The Complete Visual Guide To Building A House.pdf

- 1. The Complete VisualGuideto Building a House John Carroll and Chuck Lockhart

- 4. The Complete VisualGuideto Building a House C John Carroll and Chuck Lockhart

- 5. Text © 2013 by The Taunton Press, Inc. Illustrations © 2013 by The Taunton Press, Inc. All rights reserved. Pp The Taunton Press, Inc., 63 South Main Street, PO Box 5506, Newtown, CT 06470-5506 e-mail: tp@taunton.com Editors: Peter Chapman, Scott Gibson Copy editor: Diane sinitsky Indexer: jim curtis Jacket/Cover design: jean-marc Trodaec Interior design: carol singer | notice design Layout: Cathy Cassidy, chuck lockhart Illustrator: chuck lockhart The following names/manufacturers appearing in The Complete Visual Guide to Building a House are trademarks: Backer-On™; C. H. Hanson® Pivot Square™; CavClear®; Cor-A-Vent®; Dap® Presto Patch®; Deck- Armor™; Delta®-MS; DensShield®; DrainWrap™; DuPont StraightFlash™; DuPont™ FlexWrap™; Durock®; Festool®; FoamSealR™; HardieBacker®; Home Slicker®; Ice & Water Shield®; Jambsill Guard®; Level-Best®; McFeely’s®; MortarNet®; Osmose®; Porter-Cable®; RainDrop®; RockRipper®; Roofer’s Select™; Schluter®-DITRA; Sheetrock®; Shingle Mate®; Simpson Strong-Tie®; Stanley® Quick Square®; StormGuard®; Super ThoroSeal®; Sure-Tite™; SureCorner™; SureSill™ HeadFlash™ and HeadFlash-Flex™; Swanson® Big 12® Speed® Square; T-JAK®; Tapcon®; Telpro® Panellift®; Timberline®; Titanium® 30; Typar®; Tyvek® StuccoWrap®; Warm-N-Dri®; Warner® Tool; WaterWay™; Weathermate™ Sill Pan; WeatherTrek®; WinterGuard™; Wolman™; WonderBoard® Library of Congress Cataloging-in-Publication Data Carroll, John (John Michael), 1949- The complete visual guide to building a house / John Carroll and Chuck Lockhart. pages cm Includes index. E-Book ISBN 978-1-62710-608-5 1. House construction--Handbooks, manuals, etc. 2. House construction--Pictorial works. I. Lockhart, Chuck. II. Title. TH4813.C37 2014 690’.837--dc23 2013048589 Printed in the United States of America 10 9 8 7 6 5 4 3 2 1 About Your Safety: Construction is inherently dangerous. Using hand or power tools improperly or ignoring safety practices can lead to permanent injury or even death. Don’t try to perform operations you learn about here (or elsewhere) unless you’re certain they are safe for you. If something about an operation doesn’t feel right, don’t do it. Look for another way. We want you to enjoy working on your home, so please keep safety foremost in your mind.

- 6. For my mother, Emily J. Carroll (1923–2012) The idea for this book came from Steve Culpepper, who, at the time, served as executive book editor for The Taunton Press. In looking at the available general guides to residential building, Steve found that most were several decades old and contained outdated information. He felt there was a need for a reference that reflected today’s building industry, and, to my good fortune, he thought I should be the one to write it. Shortly after I started writing this book, however, Steve left Taunton and Peter Chapman took over as book editor. In addition to all his other duties, Peter served as the primary editor of this book. Peter’s help proved to be invaluable. I am especially grateful for his forbearance with me as a writer whose “cup runneth over” on a regular basis. In chapter after chapter, I sub- mitted too many words and too much information, so Peter would patiently work with me to pare the text down to a manageable size. With Peter’s help, I was able to identify the essential information and present it in a much more concise manner. His insights and suggestions made this book shorter, clearer, and better organized. My in-depth discussion of common building procedures would be confus- ing without accompanying drawings. To graphically represent what I’ve described, The Taunton Press brought in one of the finest illustrators in the business, Chuck Lockhart. Having worked as art director for Fine Homebuilding magazine for 18 years, Chuck brought a wealth of experience to this project. His drawings are more extensive and provide more detail than would have been possible with photographs, which require access to building projects at key moments in the job. Anything I could describe Chuck could draw. Chuck was able to highlight key details through the use of color and shading; in many drawings, Chuck skillfully employed such devices as cutaway views and cross-sectional drawings to show how the details of the job fit into the whole. After all the parts of this book were produced, the unenviable task of putting them together fell to Scott Gibson. A skilled carpenter and an accom- plished writer and editor, Scott went through every word of text and every drawing. In addition to looking for and finding mistakes, inconsistencies, and omissions, Scott extracted information from the running text and applied it, in the form of labels, to the drawings. His painstaking attention to detail, his focus on accuracy, and his knowledge of current building practices— especially the latest in building science—were extremely helpful and greatly improved the quality of this book. —John Carroll ACKNOWLEDGMENTS

- 7. Building the Structure 4 Chapter 1 Building Foundations 6 Chapter 2 Framing Floors, Walls, and Ceilings 50 Chapter 3 Framing Roofs 1: Raftered Roofs 98 Chapter 4 Framing Roofs 2: Trusses, Eaves, Rakes, and Sheathing 142 Closing the House to the Weather 182 Chapter 5 Roofing the House 184 Chapter 6 Installing Windows, Exterior Doors, Siding, and Trim 231 Chapter 7 Controlling Moisture in the Ground and in the Air 278 pa r t tw o pa r t o n e introduction table of contents

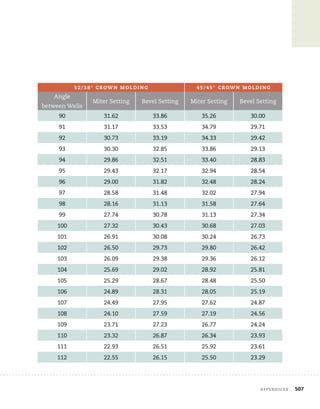

- 8. Finishing the House 308 Chapter 8 Installing Wall and Floor Coverings 310 Chapter 9 Hanging Doors 354 Chapter 10 Installing Trim and Cabinets 396 Chapter 11 Building Stairs 442 appendices Conversions 500 Base-1 Proportions of Standard Roof Pitches 501 Backing Angles for Regular Hips and Valleys 502 Base-1 Proportions of Regular Hips and Valley Pitches 503 Converting X-in-12 Roof Pitch to Degrees of an Angle 504 Converting X-in-16.97 Roof Pitch to Degrees 505 Miter and Bevel Settings for Crown Molding 506 Index 514 pa r t t h r ee

- 9. 2 In America, houses are built in areas where several feet of snow accumulate, where hurricanes can be expected, or where tempera- tures exceed 100°F. In some areas, all these conditions might occur within the same year. Within these very different climatic regions, furthermore, individual building sites pose a wide variety of challenges. The surface of the land might slope steeply; the soil might contain expansive clay or bed- rock; or there might be too much moisture in the ground. To meet these and other challenges, builders have to adjust the design of their houses to the climatic and topographical conditions of the area they live in. In Florida, for example, roof structures must be tied down with steel straps to keep them from being lifted off the walls during hur- ricanes. In Maine, on the other hand, roof frames must be beefed up to keep them from collapsing under the weight of several feet of snow. These mea- sures, which are required by building codes, go a long way toward creating durable houses. Beyond simply building houses that last, however, builders need to create houses that perform. Once viewed as basic shelters from the extremes of the weather, houses are now seen as climate-controlled enclaves. Most people expect the environment inside their house to be comfortable year-round, no matter how brutal the weather is outside. Accomplishing this goal in the face of ever-increasing energy costs is one of the biggest challenges confronting builders today. Again, the plan of attack has to be tailored to the location of the house. A house that keeps a family warm during the winter on the Northern Plains has to be built much differ- ently than a house that provides relief from the heat and humidity in the Deep South. The diverse local requirements of home building coupled with an ever-expanding choice of building materials, tools, and systems present a fundamental problem for a book like this one. Because there are so many approaches and options, it’s difficult to decide what to discuss and how detailed that discussion should be. As on any major building project, there have been many hard decisions to make and there have been many inter- esting and worthwhile topics that I could not include in this book. introduction

- 10. The first thing I decided to drop was a comparative analysis of different building systems. There are at least a half-dozen alternatives to the light wood-framed house in America. However, builders and homeowners con- tinue to vote with their wallets for the wood-framed house, which accounts for 90% of the houses in the United States and Canada. Rather than devote a good portion of this book to a discussion of the strengths and weaknesses of the other systems, I chose to focus on the one system that dominates the housing market: the wood-framed house. Along the same lines, I’ve focused on mainstream materials when describing the rest of the house. In the chapter on foundations, for example, I concentrated on concrete and masonry, and in the chapter on roofing, I focused on asphalt shingles because most houses in America are built with those materials. If you happen to use materials that are outside of the mainstream, there’s a good chance that the installation techniques pre- sented here will work, with minor adjustments, with the materials you use. I’ve also focused on common building projects and designs. Throughout the book, I posed hypothetical building projects and then suggested ways to build them. In these projects, the rectangle predominated—just as it does on most residential building sites. In general, I have steered clear of complex designs, such as octangular buildings and curved staircases—both because they couldn’t be covered adequately in the space allotted and because they are rare in American houses. Sticking with common design elements and mainstream materials has allowed me to go into considerable detail when describing building tech- niques. These details are often vital to the quality of the job, and builders who overlook them or try to force them in as an afterthought usually end up with substandard work. Throughout this book, therefore, I’ve hammered home the idea that quality work requires two things: forethought and the proper sequence of installation. It’s essential to think through the details at the beginning of the job and then install them at just the right moment. No book, including this one, can provide every important detail for every job. What I’ve tried to do here is show how to look at the job, anticipate problems, and then work in the optimal sequence to fit the parts together smoothly and correctly. Learn these lessons well and you’ll find it easy to progress to more complex jobs. introduction 3

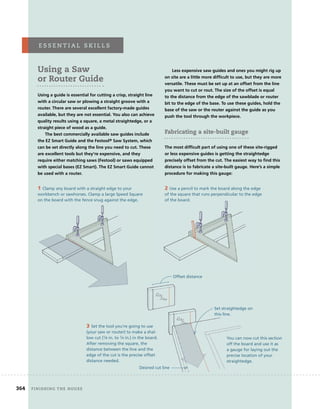

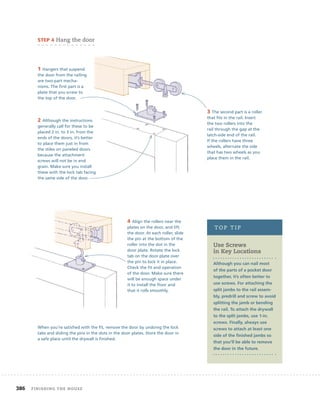

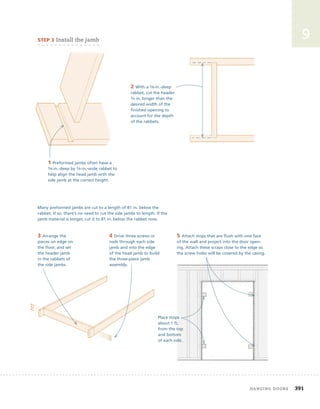

- 11. 4

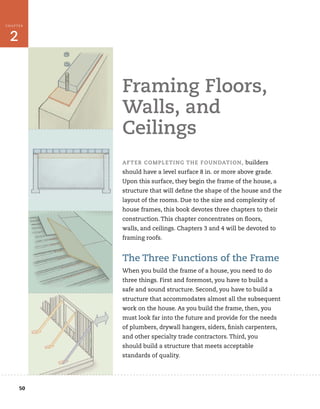

- 12. 6 50 98 142 5 PA r t o n e Building the structure C H A P T E R 1 Building Foundations C H A P T E R 2 Framing Floors, Walls, and Ceilings C H A P T E R 3 Framing Roofs 1: Raftered Roofs C H A P T E R 4 Framing Roofs 2: Trusses, Eaves, Rakes, and Sheathing

- 14. frAMing floors, wAlls, And ceilings 7 2 Assessing and Preparing the soil The loads that houses place on soils are, by engineering standards, relatively light. Most building codes, furthermore, are conservative in design. They require wide footings that spread the load of the house, allowing the footings to work in soil that is not ideal. If you carefully follow the provisions of the building code, the soil you encounter on site is usually capable of supporting the house or addition that you are building. However, problem soils do exist and they require measures that go beyond the general provisions in the building code. Foundations that settle unevenly create out-of-level fl oors and doors that don’t open and close properly. what to look for in the soil There are a few things you can do to determine if you need to bring in a soils engineer. The fi rst is to look carefully at the soil. Keep an eye on how the soil behaves under load, especially after it rains. These are commonsense observations. If the soil becomes soft and mushy underfoot and trucks and equipment frequently get mired in it, you might have a problem. Excavating for the foundation The most important person to look to for advice is your building inspector. Building offi cials are usually familiar with the problem soils in their areas and often know where they are most likely to occur. They can sometimes recognize problem soils simply by looking at them. In some extreme cases, houses have been ruined beyond repair by failed foundations. Most problem soils are classified as clay or silt or a combination thereof. The inorganic particles in these soils are very fine—less than 0.003 in. in diameter. When combined with water, clays often become sticky or mushy. When silts dry, they become fluffy; they are sometimes called rock flour. Coarse sand and rocky soils have excellent load-bearing abilities. If you encounter these soils, however, you need to make sure that they are con- sistent over the length of the footing. Good, stable soils next to unstable soils can translate into differential movement. 1 Preparing the Soil If you encounter problem soil and are required to bring in an engineer, make sure you understand what the engi- neer recommends and follow those recommendations to the letter. If you and the building inspector find the soil accept- able, you need to follow the requirements of the building code in your area. toP tiP 1

- 15. 8 Building the structure Monolithic slab: Simply scrape any organic matter off the surface. The bottom should be roughly level. Crawlspace: Scrape any organic matter off the surface but leave the grade roughly the same as you found it. Basement excavations: It’s important not to go too deep when you dig these foundations. excavation: An overview If you’re building a basement, the excavation consists of an open- ing in the ground with a roughly level bottom. This opening has to be a few feet wider and longer than the house. The correct elevation of the bottom of the opening should be determined in advance as outlined in the section on foundation layout on p. 11. As the exca- vator gets down close to this elevation, you should start checking the elevation of the bottom of the opening. At the same time, check the bottom for levelness. The techniques for measuring the eleva- tion and the levelness of the bottom of the opening are discussed in detail in the section on p. 11 on foundation layout. STEP 1 excavating for the foundation Proposed foundation STEP 2 digging the footings 1 Building codes require that the bottom of the footing be below the frost line. Wet soil that freezes expands as much as 8%. As it expands, it rises and lifts whatever is on it, including the footings of houses. To avoid frost heave, as it’s called, you are required to place the footing below the frost line (the depth to which the ground freezes). This means that in Maine it’s often necessary to dig down 48 in. or more, while in Florida a trench 8 in. deep is often sufficient for the footing. The frost line in Maine is 48 in. The frost line in Florida is 8 in.

- 16. 1 2 It’s important to make sure that no sizeable amounts of organic matter remain in the soil after the excavation. Make sure that the footing rests on well-compacted soil. The simplest and surest way to do this is to place the con- crete on undisturbed soil. Digging into undisturbed soil loosens it and fluffs it up by as much as 50%. If this disturbed soil is left loose under the footing, the weight of the house eventually compresses it back to its original size. When it does, the footing often cracks. Remove any organic matter that extends below the proposed excavation. Undisturbed soil Disturbed soil wAy s o f w o r k i n g Testing the Soil One unscientific way to test the load-bearing capacity of the soil is to push a steel stake into the ground. Building inspectors often have a T-shaped tool made out of ½-in.-dia. steel rod. To test the soil prior to a footing pour, the inspector leans on the cross of the T and sees how far the upright sinks into the ground. If the steel rod slides into the soil with little resistance, the inspector will require remedial work. A more objective way to test the soil under the foot- ing is with a penetrometer. A penetrometer is a handheld device that works like a fisherman’s scale in reverse. You push the penetrometer in the soil and check the pressure on a calibrated scale. Look for consistent readings along the length of the footing and a bearing value that meets the design load in your area (usually 1,500 lb. to 2,500 lb. per square foot). For soil found to be below that bearing capacity, most jurisdictions require a plan drawn up by an engineer. Steel stake Penetrometer Building foundAtions 9

- 17. 10 Building the structure 5 Footings spread the load they carry over a broad area. If the weight of the building is concentrated on the edge of the footing, however, it can cause the footing to rotate—just as stepping on the edge of a snowshoe set on top of freshly fallen snow would cause it to tip over. 3 To avoid the problems caused by disturbed soil in the footing, clean loose material out of the footing trench with hand tools (square shovels, mattocks, and hoes, for example). Wall centered over footing 4 Use a jumping jack compactor to reconsolidate the soil, especially in those spots where tree stumps or large rocks have been removed. For clay or silt, add sand or gravel to the original soil as you reconsolidate the area. Dampen the mixture and place it in 8-in.- deep or less layers as you compact it. Off-center wall have been removed. For clay or silt, add sand or gravel to the original soil as you reconsolidate the area. Dampen the mixture and place it in 8-in.- deep or less layers as you compact it. An off-center footing placed on soils with relatively low bearing capacity (clay, silt) can fail.

- 18. frAMing floors, wAlls, And ceilings 11 1 laying out foundations The general pattern for foundation layout is from the top down. The process begins on the ground, where there are no straight lines, no level surfaces, and no square corners. It’s up to you to create these references from scratch. The fi rst step in this process is to set up a leveling instrument to project a level plane above the ground. From this level plane, you establish the elevation of the top of the founda- tion. All subsequent elevations are then measured down from this top-of-foundation elevation. At the top-of-foundation elevation, you can install several batter boards that hold strings within a level plane at that height. You can then use the strings to precisely lay out the positions of the footings and foundation walls in plan view. On some foundations, however, it’s easier to excavate the opening for the house, then drop down to the top-of-footing elevation. At that elevation, you can use a combi- nation of batter boards and forms to lay out the precise positions of the footings and walls. Whether you lay out the footing and walls at the top-of- foundation elevation or at the top-of-footing level, the layout is suspended above the ground. It has to be this way for two reasons. First, the suspended layout establishes the exact elevations of the key components of the foundation. Second, the fl at, level plane ensures that the key parts of the foundation are the right size and in the right place. You can’t execute a precise layout on the ground; the sloped and uneven surface will distort the dimensions and render them inexact. The following section uses two examples to show how to lay out two different kinds of foundations. The designs presented here are common; however, some of the details might not be accepted where you live. Check with your local building offi cials to fi nd out what’s needed in your area. Although specifi c examples are used here, the basic procedures can be adapted to just about any foundation. It’s Essential Not to Overexcavate Digging too deep, then put- ting dirt back in the opening compromises the integrity of the soil under the footings. To avoid overexcavating, check the bottom of the opening with increasing frequency as you get closer to the desired elevation. toP tiP Leveling instrument Top of foundation

- 19. 12 Building the structure Approximately 30 ft. Corner stake Approximately 38 ft. Getting the Grade Right For the final grade around a house, most building codes require that at least 8 in. of the foundation extend out of the ground and that the soil slope away from the foundation a minimum of 6 in. within the first 10 ft. To achieve this minimum standard on the uphill side of the foundation, measure the elevation 10 ft. uphill from the planned foundation wall and set the elevation of the top of the foundation at least 14 in. higher than the eleva- tion at that point. Later, when you backfill around the foundation, you’ll have enough elevation to form the required grade on the uphill side. Leaving the founda- tion higher than this minimum standard allows you to increase the grade and hold the house up even higher out of the ground. laying out a Basement foundation In this example, the foundation is a 38-ft. by 30-ft. basement that projects about 30 in. above the highest point of the surrounding grade. The corners of the house have been roughly marked with stakes and the elevation established as 30 in. above one of the stakes. The fi rst thing you have to do is guide the excavator through the excavation of the opening for the foundation. In this phase of the layout, make sure the excavator digs in the right place, gets the opening the correct size, and makes the bottom level and at the correct height. It is upon the roughly level surface at the bottom of the excavation that you’ll lay out the footing and the foundation walls. 8 in. (min.) 6-in. (min.) slope 14 in. (min.) Top of foundation 10 ft. wAy s o f w o r k i n g

- 20. frAMing floors, wAlls, And ceilings 13 1 2 Record the elevation of the foundation. In this case, the desired elevation for the top of the foundation is 30 in. above the highest corner stake. Using a leveling instrument, measure the difference in elevation between the top of the corner stake and the top of the nearest offset stake. (See “Using a Leveling Instrument” on p. 14.) Place the offset stakes 10 ft. from the original corner stakes. Drive offset stakes deep into the ground so that very little extends above the surface. Original corner stakes Approximately 30 ft. Approximately 38 ft. In this example, the bench mark stake is 6 in. higher than the corner stake. Bench mark Corner stake The top of the foundation, therefore, should be 24 in. above the top of the bench mark stake. The top of the foundation is 30 in. above the corner stake. STEP 1 record the preliminary layout 1 When the excavator digs the oversized opening for the basement, the stakes marking the corners of the house will be obliterated. To preserve the layout, set up a line that extends over the corners of the house, then drive offset stakes into the ground along that line. Place the offset stakes a set distance away from the original corner stakes. A 10-ft. offset is common because it’s a safe distance away from the excavation and it’s an easy distance to remember. The offset stakes should be in line with the long walls (the 38-ft. walls, in this example). Flag the location of the offset stakes with nearby stakes that extend 16 in. aboveground; attach brightly colored ribbons.

- 21. 14 Building the structure Using a Leveling Instrument There are two basic kinds of leveling instruments commonly used by builders: optical levels (also called sight or telescopic levels) and laser levels. Both of these kinds of levels come in many forms and are capable of doing numerous measuring tasks. They share one feature in common, however; they all project a level line and a level plane. For most residential builders, this basic feature is the most important role of these tools. An optical tool provides a level line of sight. Swiveling the tool horizontally establishes a level plane. • MEASURING TO THE LEVEL PLANE You can measure the grade of the land, establish the elevation of key foundation components, set forms pre- cisely level, and do many other layout tasks by measuring to the level plane projected by a leveling instrument. A laser level that projects a single level line works the same way as an optical level; swiveling it establishes a level plane. • ESTABLISHING A LEVEL PLANE Different leveling instruments project a level plane in different ways. Lasers can also project a level plane that radiates in all directions from the instrument. Most leveling instruments can be mounted on a tripod. Many self-adjusting lasers have flat bottoms and can be set on any reasonably flat surface. To find the high corner of the grade after a house has been staked out, measure the distance from the ground up to the plane at all the corners. The shortest distance indicates the highest point of the grade. A sighting rod, a large measuring stick that’s marked off in feet and inches, is used to determine the measurement. A tape measure, carpenter’s rule, large measuring stick, or simply a strip of wood can serve the same purpose. House stake 14 Building the structure

- 22. frAMing floors, wAlls, And ceilings 15 1 1 1 • FINDING AND USING THE “DIFFERENCE IN ELEVATION” Key elevations are often established in relation to a single refer- ence called a bench mark. Once you know this dimension, you can quickly compute the other critical elevations. The distance from the bench mark to the top of the foundation is the difference of elevation between the two points. Bench mark Proposed top of foundation • RESETTING THE LEVEL The difference in elevation between the bench mark and any critical elevation of the foundation is constant. The elevation of the plane projected by the instrument, however, changes when the instrument is repositioned. The difference in elevation between the bench mark and any critical elevation of the foundation is constant. The elevation of the plane projected by the instrument, however, changes when the instrument is repositioned. DAY 1: Difference between site line and top of proposed foundation DAY 1: Difference between top of proposed foundation and bench mark Building foundAtions 15 DAY 2: Difference between top of proposed foundation and bench mark remains the same. DAY 2: Difference between site line and top of proposed foundation changes.

- 23. 16 Building the structure 1 Stretch strings between the corner stakes and mark the ground about 4 ft. outside of the strings. You can use a 4-ft. level as a gauge to measure the distance from the string. To mark the line, use lime or dry masonry mortar poured from a paper cup or use brightly colored spray paint. STEP 2 Mark and dig the opening Corner stake Use a 4-ft. level to gauge distance. Flag Offset stake A dry mortar line or spray paint marks the area to dig. 2 Before you begin digging, establish the exact distance that you need to dig below the bench mark. This requires that you know the design of the founda- tion, including the exact heights of the materials that you’re going to use. Make all measurements from the same reference: the targeted top-of- foundation elevation. In this example, the top of foundation elevation has been established at 24 in. above the bench mark. The bench mark is 24 in. below the planned top of the foundation. The top of the walls will be 96 in. above the top of the footing. 4 in. 100 in. (96 in. + 4 in. above the bottom of the excavation) 96 in. 76 in. (100 – 24 = 76) below the bench mark You know that the bench mark is 24 in. below the planned top of the foundation; therefore, the bottom of the excavation should be 76 in. (100 – 24 = 76) below the bench mark. 72 in.

- 24. frAMing floors, wAlls, And ceilings 17 2 3 Set up a leveling instrument outside of the opening. After leveling the instrument, measure the height that it reads above the bench mark (here, 14 in.). Add this amount to 76 in. The total, 90 in., is the distance from the level line projected by the instrument to the bottom of the excavation. 14 in. 76 in. 90 in. 86 in. Use a surveyor’s rod to check the depth of the opening. Grade stake Place a grade stake as a reference for the top of the footings. Drive this down until the top is exactly 86 in. below the level line projected by the leveling instrument. As the drawing on the facing page shows, this is 72 in. below the bench mark and 96 in. below the desired top-of-foundation. STEP 3 lay out the fi rst wall EXAMPLE 1 assumes that you removed the instrument at the end of the excavation and have returned the next day to lay out the footings. 1 Pull a string from one offset stake to the other along either of the long walls. 2 Near each side of the excavation, drive in a pair of stakes, with the string above roughly centered between them. Leave about 8 in. of the stakes above the bottom of the excavation. 3 Set up the instrument in the bottom of the opening and shoot the difference in elevation between the line projected by the instrument and the top of the grade stake. 4 Use the instrument and a measuring stick or rod to mark the four stakes at the same distance below the projected line. Offset stake Bench mark Measuring stick 1

- 25. 18 Building the structure EXAMPLE 2 assumes that you did not set a grade stake just after the excavation. 1 Set up the instrument outside the opening and shoot a level line anywhere above the bench mark. 2 The difference in elevation between the bench mark and the line projected by the instrument is 11 in. 3 The top of the footing has to be 72 in. below the bench mark. Mark the stakes at 83 in. (72 + 11 = 83 ) below the line projected by the instrument. Offset stake Bench mark Measuring stick 83 in. 4 Once you have the four stakes marked, attach a horizontal batter board between each pair of stakes, with the tops of the boards even with the marks. Use screws rather than nails to avoid jostling the stakes out of position. The batter board should be level, exactly 72 in. below the bench mark, and cross directly below the string that represents the wall. 5 Transfer the exact location of the string down to the batter boards. You also could use a 6-ft. spirit level or a plumb bob to transfer this location. String attached to bench mark 6 After marking both batter boards, set a string from one mark to the other. The string is set at the desired elevation for the top of the footing. In plan view, the string is even with the outside of the foundation wall. Location of foundation wall Set a self-leveling laser with a plumb beam on the batter board and slide it until the beam strikes the string.

- 26. frAMing floors, wAlls, And ceilings 19 2 1 1 • THE PYTHAGOREAN THEOREM IN USE: If you have a triangle with an Altitude of 12 and a Base of 16, the math goes like this: You can expand or contract any right triangle without changing its angles by multiplying or dividing all three sides by the same number. If you divide all three sides of the triangle just discussed by 4, for example, you end up with a 3-4-5 triangle that retains the exact same angles: To shrink this 3-4-5 triangle to a tri- angle with a base of 1, divide all three sides by 4: To expand this 0.75-1-1.25 triangle back to a triangle with a base of 16, multiply all three sides by 16: A B H • EXPANDING AND CONTRACTING RIGHT TRIANGLES 12 ÷ 4 = 3 16 ÷ 4 = 4 20 ÷ 4 = 5 3 ÷ 4 = 0.75 4 ÷ 4 = 1 5 ÷ 4 = 1.25 16 × 0.75 = 12 16 × 1 = 16 16 × 1.25 = 20 • LAYING OUT ACUTE AND OBTUSE ANGLES In addition to laying out a perpendicular line, you can use the geometry of a right triangle to lay out obtuse and acute angles. To lay out a 45º turn in a 30-ft.-wide foundation, for example, set up parallel lines 30 ft. apart. Calculate the hypotenuse of a right triangle with two sides of 30 ft.: √2 × 30 = 42.42 Pull the 42.42-ft. dimension from a fixed point on one line to the other and mark that point. A line drawn through these points runs at a 45° angle from the other lines. 30 ft. 42.42 ft. Working with Right Triangles A right triangle has one side perpendicular to another. This property allows you to use the geometry of a right triangle to quickly lay out 90º angles. The Pythagorean Theorem is a 2,500-year-old formula for finding the hypotenuse (the unknown measurement) of a right triangle. The formula can be written: Hypotenuse = √ Altitude² + Base² or H = √A2 + B2 . e s s e n t i A l s k i l l s Building foundAtions 19 H = √122 + 162 √144 + 256 √400 20

- 27. 20 Building the structure STEP 5 lay out the corners of the foundation 1 Measure 30 ft. from the first string set up in step 3, and drive a pair of stakes at each end to straddle the 30-ft. measurement. STEP 4 lay out the other long wall 2 Use the leveling instrument to mark the stakes at the same eleva- tion as the first two pairs of stakes (i.e., 72 in. below the bench mark). 4 Adjust the posi- tion of the string along the batter boards until it’s exactly 30 ft. away from and parallel to the first string. 3 Attach batter boards with the top edge even with the marks. First string set up Plan view of excavation 1 Mark the offset stake string at 10 ft. to establish the first corner mark. 2 Plumb down to the lower string and mark the location on the foundation wall string below. 3 Measure and mark the length of the foundation wall (38 ft.) along the lower string. 5 Pull a tape from the 38-ft. mark diagonally until the tape reads 48 ft. 5 in. 6 Repeat step 4 to locate the last corner. 7 The distance between the two marks on the second string should be 38 ft. Offset stake 4 Use the Pythagorean Theorem, as described on p. 19, to determine the hypotenuse of a right triangle with sides of 38 ft. and 30 ft. This comes to 48 ft. 5 in.

- 28. 1 STEP 6 form the footing 1 Mark the batter boards 4 in. outside of the strings that represent the outside of the foundation wall. 2 Attach lines that run from one mark to the other. 3 Place 2x4 forms 1⁄8 in. away from the string. Place stakes outside of the form. The top of the form should be even with the string. 4 To mark locations for the side walls on the forms, set strings that extend across the opening from one of the form boards to the other so the strings cross over the corner marks you made on the long wall strings. 5 Measure 4 in. from the sidewall strings and mark the location of the outside of the footings for the two side walls, then run strings between the marks. 6 Place forms along the strings. 7 On the forms, measure and mark 12 in. in from the strings representing the outside walls of the foundation. These measurements mark the inside of the footings. 8 Build a form along the inside of these lines to complete the perimeter foot- ing forms. On many houses, the plans specify footings for piers (or posts). If these are specified, carefully measure from the strings that represent the walls to lay out the exact posi- tions of the pier footings. Form the pier footings with 2x4s at the same height as the perimeter footings. Make sure that the positions of the strings that represent the foundation walls are clearly marked on the forms. Building foundAtions 21

- 29. 22 Building the structure STEP 8 Prepare for the footing pour Install steel as required by your local code and by the specifications on your plan. Check with the plumber and septic system subcontractor for possible pipe place- ment and any pipes or sleeves in the form. If a sump pump is needed, place the pipe through the form. In most jurisdictions, you’re required to have the footing examined by the building inspector at this point. Once you get the go-ahead from the inspector, calculate the volume of concrete needed and schedule a delivery. (There will be information on estimating concrete quantities in the next section.) STEP 7 dig the footings Remove the strings and dig the footing between the forms with a square shovel. Make the bottom of the footing 8 in. from the top of the form. The bottom of the trench should be flat and consist of undisturbed soil, and the sides should extend straight down from the forms. Measure frequently to avoid overdigging. Place vertical pieces of steel precisely by measuring and marking directly on the forms. To measure the depth, place a straightedge across the form and measure to its bottom edge. STEP 9 Pour the footing Pour the concrete and strike it even with the top of the form. Form a keyway in the footing, if your foundation plan calls for one. Place strips of wood in the wet concrete just after you’ve placed the concrete to mold the keyways. Pour the concrete and strike it even with the top of the form. Form a keyway in the footing, if your foundation Place strips of wood in the wet concrete just after you’ve placed the concrete to mold the keyways.

- 30. frAMing floors, wAlls, And ceilings 23 1 STEP 10 lay out the walls A few days after pouring the footings, you can lay out the foundation walls on the hardened concrete. The top of the concrete should be level and at the correct elevation. The locations of the walls are recorded on the forms. Once you’ve determined that the layout is precisely correct, you can build 96-in.-tall walls from poured con- crete, concrete block, or insulated concrete forms. Any of these wall systems would bring the foundation up to the targeted elevation. In cold climates, part of the footing may have to be dug deeper than 8 in. If you’re planning a walk-out basement door, the footing under and near the door may have to be stepped down to get it below the frost line. Check with your building inspector to see what you need. 1 Pull strings from the marks on the forms to check the layout. 2 Check the lengths of the four walls. 4 Strike chalklines on the concrete. 3 Check the diagonals in both directions to make sure the layout is correct. Marks on forms

- 31. 24 Building the structure Setting Up a Line Quickly and Accurately Because builders use stringlines extensively for concrete, masonry, and carpentry layout, it’s important to learn how to set one up quickly and accurately. Lines generally need to be drawn tightly to remove sag, so it’s usually necessary to attach them securely. • ANCHORING THE LINE TO WOOD SURFACES When you have a wood surface, it’s often possible to drive a nail halfway into the surface, then tie the line off to the nail. 1 Loop the string around your index finger, and twirl your finger several times. 2 Hook the loop over the nail. 3 Pull the loose end of the string one way and the taut end the other. 1 Loop the string around your thumb and forefinger. Method One Method Two 2 Turn your hand down to create two loops. 3 Slip the loops over the nail and pull the string tight. e s s e n t i A l s k i l l s 3 Slip the loops over the nail and pull the string tight. 24 Building the structure

- 32. frAMing floors, wAlls, And ceilings 25 1 • LINE BLOCKS Line blocks allow you to secure a line without using nails. This has a few advantages: You can attach the string to finished surfaces without making a nail hole; you can secure the string to concrete and masonry surfaces; and you can adjust the position of the line easily. 2 Wind the string back around the middle of the block. 3 Pull the string back through the kerf. 4 Hook the line block on any square edge. Tension from the line holds it in place. • LAYING OUT ONE LINE PARALLEL TO ANOTHER 1 Attach the first string at the desired location. 2 Measure the desired distance to other batter boards and mark a rough measurement. To lay out one line parallel to and a set distance away from another, use a pair of batter boards for each line. 3 Attach the second string to batter boards near the preliminary mark. 4 Swing the tape in an arc, and adjust the line until it’s at the high point of the arc. 1 Pull the string through the kerf cut in the back of the block. Building foundAtions 25

- 33. 26 Building the structure laying out a crawlspace foundation In this example, the foundation is a 24-ft. by 40-ft. crawlspace that projects about 32 in. above the high point in the grade around the house. The foun- dation will be built from 8 x 8 x 16-in. concrete blocks. (These are often specifi ed as CMUs, or concrete masonry units.) The house is being built in an area where the frost line is 24 in. The excavator has scraped the ground clear of organic matter but left the grade roughly the same as the surrounding terrain. The opening is several feet larger than the footprint of the house. The location of the house has been roughly staked out by the owner and architect. 1 Set up the leveling instrument and shoot the elevation of the four corners staked out by the owner. About 10 ft. beyond the high corner and along the line the long wall will follow, drive in two large stakes. STEP 1 find the high corner and establish the elevation of the foundation 2 Check the difference in elevation between the level line projected by the instrument and the grade at the high corner. In this example, the level line shot by the instrument is 47 in. higher than the grade at the high corner. Since the planned top of foundation elevation is 32 in. above grade at this corner, the top of the foundation should be laid out 15 in. below the level line projected by the instrument (47 – 32 = 15). Repeat for the other corners. The stakes need to be about 5 ft. long, and they should be made out of sub- stantial pieces of lumber (2x4s or 2x6s). Place stakes 4 ft. apart so they straddle the line of the long wall of the house. Hold a ruler vertically with the 15-in. dimension even with the line shot by the instrument. Use a screw gun to attach a batter board to the stakes at this elevation. Mark the stake at the bottom of the ruler. Corner stake 47 in. Level line Level sight line Proposed foundation along grade High corner High corner stake 15 in. 32 in.

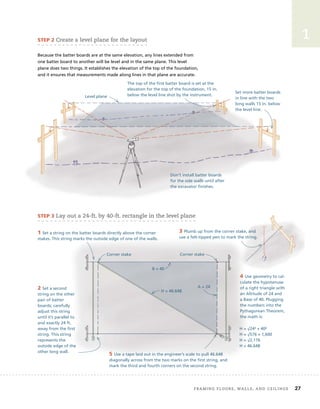

- 34. frAMing floors, wAlls, And ceilings 27 2 STEP 2 create a level plane for the layout Because the batter boards are at the same elevation, any lines extended from one batter board to another will be level and in the same plane. This level plane does two things. It establishes the elevation of the top of the foundation, and it ensures that measurements made along lines in that plane are accurate. The top of the first batter board is set at the elevation for the top of the foundation, 15 in. below the level line shot by the instrument. Set more batter boards in line with the two long walls 15 in. below the level line. Don’t install batter boards for the side walls until after the excavator finishes. Level plane STEP 3 lay out a 24-ft. by 40-ft. rectangle in the level plane 3 Plumb up from the corner stake, and use a felt-tipped pen to mark the string. 1 Set a string on the batter boards directly above the corner stakes. This string marks the outside edge of one of the walls. Corner stake 2 Set a second string on the other pair of batter boards; carefully adjust this string until it’s parallel to and exactly 24 ft. away from the first string. This string represents the outside edge of the other long wall. 4 Use geometry to cal- culate the hypotenuse of a right triangle with an Altitude of 24 and a Base of 40. Plugging the numbers into the Pythagorean Theorem, the math is: H = √24² + 40² H = √576 + 1,600 H = √2,176 H = 46.648 5 Use a tape laid out in the engineer’s scale to pull 46.648 diagonally across from the two marks on the first string, and mark the third and fourth corners on the second string. Corner stake A = 24 B = 40 H = 46.648 1 Plumb up from the corner stake, and use a felt-tipped pen to mark the string. use a felt-tipped pen to mark the string. 4 Use geometry to cal- Use geometry to cal- culate the hypotenuse culate the hypotenuse

- 35. STEP 4 record the layout on the batter boards According to the plan, the foundation walls are 8 in. wide and the footings are 16 in. wide. The footings must be centered under the walls. Around the outside of the footing, you need an additional 6 in. or 8 in. for a drain system. To accommodate the footing and the drain system, a 24-in.-wide footing trench is planned. 8-in. foundation walls 16-in. footings centered under walls Lay out both sides of the foundation walls, both sides of the footings, and the extra 8 in. for the drain system on the batter boards. Trench 8-in. foundation walls 16-in. footings centered under walls Allow 6 in. or 8 in. for a drain. Trench Measure the distance from the face of each batter board to the corner mark on the string, and record this measurement on the face of the batter board. STEP 5 Mark the ground for the footing dig 1 To mark the trench for the long walls, set up lines on the two outside marks on the batter boards. Transfer these locations to the ground with a level, a plumb bob, or a laser. 2 To mark the trench for the side walls, transfer the locations of the four corners from the string to the ground. Measure out 12 in. in both directions. 3 Set strings just above the ground at these locations, and mark the ground with lime, mortar, or spray paint. Transfer loca- tions to the ground. Measure 12 in. in both directions. Mark the ground along the strings. 28 Building the structure

- 36. STEP 6 dig the footing to the right depth 1 The bottom of the footing has to be at least 24 in. deep to get it below the frost line. Also, because the specified footing is 8 in. thick and the block courses will each be 8 in. high, the distance between the top of the founda- tion and the bottom of the footing has to be evenly divisible by 8 in. 2 In this example, you have scheduled a backhoe to dig the footing the day after the layout, which means you’ve had to move the leveling instrument. For the excavation of the footing, you set it up again; this time it projects a level line that’s 93⁄4 in. above the top of foundation. The footing needs to be at least 24 in. below the frost line. 70 in. below the top of the foundation line is not divisible by 8 in. Measure from the strings on the batter boards to find the lowest corner—in this example, 46 in.— below the top of the foundation. Increasing the trench depth to 72 in. places the footing below the frost line and conforms to the 8-in. modular scheme. The depth of the footing will be 813⁄4 in. (72 + 93⁄4) below the line shot by the instrument. The new level line is 93⁄4 in. above the proposed foundation top. 3 Remove the strings on the batter board to make room for the backhoe. To get the trench in the right place, the excavator digs to the lines you’ve made on the ground. Check the depth using the leveling instrument and a rod marked at 813⁄4 in. When the trench gets a little more than 32 in. below the surface, you can step the 32 in. below the surface, you can step the depth up 8 in. From this point, make the bottom 733⁄ 3⁄ 3 4 ⁄4 ⁄ in. (813⁄ 3⁄ 3 4 ⁄4 ⁄ – 8 = 733⁄ 3⁄ 3 4 ⁄4 ⁄ ) from the line shot by the instrument. 1 Building foundAtions 29 1

- 37. 30 Building the structure STEP 7 finish the trench by hand STEP 8 get ready for the pour 7 Lay out and dig footings for piers. They don’t have to be below the frost line but should conform to the 8-in. modular scheme men- tioned on p. 29. 1 After the excavator finishes, install batter boards for the footing side walls. Attach new strings on the long wall batter boards. Measure the distance recorded on the face of the batter board to mark one of the corners. 2 Measure 40 ft. down the string, and mark the second corner. 3 Pull the 46.648-ft. diagonals to lay out the third and fourth corners. 4 Pull strings through the corner marks to the side batter boards, and mark the batter boards where the strings cross them. Mark the foundation wall. 5 Set strings on the inside-of-trench and outside-of-trench marks on the batter boards. Level down from the strings to see how well the trench conforms to the layout. Use shovels to straighten out the sides of the trench and remove any loose dirt from the bottom. Mark both sides of the trench. 6 Measure the elevation of the bottom of the footing against the strings. It should be 72 in. in the lower area and 64 in. in the upper area. Where the distance is less than these, dig to the target distances. Be careful not to dig too deep. 1 Set lines on the marks for the outside of the footing on the batter boards. 3 Use 2x8s to form the outside of the footings. 2 Transfer these locations to the bottom of the trench to get the forms in the right place. 4 As you install the forms, measure up to the lines to make sure you get the forms at the right eleva- tion. The tops of the forms have to be at a height that conforms to the 8-in. modular scheme. The footings for the piers don’t require forms. Set the rebar for the footings as required by your local code and the specs on the plans.

- 38. 1 STEP 10 lay out the walls After the concrete hardens, set lines on the batter boards and use a level, plumb bob, or laser to transfer the locations of the walls to the top of the foot- ing. Snap chalklines on the concrete to lay out the walls. Techniques for laying the blocks up to the line will be discussed in the final section of this chapter. Before beginning the block work, make a quick checklist of the things to either allow for or include in the walls: • Drainpipe to allow moisture inside the crawlspace to go through the wall and into the perimeter drain system • Access door • Opening for an HVAC duct • Foundation vents • Beam pockets • Anchors to bolt the frame to the foundation STEP 9 Pour the footing Before the concrete truck arrives, set up the leveling instrument and measure the difference in elevation between the top of the batter boards and the line shot by the instrument. Add the amount—in 8-in. increments—that you need to go down to get the tops of the pier footings at the right height. Measure down from the level line projected by the instrument to pour the piers to the correct elevation. Inside the footing trench, pour the concrete even with the top of the forms. 72 in. 64 in. 48 in. Line shot by leveling instrument Cave-ins: A Deadly Hazard The sides of trenches and basement excavations can collapse without warning. If a person is buried over his head in such a collapse, the chances of survival are less than one in ten. There are four things you can do to reduce the chance of a deadly cave-in: • Any time you excavate an opening for a basement, make sure you dig at least 4 ft. beyond the footprint of the house; this keeps workers away from the deadly perim- eter of the excavation. • Slope the sides of the excavation away from the opening. • Pile the spoils from a trench excavation at least 2 ft. back from the edge. • Use a shoring system for deep trenches. For more on trenching safety, go to this OSHA site: http://www.osha. gov/SLTC/trenchingexcavation/ construction.html sAfety first Building foundAtions 31

- 39. 32 Building the structure Building outside the Box Although a rectangular fl oor plan has the advantages of speed and economy, designers and homeowners often desire more complicated shapes. The most common method of breaking out from the four walls of a rectangular house is to add more rectangles in the form of ells, wings, and insets. There are many occasions, however, when designers abandon the rectangle altogether and draw up buildings or parts of buildings with obtuse or acute angles or curved walls. To lay out these different shapes, follow the same basic sequence that has just been described. First, lay out a level plane at either the top-of-foundation or the top-of-footing elevation. Then lay out the shape within that plane. Adding rectangles to rectangles To lay out these foundations, start by laying out the main rectangle and then add more batter boards or forms to lay out the additional rectangles. Use geometry to get the walls of the secondary rectangles square to the primary rectangle. Main rectangle Added rectangle Parallel lines Parallel lines Parallel lines Added rectangle Added rectangle Equal diagonals Batter board

- 40. 1 Moving away from the right angle Once in a while, designers draw up buildings with walls that are not square to one another. To lay out these acute (less than 90º) or obtuse (more than 90°) angles, you can either use a precise surveying instrument or geometry. The designer should specify the point from which to pull the measurement as well as the exact dimensions of both the parallel line and the diagonal measure- ment. If the angle is simply specified in degrees, however, it’s up to you to calculate the dimensions of a right triangle that corresponds to the degrees specified. To make these calculations, use the techniques described in “Working with Right Triangles” on p. 19. 2 From a specified point, pull a specified dimension diagonally across the layout and mark the parallel line with a felt-tipped pen. 2 After loosening the clamp on the horizontal scale, point it so that it is shooting parallel to the line. 3 Set the horizontal scale to the zero mark. Turn the instru- ment to the desire angle. • SURVEYING INSTRUMENT • GEOMETRY 3 Set up batter boards and string that runs directly across the marks. This string represents the outside of the angled wall. 1 Build batter boards at the correct elevation, and affix a line a set distance from and parallel to one of the walls on the main rectangle. 1 Set the instrument directly over a point on a base line of your layout. 4 Transfer the line shot by the instrument down to the batter board and mark that point. laying out curved foundations Curved foundations are usually drawn as circles or seg- ments of circles. The first step in laying out a circular, semicircular, or arced foundation is to establish a pivot point. The location of this point should be specified in the plans. Lay out this point at the desired elevation, using a stake or a batter board. Once you’ve established the pivot point, create a beam compass to serve as the radii needed to lay out the parts of the foundation. On the beam com- pass, measure and mark the parts of the foundation out from the pivot point. These measurements include the dis- tances from the pivot point to: the inside and outside of the footing trench; the inside and outside of the concrete footing; the inside and outside of the foundation wall; and the center of the foundation wall. After setting up a form or batter board to hold the beam level, swing the compass. You can make the beam compass on site, using a strip of wood and a nail for the pivot. Mark the beam compass with foundation dimensions. Batter boards are at the same elevation. Building foundAtions 33

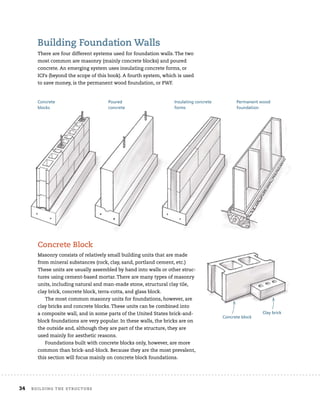

- 41. Building foundation walls There are four different systems used for foundation walls. The two most common are masonry (mainly concrete blocks) and poured concrete. An emerging system uses insulating concrete forms, or ICFs (beyond the scope of this book). A fourth system, which is used to save money, is the permanent wood foundation, or PWF. concrete Block Masonry consists of relatively small building units that are made from mineral substances (rock, clay, sand, portland cement, etc.) These units are usually assembled by hand into walls or other struc- tures using cement-based mortar. There are many types of masonry units, including natural and man-made stone, structural clay tile, clay brick, concrete block, terra-cotta, and glass block. The most common masonry units for foundations, however, are clay bricks and concrete blocks. These units can be combined into a composite wall, and in some parts of the United States brick-and- block foundations are very popular. In these walls, the bricks are on the outside and, although they are part of the structure, they are used mainly for aesthetic reasons. Foundations built with concrete blocks only, however, are more common than brick-and-block. Because they are the most prevalent, this section will focus mainly on concrete block foundations. Concrete blocks Poured concrete Permanent wood foundation Concrete block Clay brick Insulating concrete forms 34 Building the structure 34 Building the structure blocks concrete foundation forms Masonry consists of relatively small building units that are made from mineral substances (rock, clay, sand, portland cement, etc.) These units are usually assembled by hand into walls or other struc- tures using cement-based mortar. There are many types of masonry units, including natural and man-made stone, structural clay tile, The most common masonry units for foundations, however, are clay bricks and concrete blocks. These units can be combined into a composite wall, and in some parts of the United States brick-and- block foundations are very popular. In these walls, the bricks are on Concrete block Clay brick Building foundation walls There are four different systems used for foundation walls. The two most common are masonry (mainly concrete blocks) and poured concrete. An emerging system uses insulating concrete forms, or ICFs (beyond the scope of this book). A fourth system, which is used to save money, is the permanent wood foundation, or PWF. concrete Block Masonry consists of relatively small building units that are made from mineral substances (rock, clay, sand, portland cement, etc.) These units are usually assembled by hand into walls or other struc- tures using cement-based mortar. There are many types of masonry units, including natural and man-made stone, structural clay tile, clay brick, concrete block, terra-cotta, and glass block. The most common masonry units for foundations, however, are clay bricks and concrete blocks. These units can be combined into a composite wall, and in some parts of the United States brick-and- block foundations are very popular. In these walls, the bricks are on the outside and, although they are part of the structure, they are used mainly for aesthetic reasons. Foundations built with concrete blocks only, however, are more common than brick-and-block. Because they are the most prevalent, this section will focus mainly on concrete block foundations. Concrete blocks Poured concrete Permanent wood foundation Concrete block Clay brick Insulating concrete forms

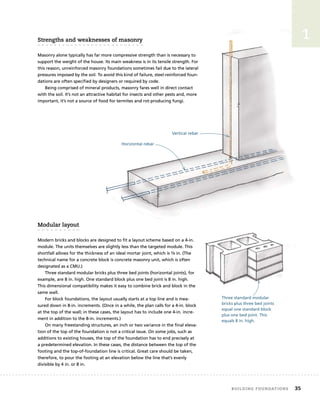

- 42. 2 strengths and weaknesses of masonry Masonry alone typically has far more compressive strength than is necessary to support the weight of the house. Its main weakness is in its tensile strength. For this reason, unreinforced masonry foundations sometimes fail due to the lateral pressures imposed by the soil. To avoid this kind of failure, steel-reinforced foun- dations are often specified by designers or required by code. Being comprised of mineral products, masonry fares well in direct contact with the soil. It’s not an attractive habitat for insects and other pests and, more important, it’s not a source of food for termites and rot-producing fungi. Modular layout Modern bricks and blocks are designed to fit a layout scheme based on a 4-in. module. The units themselves are slightly less than the targeted module. This shortfall allows for the thickness of an ideal mortar joint, which is 3⁄8 in. (The technical name for a concrete block is concrete masonry unit, which is often designated as a CMU.) Three standard modular bricks plus three bed joints (horizontal joints), for example, are 8 in. high. One standard block plus one bed joint is 8 in. high. This dimensional compatibility makes it easy to combine brick and block in the same wall. For block foundations, the layout usually starts at a top line and is mea- sured down in 8-in. increments. (Once in a while, the plan calls for a 4-in. block at the top of the wall; in these cases, the layout has to include one 4-in. incre- ment in addition to the 8-in. increments.) On many freestanding structures, an inch or two variance in the final eleva- tion of the top of the foundation is not a critical issue. On some jobs, such as additions to existing houses, the top of the foundation has to end precisely at a predetermined elevation. In these cases, the distance between the top of the footing and the top-of-foundation line is critical. Great care should be taken, therefore, to pour the footing at an elevation below the line that’s evenly divisible by 4 in. or 8 in. Horizontal rebar Vertical rebar Three standard modular bricks plus three bed joints equal one standard block plus one bed joint. This equals 8 in. high. Building foundAtions 35 strengths and weaknesses of masonry Masonry alone typically has far more compressive strength than is necessary to support the weight of the house. Its main weakness is in its tensile strength. For this reason, unreinforced masonry foundations sometimes fail due to the lateral pressures imposed by the soil. To avoid this kind of failure, steel-reinforced foun- dations are often specified by designers or required by code. Being comprised of mineral products, masonry fares well in direct contact with the soil. It’s not an attractive habitat for insects and other pests and, more important, it’s not a source of food for termites and rot-producing fungi. Modular layout Modern bricks and blocks are designed to fit a layout scheme based on a 4-in. module. The units themselves are slightly less than the targeted module. This shortfall allows for the thickness of an ideal mortar joint, which is 3⁄8 in. (The technical name for a concrete block is concrete masonry unit, which is often designated as a CMU.) Three standard modular bricks plus three bed joints (horizontal joints), for example, are 8 in. high. One standard block plus one bed joint is 8 in. high. This dimensional compatibility makes it easy to combine brick and block in the same wall. For block foundations, the layout usually starts at a top line and is mea- sured down in 8-in. increments. (Once in a while, the plan calls for a 4-in. block at the top of the wall; in these cases, the layout has to include one 4-in. incre- ment in addition to the 8-in. increments.) On many freestanding structures, an inch or two variance in the final eleva- tion of the top of the foundation is not a critical issue. On some jobs, such as additions to existing houses, the top of the foundation has to end precisely at a predetermined elevation. In these cases, the distance between the top of the footing and the top-of-foundation line is critical. Great care should be taken, therefore, to pour the footing at an elevation below the line that’s evenly divisible by 4 in. or 8 in. Horizontal rebar Vertical rebar Three standard modular bricks plus three bed joints equal one standard block plus one bed joint. This equals 8 in. high. 1 strengths and weaknesses of masonry strengths and weaknesses of masonry strengths and weaknesses of masonry Masonry alone typically has far more compressive strength than is necessary to Masonry alone typically has far more compressive strength than is necessary to Masonry alone typically has far more compressive strength than is necessary to support the weight of the house. Its main weakness is in its tensile strength. For support the weight of the house. Its main weakness is in its tensile strength. For support the weight of the house. Its main weakness is in its tensile strength. For this reason, unreinforced masonry foundations sometimes fail due to the lateral this reason, unreinforced masonry foundations sometimes fail due to the lateral this reason, unreinforced masonry foundations sometimes fail due to the lateral pressures imposed by the soil. To avoid this kind of failure, steel-reinforced foun- pressures imposed by the soil. To avoid this kind of failure, steel-reinforced foun- pressures imposed by the soil. To avoid this kind of failure, steel-reinforced foun- dations are often specified by designers or required by code. dations are often specified by designers or required by code. dations are often specified by designers or required by code. Being comprised of mineral products, masonry fares well in direct contact Being comprised of mineral products, masonry fares well in direct contact Being comprised of mineral products, masonry fares well in direct contact with the soil. It’s not an attractive habitat for insects and other pests and, more with the soil. It’s not an attractive habitat for insects and other pests and, more with the soil. It’s not an attractive habitat for insects and other pests and, more important, it’s not a source of food for termites and rot-producing fungi. important, it’s not a source of food for termites and rot-producing fungi. important, it’s not a source of food for termites and rot-producing fungi. Horizontal rebar Horizontal rebar Horizontal rebar Vertical rebar Vertical rebar Vertical rebar

- 43. 36 Building the structure unit spacing along the length of the wall The lengths of masonry units also fit into a 4-in. modular scheme. One brick with one head joint (vertical joint) is 8 in. long. One block with one head joint is 16 in. long. Similarly, the dimensions of the widths of these units also fit the modular scheme. A brick with a joint is 4 in. wide; a block with a joint is 8 in. wide. This ensures that the joints of each course are offset by half the length of the unit from the course below when you build corners. When you build corners for any masonry wall, it’s important to make sure you maintain the correct bonding pattern. After you build the first corner of a foundation, for example, you have to measure or set the units in place dry to determine which direction to place the first unit in the second corner. fudging the layout Although the 4-in. and 8-in. module is the rule in masonry, there is a little wiggle room. The courses can be expanded or contracted slightly by adjusting the thickness of the mortar joints. Most building codes, how- ever, limit the amount that mortar joints can vary. The International Residential Code, for example, speci- fies that bed joints for a masonry foundation must be between 3⁄8 in. and 1⁄2 in. thick. The one exception to this rule is that the bed joint on the footing can be up to 3⁄4 in. thick. This means that as much as 13⁄8 in. can be gained in a foundation that’s nine block courses high (1⁄8 in. × 8 = 1 + 3⁄8 in. = 13⁄8 in.). One brick with one head joint is 8 in. long. One block with one head joint is 16 in. long. Dividing space (136 in.) by 16 in. (block plus head joint) equals 81⁄2 blocks. In this example, the end block will need to be turned in line with the other wall. 72 in. (nine courses with 3⁄8-in. bed joints) 733⁄8 in. (first-course bed joint of 3⁄4 in. plus nine courses with 1⁄2-in. bed joints)

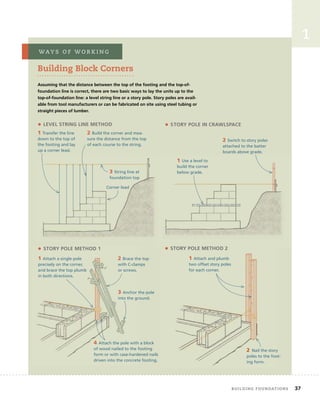

- 44. 1 wAy s o f w o r k i n g Building Block Corners Assuming that the distance between the top of the footing and the top-of- foundation line is correct, there are two basic ways to lay the units up to the top-of-foundation line: a level string line or a story pole. Story poles are avail- able from tool manufacturers or can be fabricated on site using steel tubing or straight pieces of lumber. • LEVEL STRING LINE METHOD 2 Build the corner and mea- sure the distance from the top of each course to the string. 1 Transfer the line down to the top of the footing and lay up a corner lead. 3 String line at foundation top Corner lead • STORY POLE METHOD 1 3 Anchor the pole into the ground. 4 Attach the pole with a block of wood nailed to the footing form or with case-hardened nails driven into the concrete footing. 1 Attach a single pole precisely on the corner, and brace the top plumb in both directions. 2 Brace the top with C-clamps or screws. • STORY POLE METHOD 2 2 Nail the story poles to the foot- ing form. 1 Attach and plumb two offset story poles for each corner. • STORY POLE IN CRAWLSPACE 2 Switch to story poles attached to the batter boards above grade. 1 Use a level to build the corner below grade. Building foundAtions 37

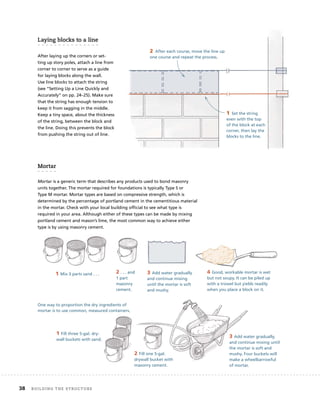

- 45. 38 Building the structure laying blocks to a line After laying up the corners or set- ting up story poles, attach a line from corner to corner to serve as a guide for laying blocks along the wall. Use line blocks to attach the string (see “Setting Up a Line Quickly and Accurately” on pp. 24–25). Make sure that the string has enough tension to keep it from sagging in the middle. Keep a tiny space, about the thickness of the string, between the block and the line. Doing this prevents the block from pushing the string out of line. Mortar Mortar is a generic term that describes any products used to bond masonry units together. The mortar required for foundations is typically Type S or Type M mortar. Mortar types are based on compressive strength, which is determined by the percentage of portland cement in the cementitious material in the mortar. Check with your local building official to see what type is required in your area. Although either of these types can be made by mixing portland cement and mason’s lime, the most common way to achieve either type is by using masonry cement. 1 Set the string even with the top of the block at each corner, then lay the blocks to the line. 2 After each course, move the line up one course and repeat the process. 4 Good, workable mortar is wet but not soupy. It can be piled up with a trowel but yields readily when you place a block on it. 1 Mix 3 parts sand . . . 2 . . . and 1 part masonry cement. 3 Add water gradually and continue mixing until the mortar is soft and mushy. One way to proportion the dry ingredients of mortar is to use common, measured containers. 1 Fill three 5-gal. dry- wall buckets with sand. 2 Fill one 5-gal. drywall bucket with masonry cement. 3 Add water gradually, and continue mixing until the mortar is soft and mushy. Four buckets will make a wheelbarrowful of mortar.

- 46. 1 troweling techniques Wielding a trowel is a physical skill that can be acquired only through practice. Although there is no substitute for picking up a trowel and having at it, here are a few basic techniques to get you started. 1 Pile mortar into a mound in a mortar pan. 2 Scoop a full but manageable trowelful. 3 With the fully loaded trowel a few inches above the footing, give the trowel a slight downward tilt. Without stopping, rotate your wrist and pull the trowel. 4 The motion is like the pull stroke when you’re working with a handsaw. • TROWELING THE FIRST COURSE • TROWELING BLOCKS To butter the end of a block (or brick), you have to turn the trowel over. The challenge is to keep the mortar from slid- ing off the overturned trowel. 1 Pick up half a trowelful. 2 With the mortar facing up, thrust the trowel straight down and stop it abruptly. 3 With the mortar flattened against the trowel, it stays put as you butter the ends of the block. Maximize the Bond In addition to having com- pressive strength, mortar has to bond the masonry units together tenaciously. To maxi- mize bond, the units should be dry and the mortar should be as wet as possible and still have enough body to sup- port the weight of the units. When mortar is spread on the surface of a dry, porous unit, the mortar is sucked into the pores, creating a mechanical as well as chemical bond. There is an enduring myth that masons should soak units before laying them in a wall. In most cases, this is false. Most clay bricks and all concrete blocks should be kept dry before laying them in a wall. On rare occasions, unusually porous and dry clay bricks have an excessively high initial rate of absorption (IRA). These bricks suck the moisture out of the mortar at such a rate that the mortar dries almost immediately. This makes them difficult to work with and can have a nega- tive effect on the bond. In these cases, the bricks should be wetted, then allowed to surface-dry before they’re set in the wall. Wet masonry units should never be laid in a wall. toP tiP Building foundAtions 39

- 47. rebar set in footing Block walls are often reinforced with steel and grout. The design should be drawn up by an engineer, or follow the specifications of the building code in your area. Rebar should be laid out so that it emerges from the footing in the center of the block cores. After the footing pour, builders sometimes bend incorrectly placed rebar to get it in line with the block core. This practice compromises the structural integrity of the system and should be avoided. It’s far better to lay out the pieces of steel correctly prior to the footing pour. create a cleanout It is important to keep the footing around the verti- cal rebar clear of mortar droppings so the cavity can be completely filled with grout later. To ensure that the footing around the vertical rebar remains clean as you lay up the wall, you need to cut a “cleanout,” a 4-in. by 4-in. opening in the first block that goes over the rebar. As the blocks are laid up, you can reach in and clean out the droppings around the rebar several times a day. As the blocks are laid up, keep the rebar in the center of the core. Wire rebar positioners are available for this purpose. grout block cavities The grout must bond the masonry units and the rebar together. To achieve this bond, grout is much richer in portland cement than concrete and it has much more water. Because grout must fill the block cavities com- pletely, pea gravel is often specified as the coarse aggre- gate. Structural engineers often specify the proportions for the grout on commercial masonry jobs. For residential projects, however, you can usually get an acceptable mix by conferring with your concrete supplier. Rebar tied to horizontal rebar set in footing prior to pour Rebar Grout Footing Cleanout Rebar positioner Rebar 40 Building the structure

- 48. Poured concrete Concrete is made of four basic ingredients: water, portland cement, sand, and coarse aggregate (usually gravel or crushed stone). In a typical batch of wet concrete, only about 12% of the mix consists of portland cement. Most of the material is aggregate; sand comprises about 28% of the mix, while gravel or crushed stone makes up 44% of the total volume. The fi nal ingredient, water, varies considerably from batch to batch. Ideally, the water content should be about 15% of the volume. On many jobs, air is also mixed into the concrete, typically accounting for about 6% of the volume. When water is mixed with the dry ingredients, a chemical reac- tion in the portland cement, called hydration, takes place. Hydration causes the most important constituents of the cement, the calcium silicates, to dissolve and then gradually reform as calcium silicate hydrate and calcium hydroxide. As hydration proceeds, these newly formed compounds harden and bond to each other and to the grains of sand and stones that they surround. Meanwhile, if air-entraining chemicals are mixed in, billions of microscopic air pockets per cubic yard are formed. After air-entrained concrete is fully cured, it stands up to freezing temperatures much better than untreated concrete. The tiny chambers relieve internal pressure on the concrete by pro- viding space for the water to expand into when it freezes. strengths and weaknesses of concrete Because the tools and skills required for installing concrete and unit masonry are so different, they are considered separate branches of the building industry. The materials, however, are often indistinguish- able. The ingredients of grout, for example, are the same as those in concrete. Concrete blocks are made from concrete. A stone wall often consists of the same materials as are found in concrete: stone, sand, and portland cement. And, while brick is made of a different material (clay), both brick and concrete are mineral substances with great compressive strength. Concrete is often reinforced with steel. Because it is made from mineral products, concrete performs well in contact with the ground. Unreinforced concrete is relatively weak in tensile strength. Before the Truck Comes The trucks used to deliver concrete and blocks are often tall enough to hit overhead power lines. When they do, they can electrocute anyone who touches any metal part of the truck. Always reconnoiter the route the truck will follow and, if a line poses a hazard, come up with an alternate route or have the line discon- nected by the power company. sAfety first 1 Building foundAtions 41

- 49. water and concrete Ready-mixed concrete is proportioned at the concrete plant and delivered by truck ready to place. The amount of water added to the mix at the plant is specified by the buyer in terms of “slump” (see “Slump Test” above). The lower the slump, the less water added and the stiffer the mix. Concrete with a 2-in. slump, for example, is so stiff that it has to be pulled down the chute of the truck and physically pulled into place and packed into forms to avoid honey- combs (voids). Concrete with a 5-in. slump, on the other hand, flows down the chute, spreads out, and fills forms easily. Slump has a direct impact on the workability of the concrete. Low-slump concrete is a lot harder to place and finish than high-slump concrete. There is a tendency, therefore, on the part of the workers in the field to want to add water to the concrete. Ready-mix trucks carry water for this purpose. Ready-mix concrete suppliers, however, carefully document the amount that is added, both at the plant and during the pour. The reason they do this is because the amount of water mixed into concrete has a direct impact on the strength and durability of the finished product. The amount of water needed to cause hydration is surprisingly small. All the dry ingredients have to be thoroughly dampened but they don’t need Slump Test To measure the consistency of wet concrete, engineers have developed the slump test. Although residential builders rarely do slump tests, they use a given “slump” to indicate how much water they want mixed in when they order concrete. Concrete with a 4-in. slump is typical for residential work. 1 Fill a cone-shaped container of specified proportions with concrete. 2 Flip the con- tainer. Slowly lift the cone off the concrete. 3 Measure how much the cone of concrete sags. tools & techniQues Ready-mixed concrete is proportioned at the concrete plant and delivered by truck ready to place. The amount of water added to the mix at the plant is specified by the buyer in terms of “slump” (see “Slump Test” above). The lower the slump, the less water added and the stiffer the mix. Concrete with a 2-in. slump, for example, is so stiff that it has to be pulled down the chute of the truck and physically pulled into place and packed into forms to avoid honey- combs (voids). Concrete with a 5-in. slump, on the other hand, flows down the Slump has a direct impact on the workability of the concrete. Low-slump concrete is a lot harder to place and finish than high-slump concrete. There is a tendency, therefore, on the part of the workers in the field to want to add Ready-mix concrete suppliers, however, carefully document the amount that is added, both at the plant and during the pour. The reason they do this 42 Building the structure