as long as it doesn’t increase cost invest aggressively in ways to reduce lead time Choosing suppliers cost and quality speed, flexibility, quality Product-design maximize performance, minimize cost modular design in order to postpone product differentiation

- 15. Problems o Most companies still treat the world as if it were predictable o Poor job of incorporating demand uncertainty into their production planning processes o Design their planning processes as if that initial forecast truly represented reality. why? • it’s complicated to factor multiple demand scenarios into planning • most companies simply don’t know how to do it o Frequent introductions of new products have two side effects • reduce the average lifetime of products • demand is divided over a growing number of SKUs • ex) GM Cadillac(Seville and Eldorado) vs. Buicks and Olds mobiles

- 16. Accurate response o Improve forecast o Redesign planning processes to minimize the impact of inaccurate forecasts costs per unit of stockouts and markdowns, costs per unit of stockouts and markdowns, mmiisssseedd ooppppoorrttuunniittyy ccoosstt pprreeddiiccttaabbllee wweellll mmaakkee iinn aaddvvaannccee uunnpprreeddiiccttaabbllee ppoossttppoonnee ddeecciissiioonnss,, eeaarrllyy iinn tthhee sseelllliinngg sseeaassoonn

- 17. Obermeyer o leading suppliers in the US fashion sky apparel market o newly designed each year o difficult to predict –weather, fashion, trends, economy Until the mid-1980s •design and show samples to retailers in March •place production orders with suppliers in March ~ April •receive goods an D/C in September~October •ship to retail outlets •design and show samples to retailers in March •place production orders with suppliers in March ~ April •receive goods an D/C in September~October •ship to retail outlets Sales volume grew Pressure to reduce Sales volume grew Pressure to reduce More complex supply chain(global) Increased lead times, markdown, stockout More complex supply chain(global) Increased lead times, markdown, stockout

- 18. First step: Shorten lead time - Quick response o Computerized systems – order process time, time to compute material requirements o Anticipate what materials it would require • pre-position in a warehouse o Air freight to expedite delivery Second step: Improving forecast o Buying committee • Group of company managers from a range of functional area Sales exceed by 200%, less than 15% of the forecast

- 19. Risk-based production sequencing nnoonn rreeaaccttiivvee ccaappaacciittyy rreeaaccttiivvee ccaappaacciittyy Demand forecast are most accurate market signals

- 20. Redesign o reduced the variety of zippers used (color, length) o use the same kinds of raw materials

- 21. orders be fulfilled ever more quickly highly customized products and services orders be fulfilled ever more quickly highly customized products and services Postponing the t Postponing the taasskk o off d diiffffeerreennttiiaattiinngg a a p prroodduucctt Organizational-design principles Organizational-design principles Product Process Supply network Product Process Supply network

- 22. Modular Design o Flexibility, quickly, inexpensively o Common components, differential components Benefits o Maximize the number of standard components • assemble those common components earlier stage • postpone the differential components o The modules of the product separately, possible at the same time • shortens the total time required for production o Easily diagnose production problems, isolate potential quality problems Considerations o Cost of materials < benefits of standardization( lead time, inventory, stockout)

- 23. Modular process o breaking down into independent sub processes o flexibility Process postponement o ex) paint store: a broad range of different paints color pigments o ex) retail apparel industry: body-measurement process+cut-and-sew process o specific garment instead of stock in all sizes and colors, eliminating discounts o relatively low-cost raw fabrics Process resequencing o ex) Benetton: dyeing, knitting knitting, dyeing o ex) HP disk driver: inserting printed circuit board, testing disk driver standard tests + customized tests Process standardization

- 24. Redesign network o Optimum number and location of factories and D/C Multi-function warehouse o perform light manufacturing

- 25. The dominant model in the PC industry A Value chain with arms-length transactions from one layer to the next suppliers manufacturer D/C customer Dell’s direct model Eliminated the time and cost of third-party distribution suppliers manufacturer customer Virtual integration Blurring the traditional boundaries and roles in the value chain suppliers masnuupfpalicetrusrer customer

- 26. Fast-cycle segmentation o The finer the segmentation, the better forecast what customer needs and when