Timann-box

- 1. © 2016 TimAnn-Box All Rights Reserved Marc van Dongen Founder June 2016 TimAnn-Box: We innovate air-freight!

- 2. © 2016 TimAnn-Box. All rights reserved. 2CONFIDENTIIAL We can do what todays air freight industry hasn’t achieved in over 40 years: Make air freight faster! IATA says: …. air cargo processes have changed very little since 1960. Transit times are no faster than 40 years ago, with the average end-to- end time for consignments around 6-7 days. and that the industry must raise the service quality and provide a more personalized service. http://www.iata.org/publications/tracker/mar-2014/Pages/wcs-2014.aspx / http://www.canadianshipper.com/sustainability/iata-says-game-changing-innovation-needed-for-air-cargo/1002958400/ Study conducted by Ericsson AS

- 3. © 2016 TimAnn-Box. All rights reserved. 3CONFIDENTIIAL 4 reasons prevent todays air freight to speed up. Our research shows 4 key reasons which, through their interaction, prevents the incumbent air freight providers to speed up global air freight: Reason 1: The incompatibility of the intermodal interface. Reason 2 : Lacking supply chain visibility inhibits agility Reason 3: The incompatibility of freight tracking systems. Reason 4: The absence of real-time in-transport event data.

- 4. © 2016 TimAnn-Box. All rights reserved. 4CONFIDENTIIAL Goods receipt Bar code Ready f. Carriage? Doc’s OK? Build up list ULD- Select Build up ULD- Tag Interim Store Handling process often requires 12 to 18 hours! Reason 1: The incompatibility of the intermodal interface. The incompatibility of the intermodal (surface-to-air) interface significantly reduces the achieveable door-to-door shipment process speed: Absence or late availability of exact dimensions and volume. Absence or late availability of exact package weight. Instable or sub-optimally sized shipment packaging; ready for carriage? Need for contour changes due to aircraft/equipment-changes. Absence or late availability of special handling requirements. (security, temperature, sensitivity). To air- side

- 5. © 2016 TimAnn-Box. All rights reserved. 5CONFIDENTIIAL Reason 2: Lack of supply chain visibility inhibits its agility! The first step toward supply chain agility is (end-to-end) visibility. Only adequate Supply Chain visibility can compensate for sudden, unexpected conditions. Without an accurate and complete picture of the entire supply chain operations cannot make adjustments. Today, supply chain operators report that they have no such visibility! Only 19% of respondents to an “e2open* study” report end-to-end supply chain visibility (41% only have visibility for their Tier 1 suppliers, 7% can see Tier 2 and 20% have no visibility at all!) Only 14% of those surveyed have access real-time data despite timeliness being a key to visibility data relevance. ( 31% have visibility with a 24 H delay. 14% with a 72 H delay) * A 2015 Pulse Report by Gatepoint Research published in Jan 2016 by e2open.com

- 6. © 2016 TimAnn-Box. All rights reserved. 6CONFIDENTIIAL Reason 3: The incompatibility of freight tracking systems. Air freight handling is a collaborative process ‘shipping’ forwarder; 1-N airlines; ‘consignee’ forwarder. No global unified track & trace system in existance to date. Each transport provider uses his own (proprietary) system. Consequence: Shippers and/or consignees must self collect and combine data. This is cost ineffective; it voids any options to respond, in real-time, to incidents or alerts; and data processing is not the shippers core competency.

- 7. © 2016 TimAnn-Box. All rights reserved. 7CONFIDENTIIAL Reason 4: The absence of real-time in-transport event data. Shippers and consignees require more data within the air-cargo process. This data should not just be about pickup/delivery times, but also, for example, data “on when things go wrong.” Air Cargo World, March 2015 quoting Robert Mellin, head of distribution logistics at Ericsson “For most companies, visibility is both the biggest opportunity and the biggest issue, and it goes beyond just knowing where a truck or a product is at a certain time.” Bart De Muynck, research director at Gartner in SCEC by Kewill What it comes down to, is to provide insight gleaned from all data collected across the entire transport chain the very second this data is created. Example: - What value does a theft-alert warning have when message comes 30 minutes after the fact.

- 8. © 2016 TimAnn-Box. All rights reserved. 8CONFIDENTIIAL Summary: What slows down todays air freight? no market maker (dominant shipper or consignee) surface- to-air- interface incompati -bility absence of a standard ‘data- carrier’ real-time /on-line data pro- cessing is new inability of the industry to innovate air freight handling still a myth for shippers highly frag- mented industry capital intensive industry with low ROI low IT- and communi cation maturity

- 9. © 2016 TimAnn-Box. All rights reserved. 9CONFIDENTIIAL Our research shows that air freight customers want: (Enhanced) Shipment visibility over the entire transport chain. A global, standardized messaging standard which reports comprehensively in real-time; is easy-to-use (Standardized plug-and-play interface(s)); Uses only one source of truth (no consolidation of multiple data sources). Flexibility (volume and routes) to accommodate erratic customer behavior. Reroute inventory at will. Including the ability to use the transport process as a virtual warehouse. Flexible but accurate shipment handling and delivery in high quality. (Radically) reduced door-to-door transit times. Excellent passive and active shipment security. Active (handling error detection, active detection of environment changes). Passive (increased shipment security). Higher pricing transparency.

- 10. © 2016 TimAnn-Box. All rights reserved. 10CONFIDENTIIAL TimAnn-Box Value Proposition. makes global door-to-door air freight processes: faster safer (theft & damage) more agile transparent cheaper integrated with a proven, state-of-the-art tools, a simple plug & play implementation process and without (large) upfront investments changing shipper handling processes.

- 11. © 2016 TimAnn-Box. All rights reserved. 11CONFIDENTIIAL TimAnn-Box; Customer Benefits. Significantly reduced door-to-door shipment cost Enhanced shipment transparency. Enable IT integration (MRP, S&OP) Facilitate in-transport destination changes (make air freight a virtual warehouse) Enhanced shipment integrity. Active shipment protection (Handling error detection) Passive shipment protection (Theft & damage) Radically reduced door-to-door transit times. Reduced capital binding Enable faster time to market Extend remaining the shelf life for perishable products.

- 12. © 2016 TimAnn-Box. All rights reserved. 12CONFIDENTIIAL TimAnn-Box customer benefits summary. lower parcel express cost with break- bulk reduced door-to- door transport time real-time on-line ERP inte- gration high shipment re-routing flexibility optimal ULD (pallet) load- factors From day one, our customers shall enjoy: reduced freight handling cost global, real-time shipment trans- parency no ULD staging, return logistics & repair cost no upfront invest- ments simple plug & play implemen -tation

- 13. © 2016 TimAnn-Box. All rights reserved. 13CONFIDENTIIAL TimAnn-Box design constraints. In order to meet the customer demand for in-process tracking data, shipment flexibility and for a significantly increased door-to-door through-put speed, the Tim-Ann-Box system, shall: be flexible and cost efficient; be CAPEX free for the customer (for basic service); be neutral to any player in the supply chain; be easy to use; be easy to install (Plug & Play) and operate independent of any customer or partner infrastructure (both IT as well as process infrastructure); use only proven tools and technologies; be truly global.

- 14. © 2016 TimAnn-Box. All rights reserved. 14CONFIDENTIIAL 80cm TimAnn-Box design constraint: Tool free build up in under 20 seconds 30cm High top load Rackable

- 15. © 2016 TimAnn-Box. All rights reserved. 15CONFIDENTIIAL TimAnn-Box design constraint: The concept shall be CAPEX free and fund itself. Based upon an all-inclusive fixed box fee (minimum volume conditions apply) - No upfront investment - Box and tracking tag cost included - Access to free tracking-apps Real life example: customer conditions may vary

- 16. © 2016 TimAnn-Box. All rights reserved. 16CONFIDENTIIAL TimAnn-Box design constraint: Know what happens, when, where; everywhere! Area Scanner Active object scanner Location / equipment identifier Fixed mounted scanner Area scanners continuously report activities of any TimAnn-Boxes within range: - Fixed scanners: Ethernet / Wifi - Mobile scanners:Wireless M2M-comm. The active RFID-Tag embedded in a TimAnn-Box, records and real-time reports, - any box movement (when it happens), - reporting who ‘touch(ed)’ them. - identifies any handling violation, and - can receive and present (changes to) handling instructions. Forklift # rack-position # Key logistics equipment (e.g. forklifts) and rack-spaces equipped with active tags report their identity the minute a TimAnn-box comes within range. @16:27 CET, Forklift 57 put box A23 at rack position A-23-4 in Building PRG1 Mobile scanner

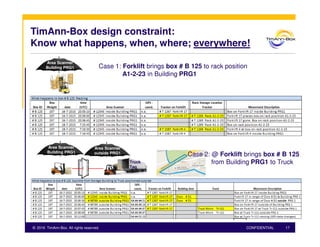

- 17. © 2016 TimAnn-Box. All rights reserved. 17CONFIDENTIIAL TimAnn-Box design constraint: Know what happens, when, where; everywhere! Case 1: Forklift brings box # B 125 to rack position A1-2-23 in Building PRG1 Area Scanner Building PRG1 Area Scanner Building PRG1 Area Scanner outside PRG1 Case 2: @ Forklift brings box # B 125 from Building PRG1 to TruckTruck Tag

- 18. © 2016 TimAnn-Box. All rights reserved. 18CONFIDENTIIAL TimAnn-Box design constraint: Data shall be easy to consume and expandable. Area 1:N Box 1:M Trackers AWB 1:N Box AWB Transport schedule shipper - consignee Freeapps Current box location Location of all boxes (fixed or GPS) assigned to AWB Subscription apps Full ‘Transaction’ history of the box (location, touch points) Plan / actual comparison of transport steps Set and check on Geo-fences Unintended alert reporter Plan / actual consignee arrival date / time 1:1 Box weight Shipment characteristics (temperature, shock, lid opening) 1:1 ship.char

- 19. © 2016 TimAnn-Box. All rights reserved. 19CONFIDENTIIAL Free “Current box location” app example. Real-time Android or IOS App Desktop enabled

- 20. © 2016 TimAnn-Box. All rights reserved. 20CONFIDENTIIAL Data, communication and systems concept. Location tags Box/ULD tags Area tags ERP TM Packing list AWB Transport order Continuous in motion tracking Location + max 10 additional sensor items (temp., G-force, acceleration) M2M communication H2M or (H)uman triggered M2M communication

- 21. © 2016 TimAnn-Box. All rights reserved. 21CONFIDENTIIAL Thank you! Contact information: Marc van Dongen Founder M.van.Dongen@TimAnn-Box.com www.TimAnn-Box.com

- 22. © 2016 TimAnn-Box. All rights reserved. 22CONFIDENTIIAL Head Office Lelienhuyze 18 5221PH ‘s-Hertogenbosch The Netherlands Design Office Brevnovska 12 16900 Prague – 6 Czech Republic +31-619929068 info@TimAnn-Box.com +420-608231012 info@TimAnn-Box.com Contact us

- 23. © 2016 TimAnn-Box. All rights reserved. 23CONFIDENTIIAL © 2016 TimAnn-Box All rights reserved. No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of TimAnn-Box. The information contained herein may be changed without prior notice. Some products marketed by TimAnn-Box and its distributors contain proprietary components of other vendors. National product specifications may vary. These materials are provided by TimAnn-Box and its affiliated companies for informational purposes only, without representation or warranty of any kind, and TimAnn-Box shall not be liable for errors or omissions with respect to the materials. The only warranties for TimAnn-Box products and services are those that are set forth in the express warranty statements accompanying such products and services, if any. Nothing herein should be construed as constituting an additional warranty. TimAnn-Box products and services mentioned herein as well as their respective logos are trademarks or registered trademarks of TimAnn-Box in The Netherlands and other countries.

- 24. © 2016 TimAnn-Box. All rights reserved. 24CONFIDENTIIAL TimAnn-Box design criteria The TimAnn-Box RFID-concept must secure the following information: Who am I? Box ID Box weight Reference to AWB & BoL’s Where am I? Exact GPS position? Pallet / ULD ID Who is doing what with me? What time is it? Who is handling me? Where am I going? May I move at this time? Am I moving to the correct position? When shall I arrive at my destination?

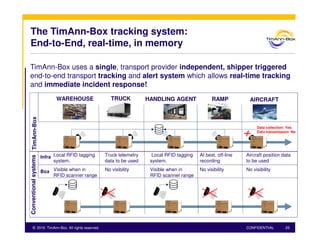

- 25. © 2016 TimAnn-Box. All rights reserved. 25CONFIDENTIIAL The TimAnn-Box tracking system: End-to-End, real-time, in memory Infra Box Local RFID tagging system. Visible when in RFID scanner range Truck telemetry data to be used No visibility Local RFID tagging system. Visible when in RFID scanner range At best, off-line recording No visibility Aircraft position data to be used No visibility WAREHOUSE TRUCK HANDLING AGENT RAMP AIRCRAFT TimAnn-Box uses a single, transport provider independent, shipper triggered end-to-end transport tracking and alert system which allows real-time tracking and immediate incident response! ConventionalsystemsTimAnn-Box Data collection: Yes Data transmission: No

- 26. © 2016 TimAnn-Box. All rights reserved. 26CONFIDENTIIAL TimAnn-Box cost / benefit assessment: Product value of standard air freight.