Sydney harbour bridge

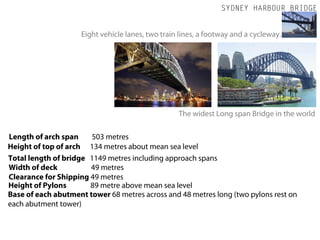

- 1. SYDNEY HARBOUR BRIDGE Eight vehicle lanes, two train lines, a footway and a cycleway. The widest Long span Bridge in the world Length of arch span 503 metres Height of top of arch 134 metres about mean sea level Total length of bridge 1149 metres including approach spans Width of deck 49 metres Clearance for Shipping 49 metres Height of Pylons 89 metre above mean sea level Base of each abutment tower 68 metres across and 48 metres long (two pylons rest on each abutment tower)

- 2. SYDNEY HARBOUR BRIDGE Shortest Hanger 7.3 metres Longest Hanger 58.8 metres

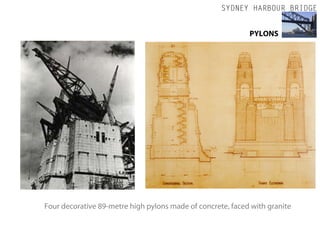

- 3. SYDNEY HARBOUR BRIDGE PYLONS Four decorative 89-metre high pylons made of concrete, faced with granite

- 4. SYDNEY HARBOUR BRIDGE • The bridge structure sits on four large concrete ‘skewbacks’. • Two are on the south shore and two on the north. • The excavation for these was directly into the solid sandstone. • Each skewback is 40 feet wide (12·192 m), 90 feet long (27·432 m) and up to 30 feet (9·144 m) deep. • The upper surface of these, for the main bearings, is at an angle of 45° to take the main bearing casting. • The concrete was poured in sections, and in an hexagonal pattern • The foundations are 12 metres (39 feet) deep, are set in sandstone. • Anchoring tunnels are 36 metres (118 feet) long and dug into the bedrock at each end. Large bolts and nuts are used to tie the thrust bearings onto their supports.

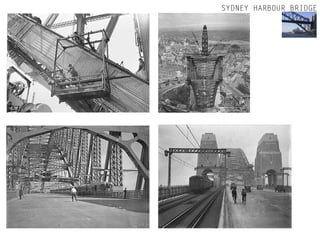

- 5. SYDNEY HARBOUR BRIDGE • Bridge is founded on sandstone rock excavated to a depth of 12 m and filled with special reinforced high-grade concrete • Built out from either side of the harbour, using a creeper crane that slowly progressed up the arch lifting steelwork into position • The half arches were secured by wire ropes, anchored in inclined U-shaped tunnels cut into the rock. • Anchorage consisted of 128 wire ropes of 70 mm diameter, about 366 m long. • After the spans were connected, a deck was put in place. The deck was hung from the arch and built from the centre out so that they would not have to move the cranes.

- 7. SYDNEY HARBOUR BRIDGE Allowance for deck expansion 420 millimetres

- 8. SYDNEY HARBOUR BRIDGE Number of rivets- Approximately 6,000,000 Bearing Pins -Each of the four pins measures 4.2 metres long and 368 mm in dia. • Two-pin arch construction, made up of two arches side by side, joined by horizontal cross-members. In this sort of arch, the vertical loads (the Bridge’s own weight plus the weight of trains, cars etc) tend to flatten the arch and push out against the abutments, creating both vertical and horizontal reaction forces. • The Bridge structure is supported on four horizontal, cylindrical forged steel pins in the main bearings, one at each end of the two arches. This allows the movement in the arch caused by temperature variations and dynamic loading to be accounted for. The arch may rise up to 180 mm due to heating during the day and cooling at night.