Sustainable Textile Services

- 1. Sustainable Textile Services For Brands & Retailers and their Industry Partners

- 2. Sustainability DyStar has an extensive program of services to help brands, retailers and their industry partners achieve sustainability in the apparel supply chain. Restricted Substance Lists Codes of Conduct Water and Energy Use Labor Conditions Chemical Residue Analysis Fair Trade Eco-fibers / Eco-processing 2 Sustainable Textile Services_Jan. 2012

- 3. Why are Sustainable Textile Services a necessity in the apparel supply chain? 3 Sustainable Textile Services_Jan. 2012

- 4. Because of 3 Common Failures found in today’s apparel supply chain 4 Sustainable Textile Services_Jan. 2012

- 5. Wrong Color Comes from… the color management process not done properly Results in… the color in the store is very different than the original inspiration improper color communication from Designer to Vendor and Textile Mill lost time lost money lost sales in the store Sustainable Textile Services eliminate restricted substances at the color creation step educate the supply chain on best practices for color communication provide checks and balances for the color development process provide supply chain discipline 5 Sustainable Textile Services_Jan. 2012

- 6. Damage to Brand Integrity Risk comes from… a lengthy, fragmented supply chain restricted substances on the garments or in waste streams NGOs and public groups are demanding corporate social responsibility social media communicating issues rapidly and globally Results in… value loss to investors and shareholders Financial loss through product recall and brand impairment Sustainable Textile Services develop and implement RSLs educate the supply chain on best practices for chemical & environmental management provide checks and balances for handling chemicals & environmental management establish and maintain sustainability initiatives provide supply chain discipline 6 Sustainable Textile Services_Jan. 2012

- 7. Unhappy Customer Comes from… returns due to quality, such as fastness and color loss after multiple washes, etc. presence of toxic chemicals on the garments, resulting in allergic reactions As a result…. one unhappy customer can have significant impact through social media Sustainable Textile Services avoid restricted substances from getting to the consumer educate the supply chain on Color Confidence® and econfidence® provide solutions to minimize failures establish the proper testing protocols to minimize failures keep your customers happy 7 Sustainable Textile Services_Jan. 2012

- 8. Sustainable Textile Services Programs DyStar’s Sustainable Textile Services maintain and support People, Planet and Profit objectives of Brands & Retailers and Industry Partners in the apparel supply chain 1. RSL Development 2. Mill Development 3. Training & Seminars 4. econfidence® 8 Sustainable Textile Services_Jan. 2012

- 9. RSL Development DyStar understands global chemical legislation and the requirements of the textile and clothing industry. Our deep know-how enables us: to assist in the development of RSLs for Brands & Retailers to provide advice and guidance on suitability of dyes and chemicals In addition, we offer advice on test methods and procedures in order to help Brands, Retailers and Industry Partners effectively monitor chemicals along the apparel supply chain 9 Sustainable Textile Services_Jan. 2012

- 10. Mill Development Mill Improvement Raise productivity and efficiency levels of Industry partners in textile processing Audit: Wet Processing Chemical Management Improvement Assist with development, communication and implementation of RSLs with Industry Partners Audit: Brand RSL Compliance Environmental Improvement Assess environmental impact of Industry partners in textile processing Audit: Environmental Impact 10 Sustainable Textile Services_Jan. 2012

- 11. Training & Seminars Audience Product Developers, Buyers, Quality Controllers, Color Managers, Dye House Managers and Supervisors, CSR Department Modules Introduction to Dyes & Fibers Garment/Laundry Effects Testing for Restricted substances Safe Handling of Chemicals Key Drivers of Sustainability in Textiles Color Measurement Color Communication Color Fastness Advanced testing of water, dye house chemicals, dyes and auxiliaries Coloration Best Practices Eco-Trainings & Workshops Eco-Seminars for your supply chain 11 Sustainable Textile Services_Jan. 2012

- 12. econfidence® DyStar products are subjected to an extensive testing program to ensure that our products are in full compliance with the relevant chemical legislation in the countries in which they are sold Confidence about the eco-performance of your textiles Your suppliers understand how to meet your eco-specifications Shorter lead-times and more reliable supply Support for your reputation and brand integrity 12 Sustainable Textile Services_Jan. 2012

- 13. Results We have a proven track record in our ability to guide textile manufacturing units to optimize production and cost while delivering same or better quality of goods required by the customer. RSL Development Examples Mill Development Examples Brand RSL compliance Mill Improvement Project Chemical Management Improvement Project Environmental Improvement Project econfidence® Examples 13 Sustainable Textile Services_Jan. 2012

- 14. Mill Improvement Project We set up key performance indicators with textile mills to track the performance in the areas of desired improvement. The table below shows the actual results: % Reduction Mill Key Performance Indicator (within 9 months) Water Consumption (Liter/Kg of Fabric) -25% Redyeing (%) -23% Centre to Selvedge problem (%) -80% Waste Production (metric tons) -46% The majority of these reductions were achieved within the first two months! Note: Actual results from a CPB dye-house producing 1,500,000 meters of fabric per month production of cellulosic material 14 Sustainable Textile Services_Jan. 2012

- 15. RSL Development Project DyStar has released several recommendations for Brands & Retailers, Industry organizations and specific product groups, to support sustainable textile production that is meeting quality and eco-requirements 15 Sustainable Textile Services_Jan. 2012

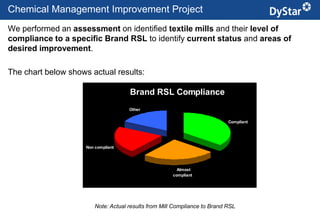

- 16. Chemical Management Improvement Project We performed an assessment on identified textile mills and their level of compliance to a specific Brand RSL to identify current status and areas of desired improvement. The chart below shows actual results: Brand RSL Compliance Other Compliant Non compliant Almost compliant Note: Actual results from Mill Compliance to Brand RSL 16 Sustainable Textile Services_Jan. 2012

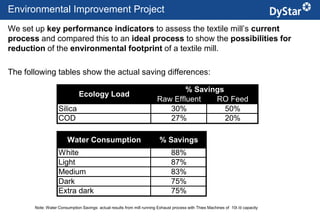

- 17. Environmental Improvement Project We set up key performance indicators to assess the textile mill’s current process and compared this to an ideal process to show the possibilities for reduction of the environmental footprint of a textile mill. The following tables show the actual saving differences: % Savings Ecology Load Raw Effluent RO Feed Silica 30% 50% COD 27% 20% Water Consumption % Savings White 88% Light 87% Medium 83% Dark 75% Extra dark 75% Note: Water Consumption Savings: actual results from mill running Exhaust process with Thies Machines of 10t /d capacity 17 Sustainable Textile Services_Jan. 2012

- 18. Ecology Load Improvement Ecology Load Existing Process CurrentProcess Existing Raw Effluent Raw Effluent RO Feed DyStar Process Ideal Process DyStar 1500 27% 1500 1500 Load (in ppm) 1000 1000 1000 500 500 20% 30% 500 50% 0 0 Silica COD Silica COD 0 Silica COD Note: the obtained savings are specific to type of machine and process followed 18 Sustainable Textile Services_Jan. 2012

- 19. Water Consumption Improvement Current Water Ideal 1:5 Ideal 1:4-1:3.5 160 75% 140 87% 83% 75% 75% 75% Water Requier (in Ltr/Kg) 120 88% 100 88% 80 88% 88% 60 40 20 0 White Light Shade Medium Shade Dark Shade Extra Dark Shade Note: the obtained savings are specific to type of machine and process followed 19 Sustainable Textile Services_Jan. 2012

- 20. econfidence® Project Renowned Brands & Retailers have chosen DyStar as their partner in supporting their Eco message to consumers via the econfidence® hangtag program 20 Sustainable Textile Services_Jan. 2012

- 21. Testimonials Morarjee Textiles Ltd. - Ashutosh Raina Sr., Vice President – Manufacturing "Expert Solutions" has helped us to drastically improve the efficiency of our yarn dye-house. (…) Thanks to " Expert Solutions ", they have not only re educated our personnel to understand the intricacies of dyeing, but also made them aware of the coloration technology with Vat as well as Reactive dyes. (…) Although our cost of dyes and chemicals has more or less remained the same , the savings in water consumption (20%), utilities, reduction of re-dyeing (8%), corrections and increase in production are in themselves of a tremendous savings to us." JCT Filament Led - Manish Dobariya, Asst Manager - Dyeing “We are using online “color XPT” Enterprise software from DyStar. We got benefit like saving of dyes, chemical and utility etc. and is directly affected on Conversation cost. It coming down side approx. 25 %. Also help of “Color XPT” we had decreased dyeing process time approx . 40 %” 21 Sustainable Textile Services_Jan. 2012

- 22. Resources DyStar can deploy a team of experienced national and international experts from the fields of chemical management and textile manufacturing and processing. Systems ABACUS® ColorXPT® 22 Sustainable Textile Services_Jan. 2012

- 23. Sustainability is our responsibility At DyStar, our products and services help customers worldwide reduce costs, shorten lead times and meet stringent quality and ecological specifications Our Vision To become the world’s most sustainable supplier of colors and chemicals to the global textile industry. We believe companies that put sustainability at the centre of their business will be more successful and have competitive edge Carbon Footprint Report 2010 Sustainability Report 2010 23 Sustainable Textile Services_Jan. 2012

- 24. Contact Go with DyStar for new horizons DyStar know-how, services and products help you make a difference to your business. Contact us for more details, or visit us at www.DyStar.com 24 Sustainable Textile Services_Jan. 2012